Preparation method of aloe polysaccharide/bacterial cellulose composite membrane for medical dressing

A technology of bacterial cellulose film and bacterial cellulose, applied in the field of preparation of aloe polysaccharide/bacterial cellulose composite film, which can solve the problems of poor strength of aloe polysaccharide film and difficulty in covering wounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

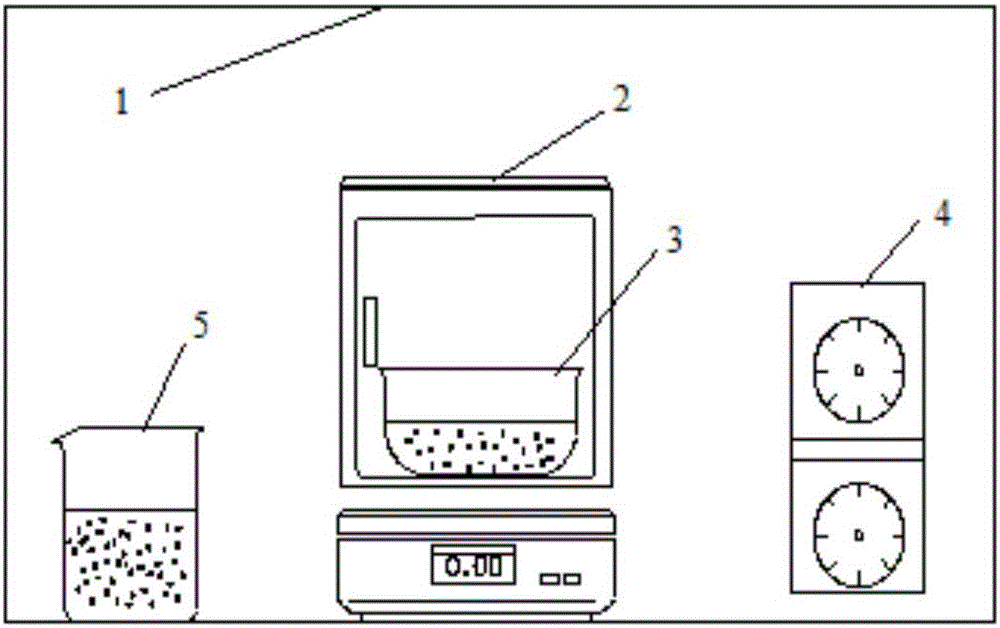

[0028] The present invention is used for the preparation method of the aloe polysaccharide / bacterial cellulose composite film of medical dressing, and concrete steps are as follows:

[0029] Step 1, the strain Acetobacter xylinum NUST4.2 is activated;

[0030] Activation of strains: Weigh the required ingredients according to the solid medium formula, add water to make up the volume, adjust to the required pH, and sterilize at 121°C for 20 minutes. After the sterilization, pour the liquid into the sterilized petri dish while it is hot and cool it down to room temperature to obtain a solid medium. The strain Acetobacter xylinum NUST4.2 was placed in a solid medium, and placed in a constant temperature incubator at 30° C. for static culture for 3-5 days to obtain activated bacteria. Among them, solid medium (w / v): glucose 2.0%, sucrose 1.0%, peptone 1.0%, yeast extract powder 0.1%, agar 1.8%, sodium dihydrogen phosphate 0.25%, citric acid 0.11%, magnesium sulfate 0.04%; pH = 6...

Embodiment 1

[0051] Step 1, the activation of strains: according to the solid medium (w / v): glucose 2.0%, sucrose 1.0%, peptone 1.0%, yeast extract powder 0.1%, agar 1.8%, sodium dihydrogen phosphate 0.25%, citric acid 0.11 %, Magnesium Sulfate 0.04%; pH=6.0, weigh the required substances and add water to make up 200ml solution, sterilize, subpackage and cool down, inoculate in a clean bench, place it at 30°C for 3-5 days, and finally get activated bacteria.

[0052] Step 2, preparation of seed liquid: according to the formula of seed medium: glucose 2.0%, ammonium sulfate 0.6%, potassium dihydrogen phosphate 0.1%, magnesium sulfate 0.04%; peptone 0.3%, yeast extract powder 0.225%, carboxymethyl cellulose Sodium 0.04% Weigh the required components, add water to make up to 50ml, place in a 25% Erlenmeyer flask, sterilize at 121°C for 20min, and cool to 30°C after sterilization to obtain a seed culture medium solution. Then, inoculate the activated strains into the obtained seed culture sol...

Embodiment 2

[0056] Steps 1 and 2 are as above and do not need to be repeated.

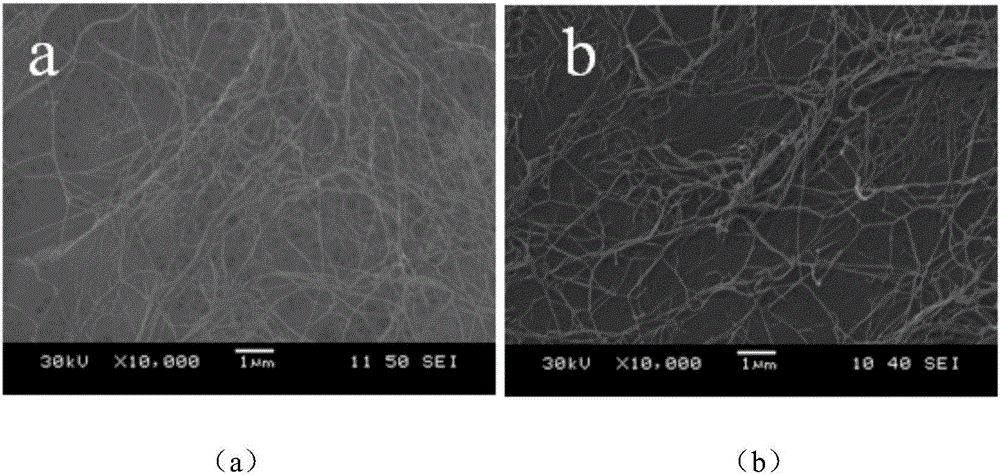

[0057] Step 3, the preparation of aloe polysaccharide / bacterial cellulose composite film: according to the fermentation medium formula: glucose 2.25%, sucrose 2.75%, ammonium sulfate 0.1%, potassium dihydrogen phosphate 0.5%, magnesium sulfate 0.07%, calcium lactate 0.02%, 1.0% peptone, 0.75% yeast extract powder, 0.15% glacial acetic acid, 0.06% citric acid, 0.04% sodium carboxymethyl cellulose, 0.2% or 0.3% aloe polysaccharide, weigh the required ingredients, add water to make up 50ml, and adjust to the desired Need pH, put it in a Erlenmeyer flask with 50% liquid content, sterilize at 121°C for 20 minutes, cool to 30°C after sterilization to obtain fermentation medium solution. The seeds are inserted into the fermentation medium solution according to the inoculation amount of 10% (volume ratio), and then placed in a constant temperature incubator at 30° C. for 7 days.

[0058] Step 4, purification of aloe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com