Modification method of corncobs, modified product of corncobs and application of modified product

A corncob, corncob flour technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of underutilization and waste of resources, and achieve excellent physical adsorption and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

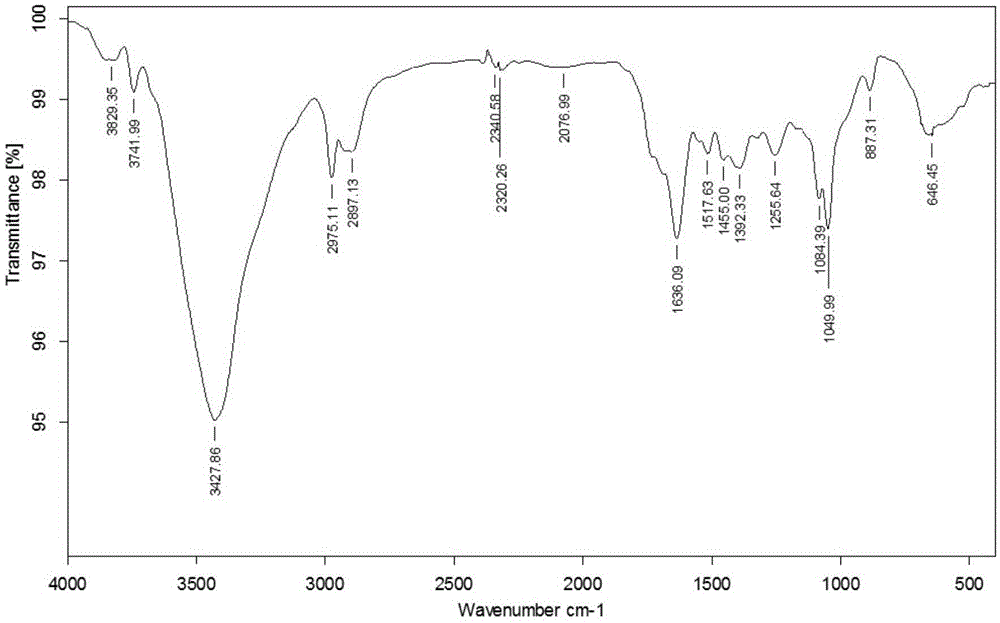

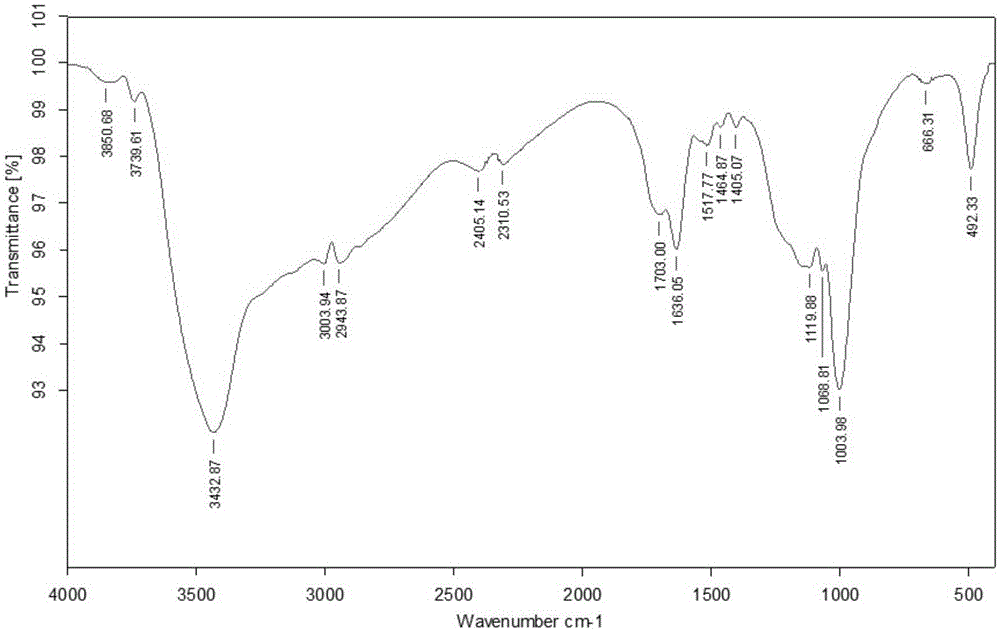

[0032] The modification method of embodiment 1 corn cob, the steps are:

[0033] (1) After chopping the corncobs, mix them with tap water and mash them, wash and soak the slag with tap water, remove suspended fine substances and soluble substances, air-dry at room temperature after filtering, and pass through a 0.5mm sieve to obtain dry corncobs;

[0034] (2) According to the volume ratio of solid-liquid ratio 1:5, (also can be 1:8, or 1:10), dry agricultural by-products and concentration are 2mol / L (also can be 1.5mol / L, or 1mol / ) L phosphoric acid solution is mixed evenly, soaked in a water bath at 40°C for 2 hours, and filtered;

[0035] (3) drying the filtered corncob phosphoric acid mixture at a temperature of 30 to 70°C for 2 to 5 hours, and then drying at a temperature of 110 to 150°C for 1.5 to 4 hours;

[0036] (4) The dried material is repeatedly washed with deionized water to PH=7;

[0037] (5) Dry the neutral material at a temperature of 30-50°C, and the obtaine...

Embodiment 2

[0038] Embodiment 2 modified material adsorption test:

[0039] Add 100mL of 500mg / L malachite green solution to each of ten 250mL Erlenmeyer flasks, then add different amounts of modified corncobs and unmodified corncobs, and shake the malachite green solution with quantitative corncobs After adsorption, directly absorb the supernatant, dilute a certain multiple, measure its absorbance value at a wavelength of 617nm with a spectrophotometer, and calculate its adsorption rate by measuring the concentration of the malachite green solution after 4 hours of adsorption. Compared. Calculated as follows:

[0040] T % = C 0 - C t C 0 × 100 % ; q = C 0 ...

Embodiment 3

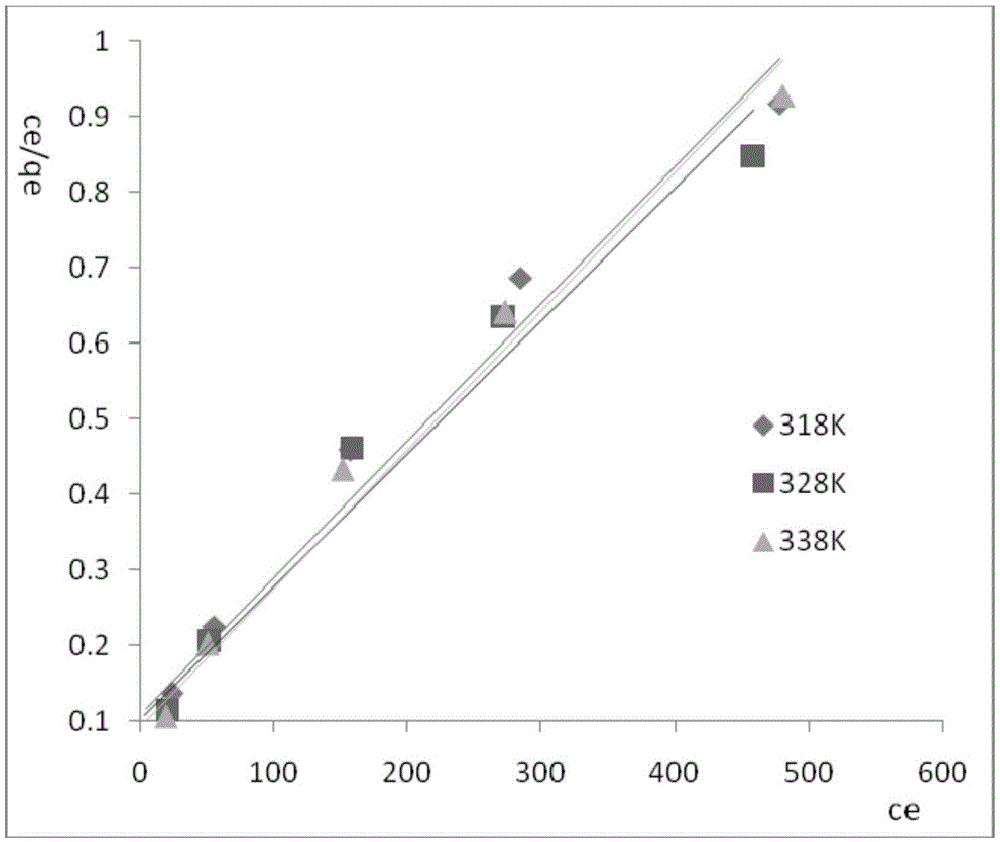

[0045] Embodiment 3 modified material isothermal adsorption experiment:

[0046] A series of 100mL malachite green solutions of different concentrations were added to a 250mL conical flask, the pH was controlled at 7.0, and 0.1g of modified corn cob adsorbent was added to the conical flask, which was shaken and adsorbed in a constant temperature water bath shaking box for 4h. Ensure that malachite green solutions of different concentrations are adsorbed and saturated, then take the supernatant and dilute it by a certain number of times to measure its absorbance, calculate the remaining malachite green concentration through the standard curve, and finally use the equilibrium mass concentration C e The equilibrium adsorption capacity qe is plotted to obtain the isotherm adsorption line of the modified corn cob to malachite green, such as Figure 6 shown, and fitted by the Langmuir adsorption equation and the Freundlich adsorption equation. The Langmuir fitting results of malach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com