Cement-based grouting material

A grouting material and cement-based technology, which is applied in the field of cement-based grouting materials, can solve the problems of poor expansion, low early strength, and poor fluidity, and achieve the effect of improving early strength, enhancing flow performance, and improving early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

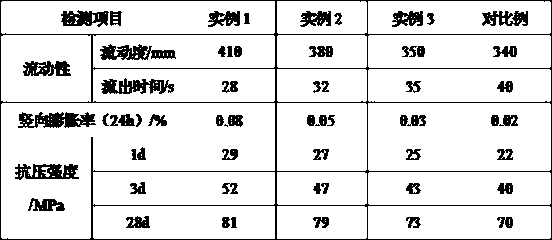

Examples

example 1

[0023]In parts by weight, take 20 parts of asphalt powder successively, 60 parts of mass fraction is 20% potassium permanganate solution, 30 parts of silane coupling agent, 30 parts of mass fraction is 50% ethanol solution, 20 parts of ethyl orthosilicate , 20 parts of nano-magnesium oxide, first put the pitch powder into the melt-spinning tube, melt it under the condition of 480°C to obtain a melt, and then spin the melt under the condition of a spinning voltage of 30kV and an acceptance distance of 10cm. Carry out spinning to get the asphalt raw silk, then add the obtained pitch raw silk and 20% potassium permanganate solution into the beaker, and move the beaker into a digital speed measuring constant temperature magnetic stirrer at a temperature of 40°C and a speed of 500r Under the condition of heating and stirring for 40min, filter to obtain a filter cake, then wash the filter cake 5 times with deionized water, then place the washed filter cake in a vacuum freeze-drying o...

example 2

[0025] In parts by weight, 20 parts of aluminum powder, 20 parts of glycerin, 20 parts of gluten, and 120 parts of water are successively added to a single-necked flask with 0.03 times the quality of aluminum powder, glycerin and aluminum powder, and the Stir and mix at 600r / min for 30min, then add gluten powder and water to the single-necked flask, stir and mix at 800r / min for 40min, let it stand for swelling for 4h, then place the single-necked flask in an ultrasonic disperser, and ultrasonically disperse for 30min to obtain Modified aluminum powder dispersion; then in parts by weight, get 40 parts of cement, 60 parts of quartz sand, 40 parts of water, 6 parts of water reducing agent, 20 parts of fly ash, 20 parts of mineral powder, 20 parts of slag, 10 parts of defoamer, 10 parts of water retaining agent, 20 parts of modified aluminum powder, cement, quartz sand, water, water reducer, fly ash, mineral powder, slag, defoamer, water retaining agent and modified aluminum powder...

example 3

[0027] In parts by weight, take 20 parts of asphalt powder successively, 60 parts of mass fraction is 20% potassium permanganate solution, 30 parts of silane coupling agent, 30 parts of mass fraction is 50% ethanol solution, 20 parts of ethyl orthosilicate , 20 parts of nano-magnesium oxide, first put the pitch powder into the melt-spinning tube, melt it under the condition of 480°C to obtain a melt, and then spin the melt under the condition of a spinning voltage of 30kV and an acceptance distance of 10cm. Carry out spinning to get the asphalt raw silk, then add the obtained pitch raw silk and 20% potassium permanganate solution into the beaker, and move the beaker into a digital speed measuring constant temperature magnetic stirrer at a temperature of 40°C and a speed of 500r Under the condition of heating and stirring for 40min, filter to obtain a filter cake, then wash the filter cake 5 times with deionized water, then place the washed filter cake in a vacuum freeze-drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com