Patents

Literature

34results about How to "Adjustable expansion coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

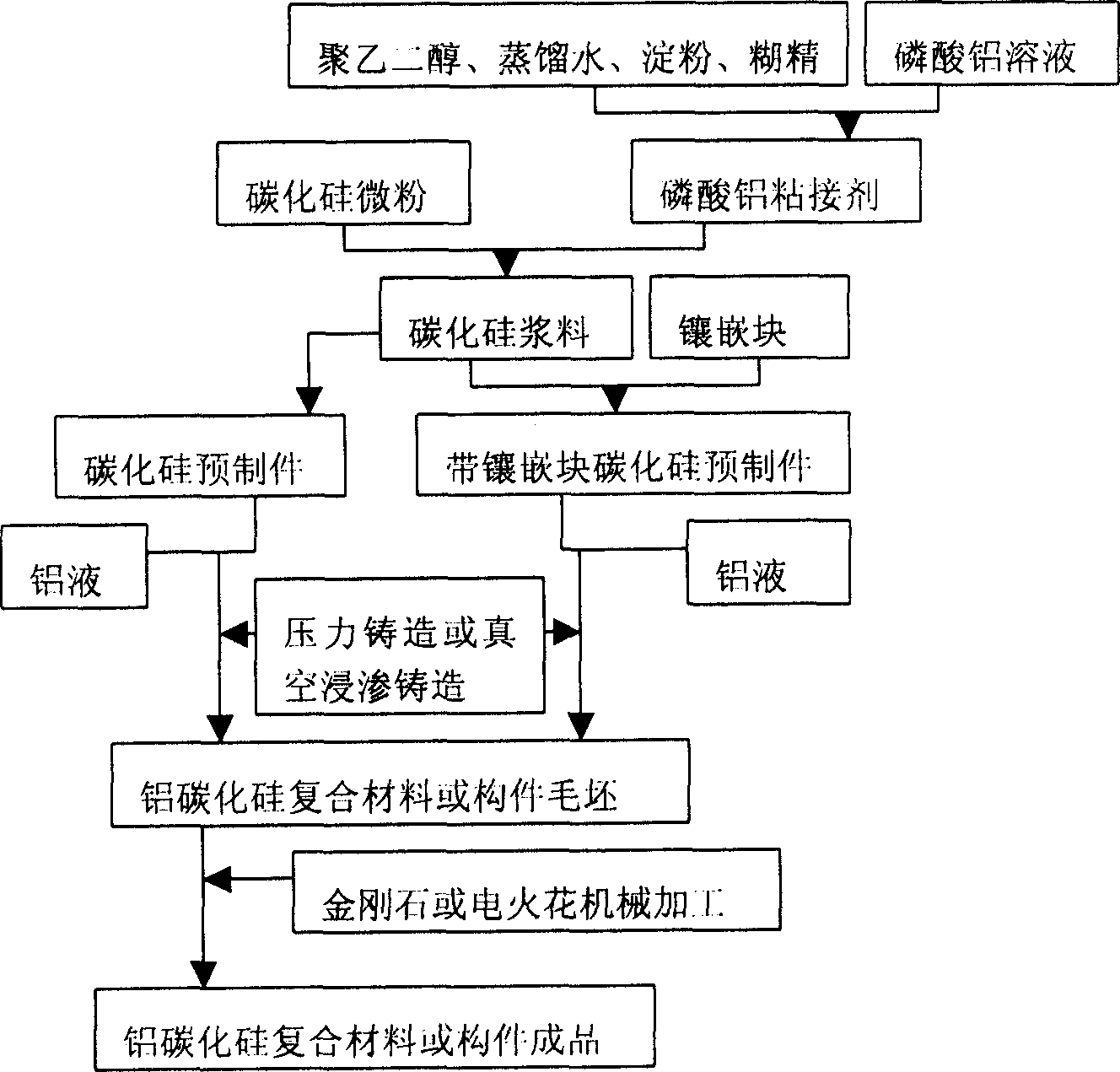

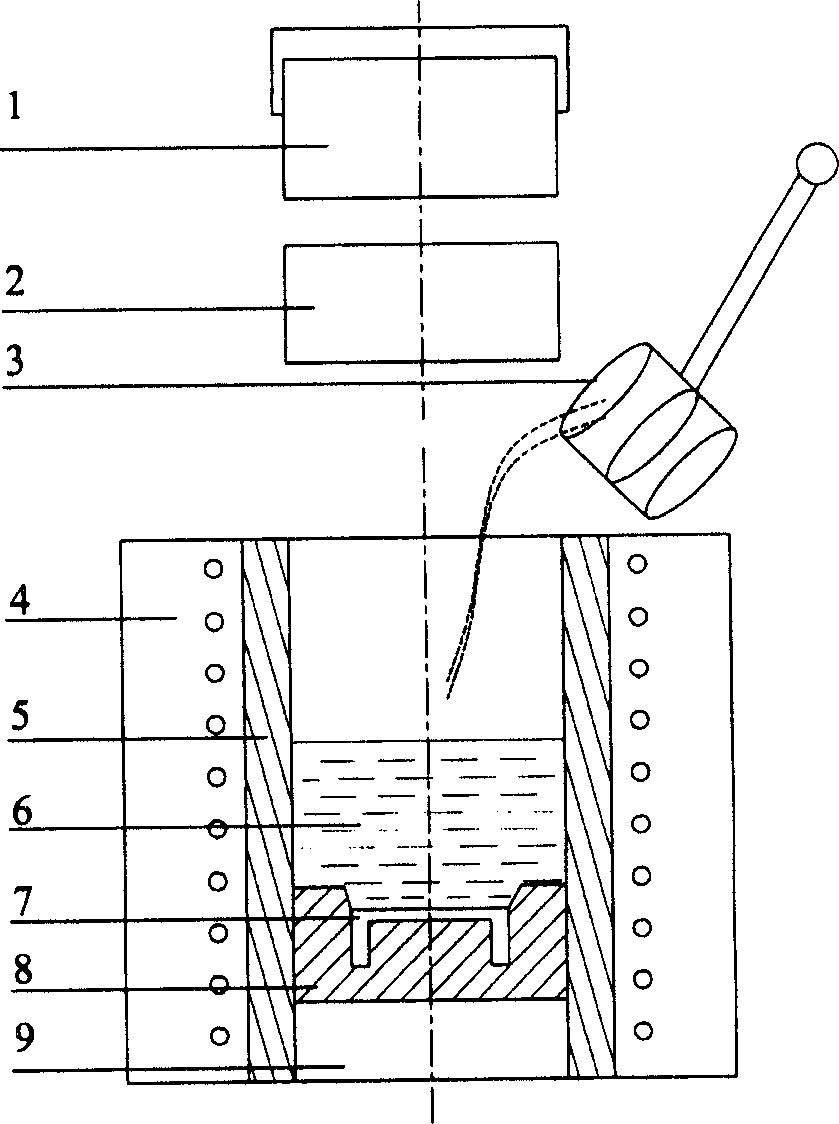

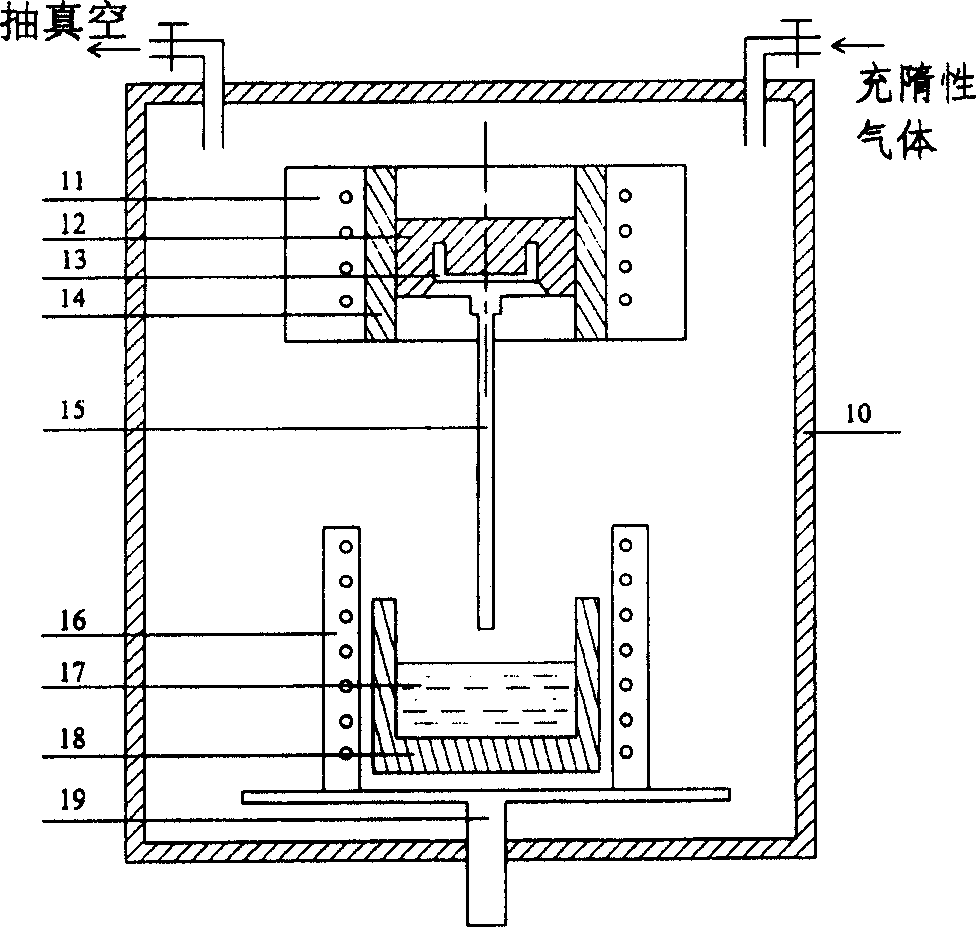

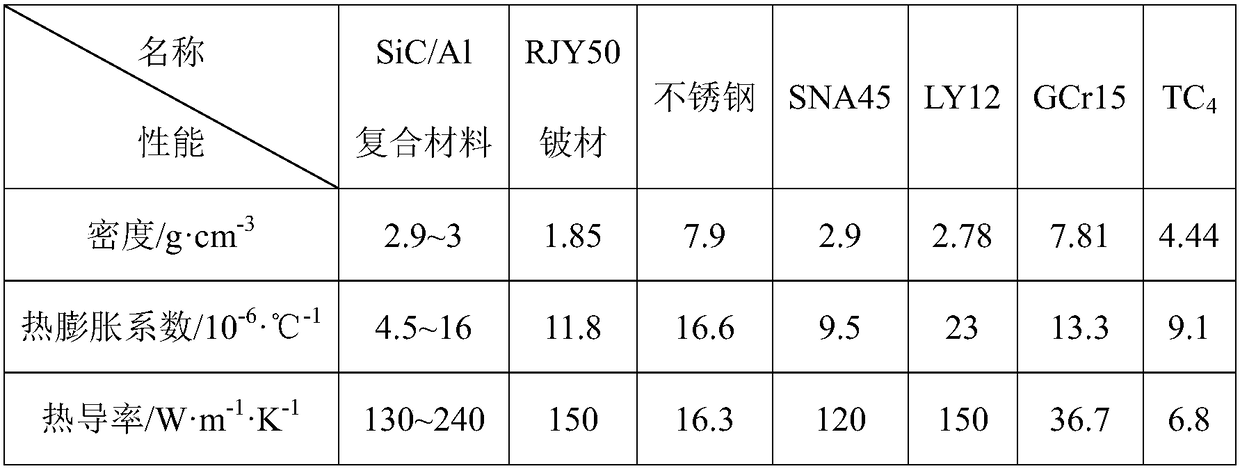

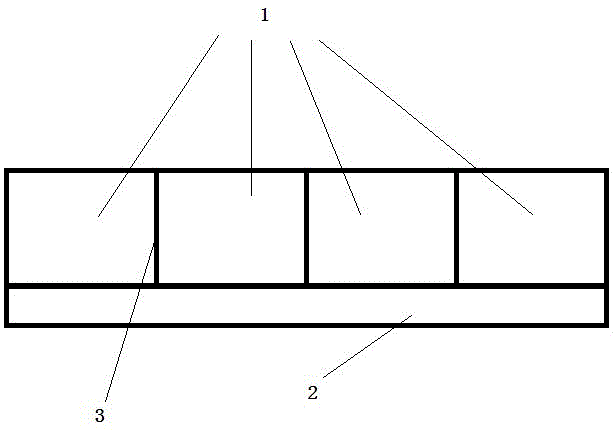

Method for preparing composite material of aluminium silicon carbide and structural piece

InactiveCN1498878ALow densityAdjustable expansion coefficientSemiconductor/solid-state device detailsSolid-state devicesHybrid integrated circuitIntegrated circuit

A composite silicon aluminocarbide material or its member is prepared through preparing the aluminum phosphate solution from phosphoric acid and aluminum hydroxide, mixing it with polyethanediol, distilled water, dextrin and glutinous rice flour to obtain binder, mixing it with silicon carbide microparticles, die pressing to obtain prefabricated raw material, heat treating in inertial gas or air, pressure casting or vacuum impregnating to osmosize the molten aluminum alloy into it, and machining by needed sizes. Its advantages are low density, adjustable expansibility, high thermal conductivity, elastic modulus and air tightness.

Owner:NAT UNIV OF DEFENSE TECH

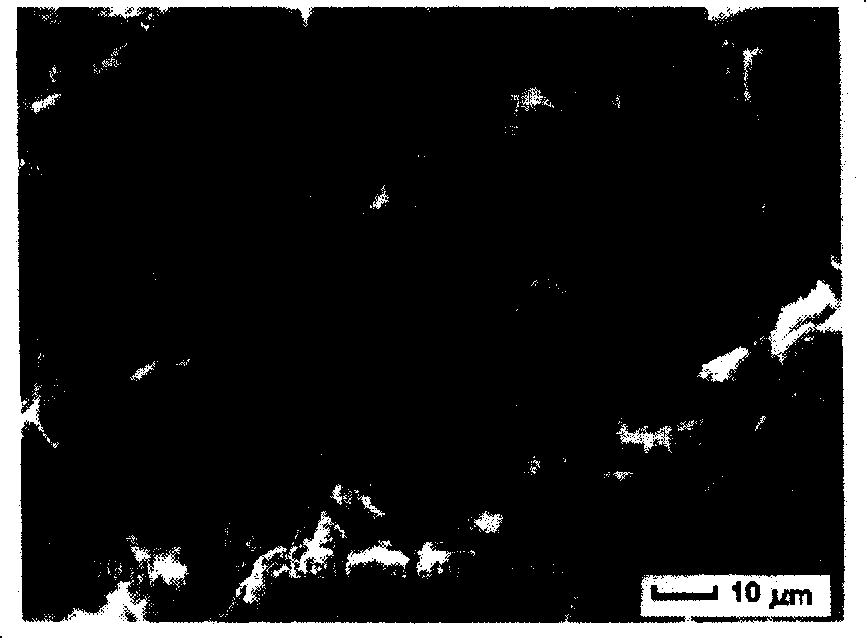

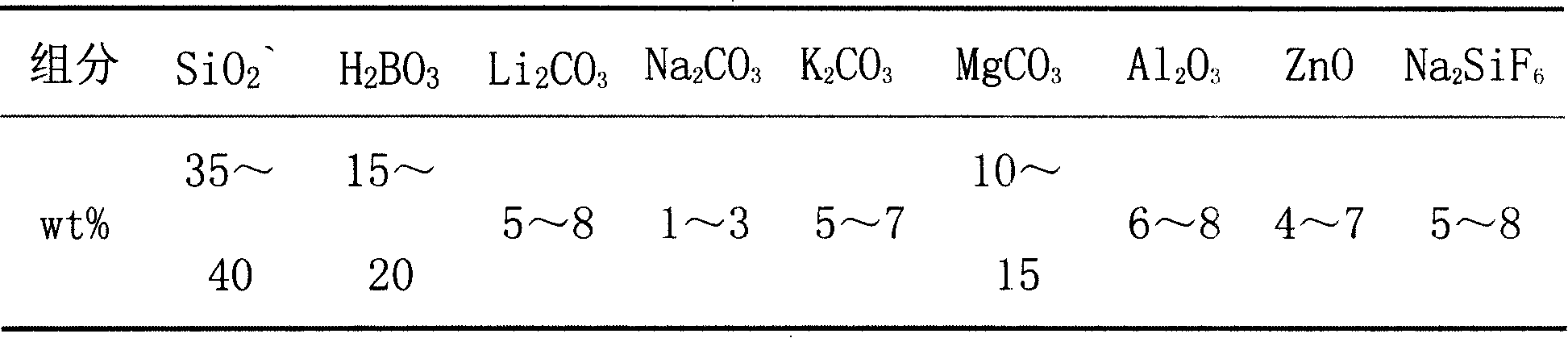

Glass-ceramics used as ultrahard material grinding wheel bond and preparation method thereof

The invention relates to a microcrystal glass and preparation method used as super-hard grinding wheel bond, which adopts the method that: quartz, boracic acid, alumina, zinc oxide, lithium carbonate, sodium carbonate, potassium carbonate and magnesium carbonate are used as basic glass materials and sodium fluorosilicate is used as nucleation agent, the materials are smelted to form the glass that is quenched and then smashed to glass powder; the glass powder is pressed, molded, and sintered, and crystallized under certain temperature so as to obtain the microcrystal glass; the main crystal phase of the microcrystal glass is fluorophlogopite, the microcrystal is a hexagonal flake structure, the size of the microcrystal is 1um-2um. The microcrystal glass can be used as super-hard grinding wheel bond in place of ceramic so as to improve the strength of super-hard grinding wheel greatly, thereby improving speed and service life of grinding wheel; the invention also has integrated with excellent performances of glass and porcelain enamel, such as wear-resistant, anti-corrosion, good anti-oxidation, excellent electrical property, adjustable expansion coefficient, and good thermal stability. The invention can widely be applied as structural materials, optical materials, and architecture materials.

Owner:HUNAN UNIV

Steel blank grinding abrasion wheel adopting microcrystal ceramic bonding agents

ActiveCN102363286AImprove the speed of useExtended service lifeAbrasion apparatusCeramic compositeTissue density

The invention relates to a steel blank grinding abrasion wheel adopting microcrystal ceramic bonding agents, which is in a structure made of polycrystalline solid materials with the coexistence of glass and crystals and adopts the bonding agents of clay, feldspar, boron-containing microcrystal glass, pyrophyllite and soapstone to be made into high-intensity and low-shrinkage engineering ceramic bonding agents, good performance of the glass and the ceramics such as high mechnical intensity, wear resistance, corrosion resistance and the like are integrated, then, the glass and the ceramics are combined with mixed grinding materials, a molding pressing method is adopted for the high-pressure double-side pressing process forming, the low-temperature firing is adopted, the positive pressure reducing atmosphere heat simulation crystallization is adopted at the 800 DEG C heat insulation section, and the mixed grinding material and micro porous glass phase high-intensity microcrystal engineering ceramic composite structure is formed, so the intensity and the bonding degree of the steel blank grinding abrasion wheel are greatly improved, the use linear speed of the abrasion wheel is accelerated, and the safety factor is high. The steel blank grinding abrasion wheel belongs to the novel efficient special steel blank grinding abrasion wheel with the characteristics that the intensity andthe hardness are high, the tissue density is uniform, the grinding ratio is great under the condition of high-speed grinding, workpieces can not be damaged through firing, and the automation of iron and steel industries is easy to realize.

Owner:江苏华东砂轮有限公司

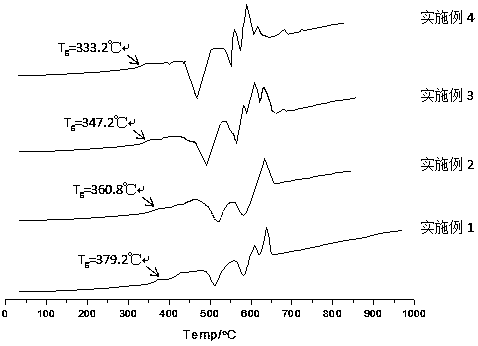

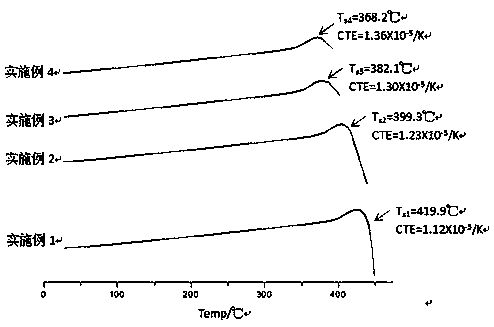

Bismuthate low-melting point and lead-free sealing grass and preparation method thereof

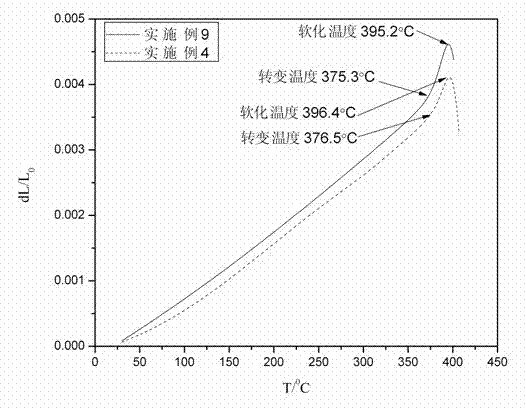

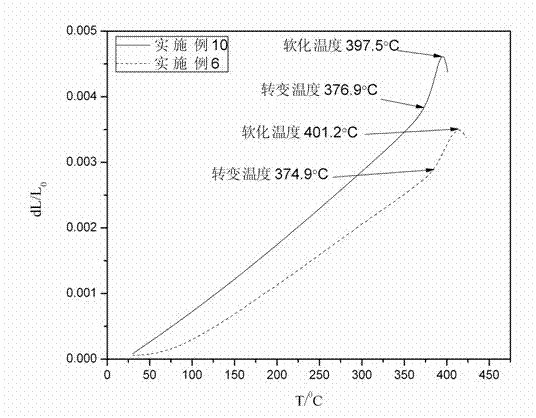

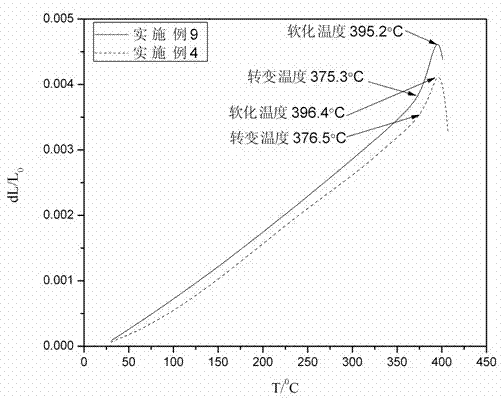

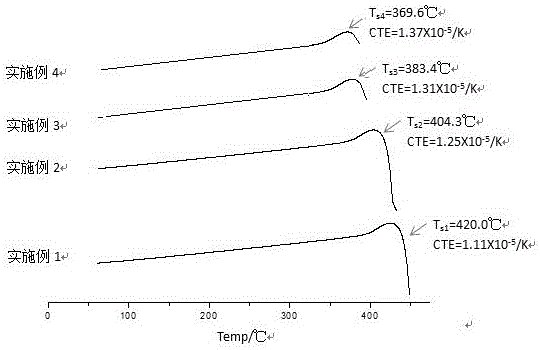

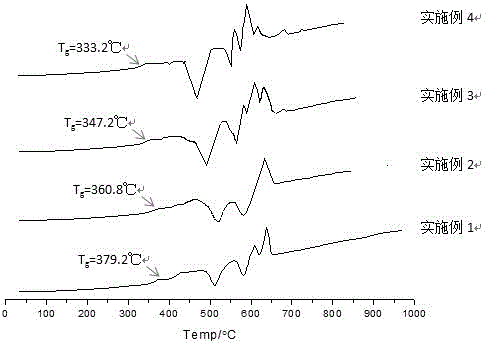

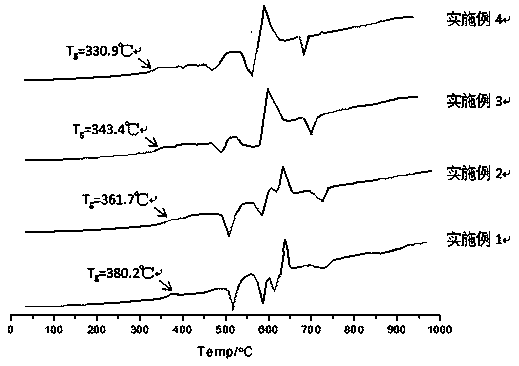

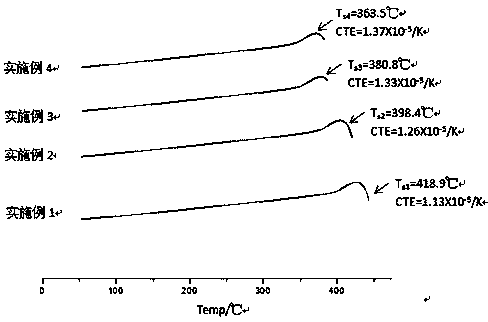

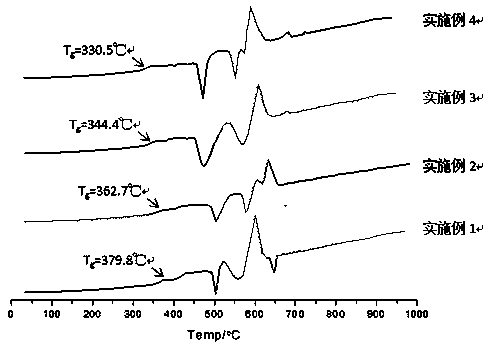

The present invention discloses a bismuthate low-melting point and lead-free sealing grass and a preparation method thereof. The bismuthate low-melting point and lead-free sealing grass powder comprises, by mass, 75-90% of base glass and 10-25% of a filler, wherein the filler is a zirconium phosphate salt with an expansion coefficient of -5*10<-6>k<-1>-5*10<-6>k<-1>. The bismuthate low-melting point and lead-free sealing grass of the present invention has characteristics of lead-free property and green environmental protection, can replace the lead-containing glass so as to eliminate the pollution due to the lead, and has excellent chemical stability. The production process is simple and the cost is low. Compared to other filler-doped sealing glass powders, the sealing temperature of the present invention is low, the glass transition temperature of the present invention is 330-370 DEG C, the softening temperature of the present invention is 370-410 DEG C, the sealing temperature of the present invention is less than 450 DEG C. With adjusting the proportion of the filler, the adjustable expansion coefficient can be realized at the low sealing temperature, wherein the adjustment range is (70-90)*10<-7> / DEG C, such that different requirements of the sealing device to the expansion coefficient of the sealing material can be met, and the sealing for VFD, PDP, CRT and other glass products can be directly performed.

Owner:CHINA JILIANG UNIV

Preparation methods of diamond/silicon carbide prefabricated part and diamond/silicon carbide/aluminium compound material

InactiveCN108821775AGuaranteed compactnessIncrease volume fractionDifferential pressureAir tightness

The invention provides preparation methods of a diamond / silicon carbide prefabricated part and a diamond / silicon carbide / aluminium compound material. The methods comprise the following steps that 1, silicon carbide powder and diamond powder are mixed according to a mass ratio of 5:2, and after continuous and even mixing, micro diamond powder is obtained; 2, a binder is added into the micro diamondpowder to obtain mixed powder; 3, a diamond prefabricated part green body obtained in last step is subjected to sintering to prepare the diamond / silicon carbide prefabricated part; 4, in a differential-pressure casting furnace, the diamond / silicon carbide prefabricated part is impregnated with aluminium alloy liquid, so that the diamond / silicon carbide / aluminium compound material is obtained. Thediamond / silicon carbide / aluminium compound material prepared through the method has the characters of being low in density, adjustable in expansion coefficient, high in heat conductivity, high in elasticity modulus, good in gas tightness and low in cost, and can be widely applied to the micro-electronics fields of hybrid integrated circuits, millimeter wave / micron wave integrated circuits, multi-chip modules, high current and power IGBT modules and the like.

Owner:XIAN AERONAUTICAL UNIV

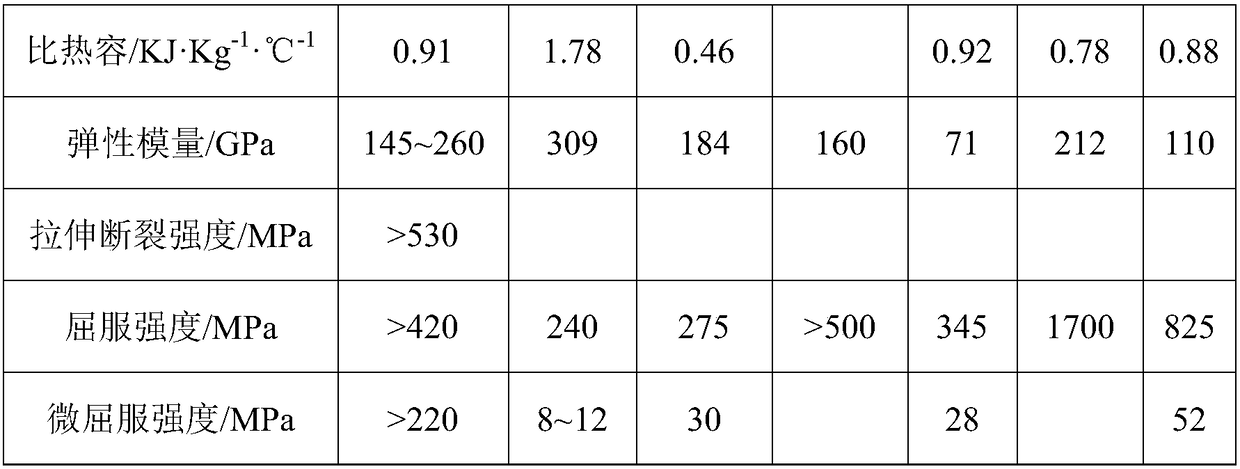

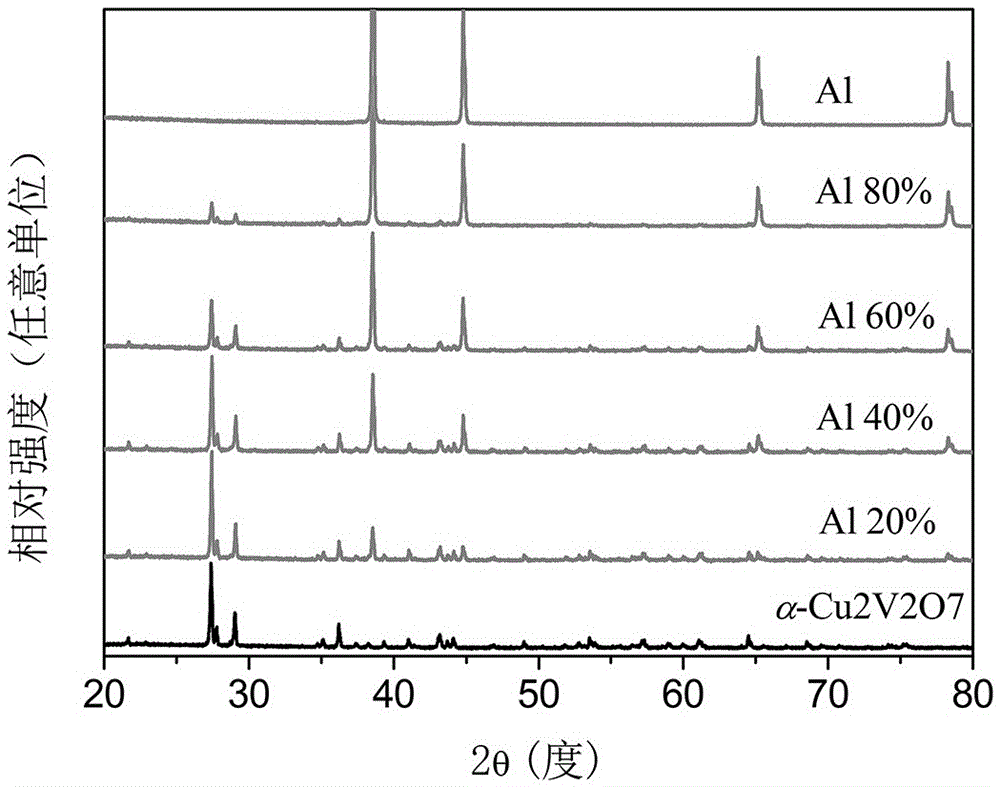

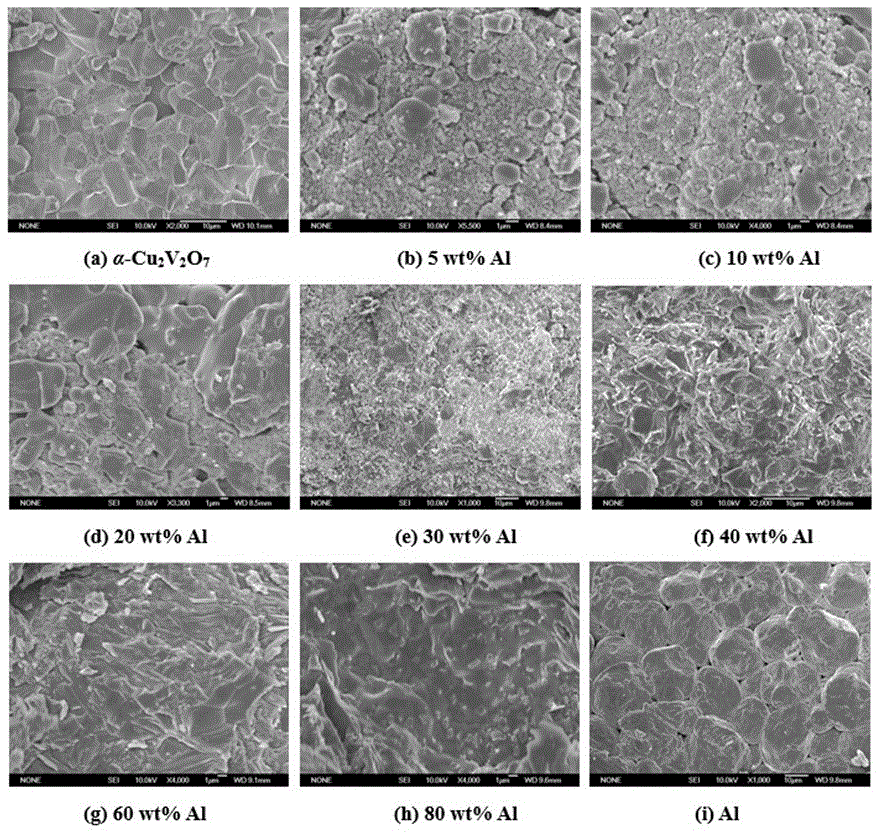

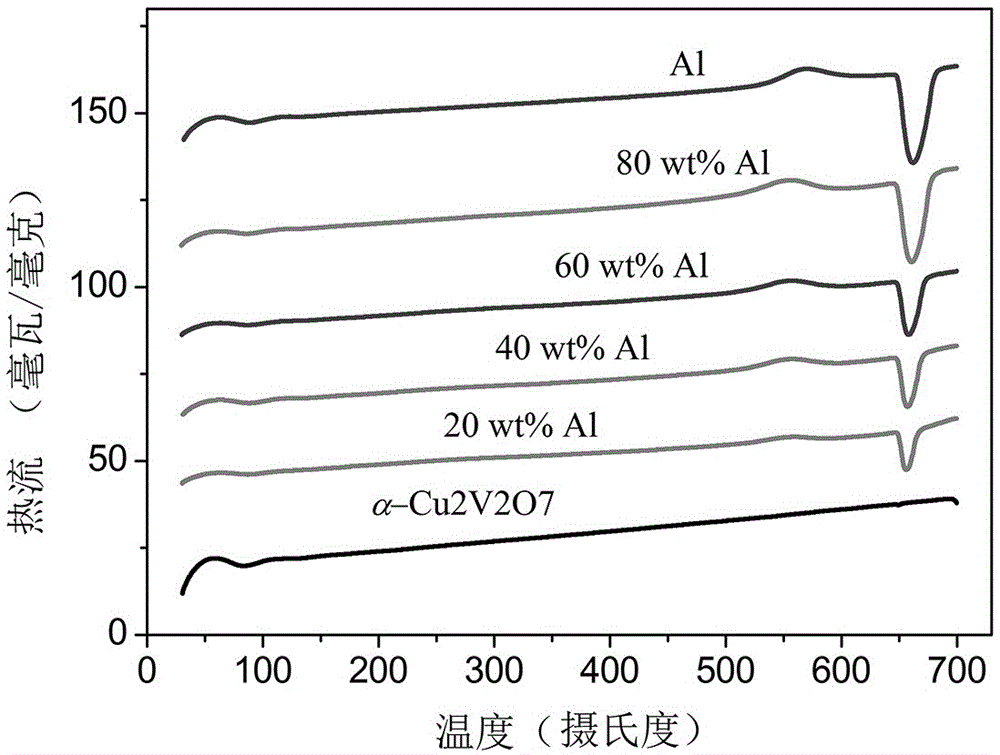

Controllable thermal expansion composite conductive ceramic material alpha-Cu2V2O7-Al

InactiveCN105648248AAdjustable expansion coefficientGood high temperature electrical conductivitySolid phasesIntegrated circuit

The invention belongs to the technical field of inorganic composite materials, and particularly relates to a novel controllable thermal expansion composite conductive ceramic material alpha-Cu2V2O7-Al and a preparing method thereof. The material is prepared through solid-phase sintering of alpha-Cu2V2O7 and Al powder, wherein the mass percent of the Al powder ranges from 5% to 80%. The preparing method comprises the steps such as material mixing, preforming blank forming and sintering. The provided controllable thermal expansion composite conductive ceramic material alpha-Cu2V2O7-Al is simple in preparing technology, low in cost, environment-friendly, free of pollution and suitable for industrial production. Meanwhile, the material has the beneficial effects that the expansion coefficient can be adjusted, and the high-temperature conductive performance is good; and the controllable thermal expansion composite conductive ceramic material alpha-Cu2V2O7-Al has wide application prospects in integrated circuits, photoelectron instruments and meters and other technical fields with the high requirements for base material heat matching and high-temperature electric conduction and related products of the technical fields.

Owner:ZHENGZHOU UNIV

Concrete mortar

The invention discloses concrete mortar and belongs to the field of mortar. The concrete mortar takes lignite as a raw material; the lignite can be pyrolyzed under a high-temperature condition to generate tar and a coke component; the tar has the effect of sticking each component; the coke component can react with hydroxyl silicate in stone material liquid in a system under the catalysis effect ofnano iron powder to generate a silicon carbide framework, so that a reinforcing effect is realized and the toughness of the system is improved; asphalt fibers are oxidized through potassium permanganate so that the adsorption force of the asphalt fibers on nano magnesium oxide is enhanced, and the adsorption performance of the asphalt fibers on silicon dioxide generated by hydrolyzing tetraethylorthosilicate can also be effectively improved; the early age strength of a cement-based grouting material is improved, and the expansion coefficient of the cement-based grouting material can be adjusted through magnesium oxide, so that the cement-based grouting material is not easy to crack after being cured. By adopting the concrete mortar provided by the invention, the problems that common mortar at present is easy to hollow and rack, and the toughness and mechanical property are poor are solved.

Owner:FOSHAN LINGCHAO NEW MATERIAL CO LTD

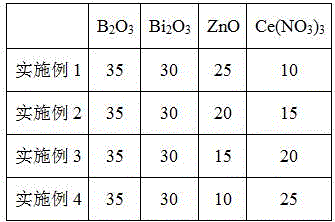

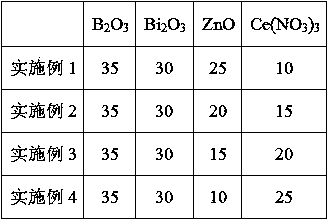

Ce-containing low-temperature sealing glass as well as preparation and application method of Ce-containing low-temperature sealing glass

The invention discloses Ce-containing low-temperature sealing glass as well as preparation and application method of the Ce-containing low-temperature sealing glass. The Ce-containing low-temperature sealing glass consists of the following raw materials: B2O3, Bi2O3, ZnO and Ce(NO3)3 in a molar ratio of (10-50):(20-40):(5-30):(0-30). Through the coordination between high-concentration Bi2O3 and B2O3, the softening temperature of glass is lowered, so that low-temperature sealing is realized; Ce<3+> in a glass network prepared by melting quenching is transformed into Ce<4+>, the transformation of Bi<3+> in glass into Bi<5+> is prevented, and the refractive index of glass is stabilized; and Ce not only can further lower the softening temperature of the sealing glass, but also can adjust the expansion factor of the glass so as to remarkably improve the sealing property of the sealing glass. Moreover, Ce remarkably reduces the surface tension of the glass, improves the interface bonding property between the sealing glass and an alloy connector and is applicable to the field of photoelectric materials and other low-temperature precise sealing. According to the invention, the preparation raw materials are simple and easily available, the cost is low, the technology is simple and feasible, and the prepared low-temperature sealing glass has good performance and stable refractive index and meets the conditions of practical utilization and industrialization.

Owner:FUZHOU UNIV

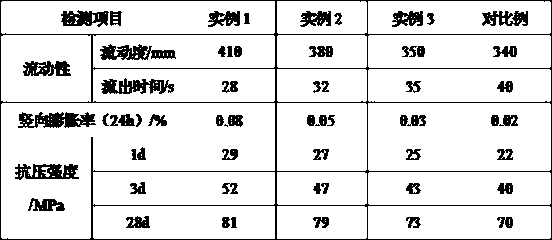

Cement-based grouting material

The invention discloses a cement-based grouting material, and belongs to the technical field of building materials. The cement-based grouting material is prepared according to the following steps: melting asphalt powder, performing high-voltage electrostatic spinningto obtain asphalt raw threads, soaking the asphalt raw threads in a potassium permanganate solution, performing oxidation to obtain oxidized asphalt fibers, mixing nano magnesium oxide, a silane coupling agent and an ethanol solution, performing ultrasonic dispersion, adding the oxidized asphalt fibers, performing mixing under stirring, adding tetraethoxysilane dropwise, performing mixing under stirring, performing filtering, performing washing, performing drying, and performing carbonizing to obtain modified asphalt fibers; mixing aluminum powder and glycerol under stirring, adding wheat gluten powder, performing mixing under stirring, adding water, performing swelling, allowing the obtained material to stand, and performing ultrasonic dispersion to obtain a modified aluminum powder dispersion liquid; and mixing cement, quartz sand, water, a water reducing agent, fly ash, mineral powder, slag, a defoaming agent, a water retaining agent, the modified asphalt fibers and the modified aluminum powder under stirring to obtain the cement-based grouting material. The cement-based grouting material obtained by the technical scheme has the advantages of good fluidity, early-stage strength and expansion performance.

Owner:郭迎庆

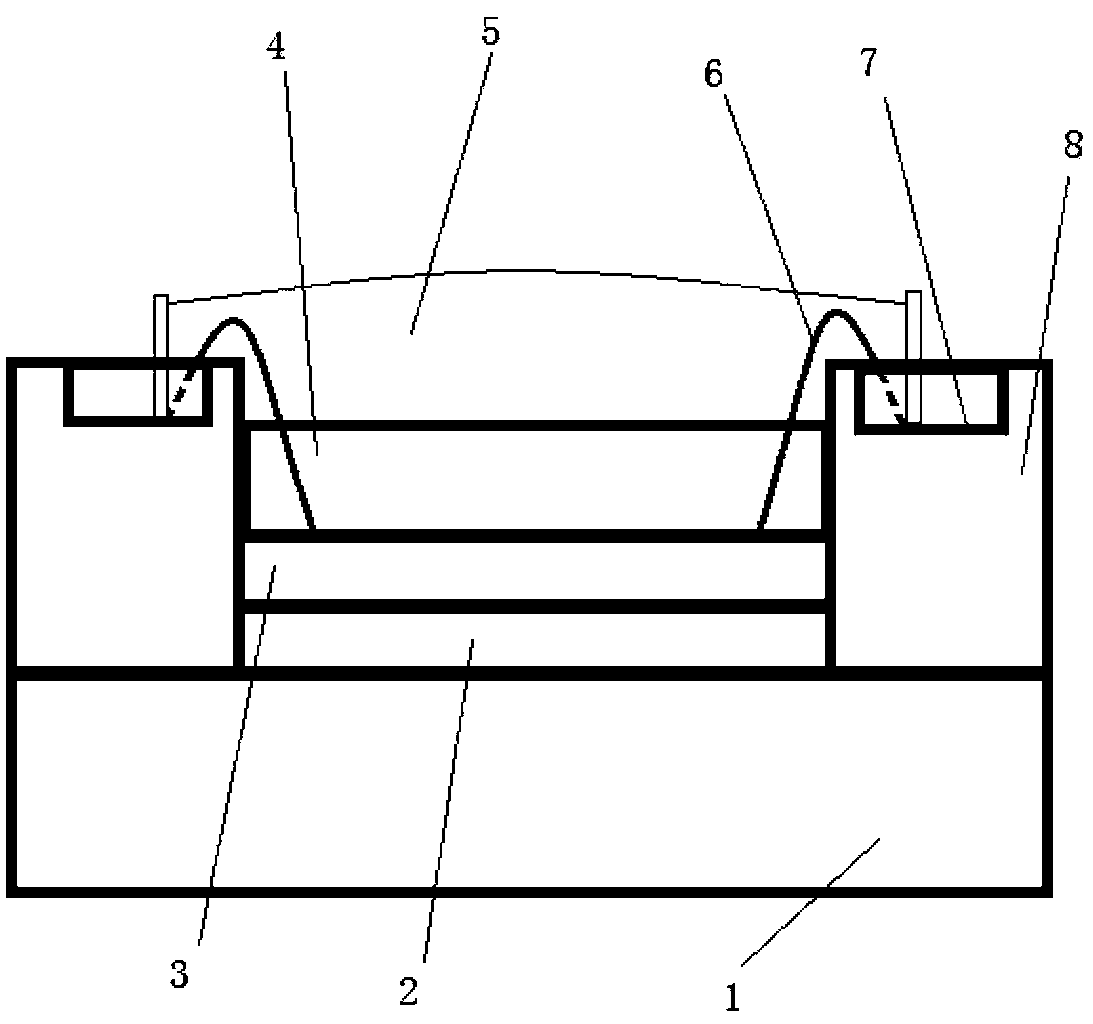

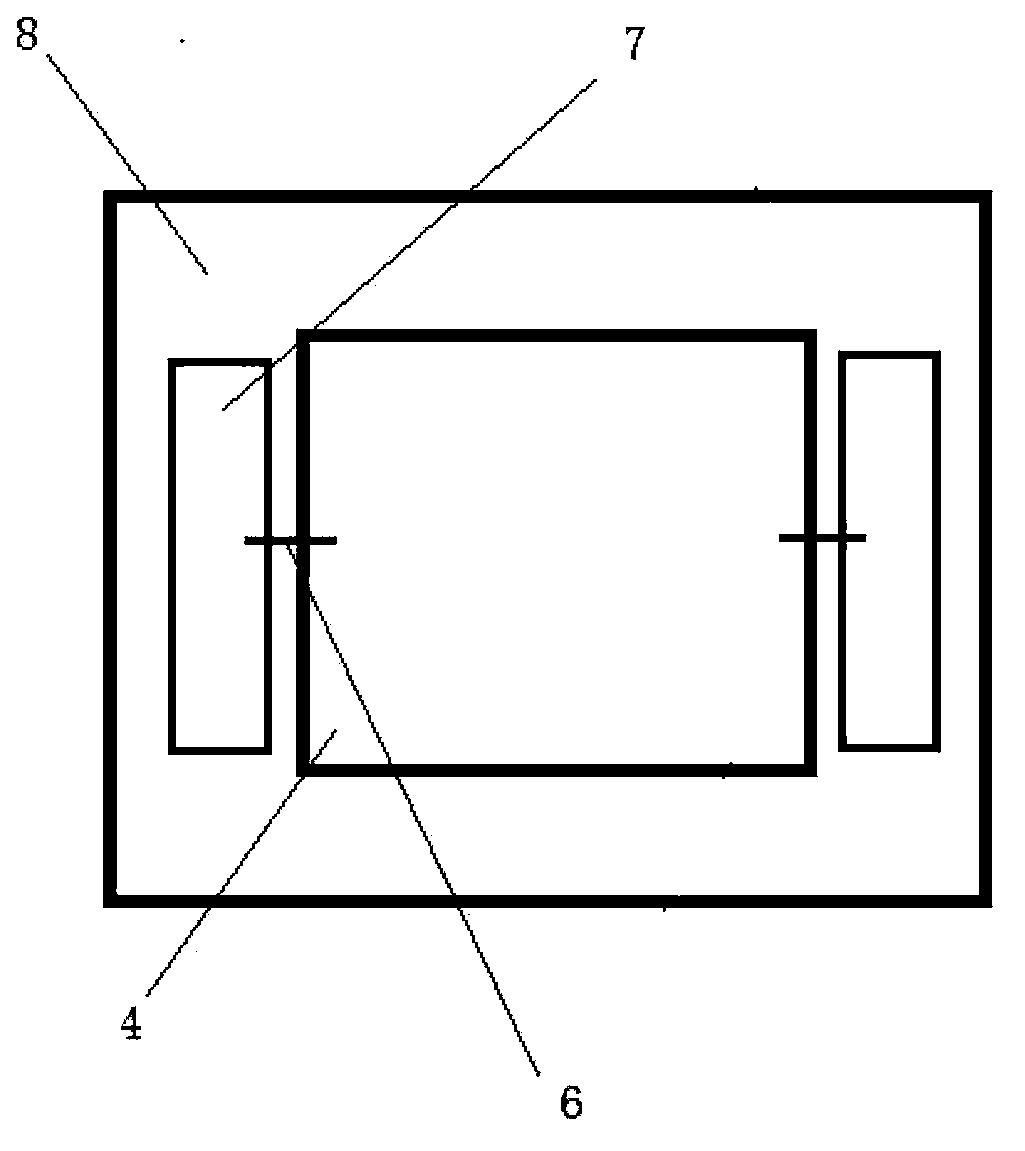

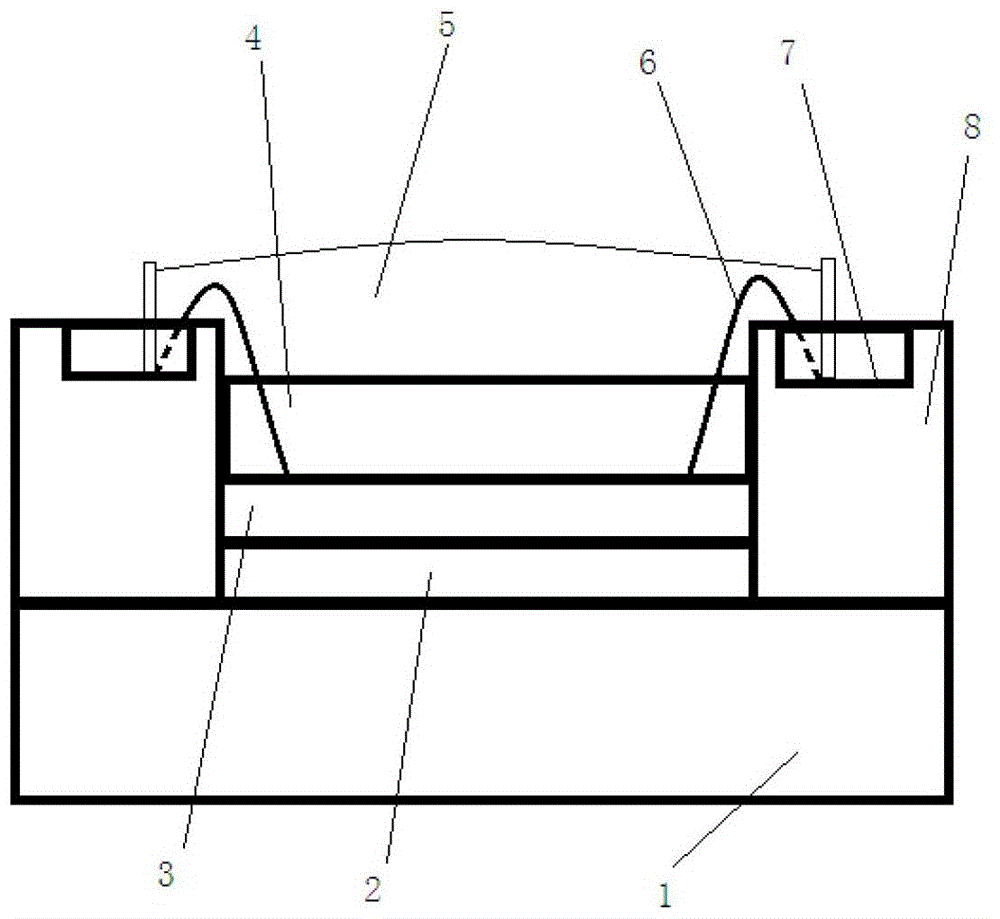

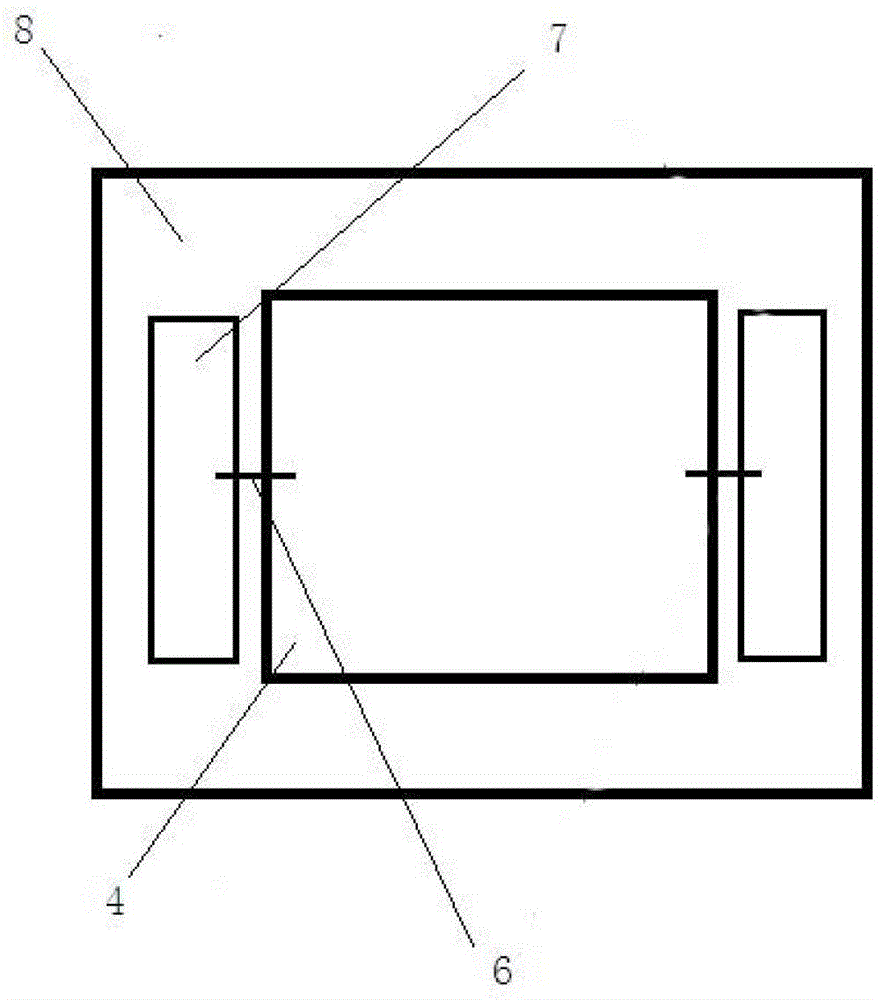

Light-emitting diode (LED) packaged with AlSiC composite substrate

The invention discloses an LED packaged with an AlSiC composite substrate. The LED comprises the AlSiC composite cooling substrate, an LED light source module, gold threads and an alumina ceramic frame, wherein the surface of the AlSiC composite cooling substrate is plated with a copper film and a silver film sequentially; the LED light source module is packaged on the AlSiC composite cooling substrate; the alumina ceramic frame is arranged on the outer side of the LED light source module and adheres to the LED light source module; two copper-film electrodes are plated on the alumina ceramic frame and connected with a positive pole and a negative pole of the LED light source module through the gold threads respectively. According to the LED, thermal expansion coefficients of the AlSiC composite substrate and an LED chip material are matched, so that an LED chip which is packaged on the substrate is not prone to falling, and the service life of the LED is prolonged.

Owner:SOUTH CHINA UNIV OF TECH

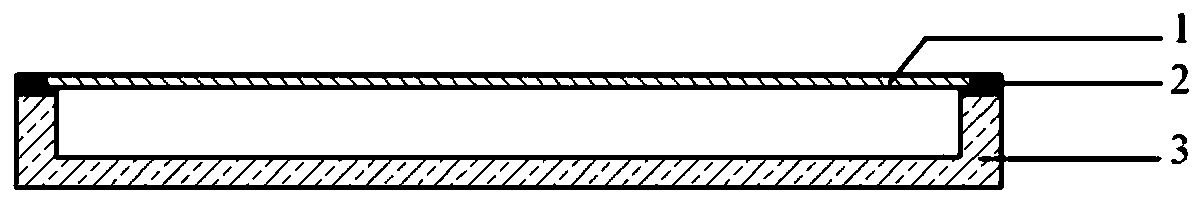

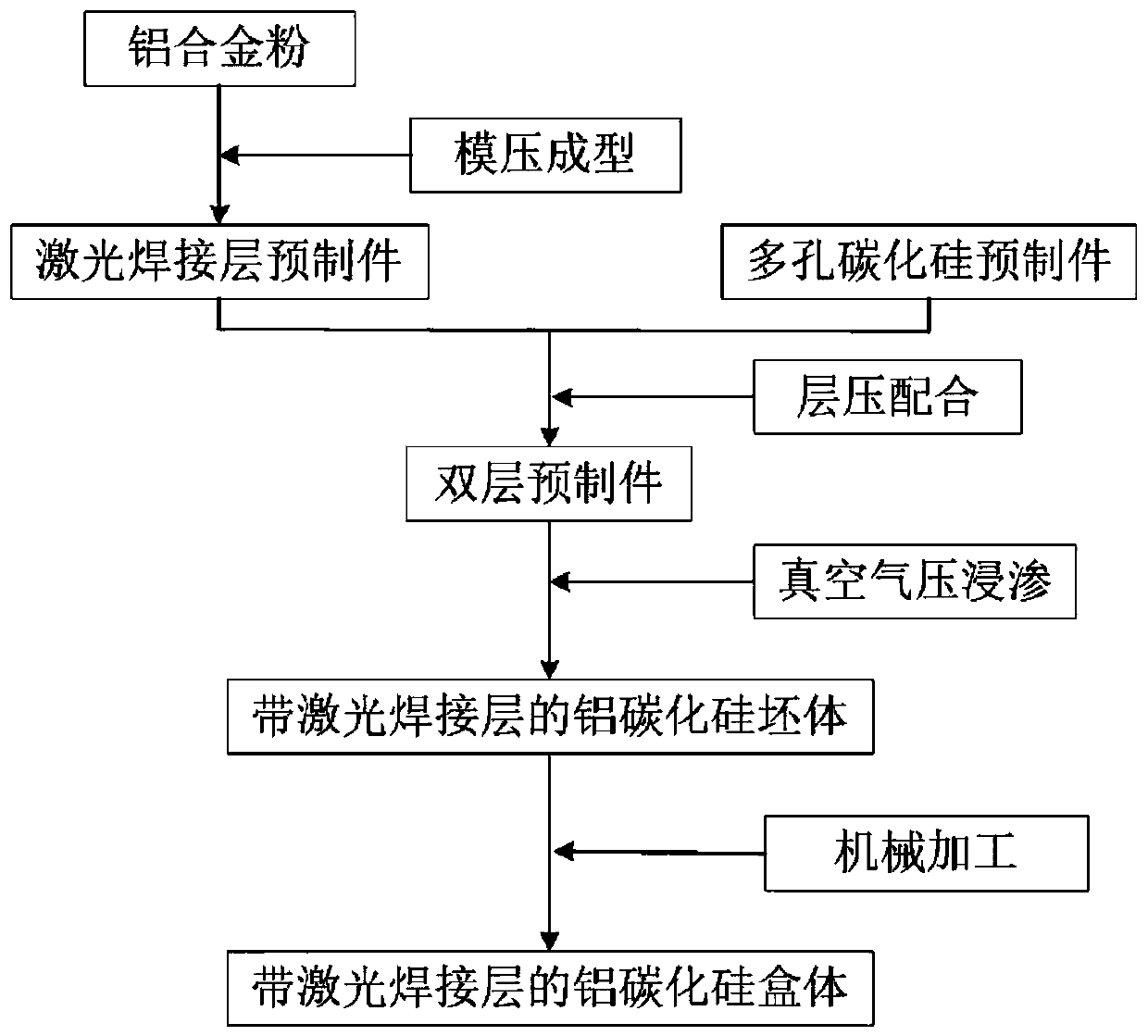

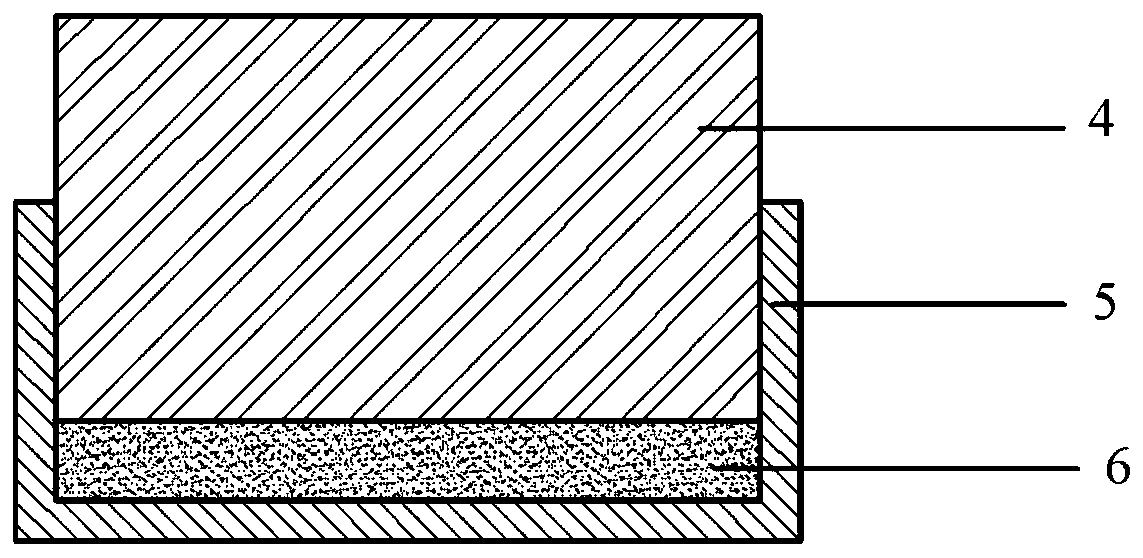

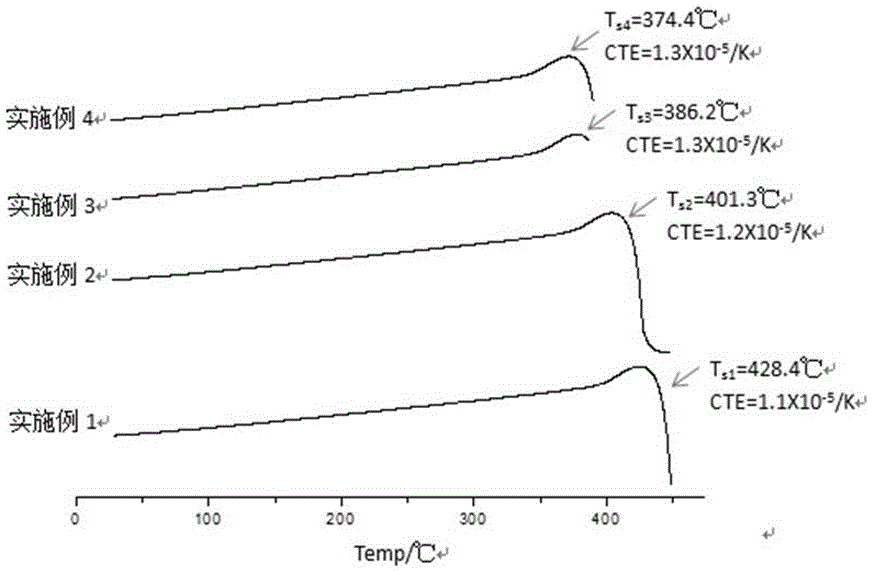

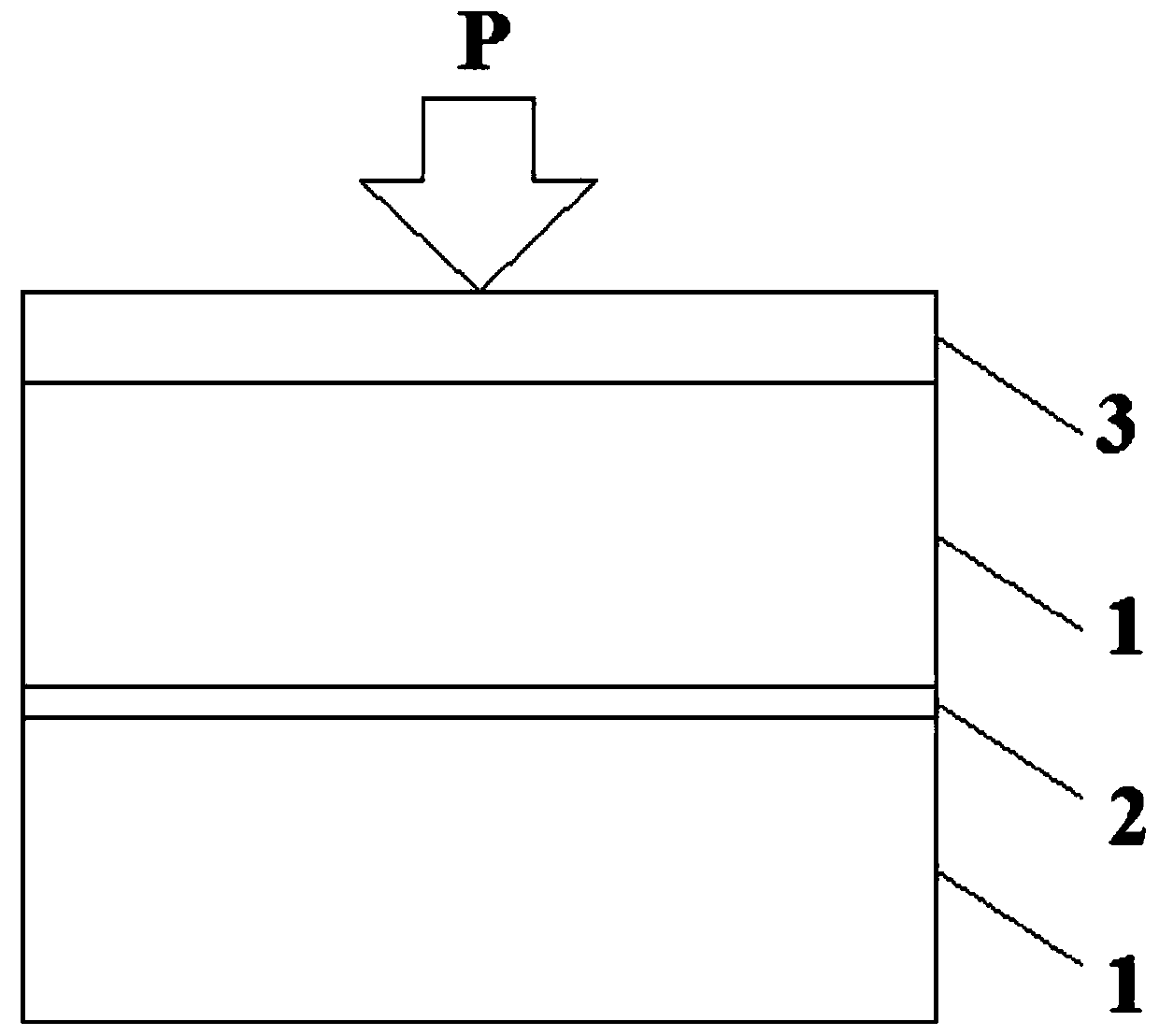

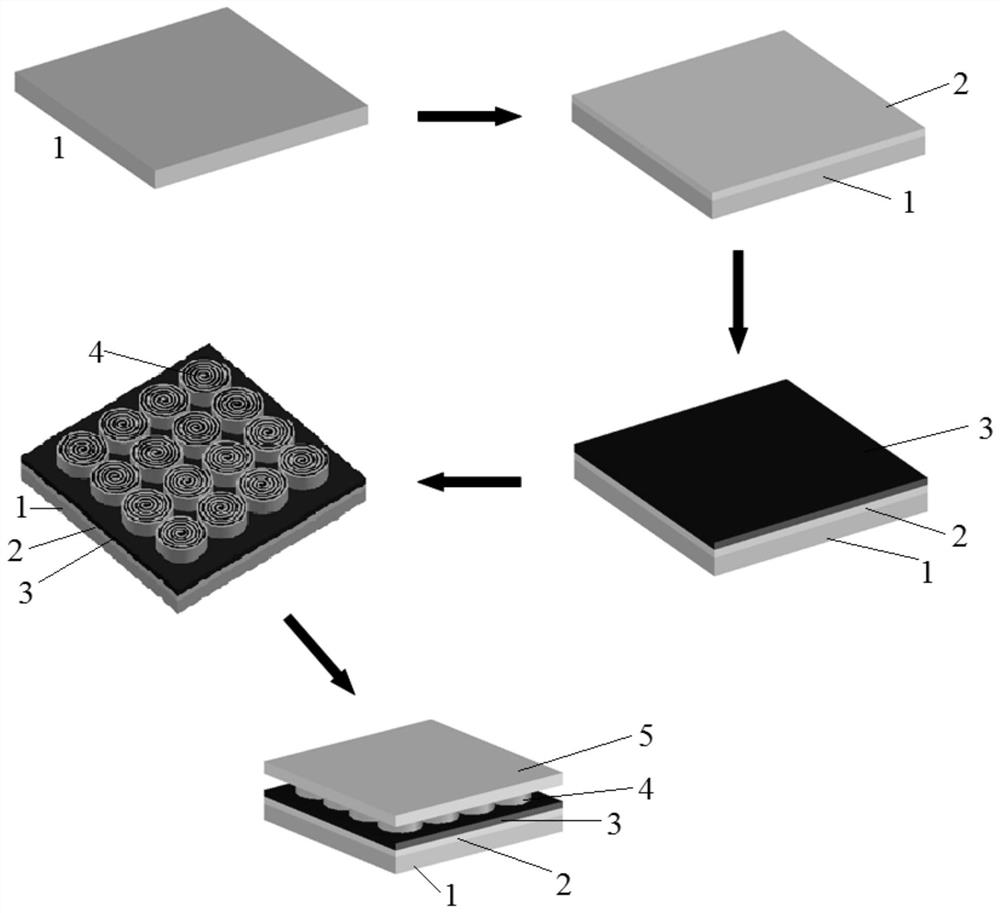

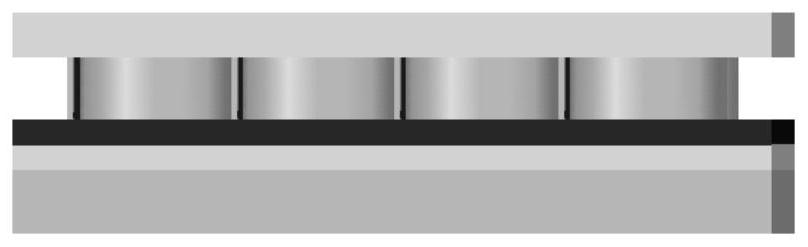

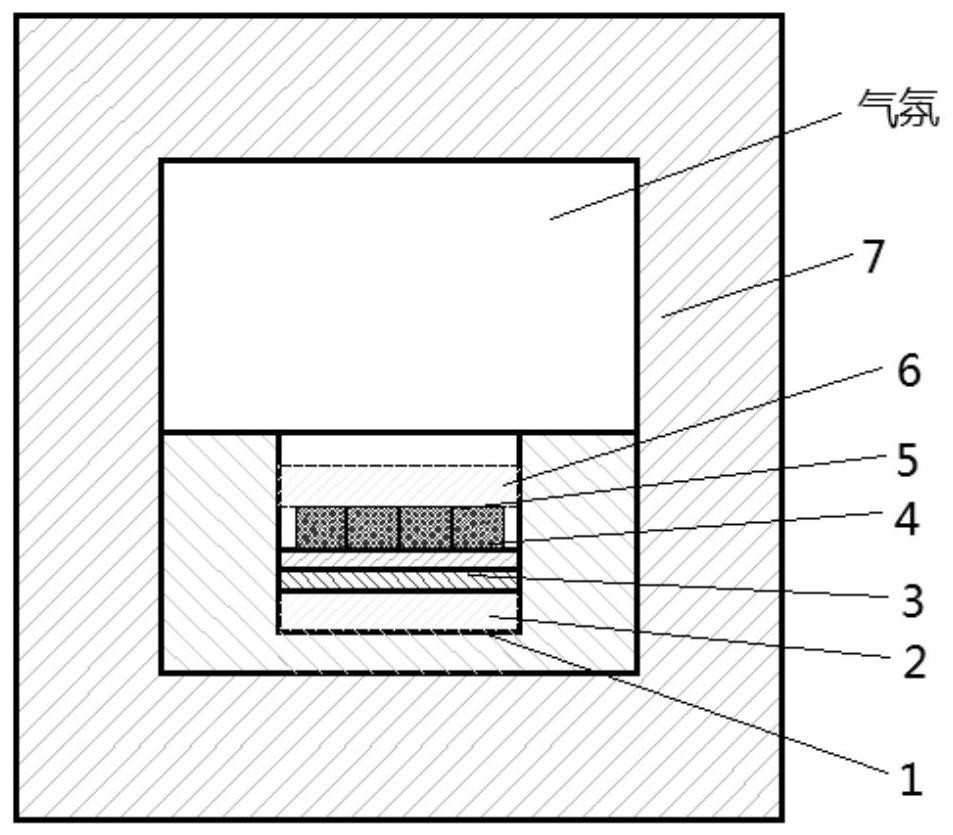

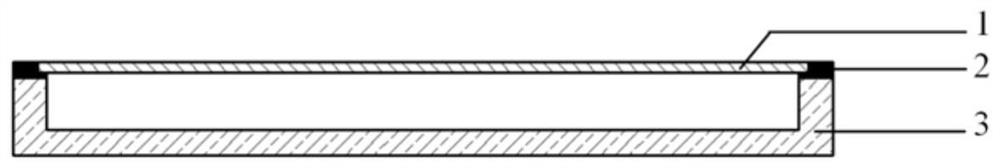

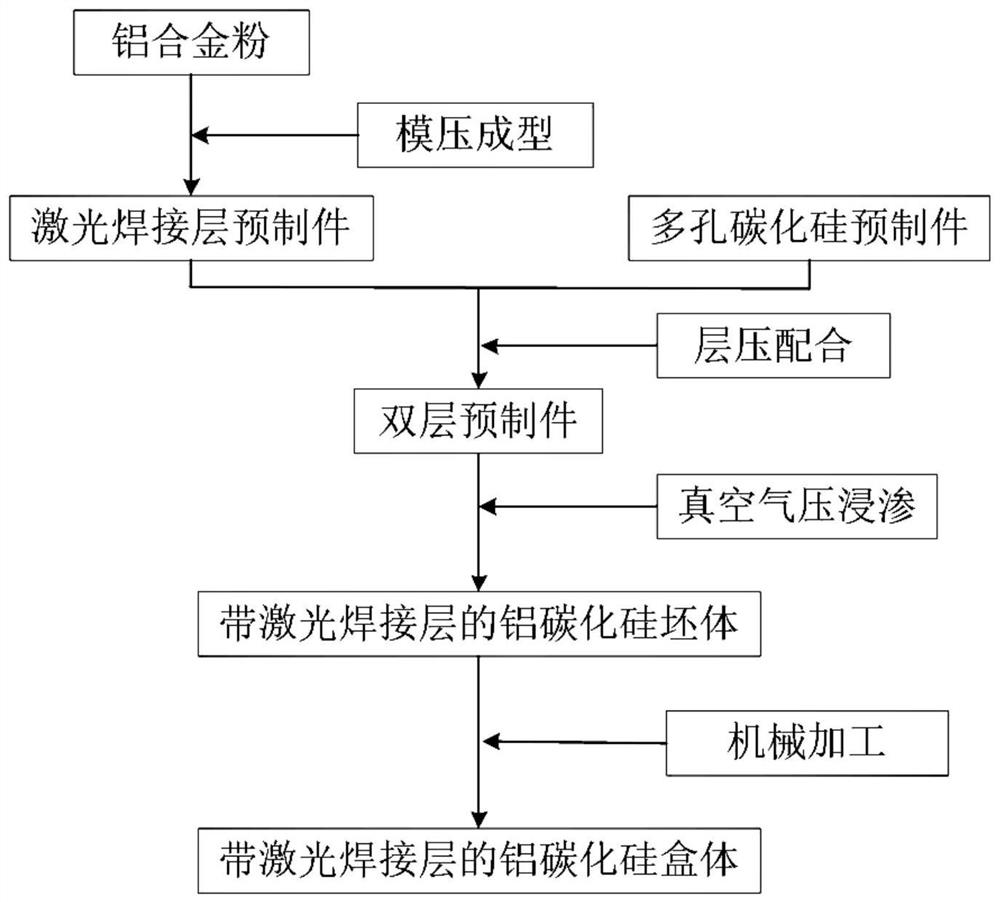

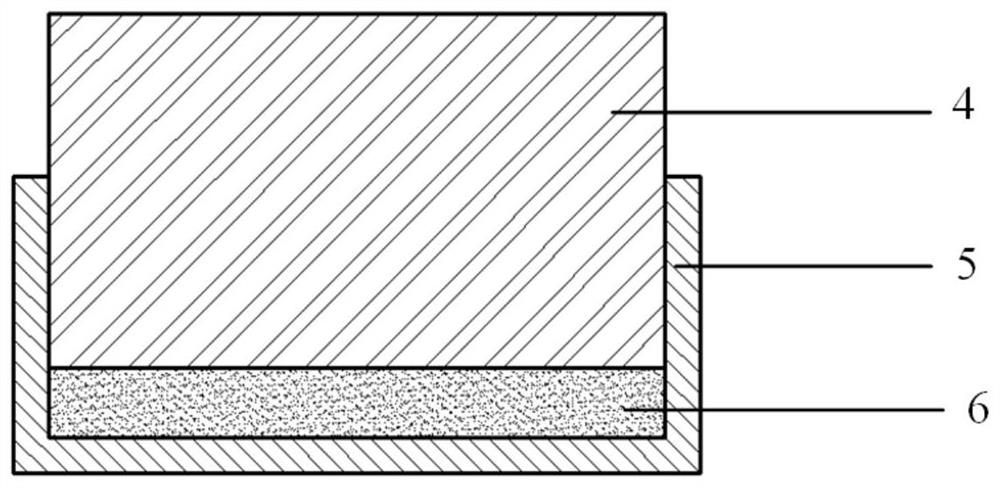

Laser welding layer prefabricated part and preparation methods for laser welding layer prefabricated part and aluminum silicon carbide box body

ActiveCN111482598AFine grainGood mechanical propertiesSemiconductor/solid-state device detailsSolid-state devicesCarbide siliconGraphite

The invention discloses a laser welding layer prefabricated part and preparation methods for the laser welding layer prefabricated part and an aluminum silicon carbide box body. The preparation methodfor the aluminum silicon carbide box body comprises the steps that 1, the laser welding layer prefabricated part is prepared; 2, the laser welding layer prefabricated part and a silicon carbide prefabricated part are laminated and matched; 3, an aluminum silicon carbide green body with the laser welding layer is prepared through vacuum air pressure infiltration; and 4, machining is carried out. The laser welding layer prefabricated part is formed by pressing particle-reinforced aluminum alloy powder, specifically, aluminum alloy powder is placed in a graphite mold, the graphite mold comprisesa female mold and a male mold, the aluminum alloy powder is laid at the bottom of the female mold, a hydraulic machine applies pressure of 0.5-2 MPa to the aluminum alloy powder in the female mold through the male mold and maintains the pressure to form the laser welding layer prefabricated part, wherein the particle size of the particle-reinforced aluminum alloy powder is 10-200 microns. A laserwelding layer is designed at the upper end of the aluminum silicon carbide box body, so that the laser welding problem between the aluminum silicon carbide box body and a cover plate is effectively solved, and the air tightness of the box body after sealing welding is ensured.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

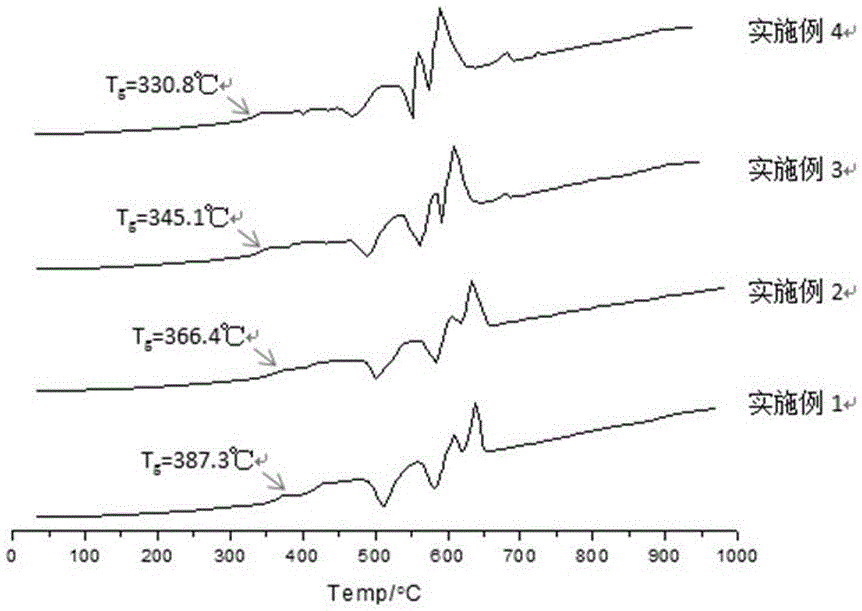

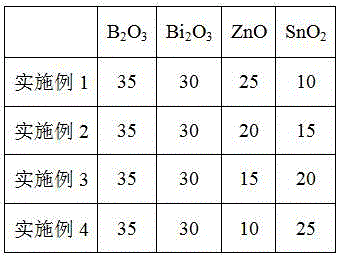

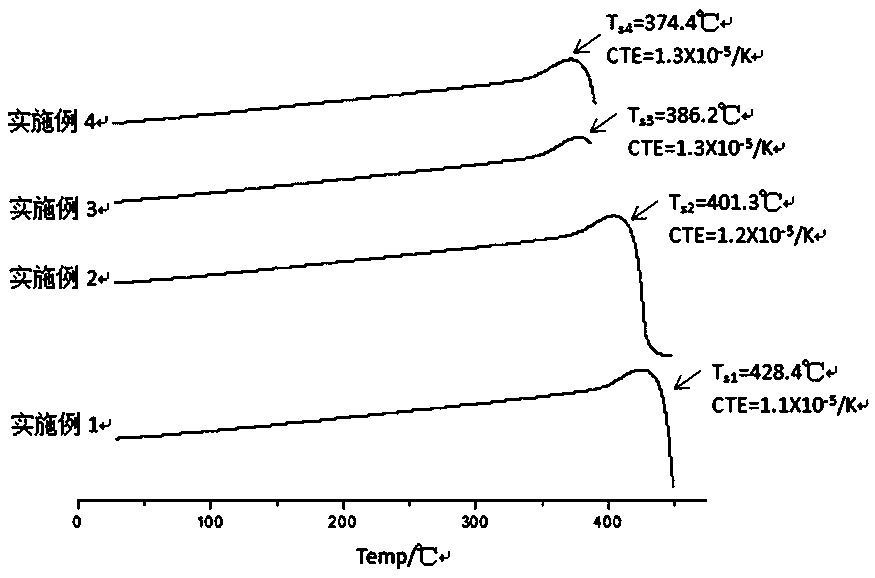

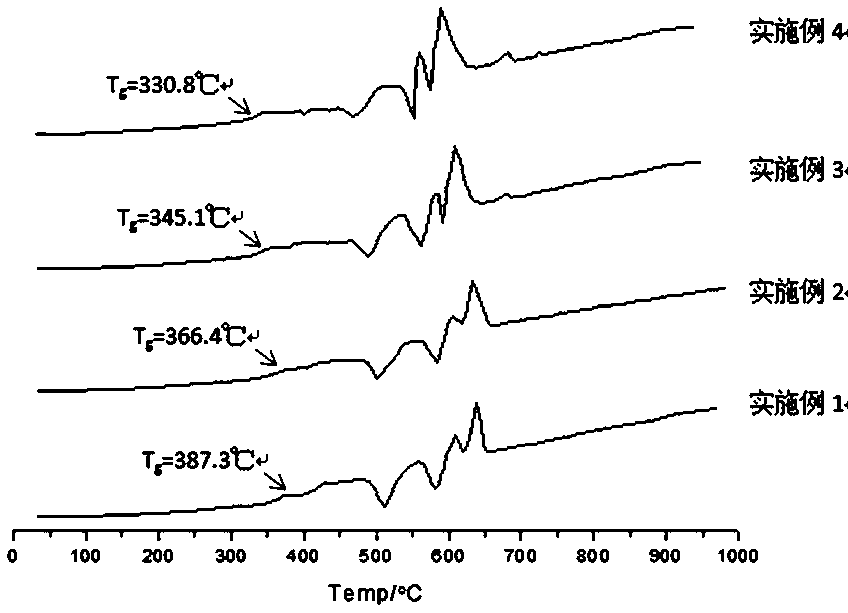

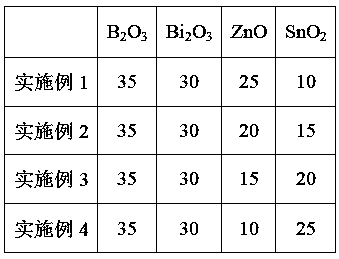

Sn-containing low-temperature seal glass and preparing and using methods thereof

The invention discloses Sn-containing low-temperature seal glass and preparing and using methods thereof. The Sn-containing low-temperature seal glass is composed of B2O3, Bi2O3, ZnO and SnO2 according to a molar ratio of 10-50:20-40:5-30:0-30. Softening temperature of the glass is lowered through synergism of high-concentration Bi2O3 and B2O3 to realize low-temperature seal; Sn2+ in a glass network prepared through melting-quenching is converted into Sn4+ in the process of heating, conversion from Bi3+ in the glass to Bi5+ is stopped, and refractivity of the glass is stabilized; Sn can further lower the softening temperature of the seal glass and can adjust expansion coefficient of the glass, so that seal performance of the seal glass is improved remarkably; the glass is suitable for photoelectric materials and other low-temperature precise seal fields. The raw materials for preparation are simple and easy to obtain, the preparation method is stable, low in cost and simple and easy to implement, and practical and industrial conditions are met.

Owner:FUZHOU UNIV

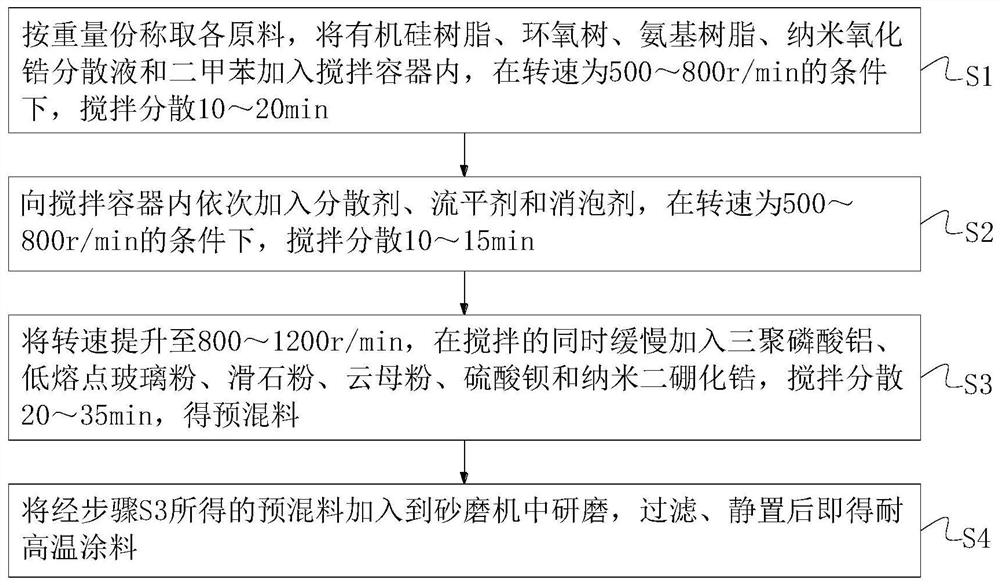

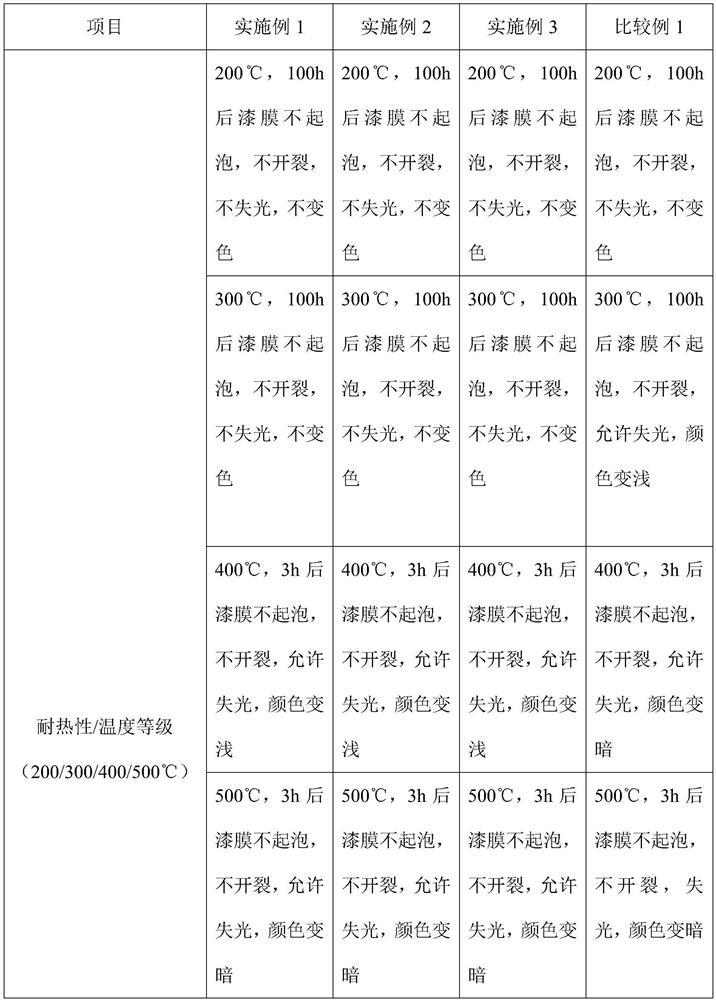

High-temperature-resistant coating for automotive upholstery and preparation method of high-temperature-resistant coating

InactiveCN112391116AImprove heat resistanceImprove high temperature resistanceFireproof paintsAnti-corrosive paintsEpoxyWeather resistance

The invention belongs to the technical field of high-temperature-resistant coatings, and particularly relates to a high-temperature-resistant coating for automotive upholstery and a preparation methodthereof. The high-temperature-resistant coating is prepared from, by weight, 30-60 parts of organic silicon resin, 4-7 parts of epoxy resin, 3-5 parts of amino resin, 6-10 parts of nano zirconium oxide dispersion liquid, 1-3 parts of aluminum tripolyphosphate, 13-15 parts of low-melting-glass powder, 3-8 parts of talcum powder, and 2-5 parts of mica powder. The heat resistance of the prepared high-temperature-resistant coating is obviously improved, the high-temperature-resistant coating can resist the high temperature of 500 DEG C, the coating has high strength and good high-temperature resistance and wear resistance by adding the nano zirconium oxide dispersion liquid component, and the coating has excellent weather resistance and corrosion resistance by adding the aluminum tripolyphosphate and the low-melting-point glass powder component; and by adding the barium sulfate and the nano zirconium diboride, the wear resistance, the high temperature resistance and the corrosion resistance of the coating are further improved, and the comprehensive performance is excellent.

Owner:清远威凛材料科技有限公司

High-strength corrosion-resistant glass glaze for automobiles and preparation method of high-strength corrosion-resistant glass glaze

The invention discloses a high-strength corrosion-resistant glass glaze for automobiles and a preparation method of the high-strength corrosion-resistant glass glaze, and relates to the field of glass glaze. A lead-free environment-friendly low-melting-point glass flux is prepared by researching a ternary glass system and introducing lead-free low-melting-point raw materials to serve as a glass binder, so that the melting temperature of the glass flux is reduced, low-melting-point glass powder is induced to crystallize when the automobile glass is tempered by pre-crystallizing the bismuth silicate crystal nucleus, the tempered glass glaze layer has good adhesion resistance and acid resistance, the copper chromite black is added as a black agent, the copper chromite black has good black hue, the advantages of excellent durability, high temperature resistance, very stable chemical properties, light resistance, weather resistance, acid-base resistance, solvent resistance, no migration, easy dispersion and the like are achieved, and the expansion coefficient can be regulated by introducing the low-expansion-coefficient raw material into the low-melting-point glass system so as to achieve the high adaptability with the automobile glass.

Owner:JIANGSU BAIFU TECH CO LTD

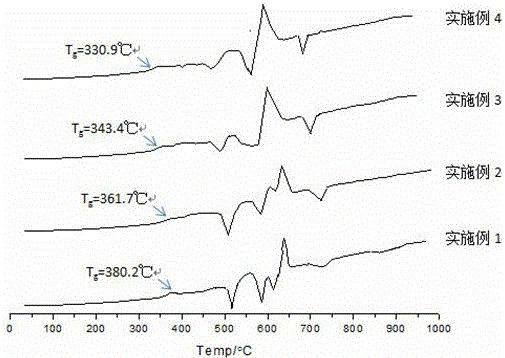

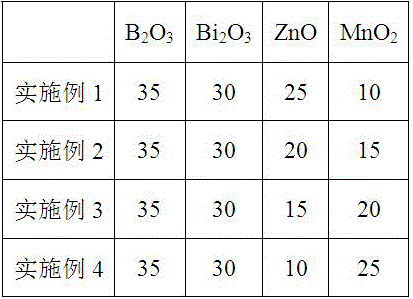

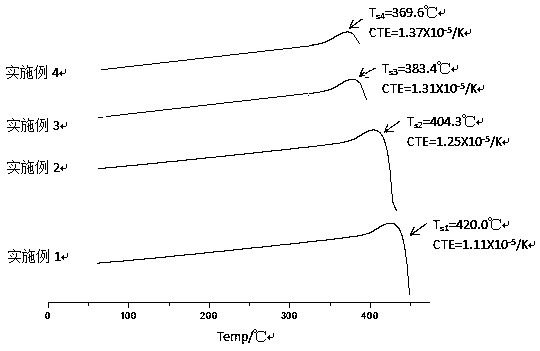

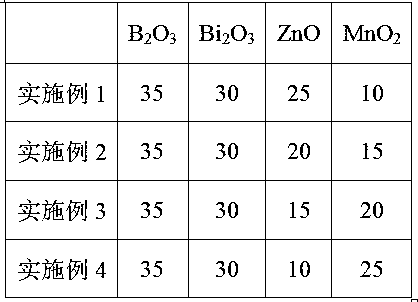

Mn-containing low-temperature seal glass as well as preparation method and use method thereof

The invention discloses Mn-containing low-temperature seal glass as well as a preparation method and use method thereof. The seal glass comprises the following raw materials: B2O3, Bi2O3, ZnO and MnO2. By virtue of the coordination of high-concentration Bi2O3 and B2O3, the softening temperature of the glass is decreased, and low-temperature sealing is realized; by adding MnO2, the refractive index of the glass can be stabilized, furthermore, the softening temperature of the seal glass is further decreased, the swelling coefficient of the glass can be further regulated, and the sealing performance of the seal glass can be remarkably improved. The preparation method has the beneficial effects that the raw materials are simple and easily available, the process is simple and stable, the cost is saved, and the practical utilization and industrialization conditions are achieved. The seal glass is applicable to the fields of photoelectric materials, low-temperature precise packaging and the like.

Owner:FUZHOU UNIV

Two-phase composite material and preparation method thereof

The invention relates to the technical field of composite materials, and in particular relates to a preparation method of a two-phase composite material, and the two-phase composite material prepared by the preparation method. According to the method provided by the invention, firstly a silicon carbide ceramic biscuit M5 is prepared by using powder formed by silicon carbide powder with different particle sizes and wax slurry, the silicon carbide ceramic biscuit M5 is used as a part of a mold, a silicon ceramic biscuit M6 is prepared by means of hot press casting, the two biscuits are combined in the form of wax diffusion, demolding is performed, sintering is performed to obtain a ceramic substrate M7, and finally an aluminum alloy melt is infiltrated into the ceramic substrate M7 to form the two-phase composite material; and the two-phase composite material combines the advantages of aluminum silicon carbide and aluminum silicon in one, and has high thermal conductivity, an adjustable expansion coefficient, a low density, good strength and good weldability, the airtightness of the product after welding is less than 10<-10>Pa*m<3> / s, and the composite material is the best choice of a high-power package type tube shell.

Owner:西安明科微电子材料有限公司

A kind of CE-containing low-temperature sealing glass and its preparation and use method

ActiveCN106495487BLow softening temperatureAchieve low temperature sealingHigh concentrationExpansion factor

The invention discloses Ce-containing low-temperature sealing glass as well as preparation and application method of the Ce-containing low-temperature sealing glass. The Ce-containing low-temperature sealing glass consists of the following raw materials: B2O3, Bi2O3, ZnO and Ce(NO3)3 in a molar ratio of (10-50):(20-40):(5-30):(0-30). Through the coordination between high-concentration Bi2O3 and B2O3, the softening temperature of glass is lowered, so that low-temperature sealing is realized; Ce<3+> in a glass network prepared by melting quenching is transformed into Ce<4+>, the transformation of Bi<3+> in glass into Bi<5+> is prevented, and the refractive index of glass is stabilized; and Ce not only can further lower the softening temperature of the sealing glass, but also can adjust the expansion factor of the glass so as to remarkably improve the sealing property of the sealing glass. Moreover, Ce remarkably reduces the surface tension of the glass, improves the interface bonding property between the sealing glass and an alloy connector and is applicable to the field of photoelectric materials and other low-temperature precise sealing. According to the invention, the preparation raw materials are simple and easily available, the cost is low, the technology is simple and feasible, and the prepared low-temperature sealing glass has good performance and stable refractive index and meets the conditions of practical utilization and industrialization.

Owner:FUZHOU UNIV

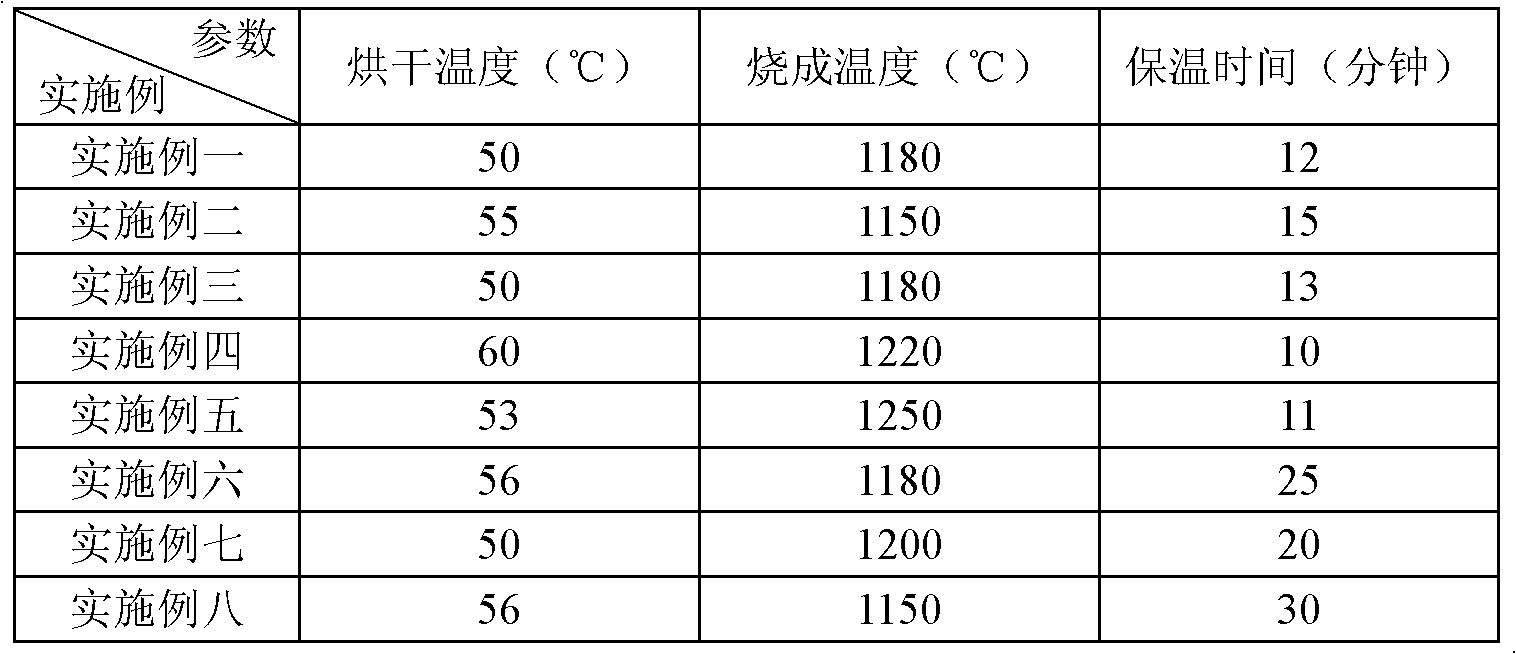

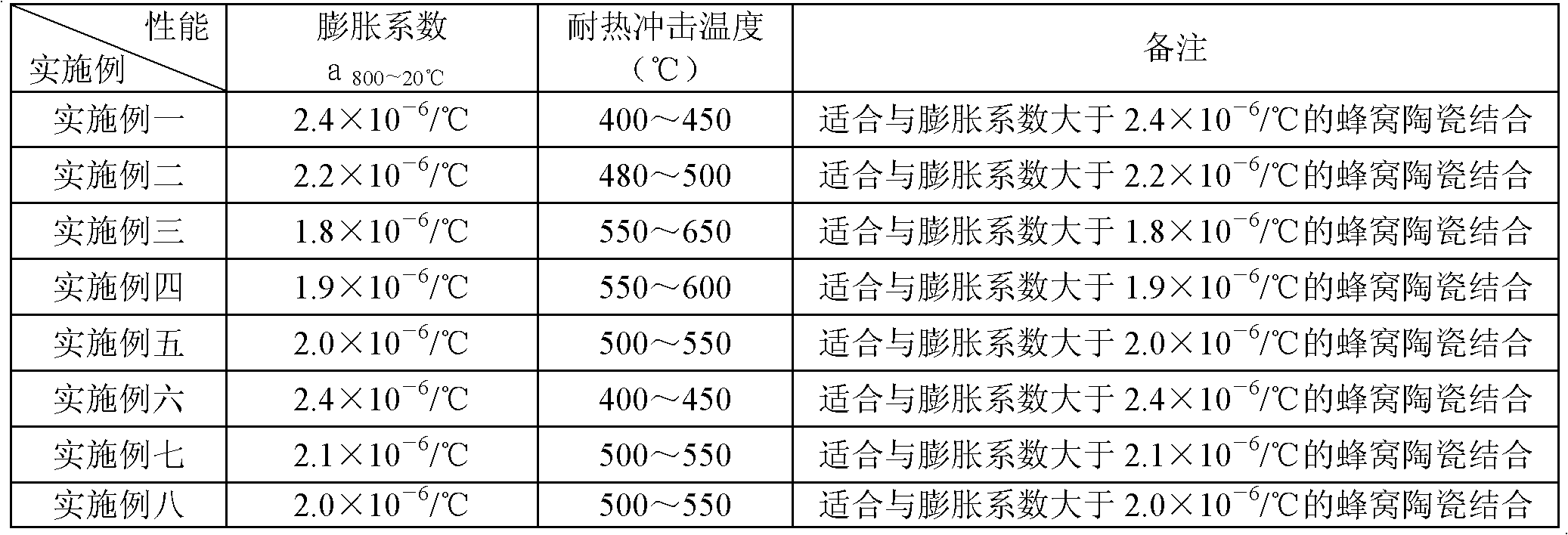

Hole plugging material for low-expansion wall flow honeycomb ceramic and plugging method thereof

ActiveCN102614724BAdjustable expansion coefficientHigh bonding strengthDispersed particle filtrationThermal impactPlasticizer

Owner:GUANGDONG DOWSTONE TECH

A kind of copper-clad alsic composite heat dissipation substrate and preparation method thereof

ActiveCN103515521BHigh thermal conductivityAdjustable expansion coefficientSemiconductor devicesSpinelThermal expansion

The invention discloses a copper-covered ALSiC composite radiating substrate which comprises an ALSiC substrate body and a copper layer attached to the ALSiC substrate body. A copper-aluminum spinel interface is formed between the copper layer and the ALSiC substrate body. The ALSiC composite radiation substrate is simple in structure, good in radiating performance, capable of solving the problem that the radiating substrate body is not matched with thermal expansion of a chip material, capable of preventing an LED chip packaged on the substrate body from being easily disengaged, capable of prolonging the service life of an LED and applicable to manufacturing of low-cost large-power LEDs.

Owner:惠州雷士光电科技有限公司 +1

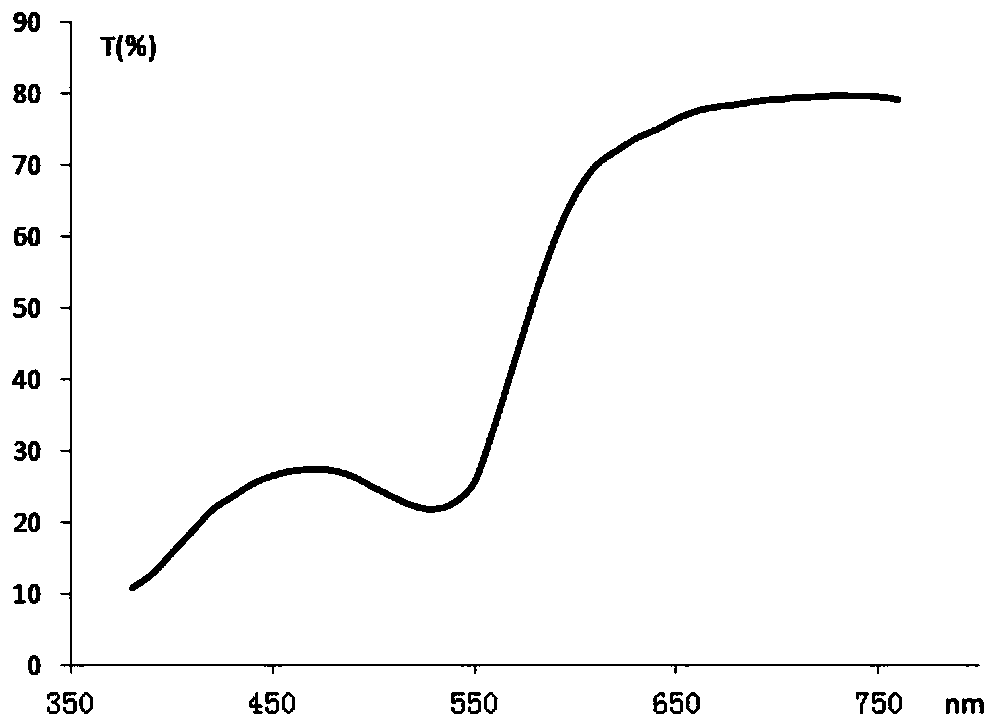

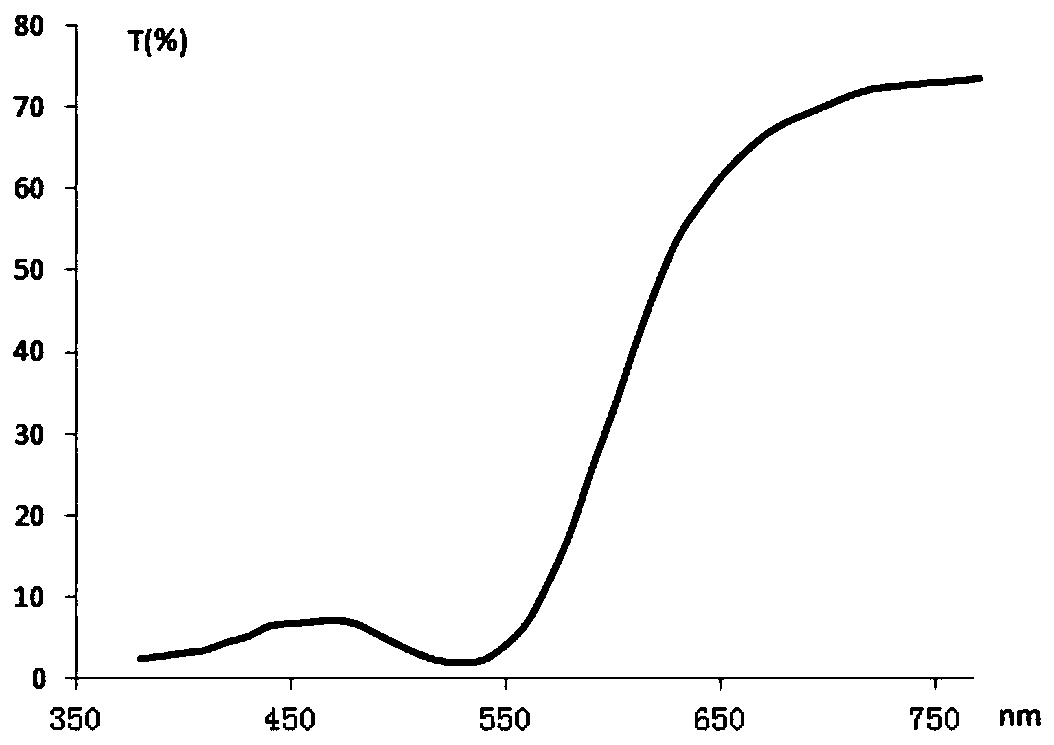

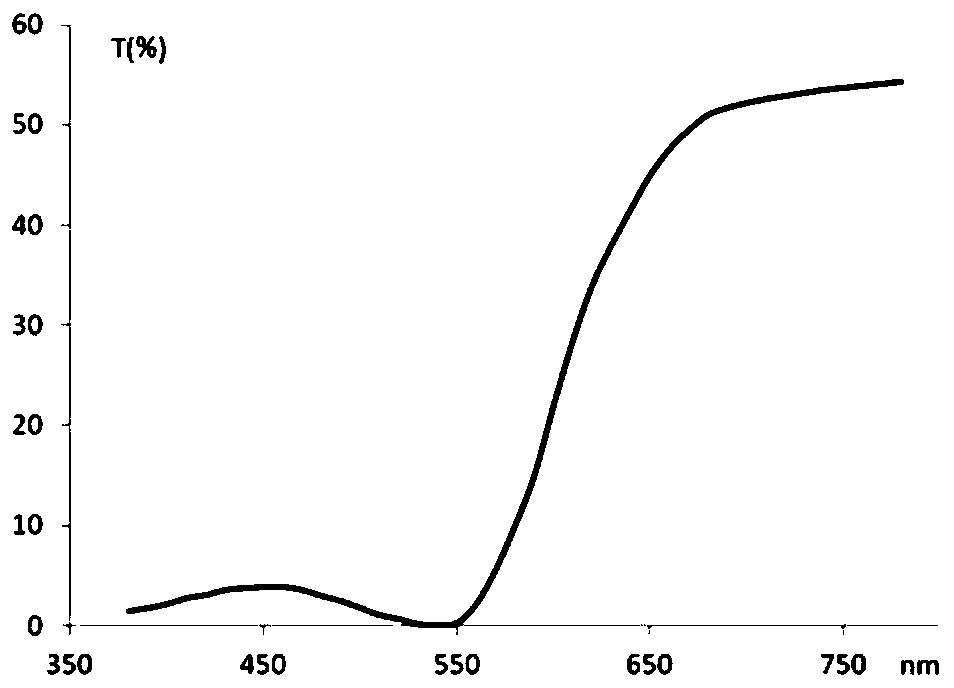

A kind of formula and preparation method of lead-free fusible gold-red glass

ActiveCN107129144BLower melting temperatureAdjustable expansion coefficientGlass shaping apparatusGold ColloidSilicate glass

The invention discloses a composition and a production method of gold colloid colored fusible gold ruby glass adopting bismuth borosilicate glass as a matrix. The composition of the fusible gold ruby glass comprises 0-10 wt% of Na2O, 0-15 wt% of K2O, 0-2 wt% of Li2O, 10-60 wt% of Bi2O3, 2-15 wt% of B2O3, 25-50 wt% of SiO2, 0-5 wt% of ZnO, 0-3 wt% of Al2O3, 0.5-3 wt% of Sb2O3, 0.5-1.5 wt% of SnO and 0.01-0.1 wt% of Au. Compared with lead-containing fusible gold ruby glass produced through traditional methods, the gold ruby glass produced in the invention has similar spectral properties and good chemical stability. The colloid colored glass produced in the invention has beautiful color and very good practical application prospect; and bismuth oxide replaces lead oxide to avoid pollution to the environment and damages to organisms during the use process, so the "green production" requirement is met.

Owner:DALIAN POLYTECHNIC UNIVERSITY

A kind of glass-ceramic solder and its preparation method and method for connecting ferrite

InactiveCN108422126BImprove corrosion resistanceImprove thermal stabilityWelding/cutting media/materialsCleaning using liquidsScreen printingHeat stability

Owner:HARBIN INST OF TECH

A kind of low temperature sealing glass containing sn and its preparation and use method

InactiveCN106495492BLow softening temperatureAchieve low temperature sealingHigh concentrationMelt quenching

The invention discloses Sn-containing low-temperature seal glass and preparing and using methods thereof. The Sn-containing low-temperature seal glass is composed of B2O3, Bi2O3, ZnO and SnO2 according to a molar ratio of 10-50:20-40:5-30:0-30. Softening temperature of the glass is lowered through synergism of high-concentration Bi2O3 and B2O3 to realize low-temperature seal; Sn2+ in a glass network prepared through melting-quenching is converted into Sn4+ in the process of heating, conversion from Bi3+ in the glass to Bi5+ is stopped, and refractivity of the glass is stabilized; Sn can further lower the softening temperature of the seal glass and can adjust expansion coefficient of the glass, so that seal performance of the seal glass is improved remarkably; the glass is suitable for photoelectric materials and other low-temperature precise seal fields. The raw materials for preparation are simple and easy to obtain, the preparation method is stable, low in cost and simple and easy to implement, and practical and industrial conditions are met.

Owner:FUZHOU UNIV

Chemical slip casting strengthening material and preparation method thereof

The invention relates to a chemical slip casting strengthening material and a preparation method thereof. A chemical slip casting strengthening material with two components (component A and component B) is provided, thus effectively solving the problems existing in conventional chemical slip casting materials, such as slow polyurethane polymerization, poor flame retardation and environment pollution. When the chemical slip casting material is used, the component A, i.e. phenolic resin, and the component B, i.e. curing agent, are mixed according to a weight ratio of 1:1. The phenolic resin is obtained by firstly mixing phenol and formaldehyde according to a weight ratio of 1:1.3-1.5, then adding the catalyst NaOH, heating the mixture to a temperature of 90-100 DEG C, causing the reaction to last 4-6 hours, carrying out neutralization and dehydration, cooling the mixture to 25 DEG C and adding foaming agent and surfactant for full mixing. The curing agent consists of 0.6-1.0 part of p-toluenesulfonic acid by weight, 0.8-1.3 parts of phosphoric acid by weight, 0.5-1.0 part of hydrochloric acid by weight and 0.1 part of ethylene glycol by weight. The chemical slip casting material needs a short time for solidification, has an inflaming retarding oxygen index higher than or equal to 54, and is suitable for the slip casting strengthening engineering of a mine, as well as the seepage-proofing, leaking stoppage and strengthening work of an ordinary underground engineering or a water conservancy engineering.

Owner:廊坊鑫美源化工建材有限公司

Composite material for thermal management and preparation method thereof

ActiveCN110564376BImprove thermal conductivityImprove matchHeat-exchange elementsThermal dilatationHeat management

The invention belongs to the technical field of graphene preparation, and in particular relates to a composite material for thermal management and a preparation method thereof. The composite material includes two metal layers arranged at intervals and a first heat transfer layer and a second heat transfer layer arranged on the two metal layers, and the heat transfer layer of the first heat transfer layer and the second heat transfer layer The interfaces are perpendicular to each other; the composite material is a thermal management material integrated in the horizontal direction and the vertical direction. It is an efficient thermal management structure vertically located between the heat source and the heat sink. The composite material has good thermal conductivity and integration with Circuit chip thermal expansion coefficient matching.

Owner:NAT CENT FOR ADVANCED PACKAGING CO LTD

A low-temperature sealing glass containing mn and its preparation and use method

ActiveCN106430979BLow softening temperatureAchieve low temperature sealingHigh concentrationRefractive index

The invention discloses Mn-containing low-temperature seal glass as well as a preparation method and use method thereof. The seal glass comprises the following raw materials: B2O3, Bi2O3, ZnO and MnO2. By virtue of the coordination of high-concentration Bi2O3 and B2O3, the softening temperature of the glass is decreased, and low-temperature sealing is realized; by adding MnO2, the refractive index of the glass can be stabilized, furthermore, the softening temperature of the seal glass is further decreased, the swelling coefficient of the glass can be further regulated, and the sealing performance of the seal glass can be remarkably improved. The preparation method has the beneficial effects that the raw materials are simple and easily available, the process is simple and stable, the cost is saved, and the practical utilization and industrialization conditions are achieved. The seal glass is applicable to the fields of photoelectric materials, low-temperature precise packaging and the like.

Owner:FUZHOU UNIV

A led packaged with alsic composite substrate

The invention discloses an LED packaged with an AlSiC composite substrate. The LED comprises the AlSiC composite cooling substrate, an LED light source module, gold threads and an alumina ceramic frame, wherein the surface of the AlSiC composite cooling substrate is plated with a copper film and a silver film sequentially; the LED light source module is packaged on the AlSiC composite cooling substrate; the alumina ceramic frame is arranged on the outer side of the LED light source module and adheres to the LED light source module; two copper-film electrodes are plated on the alumina ceramic frame and connected with a positive pole and a negative pole of the LED light source module through the gold threads respectively. According to the LED, thermal expansion coefficients of the AlSiC composite substrate and an LED chip material are matched, so that an LED chip which is packaged on the substrate is not prone to falling, and the service life of the LED is prolonged.

Owner:SOUTH CHINA UNIV OF TECH

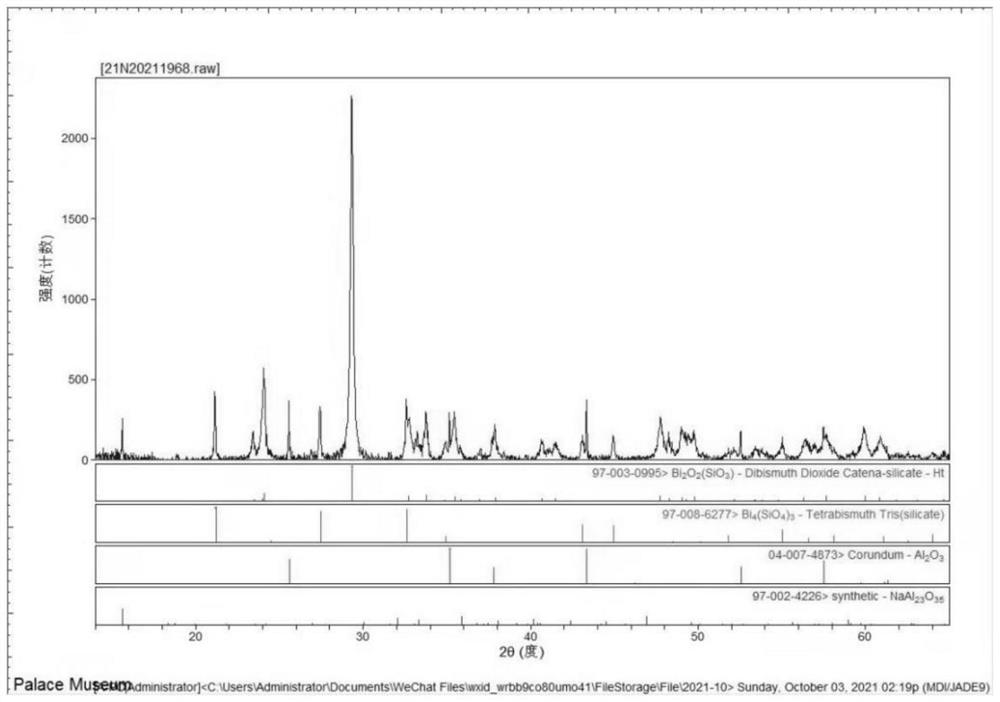

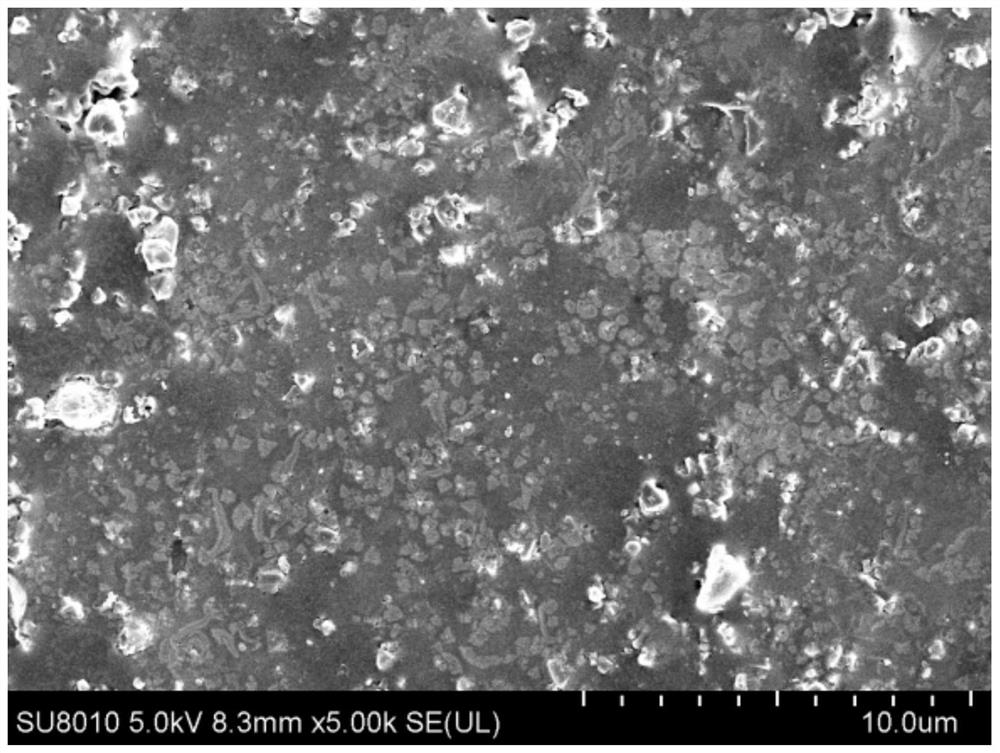

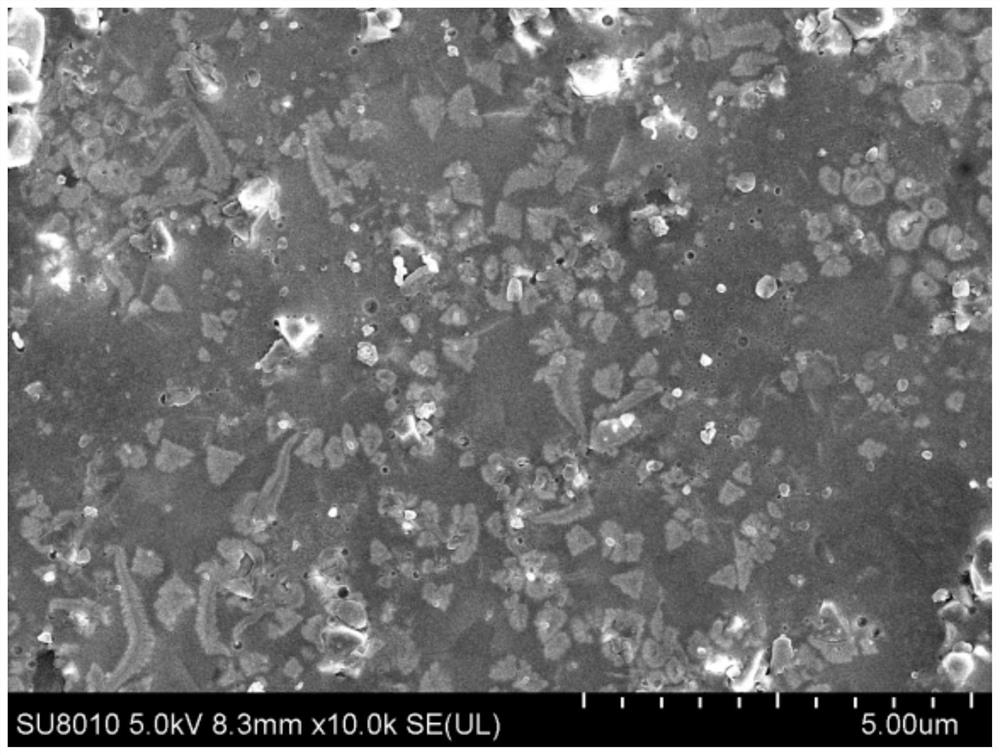

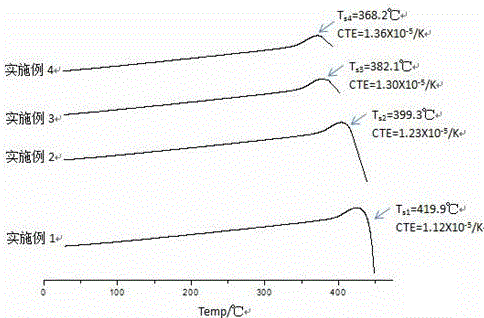

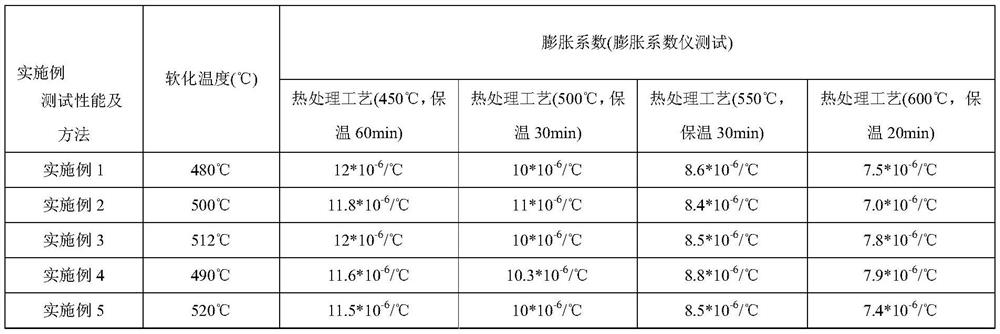

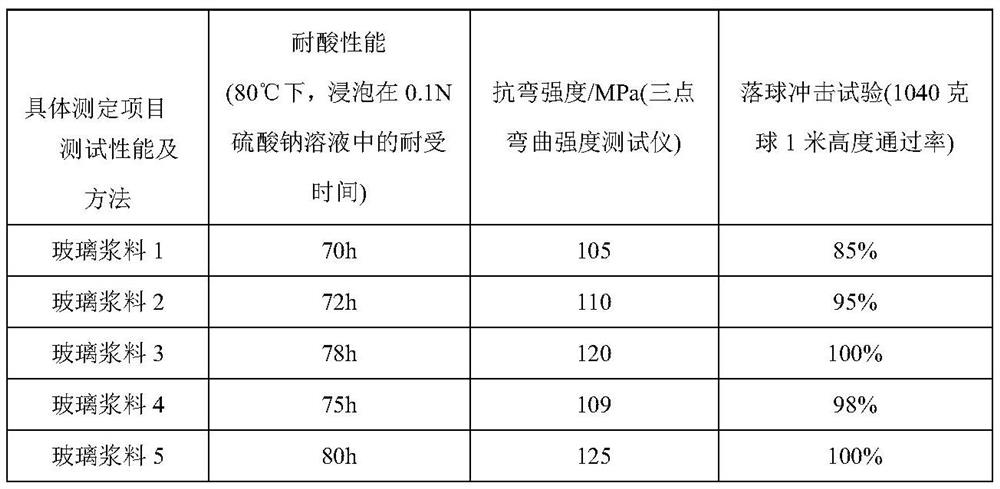

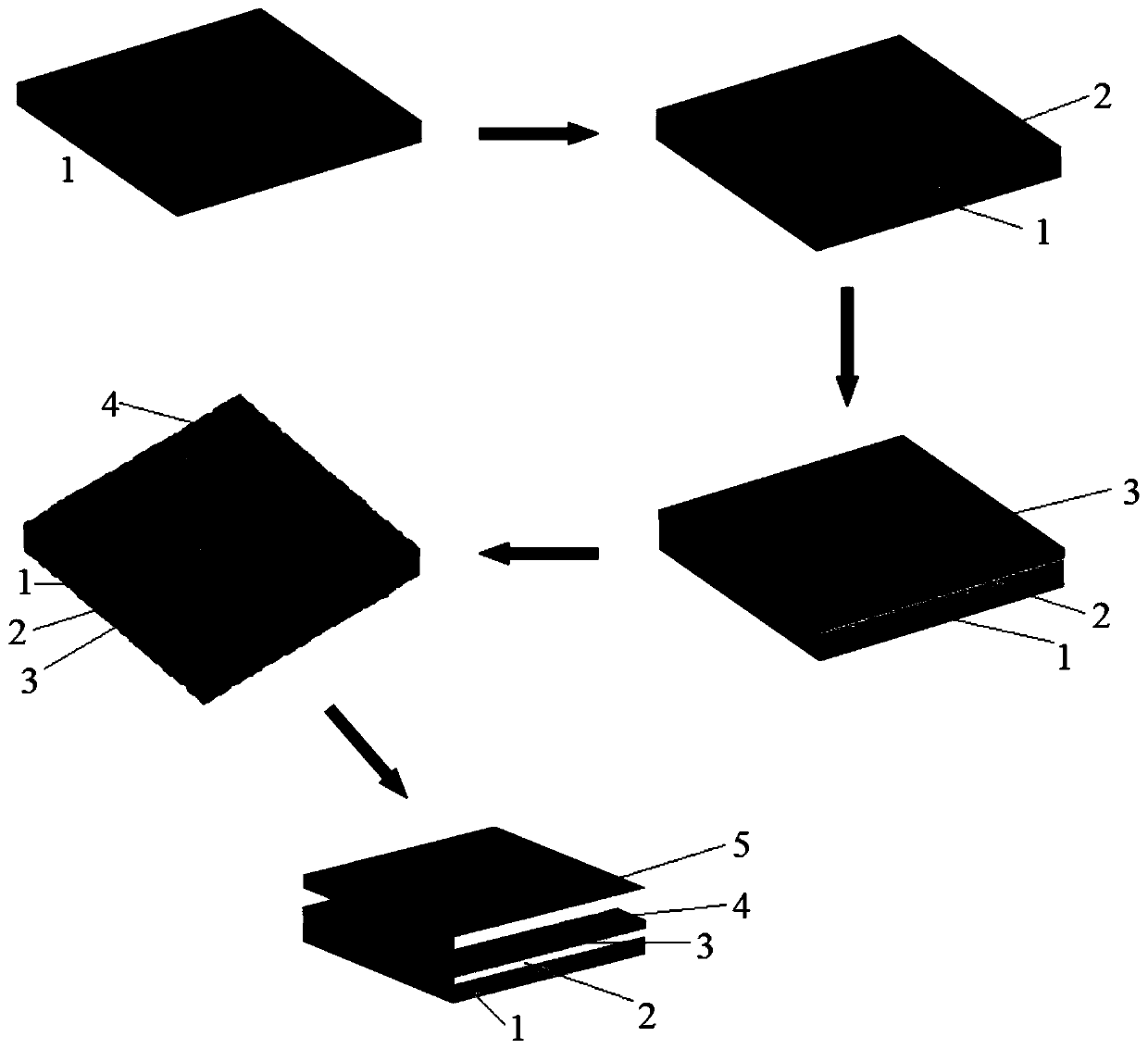

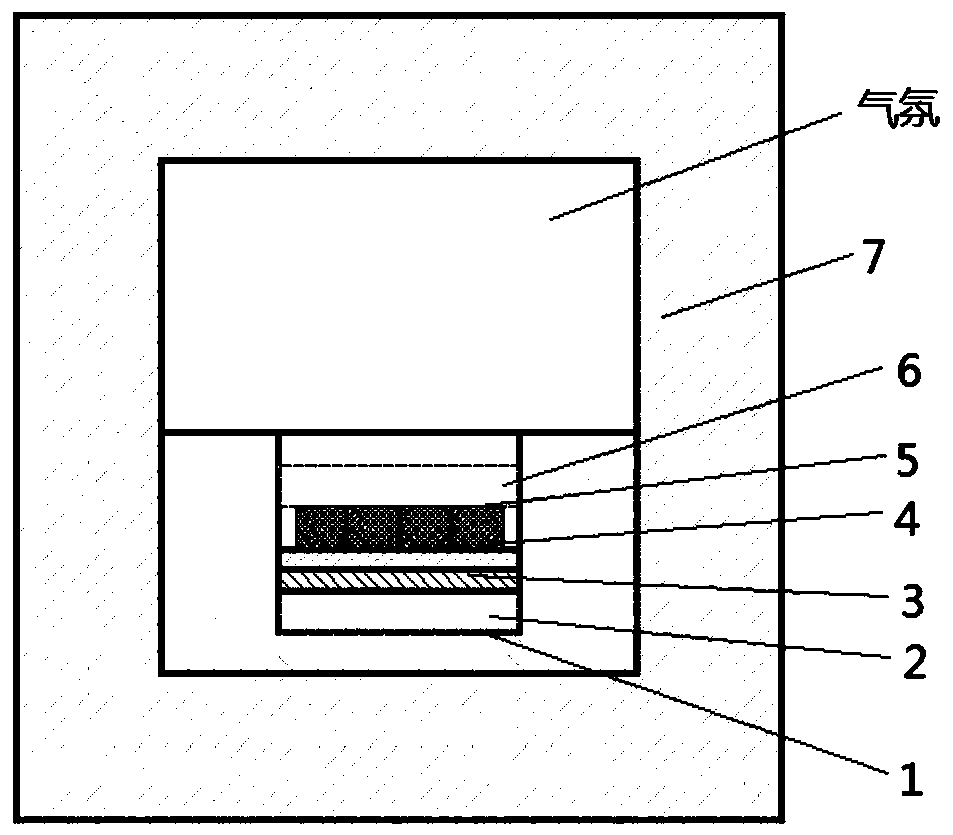

Glass powder with strong impact resistance and adjustable expansion coefficient and preparation method thereof

The invention discloses glass powder with strong impact resistance and adjustable expansion coefficient and a preparation method thereof. The glass powder is prepared from the following raw materialsin parts by weight: 20-50 parts of SiO2, 20-40 parts of Bi2O3, 0-6 parts of Al2O3, 2-10 parts of ZnO, 5-20 parts of B2O3, 0-4 parts of SnO2, 0-2 parts of BaO, 1-8 parts of TiO2, 1-5 parts of Na2O and2-8 parts of Li2O. The preparation method of the glass powder comprises the following steps of mixing the raw materials, melting at high temperature, water quenching and cooling, performing ball milling, drying and sieving. Before the prepared glass powder is used, the glass powder with different expansion coefficients can be obtained through different heat treatment processes. The glass powder with different expansion coefficients can be obtained through a subsequent heat treatment process, can be matched with different glass, ceramic, metal and other base materials, and has a wide application range; and silicon oxide and bismuth oxide in the glass powder raw material can form bismuth silicate crystals at a certain temperature, so that the impact resistance and the acid resistance are enhanced.

Owner:黄山市晶特美新材料有限公司

Composite material for thermal management and preparation method of composite material

ActiveCN110564376AImprove thermal conductivityImprove matchHeat-exchange elementsThermal expansionGraphene

The invention belongs to the technical field of graphene preparation, and particularly relates to a composite material for thermal management and a preparation method of the composite material. The composite material comprises two metal layers which are arranged at an interval, and a first heat transfer layer and a second heat transfer layer which are arranged between the two metal layers, and heat transfer interfaces of the first heat transfer layer and the second heat transfer layer are perpendicular to each other. The composite material is a thermal management material integrating the horizontal direction and the vertical direction, is an efficient thermal management structure vertically located between a heat source and a heat sink, and has better thermal conductivity and thermal expansion coefficient matching performance with an integrated circuit chip.

Owner:NAT CENT FOR ADVANCED PACKAGING

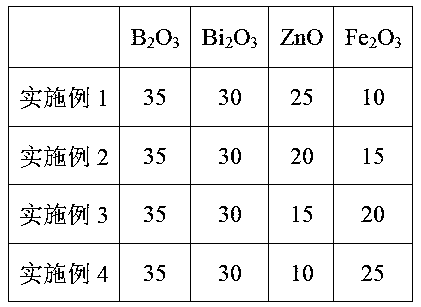

A kind of Fe-containing low-temperature sealing glass and its preparation and use method

ActiveCN106477894BLow softening temperatureAchieve low temperature sealingMetallurgyRefractive index

The invention discloses Fe-containing low-temperature sealing glass as well as preparation and use methods thereof. The Fe-containing low-temperature sealing glass is prepared from the following raw materials: B2O3, Bi2O3, ZnO and Fe2O3. Through the coordinating function of Bi2O3 and B2O3, the softening temperature of glass is reduced, and the low-temperature sealing is realized; by the adding of Fe2O3, the softening temperature of the sealing glass can be further reduced, and the refractive index of the glass can be stabilized; and furthermore, magnetic Fe3O4 generated inside can improve the automatic application efficiency of a sealing process. The preparation raw materials are simple and readily available; the process is stable, and the cost is reduced; and the Fe-containing low-temperature sealing glass is applicable to the field of photoelectric materials and other low-temperature precision packages.

Owner:FUZHOU UNIV

A kind of laser welding layer preform and preparation method thereof and aluminum silicon carbide box body

ActiveCN111482598BFine grainImprove mechanical propertiesSemiconductor/solid-state device detailsSolid-state devicesCarbide siliconVacuum pressure

The invention discloses a laser welding layer preform and a method for preparing the same and an aluminum silicon carbide box body, comprising steps 1: preparing a laser welding layer preform; step 2: laminating and matching the laser welding layer preform and the silicon carbide preform ; Step 3: vacuum pressure infiltration to prepare an aluminum silicon carbide body with a laser welding layer; Step 4: perform mechanical processing; the laser welding layer preform is pressed from particle-reinforced aluminum alloy powder, specifically the The aluminum alloy powder is placed in a graphite mold, and the graphite mold includes a concave mold and a convex mold, the aluminum alloy powder is spread on the bottom of the concave mold, and the hydraulic press applies 0.5-2MPa to the aluminum alloy powder in the concave mold through the convex mold. The particle size of the particle-enhanced aluminum alloy powder is 10-200 μm, and the laser welding layer is designed on the upper end of the aluminum silicon carbide box to effectively solve the problem of aluminum carbonization. The laser welding problem between the silicon box body and the cover plate ensures the airtightness of the box body after sealing and welding.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com