High-temperature-resistant coating for automotive upholstery and preparation method of high-temperature-resistant coating

A technology for high-temperature resistant coatings and automotive interior parts, applied in anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve the problems of insufficient strength, weather resistance, wear resistance and corrosion resistance, poor high temperature resistance performance, and comprehensive performance. Improvement and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

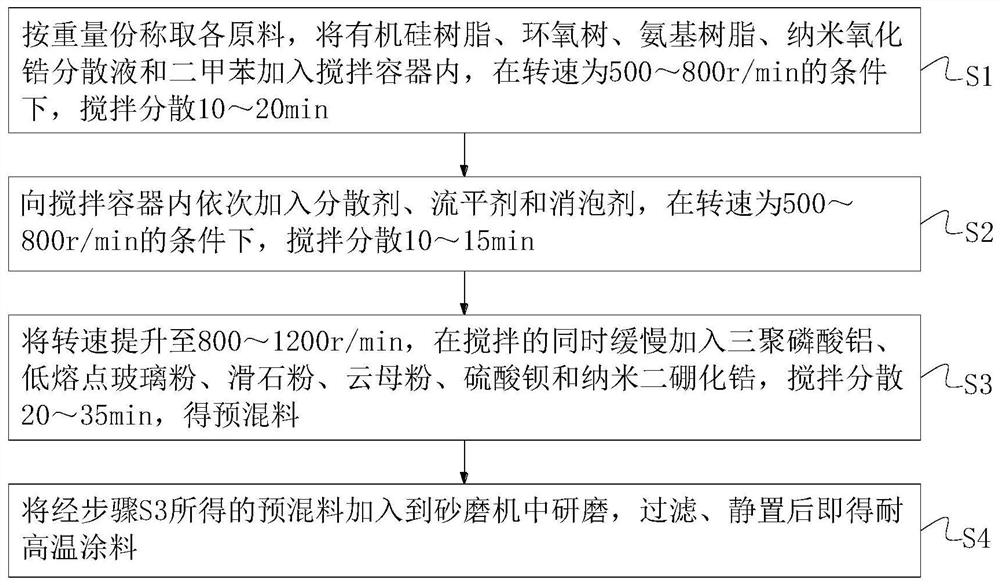

[0025] see figure 1 , the present invention provides the following technical solutions: a high-temperature-resistant coating for automotive interior parts, the high-temperature-resistant coating is composed of the following components in parts by weight: 45 parts of silicone resin, 6 parts of epoxy resin, 4 parts of amino resin, 7 parts of nano zirconia dispersion liquid, 2 parts of aluminum tripolyphosphate, 14 parts of low melting point glass powder, 6 parts of talc powder, 3 parts of mica powder, 2 parts of barium sulfate, 2 parts of nano zirconium diboride, 1 part of dispersant, 0.3 parts of leveling agent, 0.7 parts of defoamer, 7 parts of xylene.

[0026] Specifically, the nano-zirconia dispersion liquid is a nano-zirconia aqueous slurry formed by dispersing nano-zirconia powder with a solid content of 30% in an aqueous medium, and the average particle size of the nano-zirconia powder is 30nm.

[0027] Specifically, both talcum powder and mica powder are 600-mesh powder...

Embodiment 2

[0038] see figure 1 , the present invention provides the following technical solutions: a high-temperature-resistant coating for automotive interior parts, the high-temperature-resistant coating is composed of the following components in parts by weight: 30 parts of silicone resin, 7 parts of epoxy resin, 5 parts of amino resin, 10 parts of nano zirconia dispersion liquid, 3 parts of aluminum tripolyphosphate, 15 parts of low melting point glass powder, 8 parts of talc powder, 5 parts of mica powder, 3 parts of barium sulfate, 3 parts of nano zirconium diboride, 1.5 parts of dispersant, 0.5 parts of leveling agent, 1 part of defoamer, 8 parts of xylene.

[0039] Specifically, the nano-zirconia dispersion liquid is a nano-zirconia aqueous slurry formed by dispersing nano-zirconia powder with a solid content of 20% in an aqueous medium, and the average particle size of the nano-zirconia powder is 30 nm.

[0040] Specifically, both talcum powder and mica powder are 600-mesh powd...

Embodiment 3

[0051] see figure 1 , the present invention provides the following technical solutions: a high-temperature-resistant coating for automotive interior parts, the high-temperature-resistant coating is composed of the following components in parts by weight: 60 parts of silicone resin, 4 parts of epoxy resin, 3 parts of amino resin, 6 parts of nano zirconia dispersion liquid, 1 part of aluminum tripolyphosphate, 13 parts of low melting point glass powder, 3 parts of talc powder, 2 parts of mica powder, 1 part of barium sulfate, 1 part of nano zirconium diboride, 0.5 part of dispersant, 0.1 parts of leveling agent, 0.4 parts of defoamer, 5 parts of xylene.

[0052]Specifically, the nano-zirconia dispersion liquid is a nano-zirconia aqueous slurry formed by dispersing nano-zirconia powder with a solid content of 40% in an aqueous medium, and the average particle size of the nano-zirconia powder is 30 nm.

[0053] Specifically, both talcum powder and mica powder are 600-mesh powders...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com