High-strength corrosion-resistant glass glaze for automobiles and preparation method of high-strength corrosion-resistant glass glaze

A glass glaze, high-strength technology, applied in the field of glass glaze, can solve the problems of insufficient acid and alkali resistance, mismatched expansion coefficient, poor anti-stickiness, etc., to achieve excellent durability, high adaptability, good black tone Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment is a preparation method of glass flux, comprising the following steps:

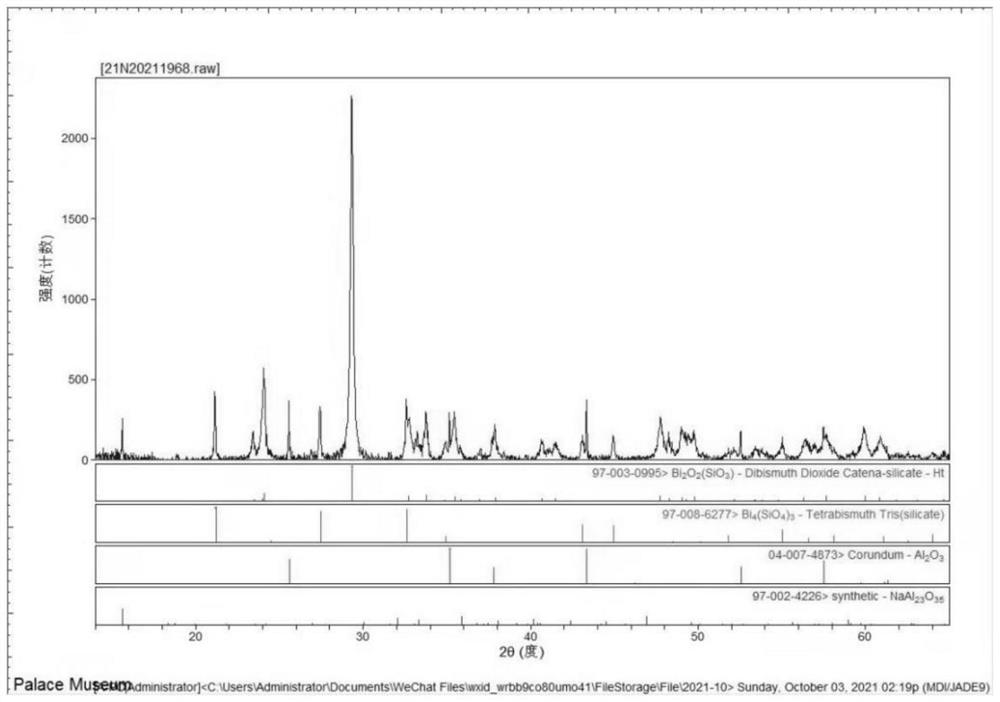

[0037] Step 1: Take Na by weight 2 O 2 parts, ZnO 6 parts, B 2 o 3 12 copies, Bi 2 o 3 53 parts, SiO 2 25 parts, TiO 2 2 copies and Li 2 O 0 copies, spare;

[0038] Step 2: Na 2 O, ZnO, B 2 o 3 、 Bi 2 o 3 , SiO 2 、TiO 2 and Li 2 O mix homogeneously, obtain compound;

[0039] Step 3: melting the mixture to obtain molten glass;

[0040] Step 4: Pour the molten glass into a copper mold and cool it down to 20°C naturally to obtain low-melting glass;

[0041] Step five: crushing the low-melting point glass to obtain glass flux.

Embodiment 2

[0043] This embodiment is a preparation method of glass flux, comprising the following steps:

[0044] Step 1: Take Na by weight 2 O 2 parts, ZnO 6 parts, B 2 o 3 12 copies, Bi 2 o 3 53 parts, SiO 2 25 parts, TiO 2 2 copies and Li 2 O 3 parts, spare;

[0045] Step 2: Na 2 O, ZnO, B 2 o 3 、 Bi 2 o 3 , SiO 2 、TiO 2 and Li 2 O mix homogeneously, obtain compound;

[0046] Step 3: melting the mixture to obtain molten glass;

[0047] Step 4: Pour the molten glass into a copper mold and cool it down to 20°C naturally to obtain low-melting glass;

[0048] Step five: crushing the low-melting point glass to obtain glass flux.

Embodiment 3

[0050] This embodiment is a preparation method of glass flux, comprising the following steps:

[0051] Step 1: Take Na by weight 2 O 2 parts, ZnO 6 parts, B 2 o 3 12 copies, Bi 2 o 3 53 parts, SiO 2 25 parts, TiO 2 2 copies and Li 2 O 6 parts, spare;

[0052] Step 2: Na 2 O, ZnO, B 2 o 3 、 Bi 2 o 3 , SiO 2 、TiO 2 and Li 2 O mix homogeneously, obtain compound;

[0053] Step 3: melting the mixture to obtain molten glass;

[0054] Step 4: Pour the molten glass into a copper mold and cool it down to 20°C naturally to obtain low-melting glass;

[0055] Step five: crushing the low-melting point glass to obtain glass flux.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| acid resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com