A kind of glass-ceramic solder and its preparation method and method for connecting ferrite

A technology of glass ceramics and connecting iron, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problem of large differences in electromagnetic properties and corrosion resistance of ferrite metal-based solder brazing , poor thermal stability and impermeability, affecting the performance and stability of microwave ferrite devices, etc., to achieve the effect of improving service life and full-cycle stability, good thermal stability and impermeability, and high joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

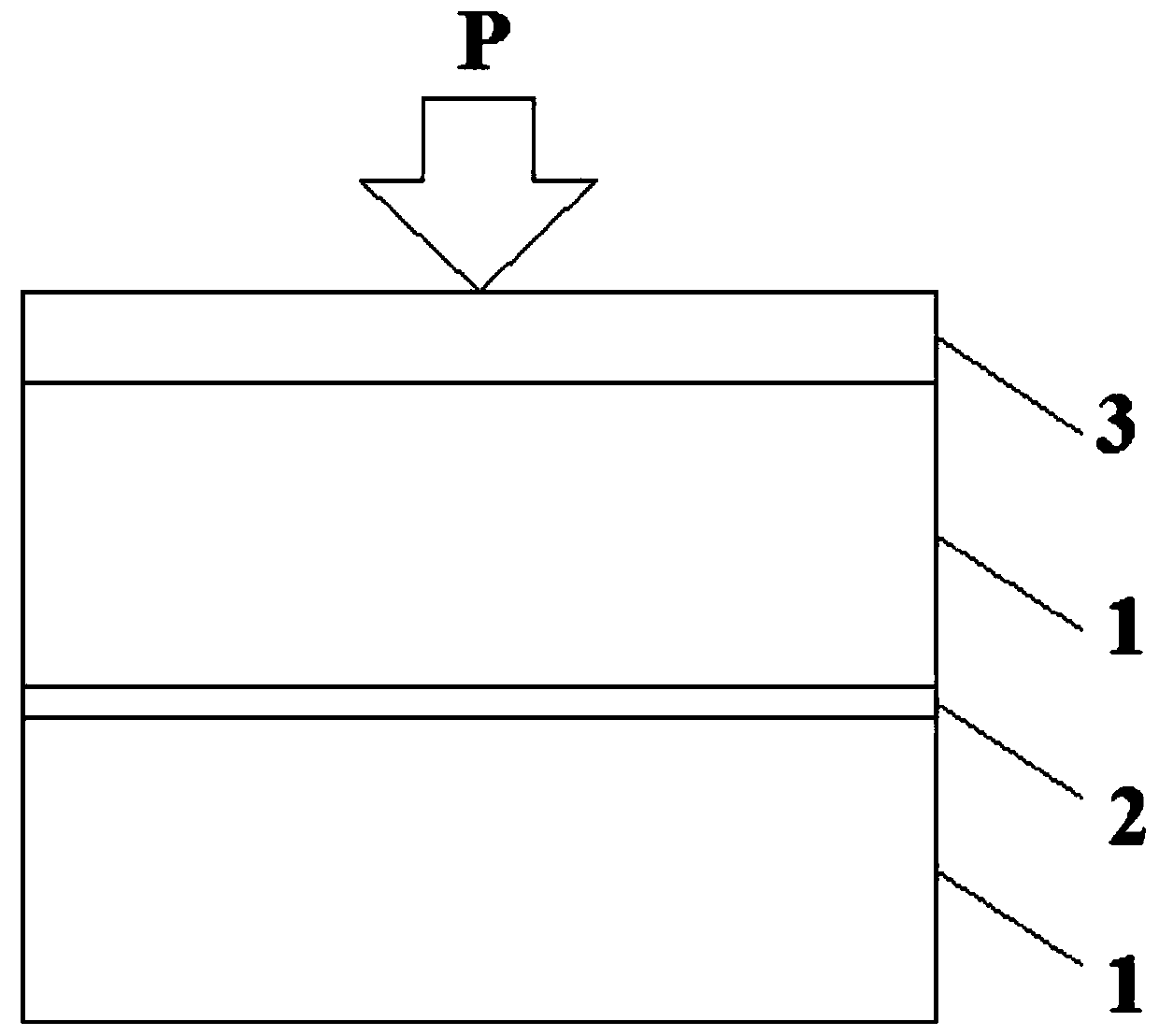

Image

Examples

specific Embodiment approach 1

[0027] Specific embodiment one: In terms of mass percentage, the glass-ceramic solder of the present invention is 20Y 2 o 3 -35Fe 2 o 3 -18BaO-25SiO 2 -2Cr 2 o 3 ; Above-mentioned glass-ceramic solder is carried out according to the following steps:

[0028] Step 1. Weigh the raw material Y according to the predetermined mass percentage 2 o 3 , Fe 2 o 3 , BaO, SiO 2 、Cr 2 o 3 After mixing, use wet grinding method to grind, and dry at 65°C for 10 hours;

[0029] Wherein, the ball milling speed n=300r / min described in step one, the ball milling time is 2h, all raw materials: grinding ball: dispersant=1:2:1, dispersant is dehydrated alcohol;

[0030] Step 2: Melting at 1200°C for 2 hours, pouring into water and quenching to form granules, grinding by wet grinding method, and drying at 65°C for 10 hours to obtain glass-ceramic solder;

[0031] Wherein, the rotational speed of the ball mill in step 2 is n=500r / min, the grinding time is 12h, the particle:grinding ball:...

specific Embodiment approach 2

[0039] Specific embodiment two: in terms of mass percentage, the glass-ceramic solder of the present invention is 20Li 2 O-35Fe2 o 3 -15BaO-25SiO 2 -5Cr 2 o 3 ; Above-mentioned glass-ceramic solder is carried out according to the following steps:

[0040] Step 1, take the raw material Li according to the established mass percentage 2 O, Fe 2 o 3 , BaO, SiO 2 、Cr 2 o 3 After mixing, use wet grinding method to grind, and dry at 65°C for 10 hours;

[0041] Wherein, the ball milling speed n=300r / min described in step one, the ball milling time is 2h, all raw materials: grinding ball: dispersant=1:2:1, dispersant is dehydrated alcohol;

[0042] Step 2: Melting at 1200°C for 2 hours, pouring into water and quenching to form granules, grinding by wet grinding method, and drying at 65°C for 10 hours to obtain glass-ceramic solder;

[0043] Wherein, the rotational speed of the ball mill in step 2 is n=500r / min, the grinding time is 12h, the particle:grinding ball:dispersant=...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com