Laser welding layer prefabricated part and preparation methods for laser welding layer prefabricated part and aluminum silicon carbide box body

A technology of laser welding and silicon carbide box, which is applied in the direction of electrical components, electrical solid devices, semiconductor devices, etc., can solve problems such as cracking at the interface joint, shedding of gold coating, poor performance of laser welding of infiltrated aluminum silicon, etc., and achieve crystal grain The effect of small size and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

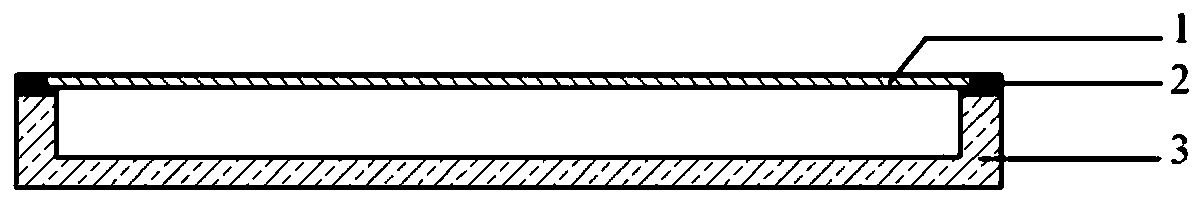

[0053] The aluminum silicon carbide box body structure of the band laser welding layer of the present invention is as follows figure 1 As shown, the laser welding layer 1 is located on the upper end of the aluminum silicon carbide layer 2; the two layers are macroscopically layered, and the microscopic layer is not layered, and there is a good metallurgical bond between the two layers. Wherein the laser welding layer 1 has a thickness of 2mm, and is composed of 6063 aluminum alloy powder and Zl102 aluminum alloy as a reinforcing phase, wherein the volume fraction of 6063 aluminum alloy powder is 60%, and the volume fraction of Zl102 aluminum alloy matrix is 40% %. The aluminum silicon carbide layer 2 is composed of silicon carbide particles and Zl102 aluminum alloy matrix, wherein the volume fraction of silicon carbide is 63%, and the volume fraction of Zl102 aluminum alloy is 37%.

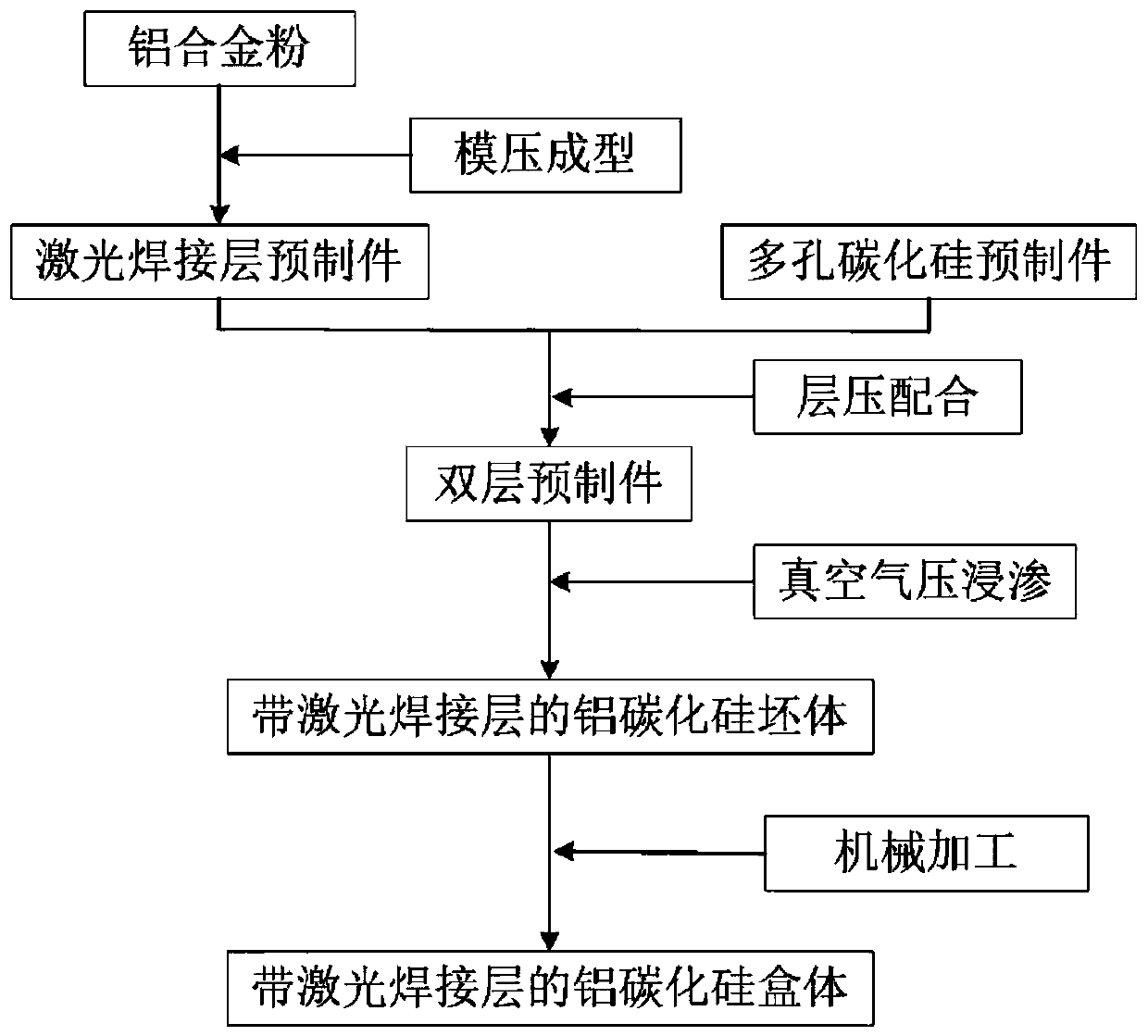

[0054] A method for preparing an aluminum silicon carbide box body with a laser welding lay...

Embodiment 2

[0061] Aluminum silicon carbide box structure with laser welding layer such as figure 1 As shown, the thickness of the laser welding layer 1 is 1.8mm, which is composed of 3003 aluminum alloy powder and Zl101A aluminum alloy as the reinforcing phase, wherein the volume fraction of 3003 aluminum alloy powder is 55%, and the volume fraction of Zl101A aluminum alloy matrix 45%. The aluminum silicon carbide layer 2 is composed of silicon carbide particles and Zl101A aluminum alloy matrix, wherein the volume fraction of silicon carbide is 60%, and the volume fraction of Zl102 aluminum alloy is 40%.

[0062] A method for preparing an aluminum silicon carbide box body with a laser welding layer for electronic packaging, the specific steps are as follows:

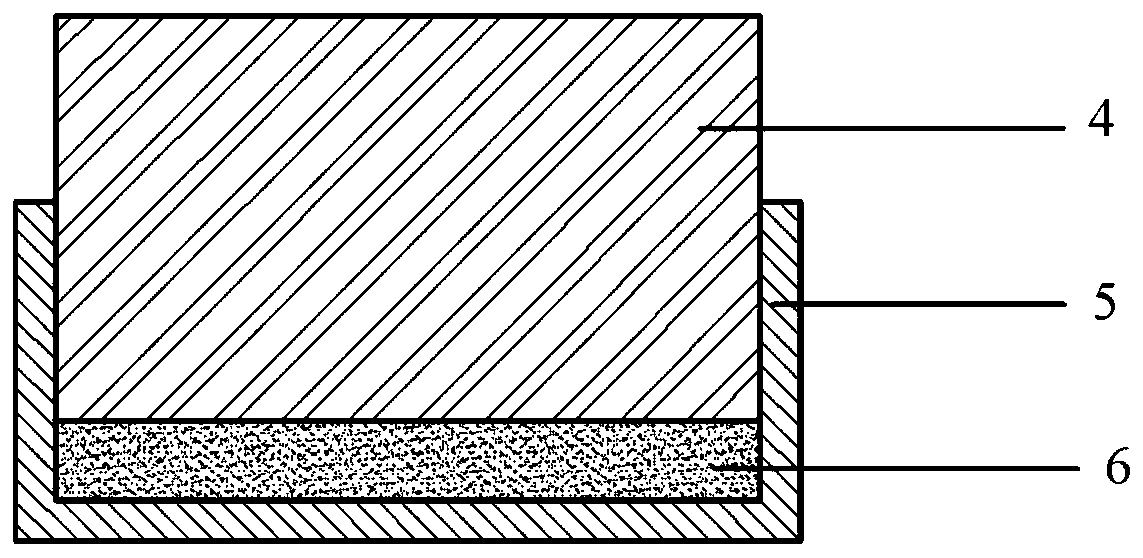

[0063] 1) Prepare a laser welded layer preform. Weigh 3003 aluminum alloy particle powder 6 with a particle size of 100-150 μm, spread it on the bottom of the graphite mold die 5, apply a pressure of 1.5 MPa to the 3003 aluminum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com