Composite material for thermal management and preparation method of composite material

A composite material and heat management technology, applied in the field of thermal management composite materials and its preparation, can solve problems such as poor thermal conductivity, thermal expansion coefficient matching of integrated circuit chips does not meet the requirements, etc., and achieve good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

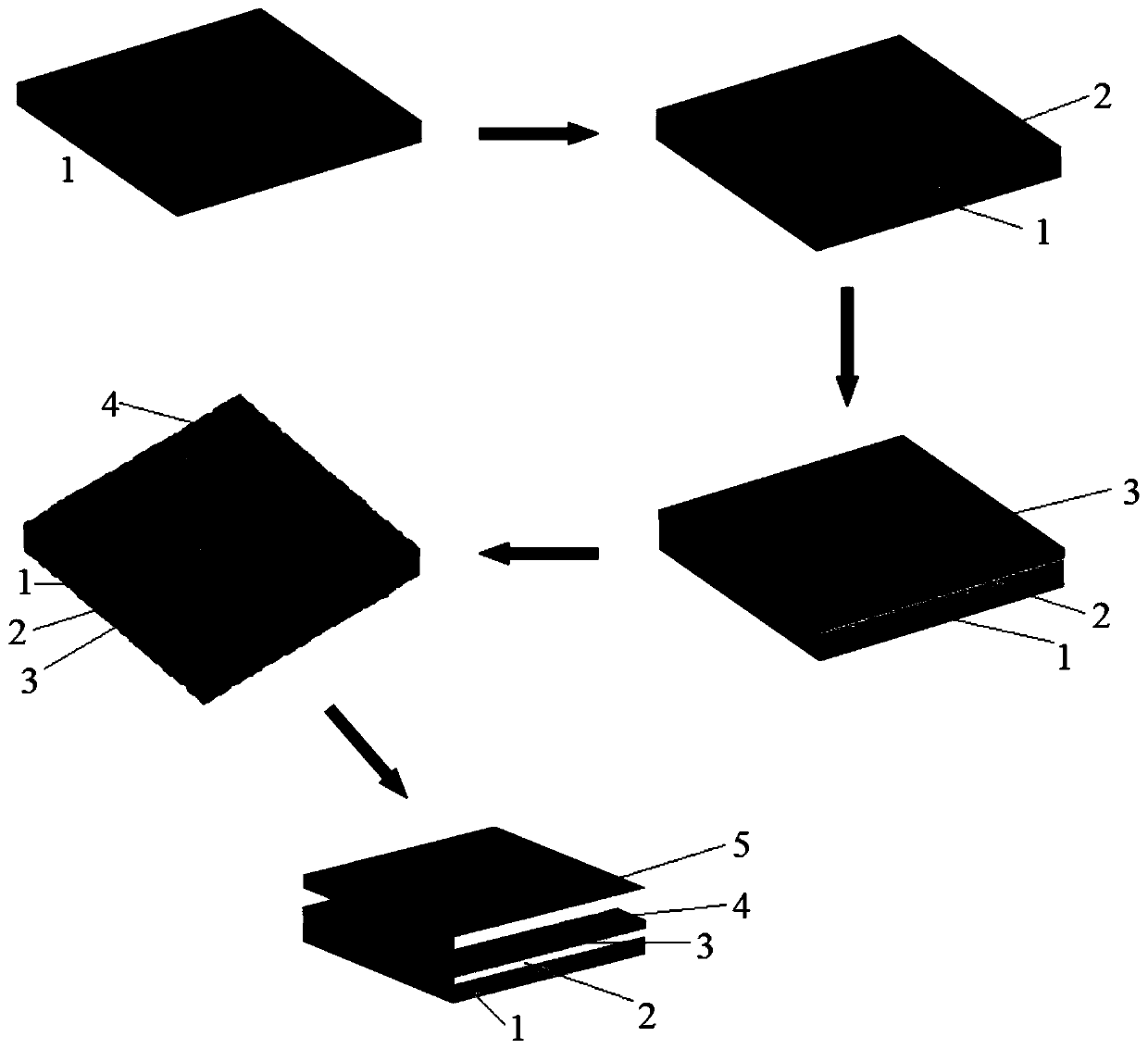

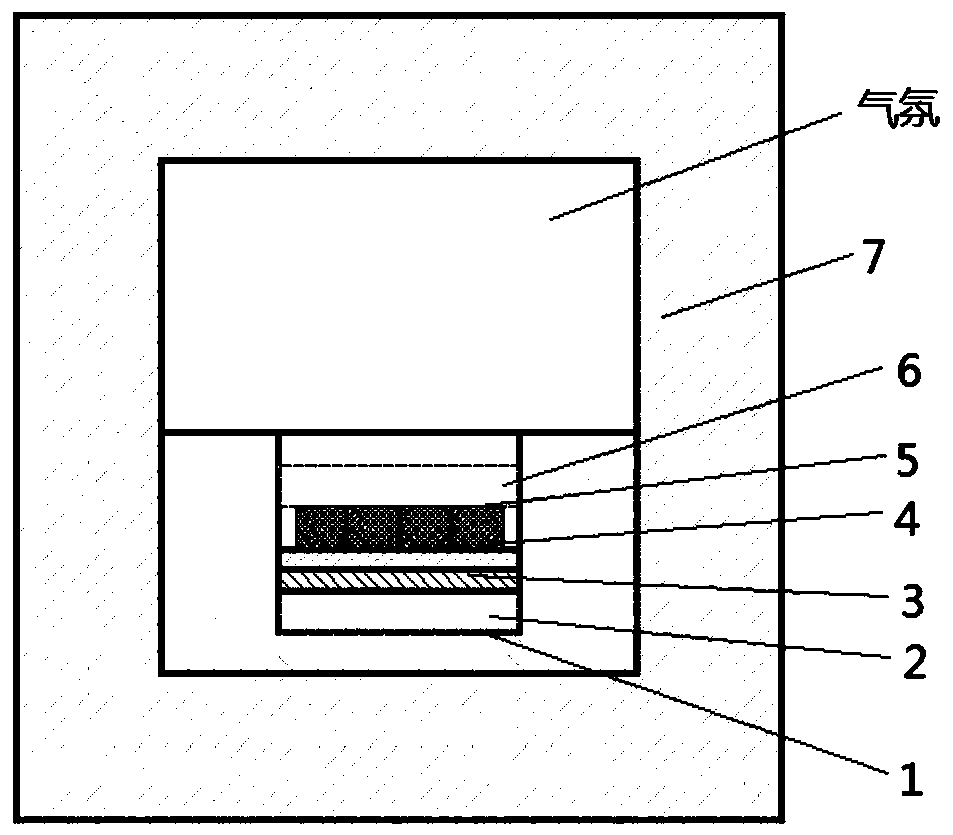

[0049] This embodiment provides a composite material for thermal management and a preparation method thereof, which specifically includes the following steps:

[0050] Preparation of graphene film: disperse graphene oxide powder in deionized water, ultrasonically disperse, and make 1.0g / L graphene oxide dispersion liquid, prepare by vacuum filtration method to obtain length 50mm, width 30mm and thickness A 200μm graphene film is formed under a pressure of 1 bar, and then reduced with HI solution to obtain a graphene film;

[0051] Helical structure graphene: Curling the graphene film forms a cylindrical graphene film roll with a diameter of 1 mm, and makes the cross-section of the graphene film spiral. Cutting the graphene film roll makes its height 0.3mm, for subsequent use;

[0052] The cladding method is used to prepare composite materials for thermal management: WCu10 with a length, width and thickness of 10mm×10mm×0.5mm is used as the heat sink substrate 1, and copper fo...

Embodiment 2

[0054] This embodiment provides a composite material for thermal management and a preparation method thereof, which specifically includes the following steps:

[0055] Preparation of graphene film: disperse graphene oxide powder in deionized water, ultrasonically disperse, and prepare a 0.1g / L graphene oxide dispersion, and prepare it with a length of 100 mm, a width of 100 mm and a thickness of 100 mm by vacuum filtration. It is a graphene film of 200 μm, the film forming pressure is 0.5 bar, and then the graphene film is obtained after reduction with sodium borohydride solution;

[0056] Helical structure graphene: Curling the graphene film forms a cylindrical graphene film roll with a diameter of 5mm, and makes the cross section of the graphene film spiral. Cutting the graphene film roll makes its height 0.5mm, for subsequent use;

[0057] The cladding method is used to prepare composite materials for thermal management: 50mm×50mm×0.5mm MoCu30 is used as the heat sink subs...

Embodiment 3

[0059] This embodiment provides a composite material for thermal management and a preparation method thereof, which specifically includes the following steps:

[0060] Preparation of graphene film: using chemical vapor deposition method, a single-layer graphene film is grown on the surface of copper to obtain a copper-graphene film with a length of 100 mm, a width of 50 mm and a thickness of 30 μm;

[0061] Helical structure graphene: Curling the graphene film forms a cylindrical copper-graphene film roll with a diameter of 3 mm, and makes the cross-section of the copper-graphene film spiral. Cutting described copper-graphene film roll makes its height be 0.5mm, standby;

[0062] Composite materials for thermal management prepared by cladding method: 50mm×50mm×0.5mm WCu20 is used as the heat sink substrate, and 50mm×50mm×0.03mm aluminum foil (first metal layer 2), 50mm×50mm×0.03mm aluminum foil (first metal layer 2), 50mm× 50mm×0.03mm copper-graphene film (first heat transfer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com