Controllable thermal expansion composite conductive ceramic material alpha-Cu2V2O7-Al

A -cu2v2o7--al, composite conductive technology, applied in the field of inorganic composite materials, can solve the problems of damaged instruments, decreased instrument performance, shortened lifespan, etc., and achieves the effects of simple preparation process, good high-temperature conductivity, and adjustable expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The novel composite conductive ceramic material α-Cu prepared in this embodiment 2 V 2 o 7 --The mass fraction of Al in Al is 0.05 (that is, Al accounts for 5% of the total mass in the composite material), and its preparation method is as follows:

[0023] (1) Al powder and α-Cu 2 V 2 o 7 Add an appropriate amount of absolute ethanol to the agate mortar, grind for 1 hour, ensure that the mixture is uniform, and then dry it in a 60°C oven for 30 minutes, and set aside;

[0024] (2) Press the uniformly mixed material obtained in step (1) into a cylindrical blank body with a diameter of 10 mm and a height of 5 mm using a 769YP-15A powder uniaxial tablet press under a pressure of 200 MPa;

[0025] (3) Place the plain body obtained in step (2) in a tube furnace, sinter at 650°C for 10 hours, and then cool down naturally.

Embodiment 2

[0027] The novel composite conductive ceramic material α-Cu prepared in this embodiment 2 V 2 o 7 --The mass fraction of Al in Al is 0.10 (that is, Al accounts for 10% of the total mass in the composite material).

[0028] The preparation method is the same as in Example 1.

Embodiment 3

[0030] The novel composite conductive ceramic material α-Cu prepared in this embodiment 2 V 2 o 7 --The mass fraction of Al in Al is 0.20 (that is, Al accounts for 20% of the total mass in the composite material).

[0031] The preparation method is the same as in Example 1.

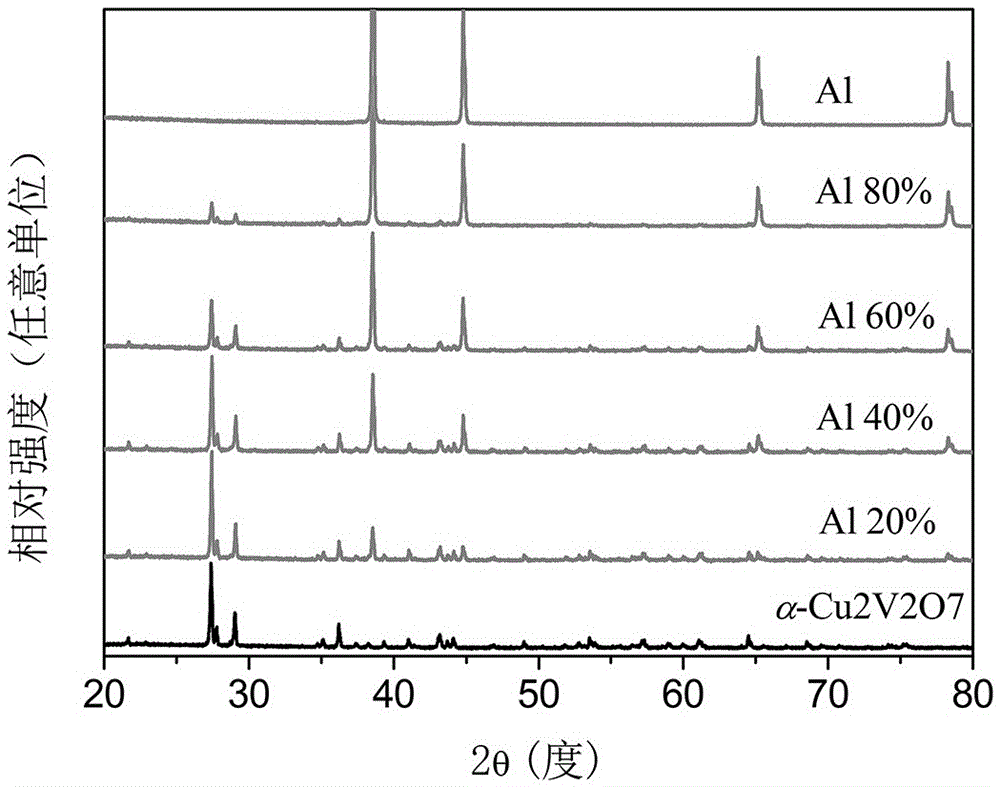

[0032] For the prepared new composite conductive ceramic material α-Cu 2 V 2 o 7 --Al conducts X-ray diffraction (XRD) spectrum phase analysis, and the results are as follows figure 1 As shown, the analysis shows that its main component is α-Cu 2 V 2 o 7 - and Al.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average linear thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com