A led packaged with alsic composite substrate

A composite substrate, LED light source technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low reactivity of metals and ceramics, poor wettability of metals and ceramics, and high requirements for forming dimensional accuracy, and achieves a suitable size for large Large-scale production, high specific stiffness, and the effect of improving reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

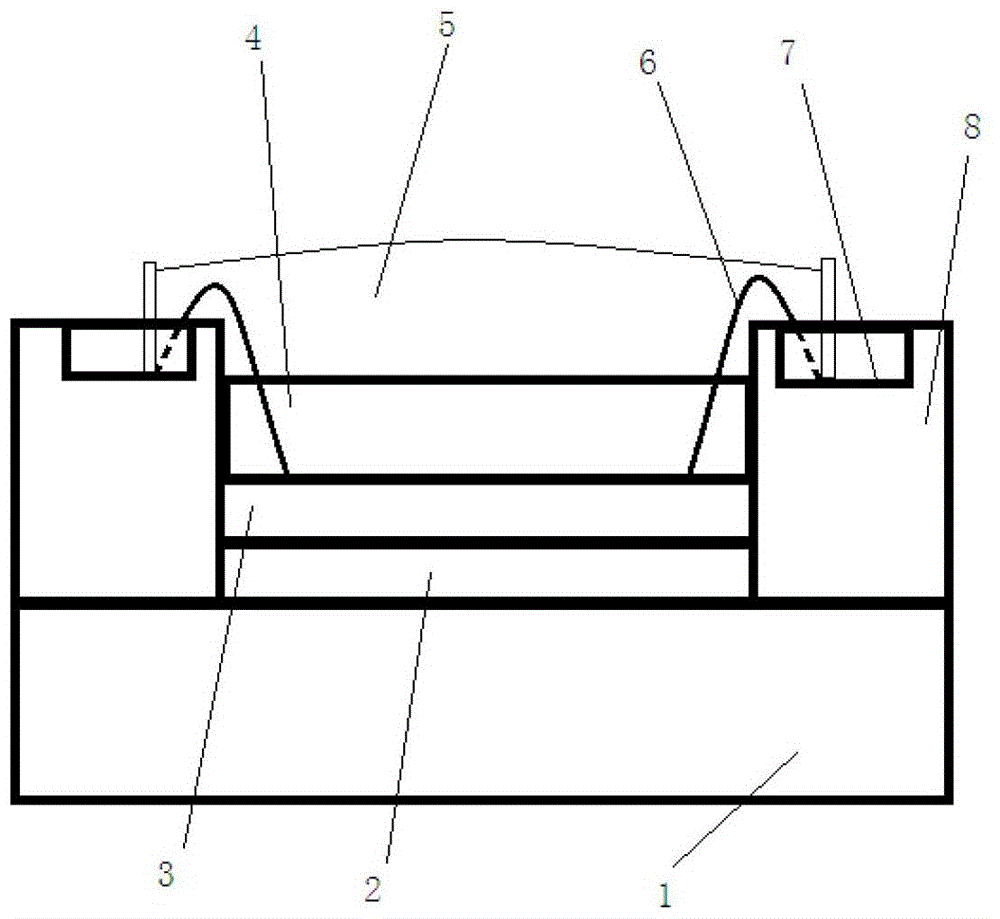

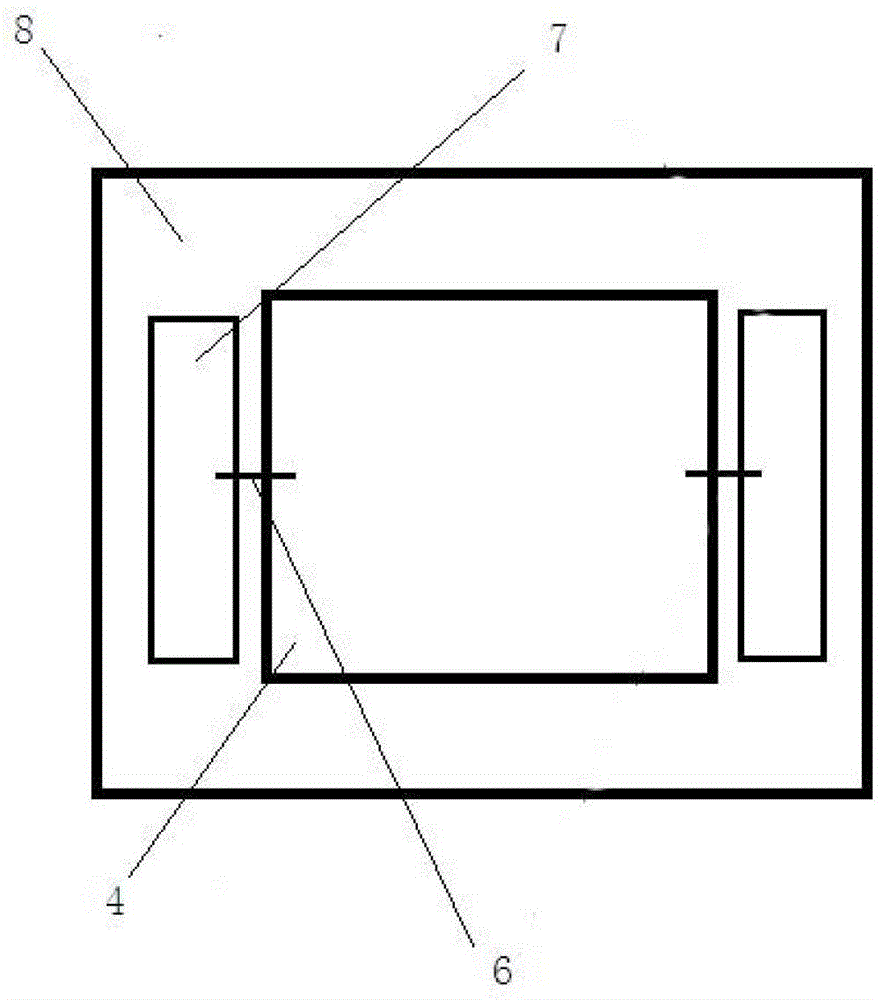

[0020] like Figure 1~2 As shown, an LED packaged with an AlSiC composite substrate in this embodiment includes an AlSiC composite heat dissipation substrate 1 coated with a copper film 2 and a silver film 3 in sequence on the surface, an LED light source module 4, a gold wire 6 and an alumina ceramic frame 8 The LED light source module 4 is packaged on the AlSiC composite heat dissipation substrate 1 using a COB packaging process; the alumina ceramic frame 8 is arranged on the outside of the LED light source module 4 and bonded to the LED light source module 4; the alumina ceramic frame 8 Two copper film electrodes 7 are plated on the top, and the two copper film electrodes 7 are respectively connected to the positive and negative electrodes of the LED light source module 4 through gold wires 6. The transparent silica gel 5 wraps the gold wire 6, and the copper film electrodes 7 are connected to the gold wire 6. part.

[0021] The copper film includes a first layer of copper...

Embodiment 2

[0030] This embodiment is the same as Embodiment 1 except the following features.

[0031] The thickness of the first copper film of the LED packaged with the AlSiC composite substrate in this embodiment is 1 μm, and the thickness of the second layer copper film is 20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com