Hole plugging material for low-expansion wall flow honeycomb ceramic and plugging method thereof

A technology of honeycomb ceramics and low expansion, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of inability to ensure the sealing of blocked pores, unadjustable expansion coefficient, and poor thermal shock resistance. Achieve the effects of promoting and using, reducing sintering temperature and time, and improving thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

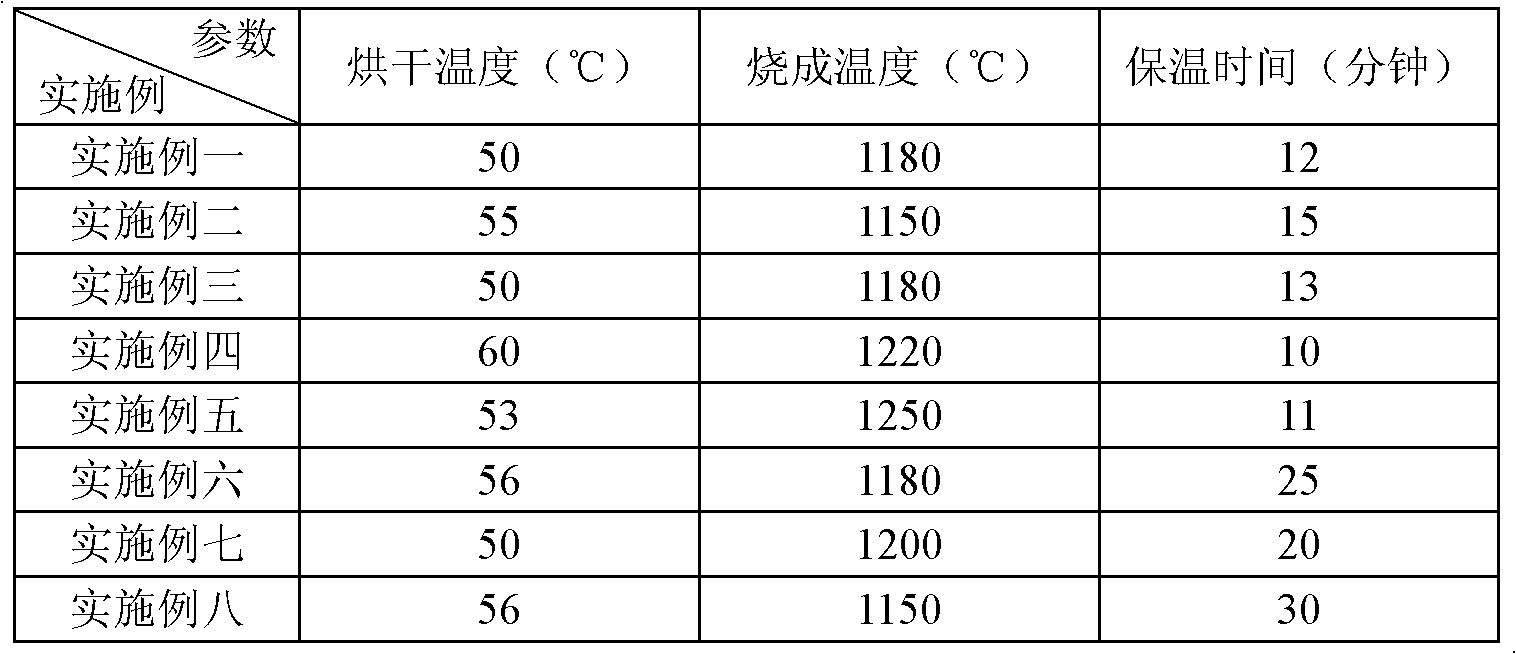

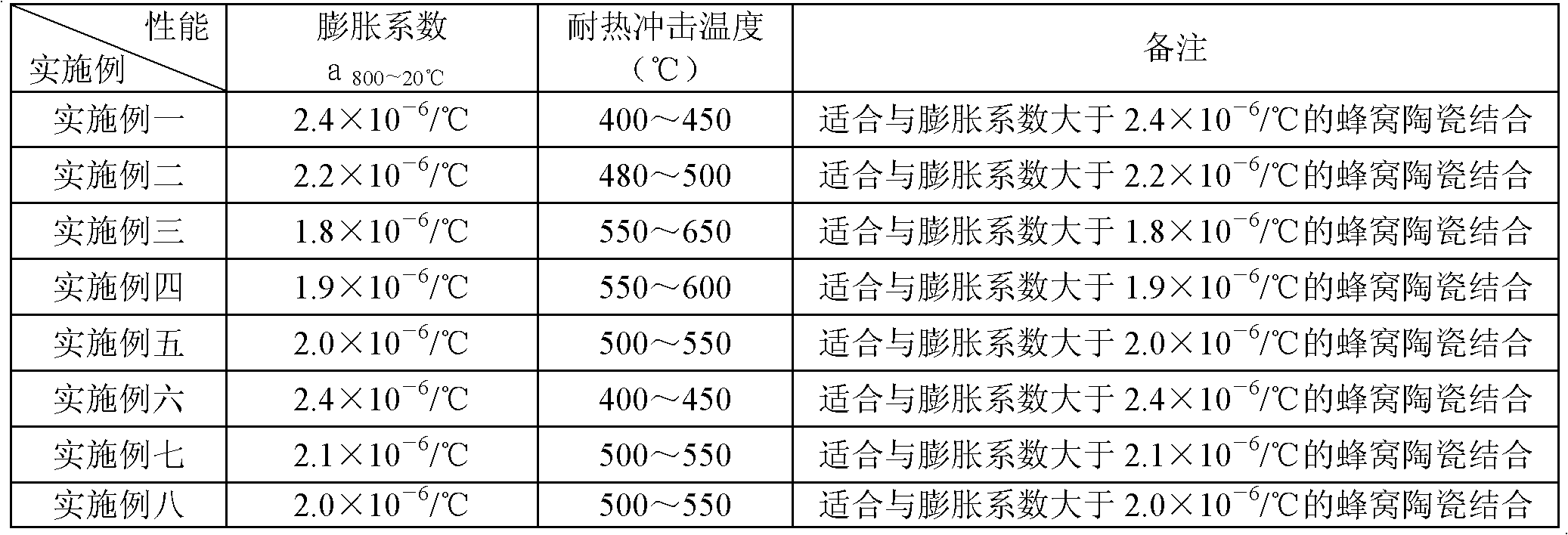

Embodiment 1

[0017] This embodiment is used for the plugging material of low-expansion wall-flow honeycomb ceramics. According to the mass percentage, the base material is composed of: 40% mullite, 20% spodumene, 30% spodumene, and 10% kaolin; and, Add 4% of carboxymethyl cellulose and 30% of water relative to the mass percentage of the base material.

Embodiment 2

[0019] This embodiment is used for the plugging material of low-expansion wall-flow honeycomb ceramics. According to the mass percentage, its base material is composed of: 40% cordierite, 25% spodumene, 20% spodumene, and 15% kaolin; and, relatively 4% of carboxymethyl cellulose and 35% of water are added in the mass percentage of the base material.

Embodiment 3

[0021] This embodiment is used for the plugging material of low-expansion wall-flow honeycomb ceramics. According to the mass percentage, its base material is composed of: 60% cordierite, 20% kyanite, 10% lepidolite, and 10% kaolin; and, the relative base Add carboxymethyl cellulose 4%, water 30% in the mass percentage of material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com