A kind of formula and preparation method of lead-free fusible gold-red glass

A technology of glass and gold colloid, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of biological hazards, raw material lead oxide pollution of the environment, etc., achieve low melting temperature, adjustable expansion coefficient, and wide application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

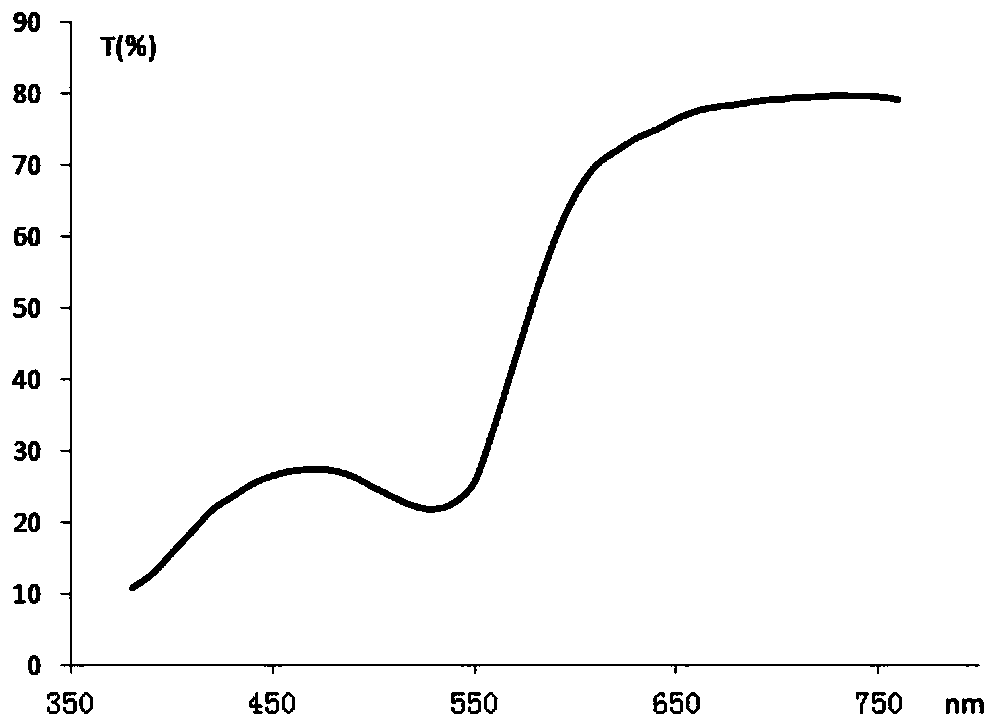

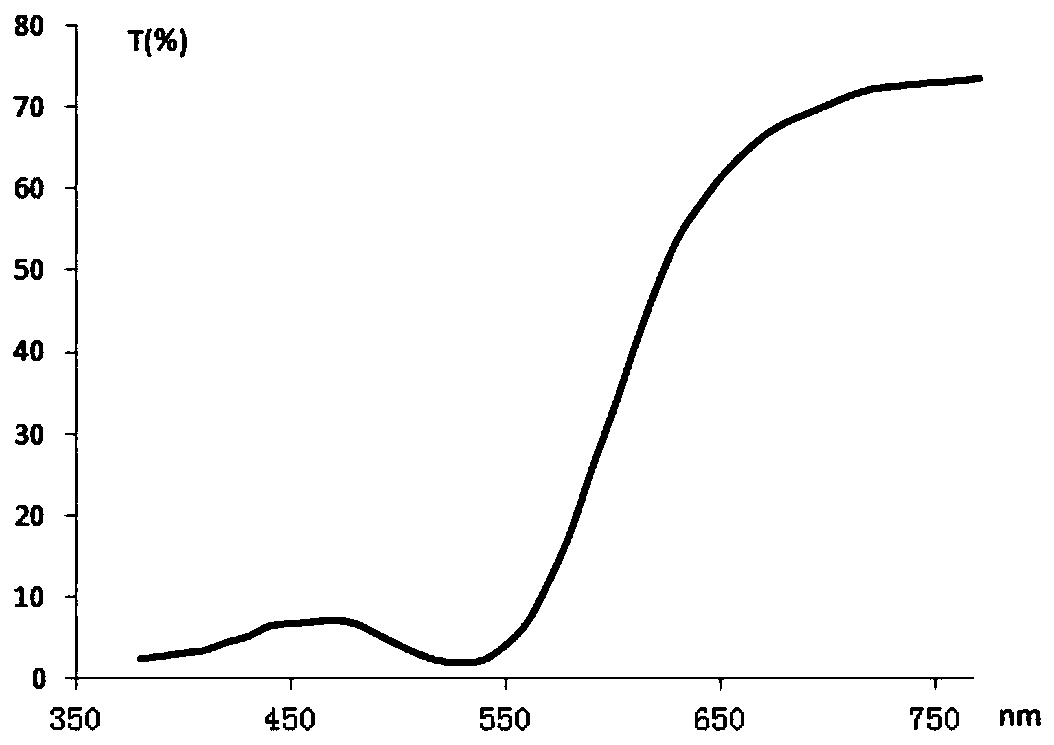

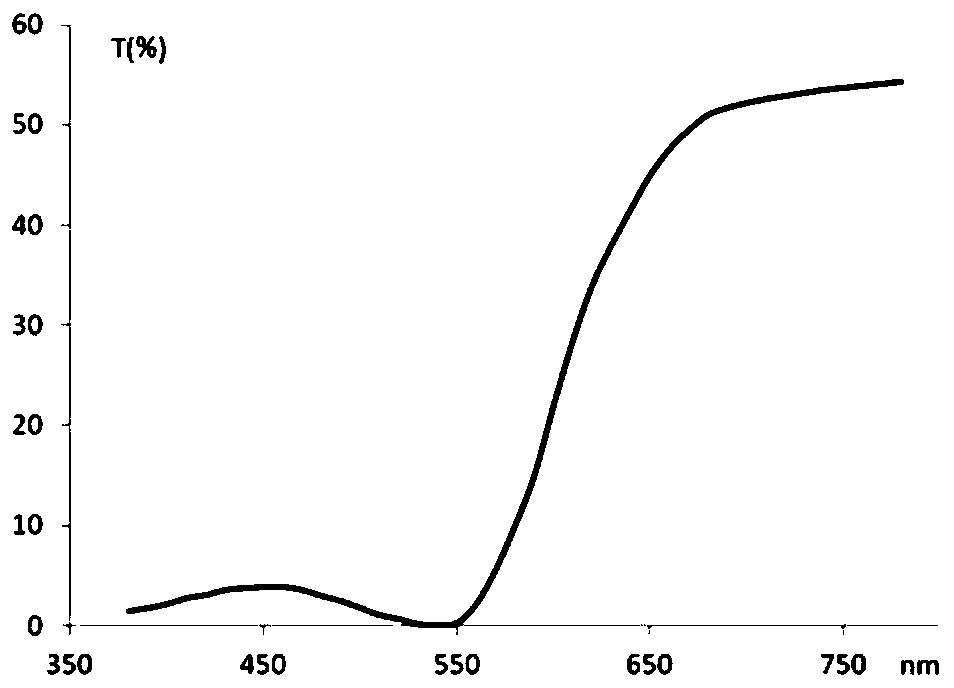

Image

Examples

Embodiment 1

[0024] Preparation Process:

[0025] (1) Composition design and batch preparation

[0026] The composition design of the glass is shown in Table 1

[0027] The glass composition (wt %) of table 1 embodiment 1 design

[0028] SiO 2

B 2 o 3

al 2 o 3

Bi 2 o 3

ZnO K 2 o

Na 2 o

Li 2 o

Sb 2 o 3

SnO Au 40.88 12.5 1 30.9 2 8.0 2.5 0.5 1.0 0.67 0.05

[0029] where B 2 o 3 by H 3 BO 3 Introduced Al 2 o 3 from Al(OH) 3 Bring in, Li 2 O by Li 2 CO 3 Introduced, K 2 O is composed of potassium carbonate and KNO 3 Introduce, Na 2 O is introduced by soda ash, SnO 2 by SnCl 2 2H 2 O is introduced, the colorant is introduced by gold sand, and the rest are directly introduced by their respective oxides. Calculate the amount of various raw materials according to the composition of the glass, accurately weigh each raw material, put them into the ceramic grinding body, grind and mix them thorou...

Embodiment 2

[0046] Preparation Process:

[0047] (1) Glass composition design and batch preparation

[0048] The composition design of the glass is shown in Table 2

[0049] The glass composition (wt%) of table 2 embodiment 2 designs

[0050] SiO 2

B 2 o 3

Al 2 o 3

Bi 2 o 3

ZnO K 2 o

Na 2 o

Li 2 o

Sb 2 o 3

SnO Au 44 16 1.2 22 2 10 1.6 1 1.32 0.8 0.08

[0051] Raw material and compound preparation method are with embodiment 1.

[0052] (2) Put the mixed raw materials into a high-alumina crucible, and melt them in a silicon-carbon rod high-temperature resistance furnace at a melting temperature of 1300° C., and keep warm for 3 hours.

[0053] (3) The fully melted and homogenized glass melt is quickly poured into a preheated graphite mold for molding, and then quickly taken out and annealed in a muffle furnace for 30 minutes at an annealing temperature of 500°C, and then cooled with the furnace.

[00...

Embodiment 3

[0063] Preparation Process:

[0064] (1) Glass composition design and batch preparation

[0065] The composition design of the glass is shown in Table 3

[0066] The glass composition (wt%) of table 3 embodiment 3 designs

[0067] SiO 2

B 2 o 3

al 2 o 3

Bi 2 o 3

ZnO K 2 o

Na 2 o

Li 2 o

Sb 2 o 3

SnO Au 35 10 1.5 41 1 8.0 0 1 1.6 0.8 0.1

[0068] Raw material and compound preparation method are with embodiment 1.

[0069] (2) Put the mixed raw materials into a high-alumina crucible, and melt them in a silicon-carbon rod high-temperature resistance furnace at a melting temperature of 1250° C., and keep warm for 2.0 hours.

[0070] (3) The fully melted and homogenized glass melt is quickly poured into the preheated carbon film to form it, and then quickly taken out and annealed in the muffle furnace for 30 minutes. The annealing temperature is 460 ° C, and then cooled with the furnace.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com