Blue-light and green-light lignin carbon quantum dots with high quantum yield as well as preparation method and application thereof

A plain carbon quantum and high quantum technology, which is applied in the field of lignin carbon quantum dots and its preparation, can solve the problems of harsh preparation conditions and low quantum yield, and achieve the effect of low price, wide sources, and improved quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 0.05g of modified lignin and 7.6852g of citric acid, disperse in 25ml of ultrapure water under magnetic stirring, add 1g of ethylenediamine, disperse with ultrasonic oscillation for 20min; , after natural cooling to room temperature, the crude lignin carbon quantum dot product was obtained; the crude product was centrifuged, the obtained supernatant was separated with a 0.22 μm filter membrane, and the filtrate was collected; Plain carbon quantum dot solution, its quantum yield is measured to be 43.26%. The lignin carbon quantum dot solution is rotatively evaporated at 30° C., and then freeze-dried to obtain the lignin carbon quantum dot solid powder.

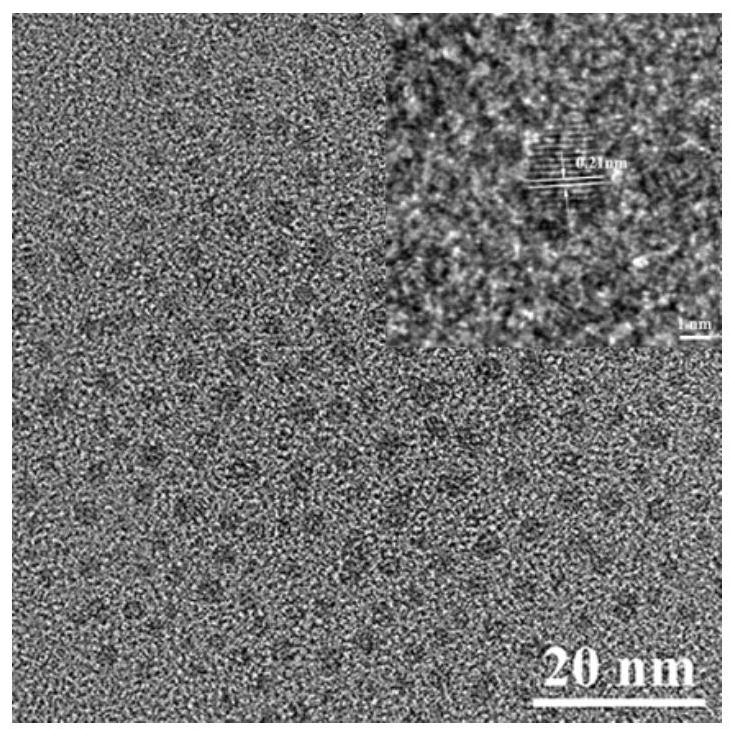

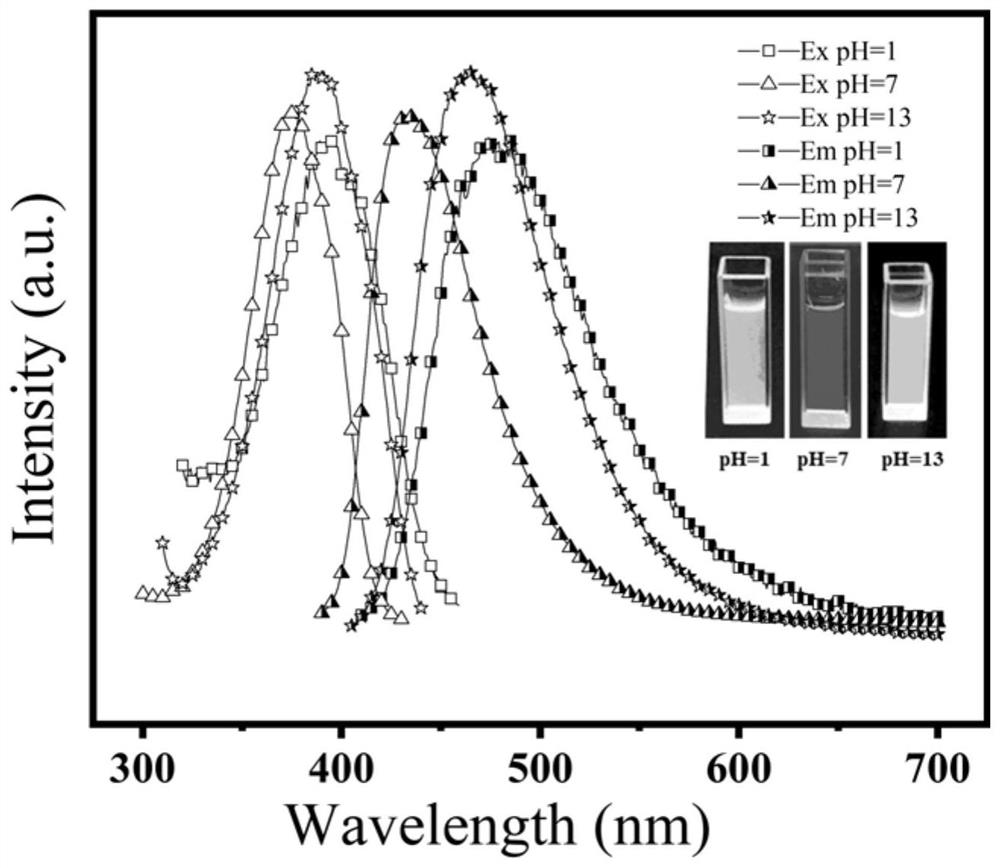

[0036] The electron microscope picture (inset is the corresponding high-resolution TEM picture) of the lignin carbon quantum dot obtained in the present embodiment is as follows figure 1 As shown, transmission electron microscope observation shows that lignin carbon quantum dots are well dispersed, almost spherica...

Embodiment 2

[0039] Weigh 1g of modified lignin and 3.8426g of citric acid, disperse in 50ml of ultrapure water under magnetic stirring, add 0.5g of o-phenylenediamine, disperse with ultrasonic oscillation for 5min; Take it out, cool it down to room temperature naturally, and get the crude product of lignin carbon quantum dots; centrifuge the crude product, separate the obtained supernatant with a 0.22 μm membrane filter, and collect the filtrate; after the filtrate is dialyzed and purified with a 3500Da specification dialysis bag, you can get The lignin carbon quantum dot solution has a measured quantum yield of 53.46%. The lignin carbon quantum dot solution is rotatively evaporated at 50° C., and then freeze-dried to obtain the lignin carbon quantum dot solid powder.

Embodiment 3

[0041] Weigh 0.5g of modified lignin and 11.5278g of citric acid, disperse in 30ml of ultrapure water under magnetic stirring, add 1g of urea, disperse with ultrasonic oscillation for 30min; After cooling to room temperature, the crude lignin carbon quantum dot product is obtained; the crude product is centrifuged, the obtained supernatant is separated with a 0.22 μm filter membrane, and the filtrate is collected; the filtrate is dialyzed and purified with a 1000Da dialysis bag to obtain lignin carbon The quantum dot solution has a measured quantum yield of 43.46%. The lignin carbon quantum dot solution is rotatively evaporated at 70° C., and then freeze-dried to obtain the lignin carbon quantum dot solid powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com