Preparation method of composite material for mobile phone shell

A technology of composite materials and mobile phone shells, applied in the field of materials, can solve problems such as low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

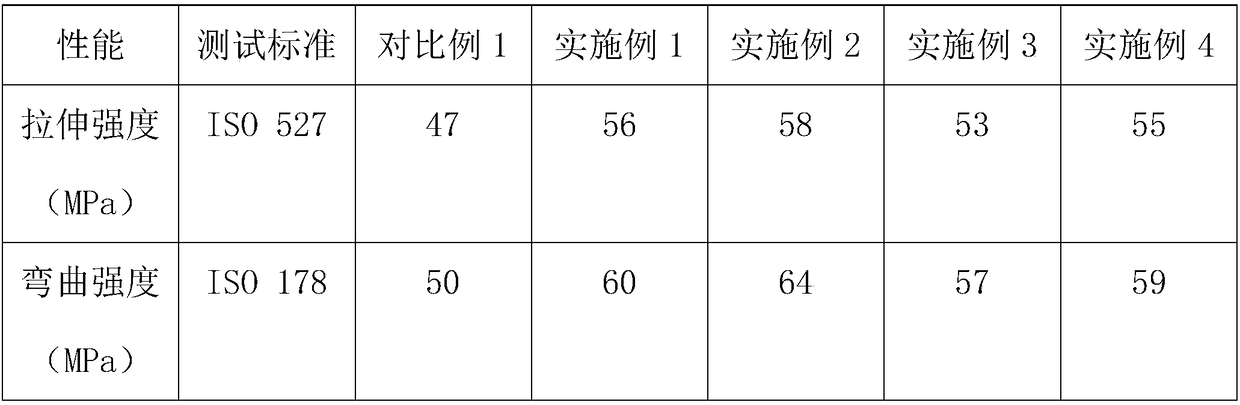

Examples

Embodiment 1

[0018] A preparation method of a composite material for a mobile phone shell, comprising the steps of: by weight, 82 parts of polycarbonate, 36 parts of acrylonitrile-butadiene-styrene copolymer, 15 parts of modified carbon fiber, styrene-acrylonitrile ‐8 parts of ternary random copolymer of maleic anhydride, 2 parts of tributyl phosphate, 4 parts of EC type brominated epoxy resin, 0.5 parts of tris(2·4-di-tert-butylphenyl) phosphite, Add 2 parts of pentaerythritol stearate and 0.5 part of bis-2,6-di-tert-butylphenol into a high-speed mixer, and mix for 5 minutes to obtain a compound; extrude the compound on a twin-screw extruder to obtain .

Embodiment 2

[0020] A preparation method of a composite material for a mobile phone shell, comprising the steps of: mixing 95 parts of polycarbonate, 33 parts of acrylonitrile-butadiene-styrene copolymer, 25 parts of modified carbon fiber, styrene-acrylonitrile ‐3 parts of ternary random copolymer of maleic anhydride, 4 parts of tributyl phosphate, 2 parts of EC type brominated epoxy resin, 1 part of tris(2·4-di-tert-butylphenyl) phosphite, Add 1 part of pentaerythritol stearate and 2 parts of bis-2,6-di-tert-butylphenol into a high-speed mixer, and mix for 3 minutes to obtain a compound; extrude the compound on a twin-screw extruder to obtain .

Embodiment 3

[0022] A preparation method of a composite material for a mobile phone shell, comprising the steps of: by weight, 82 parts of polycarbonate, 36 parts of acrylonitrile-butadiene-styrene copolymer, 15 parts of modified carbon fiber, styrene-acrylonitrile ‐8 parts of ternary random copolymer of maleic anhydride, 2 parts of tributyl phosphate, 4 parts of EC type brominated epoxy resin, 0.5 parts of tris(2·4-di-tert-butylphenyl) phosphite, Add 2 parts of pentaerythritol stearate and 0.5 part of bis-2,6-di-tert-butylphenol into a high-speed mixer, and mix for 5 minutes to obtain a compound; extrude the compound on a twin-screw extruder to obtain The set temperatures of each section of the twin-screw extruder are: the first section is 195°C, the second section is 230°C, the third section is 232°C, and the fourth section is 210°C;

[0023] The preparation of described modified carbon fiber:

[0024] S1. Reflux the carbon fiber with acetone for 35 hours, take it out, wash it with deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com