Polymer water-absorbent resin for diapers and preparation method thereof

A technology for polymer water absorption and diapers, which is applied in the field of resin preparation, can solve the problems of insufficient antibacterial and toughness properties of polymer water absorbent resins for diapers, achieve large surface area, improve antibacterial and toughness, and improve antibacterial and toughness properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

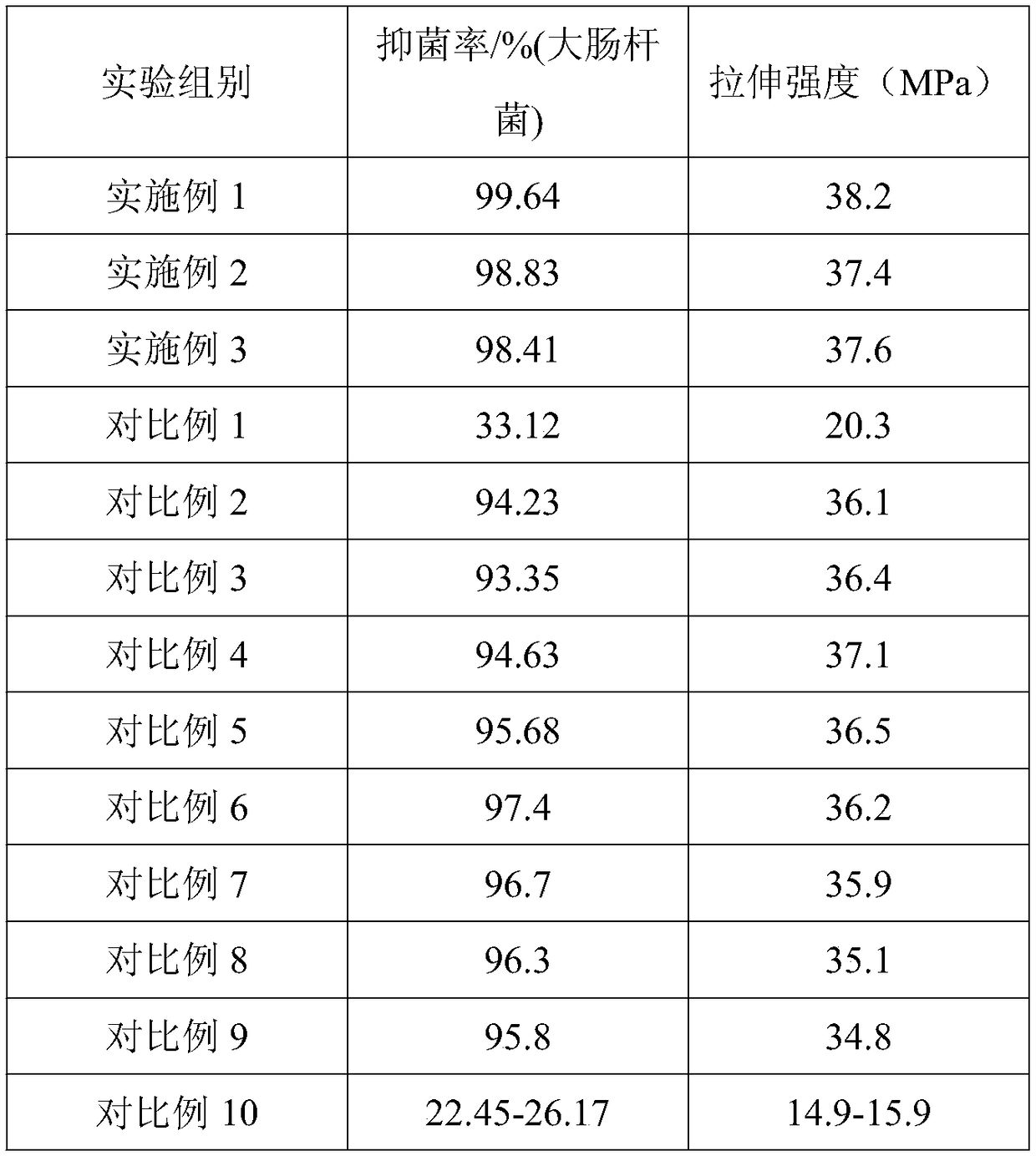

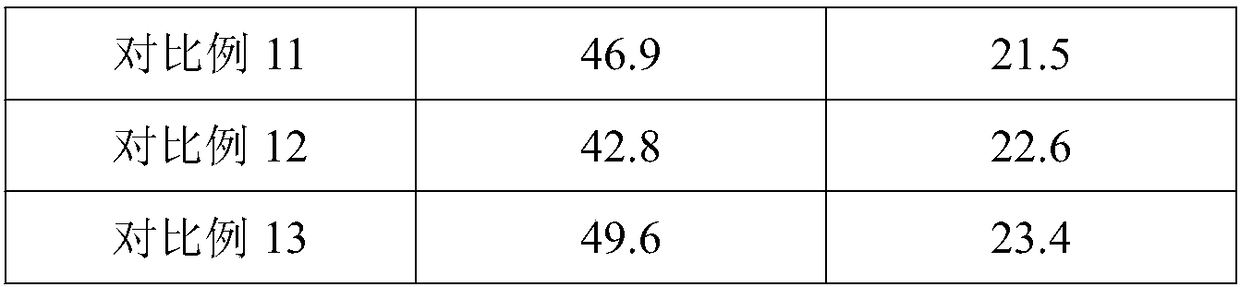

Examples

preparation example Construction

[0031] The preparation method of described diapers with polymer water-absorbent resin, comprises the following steps:

[0032] S1. Mix bisphenol A polysulfone resin, acrylic acid, N,N-methylenebisacrylamide, potassium persulfate and sodium sulfite evenly, then raise the temperature to 60-70°C, keep it warm for 10-20min, and then add methylene Mix succinic acid, sodium hydroxide and acrylamide evenly, stir at 4000-6000r / min for 10-15min, then add kelp and mix evenly, heat up to 80-90°C, keep warm for 1-2h, and stir at 650-850r / min Stir for 1-2h, cool to room temperature to obtain the base material;

[0033] S2. After mixing polycarbonate, polylactic acid and silane coupling agent KH-560, heat up to 50-60°C, keep warm for 1-3h, keep stirring during the heat preservation process, then add bamboo charcoal fiber, carbon nanotubes, modified Mix the non-toxic antibacterial additive and the toughening modification additive evenly, continue to heat up to 70-80°C, stir and disperse at ...

Embodiment 1

[0037] A polymer water-absorbent resin for diapers, in parts by weight, comprising the following raw materials: 14.8 parts of bisphenol A polysulfone resin, 6.4 parts of polycarbonate, 9.9 parts of polylactic acid, 5.2 parts of bamboo charcoal fiber, carbon nanotubes 5.1 parts, 2.2 parts of silane coupling agent KH-560, 210 parts of acrylic acid, 0.02 parts of N,N-methylenebisacrylamide, 2.1 parts of potassium persulfate, 3.4 parts of sodium sulfite, 14.6 parts of methylene succinic acid, 165 parts of sodium, 13.6 parts of kelp, 38.9 parts of acrylamide, 19.6 parts of modified antibacterial additives, and 24.6 parts of toughening modified additives.

[0038] The antibacterial modification additive is prepared according to the following process: 15 parts by weight of N-(4-hydroxy-3-methoxy-benzyl) acrylamide and 6 parts of N,N-dimethylacetamide are mixed evenly, Stir at 746r / min for 32min, then raise the temperature to 78°C, keep it warm for 2.2h, then blow in nitrogen, add 3.9...

Embodiment 2

[0045] A polymer water-absorbent resin for diapers, in parts by weight, comprising the following raw materials: 10 parts of bisphenol A polysulfone resin, 9 parts of polycarbonate, 8 parts of polylactic acid, 6 parts of bamboo charcoal fiber, carbon nanotubes 2 parts, silane coupling agent KH-5603 parts, 100 parts of acrylic acid, 0.03 parts of N,N-methylenebisacrylamide, 1 part of potassium persulfate, 5 parts of sodium sulfite, 10 parts of methylene succinic acid, hydrogen 230 parts of sodium, 7 parts of kelp, 60 parts of acrylamide, 15 parts of modified antibacterial additives, and 32 parts of toughening modified additives.

[0046] The antibacterial modified auxiliary agent is prepared according to the following process: 10 parts by weight of N-(4-hydroxy-3-methoxy-benzyl) acrylamide and 8 parts of N,N-dimethylacetamide are mixed evenly, Stir at 650r / min for 40min, then raise the temperature to 75°C, keep it warm for 3h, then blow in nitrogen, add 2 parts of calcium nitrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com