Preparation method and application of grinding and dispersing agent

A technology of dispersant and reactant, applied in the field of preparation of grinding dispersant, can solve the problems affecting the glossiness of finished paper surface characteristics, printing adaptability, large particle size distribution range, etc., and achieve the improvement of surface optical characteristics and printing performance, The effect of high dispersion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

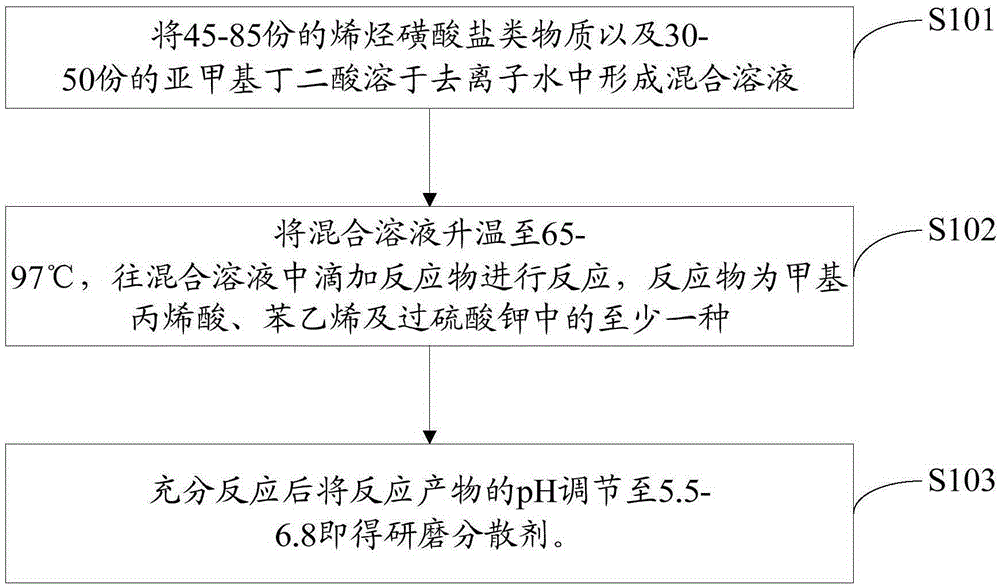

[0018] see figure 1 , figure 1 It is a flowchart of a preparation method of a grinding dispersant provided by an embodiment of the present invention. As shown in the figure, the preparation method of a grinding dispersant of the embodiment of the present invention includes the following steps:

[0019] S101: Dissolving 45-85 parts of olefin sulfonate and 30-50 parts of methylene succinic acid in deionized water to form a mixed solution.

[0020] In the embodiment of the present invention, olefin sulfonate substances and methylene succinic acid are used as the main reacting substances. In theory, all olefin sulfonate substances can achieve the purpose of the present invention. However, as a preferred implementation of the present invention, the olefin sulfonate is preferably an alkali metal olefin sulfonate, for example, sodium allyl sulfonate, potassium allyl sulfonate, vinyl sulfonate Sodium acid and potassium vinylsulfonate, etc., of course, are not limited thereto. As th...

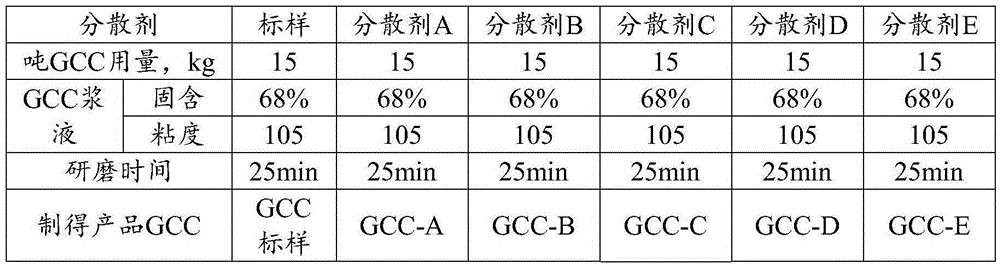

Embodiment 1

[0039] Weigh 30 parts of methylene succinic acid, mix 15 parts of sodium propenyl sulfonate, dissolve with deionized water, slowly drop into 5 parts of (methacrylic acid, styrene, potassium persulfate mixed solution), keep the solution temperature at At 96°C, react for 2 hours to prepare Dispersant A.

Embodiment 2

[0041]Weigh 22 parts of methylene succinic acid, mix 10 parts of sodium propenyl sulfonate, dissolve with deionized water, slowly drop into 8 parts of (mixed solution of acrylic acid and styrene), keep the solution temperature at 85°C, and react for 1.5 h, make dispersant B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com