Paper-plastic compound adhesive and preparation method thereof

A paper-plastic compounding and adhesive technology, applied in the direction of adhesive types, ester copolymer adhesives, etc., can solve the problems of poor stability, restrict the development of the packaging industry, low bonding strength, etc., achieve high stability, The effect of non-toxic triggering efficiency and bonding strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

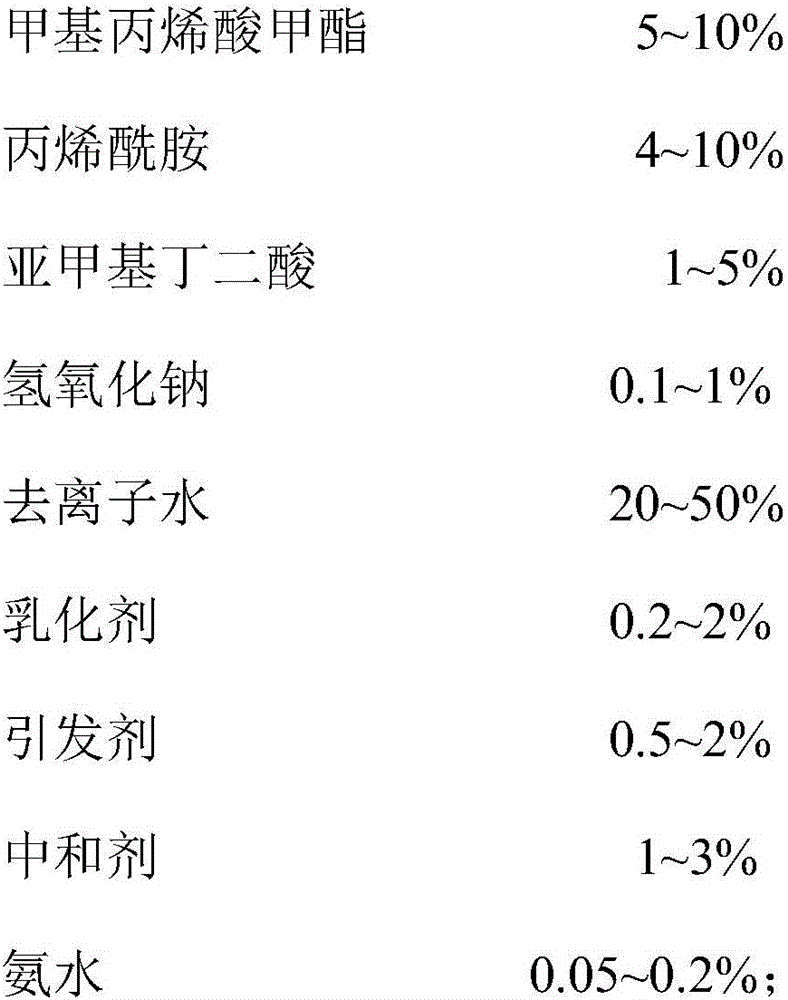

[0035] Prepare paper-plastic composite adhesive, see Table 1 for specific components and contents, and the preparation method is as follows:

[0036] Step 1, pre-emulsification: add butyl acrylate, vinyl acetate, methyl methacrylate, acrylamide, methylene succinic acid, and deionized water to the pre-emulsification device to react to form a mixed solution according to the above mass percentage, and then Distill the mixed solution under reduced pressure and wash it with sodium hydroxide, and finally stir for 25-45 minutes to make the mixed solution appear uniform milky white to obtain a pre-emulsion; the pressure range of the reduced-pressure distillation is -0.04~-0.01MPa , The temperature range of vacuum distillation is 60~68℃.

[0037] Step 2, seed emulsion polymerization: add deionized water, emulsifier, protective colloid, neutralizer, buffer, cosolvent, and initiator accounting for 50% of the total amount of initiator in the reaction kettle in sequence, heat and stir, Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com