Corrosion and scale inhibitor for circulation cooling water system with desalted seawater as replenishing water

A technology of circulating cooling water and corrosion and scale inhibitors, which is applied in seawater treatment, descaling and water softening, water/sludge/sewage treatment, etc. It can solve the problems of difficulty in meeting discharge standards, poor economy, and large amount of dosing, etc. Problems, to achieve the effect of not easy to decompose, prolong service life and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

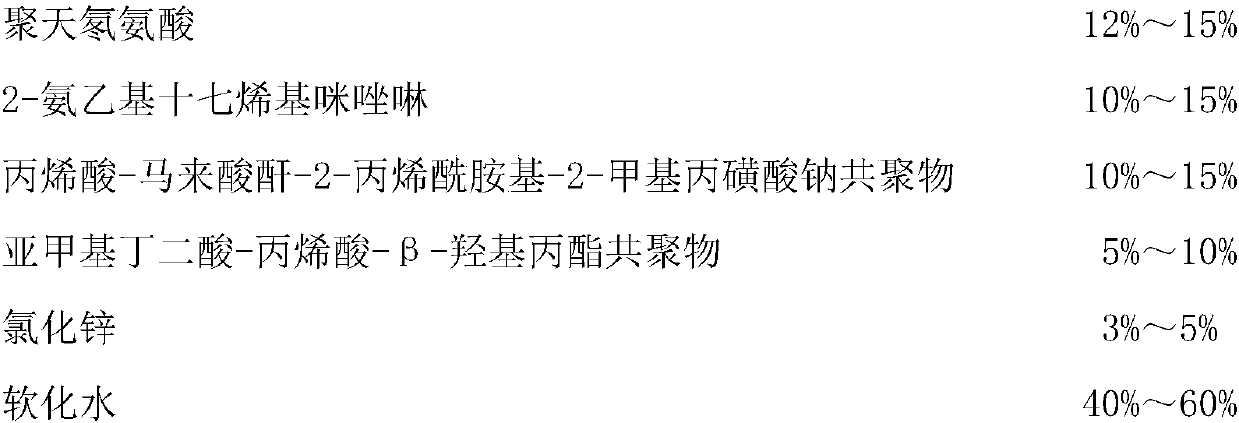

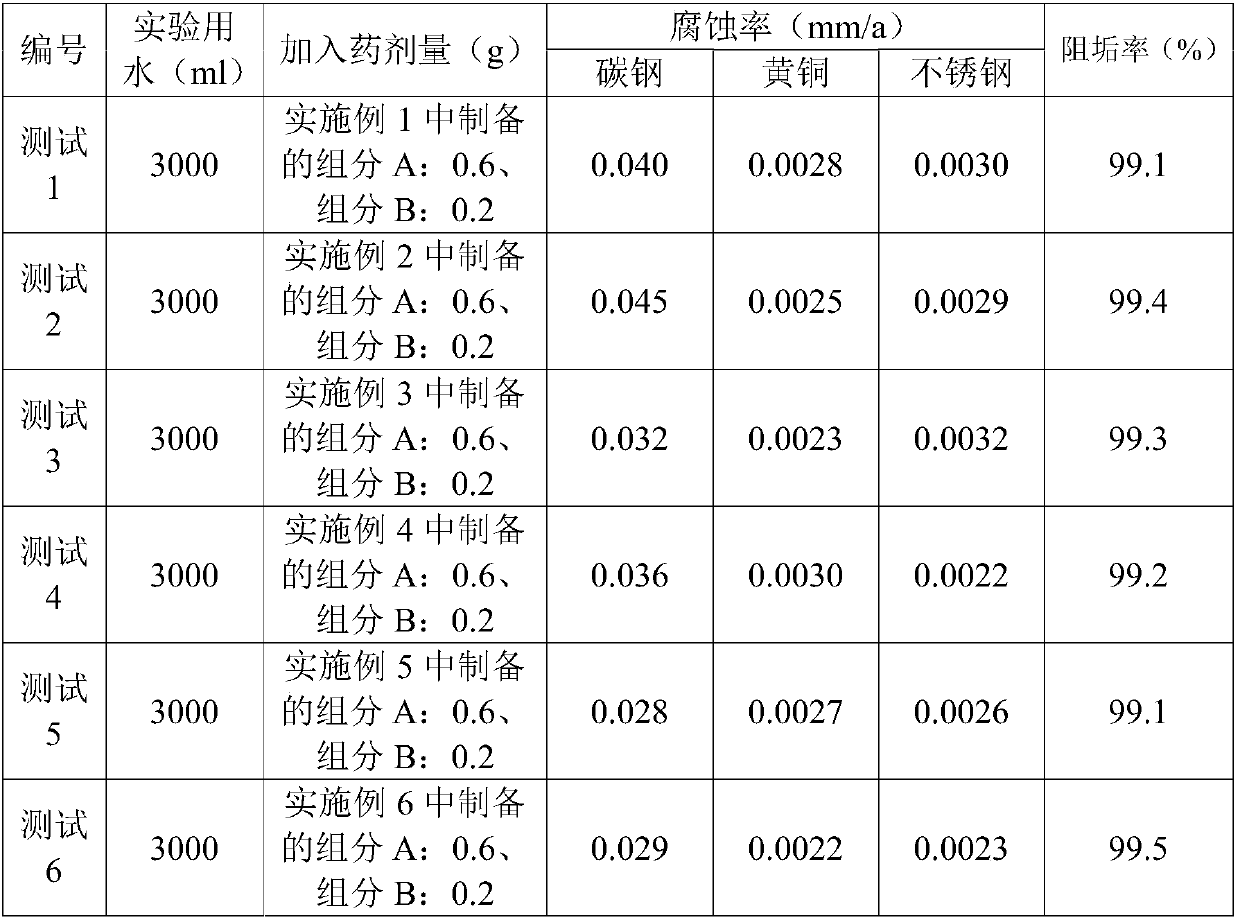

[0032] Preparation of Component A: Take 24g of polytenon acid, add 120g of demineralized water, stir well until the polytenon acid is completely dissolved, then add acrylic acid-maleic anhydride-2-acrylamido-2-methylpropanesulfonic acid Sodium copolymer 20g, after stirring evenly, then add 10g of methylene succinic acid-acrylic acid-β-hydroxypropyl ester copolymer, stir again until the solution is uniform, then add 20g of 2-aminoethyl heptadecenyl imidazoline, and then Stir until the solution is uniform, and finally add 6g of zinc chloride, and mix and stir evenly.

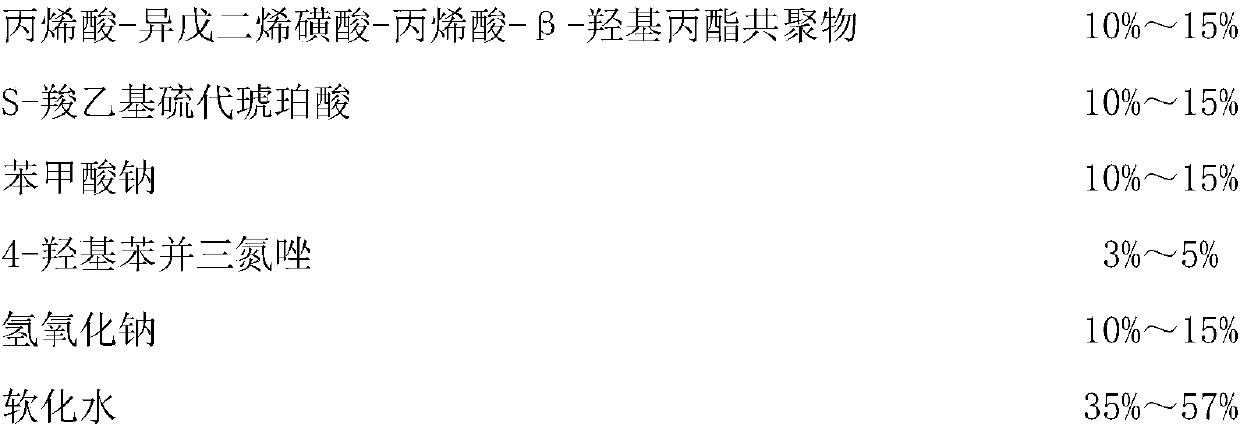

[0033] Preparation of component B: Take 20g of sodium hydroxide, add 114g of demineralized water, stir well until the sodium hydroxide is completely dissolved, then add 6g of 4-hydroxybenzotriazole and stir until the solution is uniform, then add S-carboxyethylthio Stir 20g of succinic acid until the solution is uniform, then add 20g of acrylic acid-isoprenesulfonic acid-acrylic acid-β-hydroxypropyl ester copolyme...

Embodiment 2

[0035] Preparation of Component A: Take 26g of polytenon acid, add 112g of demineralized water, stir well until the polytenon acid is completely dissolved, then add acrylic acid-maleic anhydride-2-acrylamido-2-methylpropanesulfonic acid Sodium copolymer 22g, after stirring evenly, then add 12g of methylene succinic acid-acrylic acid-β-hydroxypropyl ester copolymer, stir again until the solution is uniform, then add 22g of 2-aminoethylheptadecenyl imidazoline, and then Stir until the solution is uniform, and finally add 6g of zinc chloride, and mix and stir evenly.

[0036] Preparation of component B: Take 22g of sodium hydroxide, add 106g of demineralized water, stir well until the sodium hydroxide is completely dissolved, then add 6g of 4-hydroxybenzotriazole and stir until the solution is uniform, then add S-carboxyethylthio Stir 22g of succinic acid until the solution is uniform, then add 22g of acrylic acid-isoprenesulfonic acid-acrylic acid-β-hydroxypropyl ester copolymer...

Embodiment 3

[0038] Preparation of Component A: Take 26g of polytenon acid, add 104g of demineralized water, stir well until the polytenon acid is completely dissolved, then add acrylic acid-maleic anhydride-2-acrylamido-2-methylpropanesulfonic acid Sodium copolymer 24g, after stirring evenly, then add 14g of methylene succinic acid-acrylic acid-β-hydroxypropyl ester copolymer, stir again until the solution is uniform, then add 24g of 2-aminoethyl heptadecenyl imidazoline, and then Stir until the solution is uniform, finally add 8g of zinc chloride, and mix and stir evenly.

[0039] Preparation of component B: Take 24g of sodium hydroxide, add 96g of demineralized water, stir well until the sodium hydroxide is completely dissolved, then add 8g of 4-hydroxybenzotriazole and stir until the solution is uniform, then add S-carboxyethylthio Stir 24g of succinic acid until the solution is uniform, then add 24g of acrylic acid-isoprenesulfonic acid-acrylic acid-β-hydroxypropyl ester copolymer and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com