Phosphorus-free water treatment agent, and preparation method and application thereof

A technology of water treatment agent and treatment cycle, applied in water/sludge/sewage treatment, chemical instruments and methods, descaling and water softening, etc. Advanced problems, to achieve good flocculation effect, good scale and corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

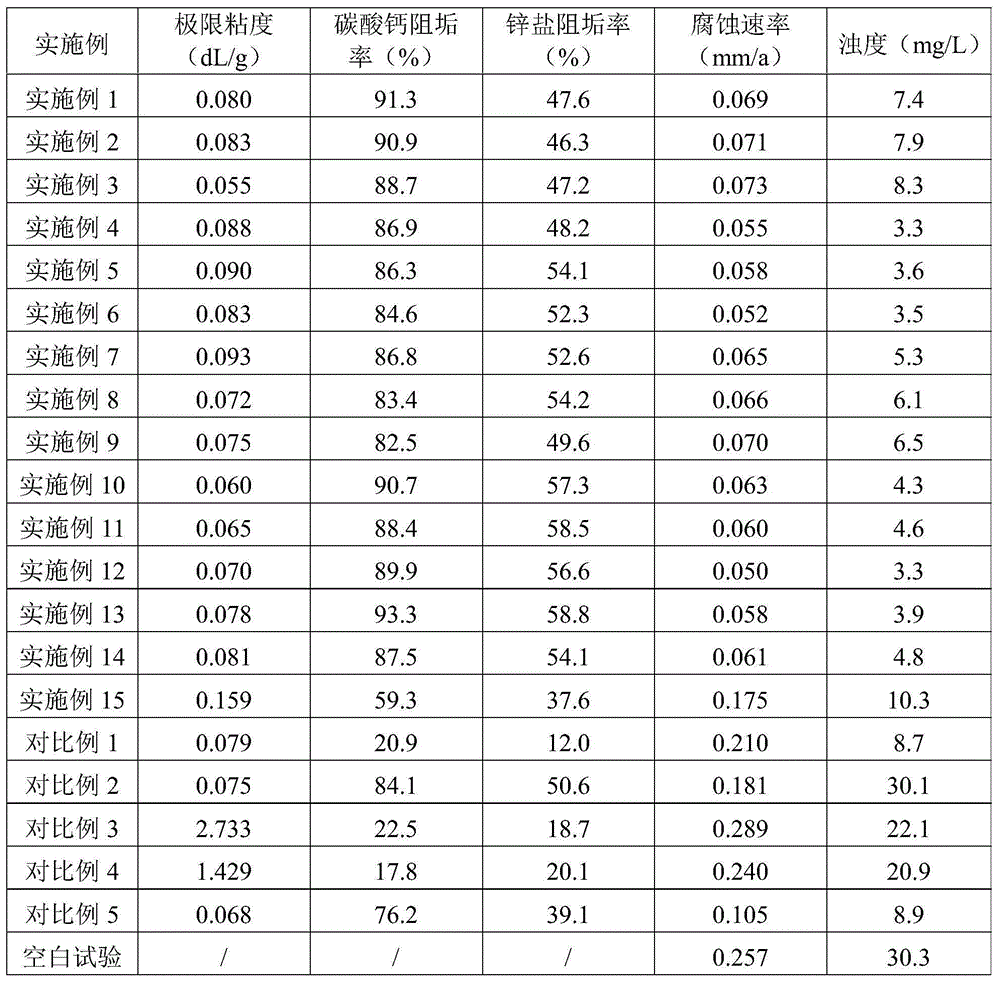

Examples

preparation example Construction

[0018] The method for preparing a phosphorus-free water treatment agent provided by the present invention comprises: mixing monomers, initiators and molecular weight regulators at 50-95°C, and then continuing at 75-95°C (preferably 85-95°C) Reaction 1-4h, described monomer is dimethyl diallyl ammonium chloride, unsaturated carboxylic acid and acrylate, wherein, described unsaturated carboxylic acid is selected from acrylic acid, maleic acid, methacrylic acid or subacrylic acid Methyl succinic acid, the acrylate is selected from methyl acrylate, ethyl acrylate or hydroxypropyl acrylate (preferably hydroxypropyl acrylate); the mixed mode is:

[0019] (a) the solution of the monomer and the solution of the initiator are respectively added dropwise to the solution of the molecular weight regulator, or

[0020] (b) adding dropwise the solution of the monomer and the solution of the molecular weight regulator into the solution of the initiator respectively, or

[0021] (c) The solu...

Embodiment 1

[0042] Add 3.6 g of sodium metabisulfite and 50 ml of water into a four-necked flask equipped with a stirrer, a reflux condenser, a constant pressure dropping funnel and a thermometer, and start stirring to fully dissolve the sodium metabisulfite. Add 10g of dimethyl diallyl ammonium chloride, 6g of methyl acrylate, 48g of acrylic acid and 25ml of water in a constant pressure dropping funnel, shake well; add 4.8g of ammonium persulfate in another constant pressure dropping funnel and 80ml of water, shake well; start to heat up, when the temperature rises to 50°C, start to add the liquid in the two constant pressure dropping funnels dropwise, while continuing to raise the temperature to 85°C, control the rate of addition so that the two constant pressure The liquid in the dropping funnel was added dropwise within 1 hour, then continued the insulation reaction for 2 hours, stopped the test, and cooled to obtain a product with a solid content of 30.1%.

Embodiment 2

[0044] Add 4.8 g of ammonium persulfate and 80 ml of water to a four-neck flask equipped with a stirrer, reflux condenser, constant pressure dropping funnel, and thermometer, and start stirring to fully dissolve sodium metabisulfite. In a constant pressure dropping funnel, add dimethyl diallyl ammonium chloride 10g, methyl acrylate 6g, acrylic acid 48g and 25ml water, shake up; in another constant pressure dropping funnel, add sodium metabisulfite 3.6g and 50ml of water, shake well; start to heat up, when the temperature rises to 50°C, start to drop the liquid in the two constant pressure dropping funnels, at the same time continue to raise the temperature to 85°C, control the dropping speed so that the two constant pressure drops The liquid in the liquid funnel was added dropwise within 1 hour, and then the insulation reaction was continued for 2 hours, the test was stopped, and the product was obtained after cooling, and the solid content of the product was 29.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com