Tearing strength reinforcing agent for papermaking and preparation method of tearing strength reinforcing agent

A technology of tear resistance and reinforcing agent, which can be used in the addition of reinforcing agent, papermaking, textiles and papermaking, etc., can solve the problems of complex preparation process, and achieve the effect of increased tear resistance, good wet strength and dry strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

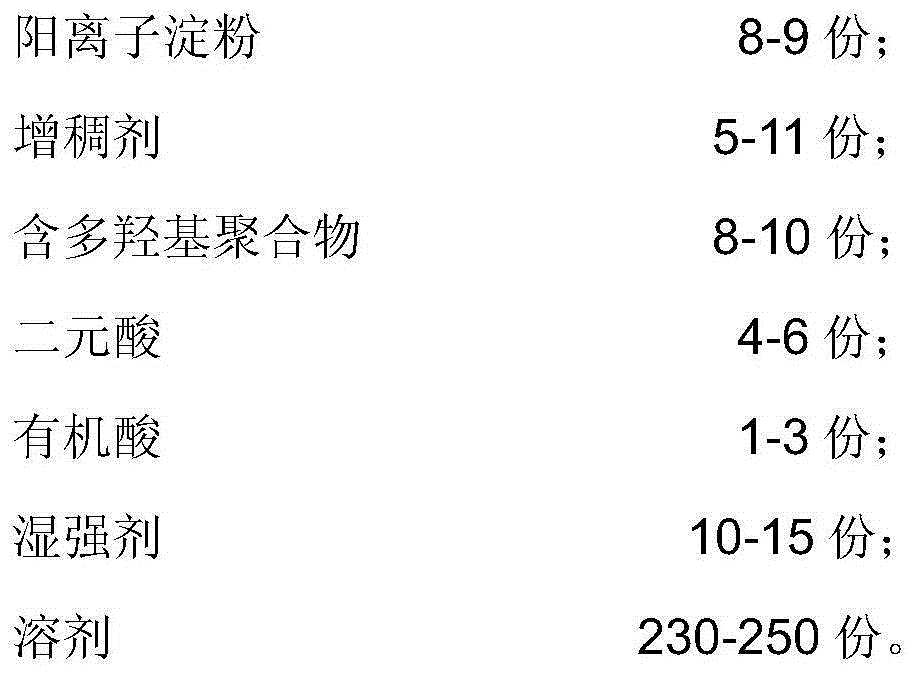

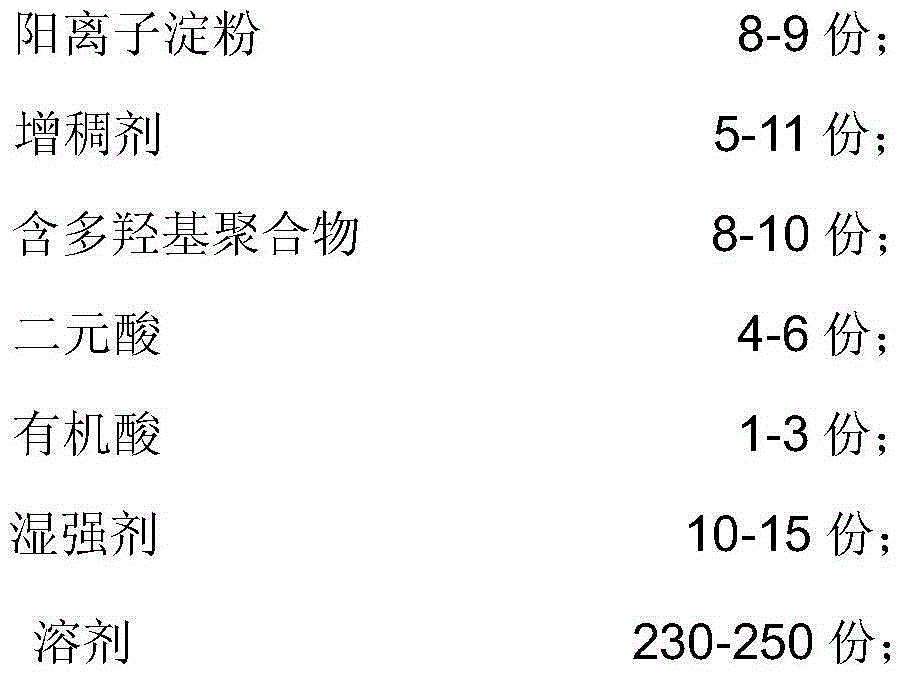

[0038] A method for preparing a tear strength enhancer includes the following steps: (1) Add 250kg of deionized water into a reactor, turn on the stirring, and add 6kg of guar gum, 3kg of Tianqing gum, and 9kg of cationic starch under stirring. 2kg of acetic acid, stirring at room temperature for 30 minutes; (2) 8kg of polyvinyl alcohol and 5kg of methylene succinic acid at room temperature. Mix the two uniformly; (3) Under stirring, add (2) to (1), heat the system to 75°C, and stir at this temperature for 40 minutes; (4) Add polyamide imine epichlorohydrin ( Add 10 parts of PAE) to (3), stir at 75°C for 30 minutes, and then cool to room temperature to obtain the tear strength enhancer with a solid content of 14.67% and a viscosity of 23 cps.

Embodiment 2

[0040] A method for preparing a tear strength enhancer includes the following steps: (1) Add 240kg of deionized water into a reactor, turn on the stirring, and add 6kg of guar gum, 5kg of Tianqing gum, and 9kg of cationic starch under stirring. Acetic acid 3kg, stirring at room temperature for 30 minutes; (2) 10kg of polyvinyl alcohol and 6kg of methylene succinic acid at room temperature. Mix the two uniformly; (3) Under stirring, add (2) to (1), heat the system to 60°C, and stir at this temperature for 60 minutes; (4) Add the polyamide imine epichlorohydrin ( Add 8 parts of PAE) to (3), stir at 60°C for 60 minutes, and then cool to room temperature to obtain the tear strength enhancer with a solid content of 16.37% and a viscosity of 32 cps.

Embodiment 3

[0042] A method for preparing a tear strength enhancer includes the following steps: (1) Add 230kg of deionized water to the reactor, turn on the stirring, and add 6kg of guar gum, 3kg of Tianqing gum, and 9kg of cationic starch under stirring. Acetic acid 1 kg, stirring at room temperature for 30 minutes; (2) 9 kg of polyvinyl alcohol and 4 kg of methylene succinic acid at room temperature. Mix the two uniformly; (3) Under stirring, add (2) to (1), heat the system to 70°C, and stir at this temperature for 40 minutes; (4) Add polyamide imine epichlorohydrin ( Add 9 parts of PAE) to (3), stir at 70° C. for 50 minutes, and then cool to room temperature to obtain the tear strength enhancer with a solid content of 15.19% and a viscosity of 27 cps.

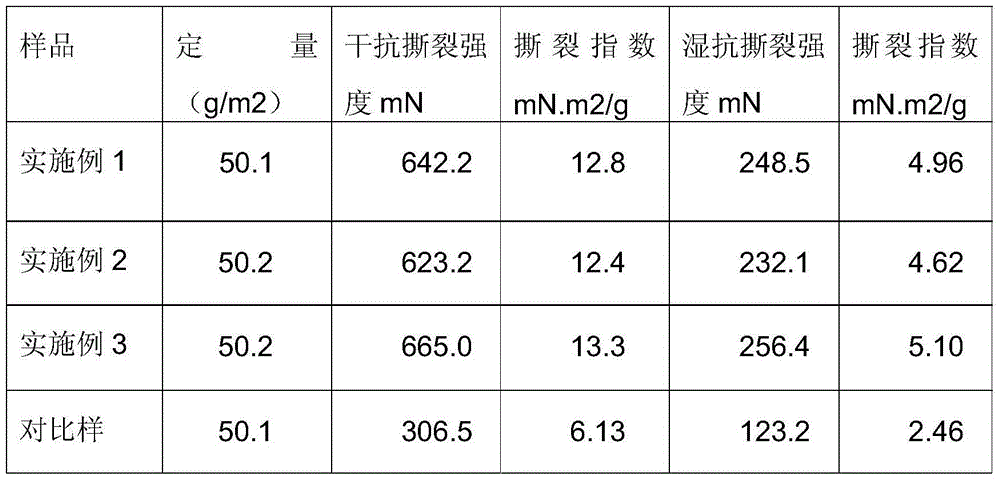

[0043] The following is a performance comparison of the sample prepared in the example and the comparison sample, the method is as follows:

[0044] Stir the slurry with a mass concentration of 3.0%, softwood pulp: hardwood pulp=4:6, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com