Composite scale and corrosion inhibitor

A technology of scale and corrosion inhibitor, circulating cooling water, applied in complex/solubilizer treatment, descaling and water softening, water/sludge/sewage treatment, etc., can solve the problem that water cannot be directly recycled, etc. To achieve the effect of enhanced scale and corrosion inhibition, good corrosion and scale inhibition performance, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

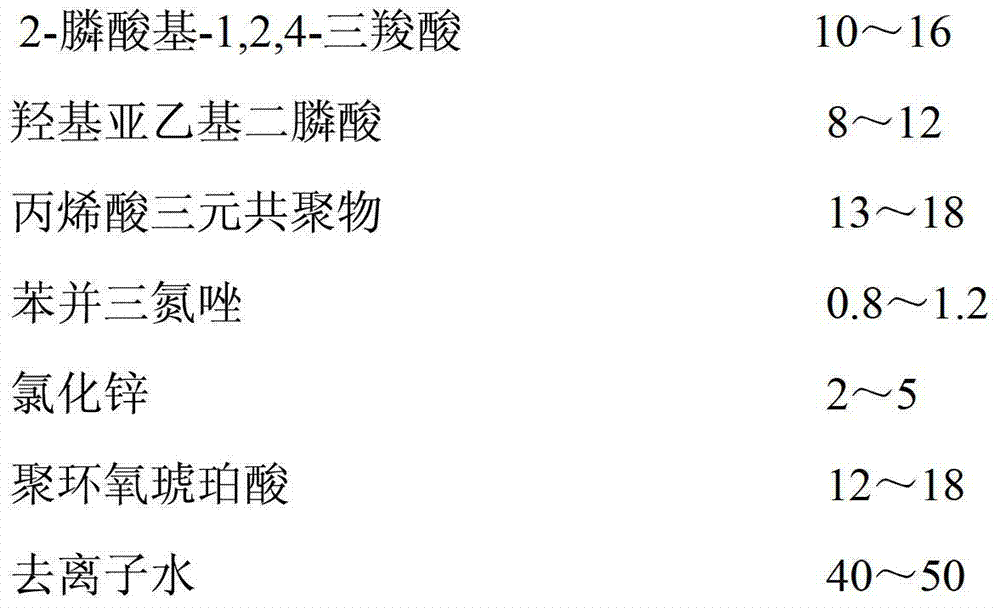

Embodiment 1

[0024] 10.0g 2-phosphono-1,2,4-butane tricarboxylate (PBTCA), 8.0g hydroxyethylene diphosphonic acid (HEDP), 1.0g benzotriazole (BTA), 1.0g chlorine Zinc chloride, 15.0g acrylic acid / hydroxypropyl acrylate / 2-acrylamide-2-methylpropanesulfonic acid (AA / HPA / AMPS), 10.0g polyepoxysuccinic acid (PESA) and dilute to 100g with deionized water, Formulated as a composite scale and corrosion inhibitor.

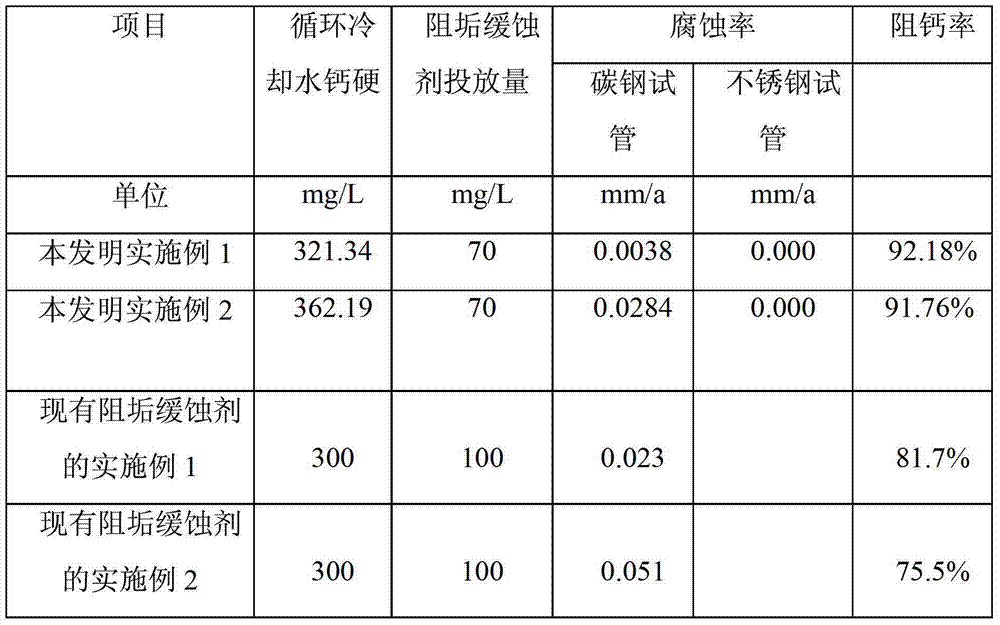

[0025] Put the composite scale and corrosion inhibitor formulated above into the circulating cooling water described in the table below at a temperature of 50°C and a speed of 75r / min. The test time is 72 hours. The calcium hardness in the table is expressed as CaCO 3 count.

[0026] project

Embodiment 2

[0028] 15g of 2-phosphono-1,2,4-butane tricarboxylate (PBTCA), 10g of hydroxyethylidene diphosphonic acid (HEDP), 1.2g of benzotriazole (BTA), 7.5g of zinc chloride , 10.0g acrylic acid / hydroxypropyl acrylate / 2-acrylamide-2-methylpropane sulfonic acid (AA / HPA / AMPS), 7.5g polyepoxysuccinic acid (PESA) plus deionized water diluted to 100g, prepared Composite scale and corrosion inhibitor.

[0029] Put the composite scale and corrosion inhibitor formulated above into the circulating cooling water described in the table below at a water temperature of 50°C and a rotational speed of 75r / min. The test time is 72 hours. The calcium hardness in the table is expressed as CaCO 3 count.

[0030] project

calcium hard

Cl -

SO 4 2-

pH

unit

μs / cm

mg / L

mg / L

mg / L

mg / L

data

432

162.19

46.41

11.12

162.23

7.73

[0031] Embodiment result is:

[0032]

[0033] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com