Phosphorus-free descaling corrosion inhibitor

A corrosion inhibitor, phosphorus-free scale inhibition technology, applied in the direction of scale removal and water softening, complex/solubilizer treatment, special treatment targets, etc., can solve problems such as equipment corrosion operation difficulties, and achieve improved scale inhibition and anticorrosion performance , Save equipment investment and protect the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

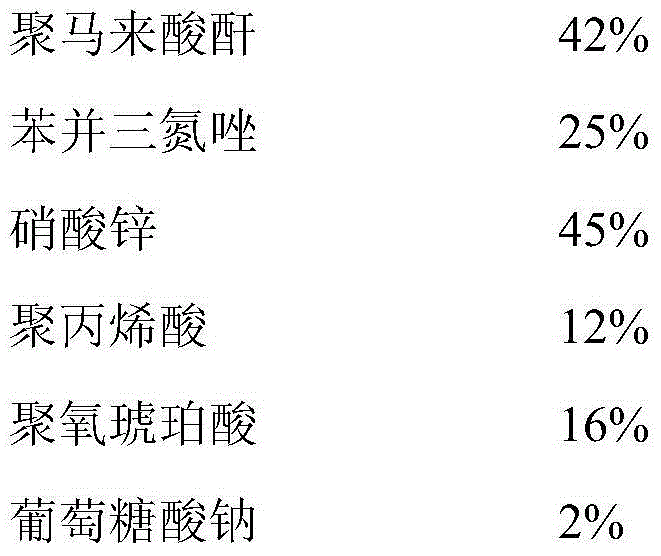

Embodiment 1

[0015]

[0016] Appropriate amount of deionized water.

[0017] The preparation method of the phosphorus-free descaling and corrosion inhibitor is to uniformly mix polymaleic anhydride, benzotriazole, zinc nitrate, polyacrylic acid, polyoxysuccinic acid, sodium gluconate and deionized water to obtain the product.

[0018] The invention combines biochemical technology and surface technology with traditional water quality stabilization technology to effectively improve the scale inhibition and anticorrosion performance of the metal interface of the heat exchanger, especially for industries with high hardness, high alkalinity and easy structure of water quality in northern my country It breaks through the limitations of traditional water quality stabilization technology in increasing the concentration multiple, and creatively solves the scale inhibition problem of super-concentrated circulating water treatment. Yes, circulating cooling water can operate under super-concentrated ...

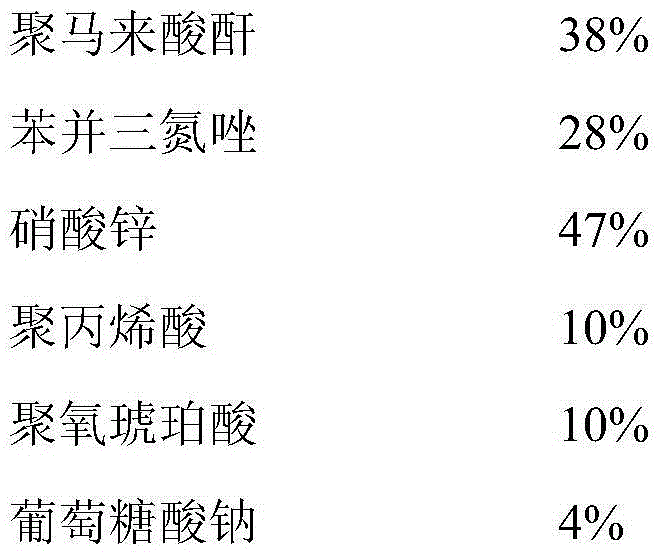

Embodiment 2

[0020]

[0021] Appropriate amount of deionized water.

[0022] The preparation method is the same as in Example 1.

[0023] The invention does not need to add acid treatment, and adopts natural pH value operation, which not only saves equipment investment, simplifies the operation procedure, but also helps to improve the life of the equipment, protect the safe operation of the system, and avoid the corrosion of equipment and system leakage caused by traditional acid treatment. and other hidden dangers

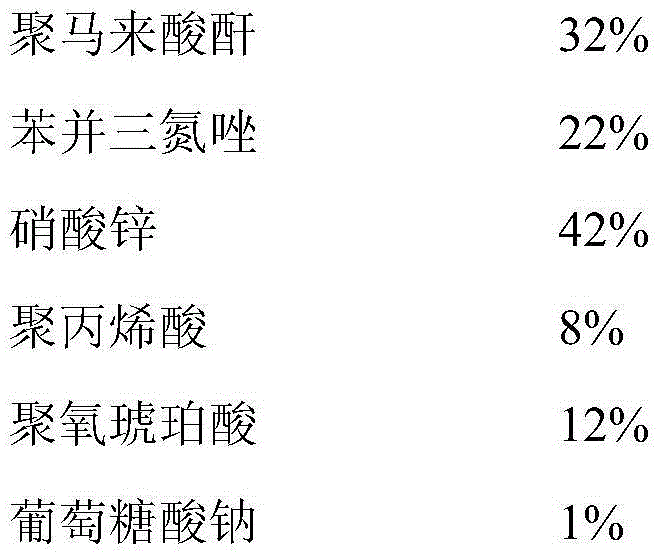

Embodiment 3

[0025]

[0026] Appropriate amount of deionized water.

[0027] The preparation method is the same as in Example 1.

[0028] It is not easy to form calcium phosphate scale during use, and the phosphorus content in the discharged water is far lower than the national standard, which is an environmentally friendly water treatment agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com