Water treatment bactericide

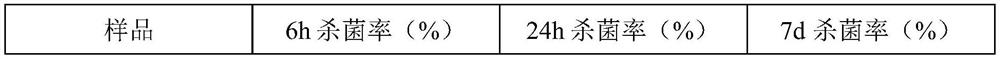

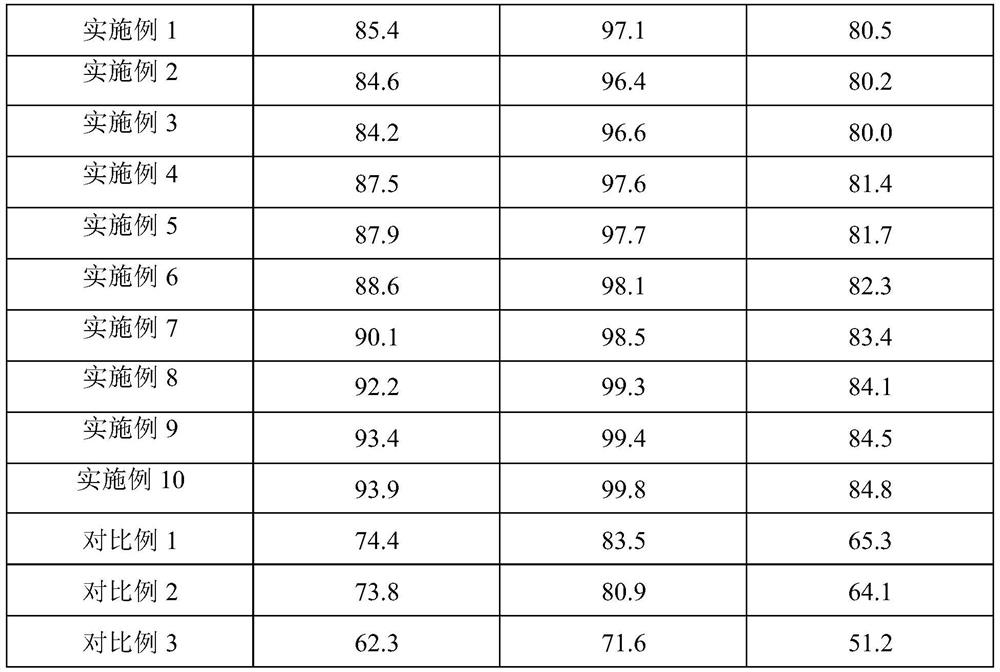

A bactericide and water treatment technology, applied in the field of water treatment, can solve the problem of low sterilization rate, and achieve the effects of long sterilization time, delaying the formation rate of dirt, and excellent scale and corrosion inhibition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The fungicide includes the following components by weight: 15 parts of isothiazolinone, 2 parts of copper sulfate, 6 parts of dodecyldimethylbenzyl ammonium bromide, 3 parts of water-soluble sterol oil, diiodomethyl p-formaldehyde 4 parts of phenyl sulfone, 90 parts of water, 15 parts of ethanol, 0.075 part of fluorinated alkyl phosphate and 0.04 part of sodium tripolyphosphate;

[0028] The preparation method of the bactericide is as follows: 1) 90% water is taken from the total water and added into the reaction kettle, and ethanol, isothiazolone, copper sulfate, dodecyldimethylbenzyl ammonium bromide, Water-soluble sterol oil, diiodomethyl p-methylphenyl sulfone, fluorinated alkyl phosphate and sodium tripolyphosphate are pumped into the reactor, and finally the remaining water is pumped into the reactor; 2) The materials are stirred for 35 minutes after pumping , when the mixed solution is clear and transparent, the bactericide is prepared.

Embodiment 2

[0030] The fungicide includes the following components by weight: 10 parts of isothiazolinone, 1 part of copper sulfate, 2 parts of dodecyldimethylbenzyl ammonium bromide, 1 part of water-soluble sterol oil, diiodomethyl p-formaldehyde 2 parts of phenyl sulfone, 80 parts of water, 10 parts of ethanol, 0.05 part of fluorinated alkyl phosphate and 0.02 part of sodium tripolyphosphate;

[0031] The preparation method of the bactericide is as follows: 1) 90% water is taken from the total water and added into the reaction kettle, and ethanol, isothiazolone, copper sulfate, dodecyldimethylbenzyl ammonium bromide, Water-soluble sterol oil, diiodomethyl-p-tolylsulfone, fluorinated alkyl phosphate and sodium tripolyphosphate are pumped into the reactor, and finally the remaining water is pumped into the reactor; 2) The materials are stirred for 30 minutes after pumping , when the mixed solution is clear and transparent, the bactericide is prepared.

Embodiment 3

[0033] The fungicide includes the following components by weight: 20 parts of isothiazolinone, 3 parts of copper sulfate, 10 parts of dodecyl dimethyl benzyl ammonium bromide, 5 parts of water-soluble sterol oil, diiodomethyl p-formaldehyde 6 parts of phenyl sulfone, 100 parts of water, 20 parts of ethanol, 0.1 part of fluorinated alkyl phosphate and 0.06 part of sodium tripolyphosphate;

[0034] The preparation method of the bactericide is as follows: 1) 90% water is taken from the total water and added into the reaction kettle, and ethanol, isothiazolone, copper sulfate, dodecyldimethylbenzyl ammonium bromide, Water-soluble sterol oil, diiodomethyl p-methylphenyl sulfone, fluorinated alkyl phosphate and sodium tripolyphosphate are pumped into the reactor, and finally the remaining water is pumped into the reactor; 2) The materials are stirred for 40 minutes after pumping , when the mixed solution is clear and transparent, the bactericide is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com