Antibacterial fiber material and preparation process thereof

An antibacterial fiber and antibacterial agent technology, applied in the field of antibacterial fiber materials and their preparation, can solve the problems of inability to effectively inhibit the reproduction of microorganisms, damage to polyester fiber fabrics, unfavorable health of wearers, etc., so as to improve antistatic properties and human body irritation. Small, less toxic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

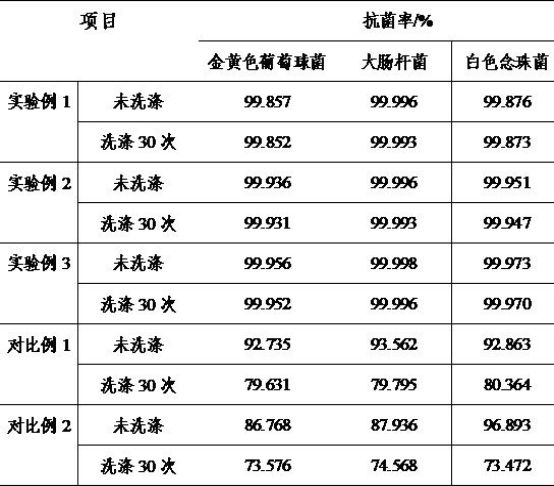

Embodiment 1

[0031] An antibacterial fiber material is composed of the following raw materials in parts by weight: 100 parts of PET polyester chips, 3 parts of antibacterial masterbatch;

[0032] The antibacterial masterbatch consists of an appropriate amount of PET polyester chips and its mass is 6% of antibacterial agent, 0.3% of ultraviolet absorber, 0.2% of antistatic agent, 0.6% of zinc stearate, and 1.5% of sodium hypophosphite and 2.8% of 3-hydroxy-1,3,5-glutamic acid.

[0033] The preparation method of antibacterial agent comprises the following steps:

[0034] Weigh an appropriate amount of modified starch, and dissolve it in an appropriate amount of hot water at a temperature of 60°C to prepare a modified starch dispersion with a concentration of 15%; then add 2% of modified starch into it. Vinyl alcohol, after ultrasonic mixing; add the modified starch dispersion obtained above to the mixture, emulsify at high speed with a shearing machine, add 0.6% sodium borate to it, and St...

Embodiment 2

[0050] An antibacterial fiber material is composed of the following raw materials in parts by weight: 110 parts of PET polyester chips, 5 parts of antibacterial masterbatch;

[0051] The antibacterial masterbatch is composed of an appropriate amount of PET polyester chips and its mass is 8% antibacterial agent, 0.5% ultraviolet absorber, 0.4% antistatic agent, 1.2% zinc stearate, and 3.0% sodium hypophosphite and 3.6% of 3-hydroxy-1,3,5-glutamic acid.

[0052] The preparation method of antibacterial agent comprises the following steps:

[0053] Weigh an appropriate amount of modified starch, and dissolve it in an appropriate amount of hot water at a temperature of 65°C to prepare a modified starch dispersion with a concentration of 20%; then add 4% of modified starch into it. Vinyl alcohol, after ultrasonic mixing; add the modified starch dispersion obtained above to the mixed liquid, emulsify at high speed with a shearing machine, add sodium borate with a mass of 1.2% to it,...

Embodiment 3

[0069] An antibacterial fiber material is composed of the following raw materials in parts by weight: 120 parts of PET polyester chips, 6 parts of antibacterial masterbatch;

[0070] The antibacterial masterbatch consists of an appropriate amount of PET polyester chips and its mass is 10% antibacterial agent, 0.8% ultraviolet absorber, 0.6% antistatic agent, 1.8% zinc stearate, and 3.6% sodium hypophosphite and 4.2% of 3-hydroxy-1,3,5-glutamic acid.

[0071] The preparation method of antibacterial agent comprises the following steps:

[0072] Weigh an appropriate amount of modified starch, and dissolve it in an appropriate amount of hot water at a temperature of 70°C to prepare a modified starch dispersion with a concentration of 25%; then add 6% of modified starch into it. Vinyl alcohol, after ultrasonic mixing; add the modified starch dispersion obtained above to the mixed liquid, emulsify at a high speed with a shearing machine, add sodium borate with a mass of 1.8% to it,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com