Continuous water bath sterilization pot

A technology of water bath sterilization and sterilization area, which is applied in food preservation, food science, heating, etc. It can solve the problems of maintaining the physical indicators of the object to be sterilized, failing to achieve product quality consistency, and damaging the color, fragrance, and flavor of nutrients, etc. problems, to achieve the effect of shortening the sterilization treatment time, balancing and stabilizing the sterilization effect, and shortening the sterilization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

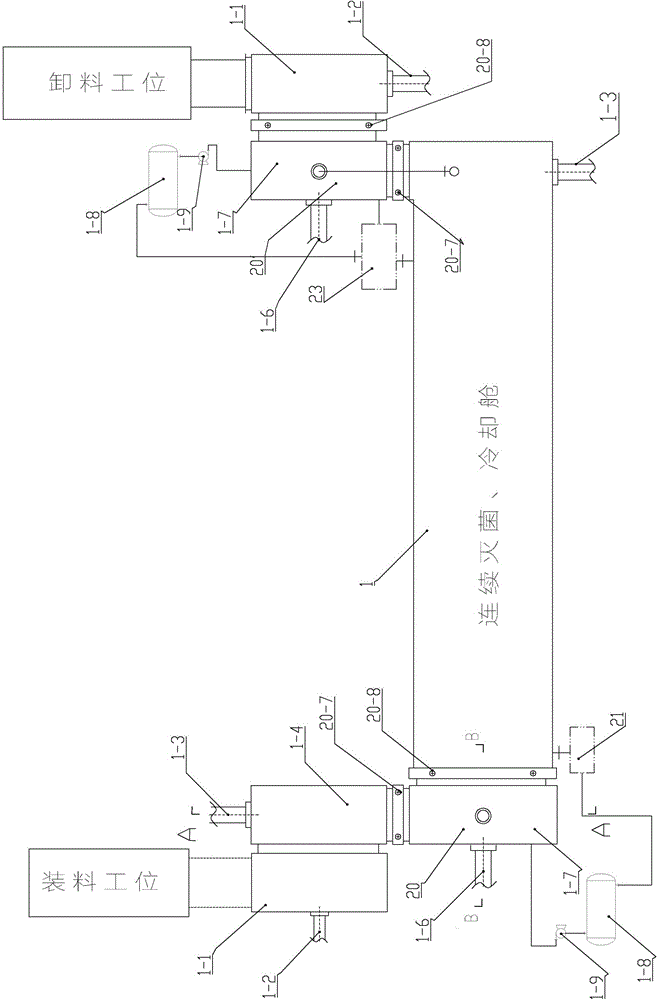

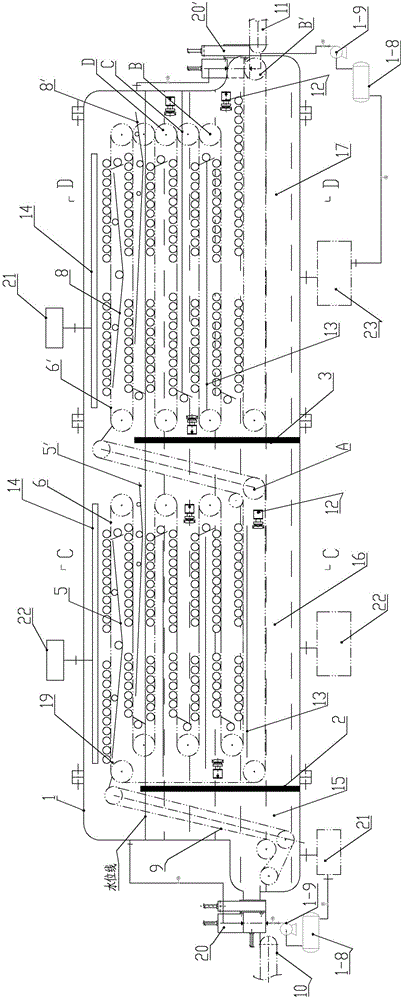

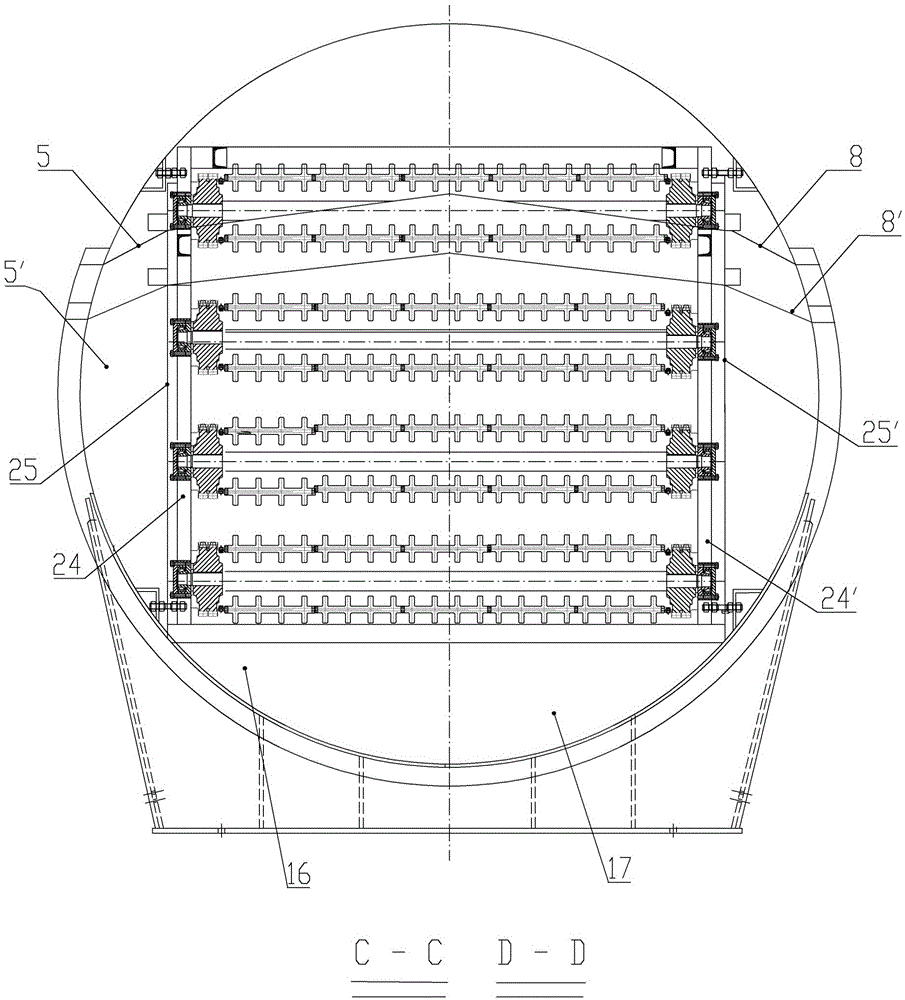

[0030] A kind of continuous water-bath sterilizer is not limited to described embodiment, describes invention working process by accompanying drawing below:

[0031] Such as figure 1 , 2 , 3: If the processed items are suitable for the sterilization processing of soft-packed beverages, soft-packed medicines, ham sausages, soft-packed foods, etc., and cans, ham sausages, plastic packaging and plastic cans, etc., can be loaded in multiples This package can be made round or square in one basket.

[0032] The working process of the flat-push ram-type feeding sealing device (20) is: the processed materials are placed in the processed material basket (19) and the processed material basket (19) transported from the production line (10) needs to be sterilized. Baskets are fed one row at a time or three rows at a time. The soft-packed items run on the conveyor chain of the loading station to the loading platform (1-1) through the loading basket, and the loading basket passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com