Composite adhesive, pole piece prepared by means of the composite adhesive, preparation method and application thereof

A binder and pole piece technology, which is applied in the manufacture of hybrid/electric double layer capacitors, battery electrodes, structural parts, etc., can solve the problem of reducing the energy density of lithium-ion batteries or supercapacitors and their comprehensive performance cycle life, and increasing the pole piece Resistance, deterioration of battery performance and other issues, to achieve low internal resistance, improved cycle life, and high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

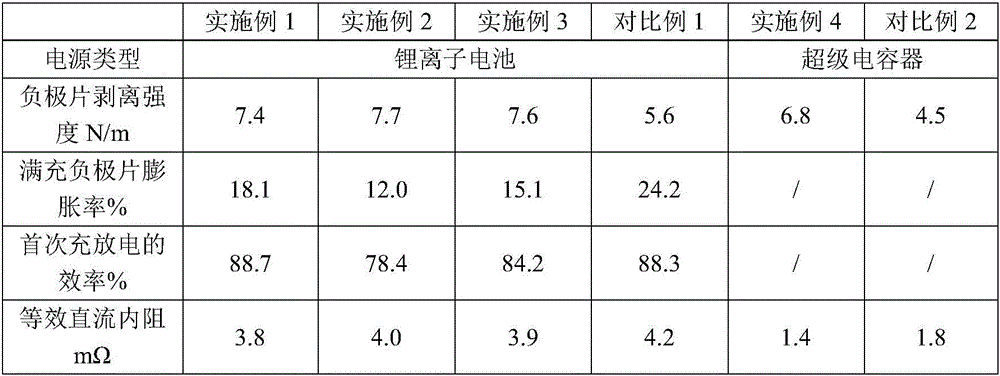

Examples

Embodiment 1

[0042] The composite binder of this embodiment is composed of the following components in weight percentage: 1% phosphoric acid, 20% polyvinylidene fluoride, 5% phenolic resin, 2% methylated melamine resin, 6% polymethyl methacrylate, Methyl methacrylate-butyl acrylate-acrylic acid terpolymer latex 30%, sodium carboxymethyl cellulose 1%, polyimide 15%, ethanol 2%, N-methylpyrrolidone 18%. The mass fraction of the above-mentioned phosphoric acid is 20%.

[0043] The preparation method of the above-mentioned composite binder comprises the steps of: mixing the phosphoric acid, polyvinylidene fluoride, phenolic resin, methylated melamine resin, polymethyl methacrylate, methyl methacrylate-butyl acrylate-acrylic acid three The multi-polymer latex, sodium carboxymethyl cellulose, polyimide, ethanol, and N-methylpyrrolidone are mixed uniformly.

[0044] The positive electrode sheet of this embodiment is prepared by using the above-mentioned composite binder, and its preparation meth...

Embodiment 2

[0053] The composite binder of this embodiment is composed of the following components in weight percentage: 13% phosphoric acid, 45% polyvinylidene fluoride, 7% phenolic resin, 2.5% methylated melamine resin, and 8.5% polymethyl methacrylate , Methyl methacrylate-butyl acrylate-acrylic acid terpolymer latex 10%, sodium carboxymethyl cellulose 2%, polyimide 3%, ethanol 3%, N-methylpyrrolidone 6%. The mass fraction of the above-mentioned phosphoric acid is 10%.

[0054] The preparation method of the composite binder of the present embodiment comprises the following steps: the phosphoric acid, polyvinylidene fluoride, phenolic resin, methylated melamine resin, polymethyl methacrylate, methyl methacrylate-butyl acrylate - Acrylic terpolymer latex, sodium carboxymethyl cellulose, polyimide, ethanol, and N-methylpyrrolidone are mixed uniformly.

[0055] The positive electrode sheet of this embodiment is prepared by using the above-mentioned composite binder, and its preparation me...

Embodiment 3

[0064] The composite adhesive of this embodiment is composed of the following components in weight percentage: 7% phosphoric acid, 30% polyvinylidene fluoride, 9% phenolic resin, 3% methyl etherified melamine resin, 11% polymethyl methacrylate , Methyl methacrylate-butyl acrylate-acrylic acid terpolymer latex 15%, sodium carboxymethyl cellulose 4%, polyimide 7%, ethanol 4%, N-methylpyrrolidone 10%. The mass fraction of the above-mentioned phosphoric acid is 20%.

[0065] The preparation method of the composite binder of the present embodiment comprises the following steps: the phosphoric acid, polyvinylidene fluoride, phenolic resin, methylated melamine resin, polymethyl methacrylate, methyl methacrylate-butyl acrylate - Acrylic terpolymer latex, sodium carboxymethyl cellulose, polyimide, ethanol, and N-methylpyrrolidone are mixed uniformly.

[0066] The positive electrode sheet of this embodiment is prepared by using the above-mentioned composite binder, and its preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com