Process of cultivating salvia miltiorrhiza by raising seedlings in greenhouse

A technology of salvia miltiorrhiza and greenhouse, which is applied in the field of artificial cultivation of salvia miltiorrhiza, which can solve the problems of the seeds of salvia miltiorrhiza not being resistant to storage, failing to meet medicinal requirements, and low germination rate, so as to prevent the root system of salvia miltiorrhiza from being connected in series, ensure the survival rate of transplanting, and ensure the vigorous growth The effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

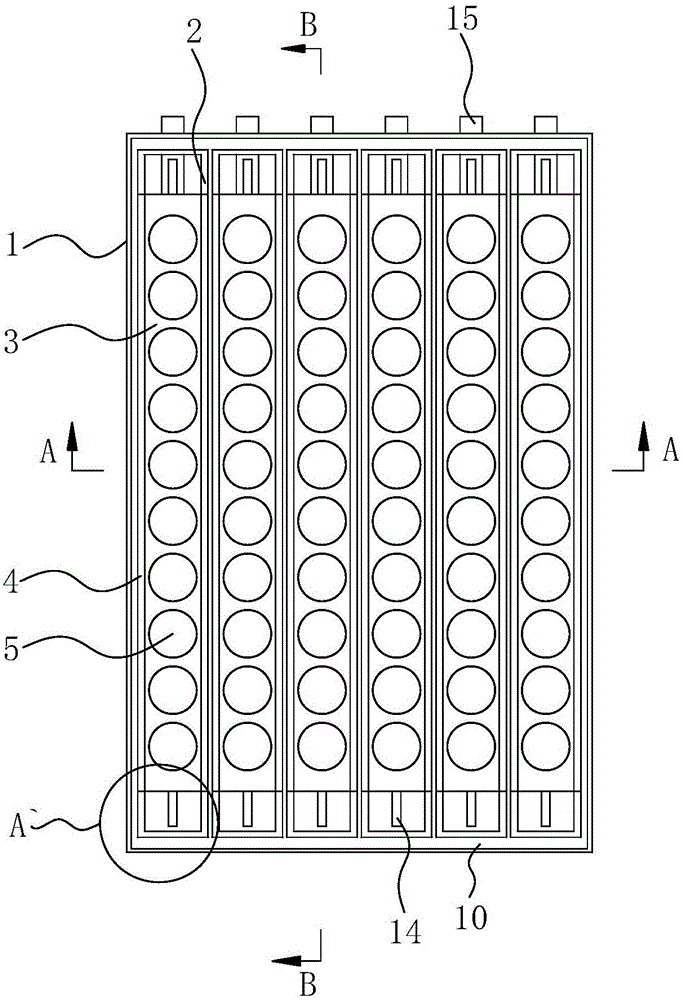

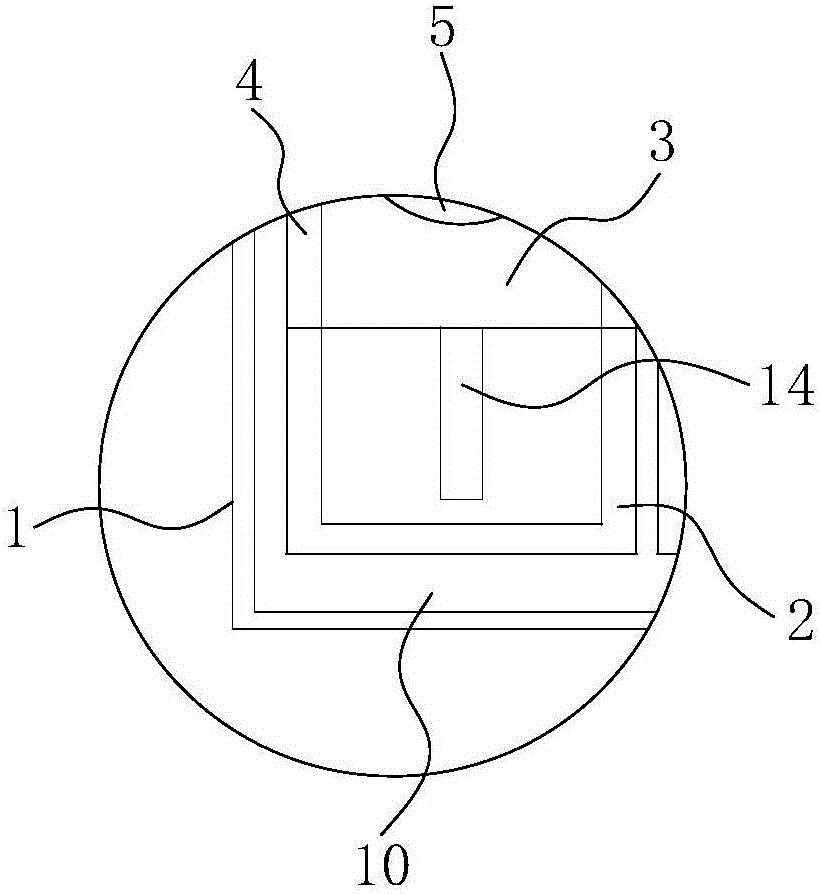

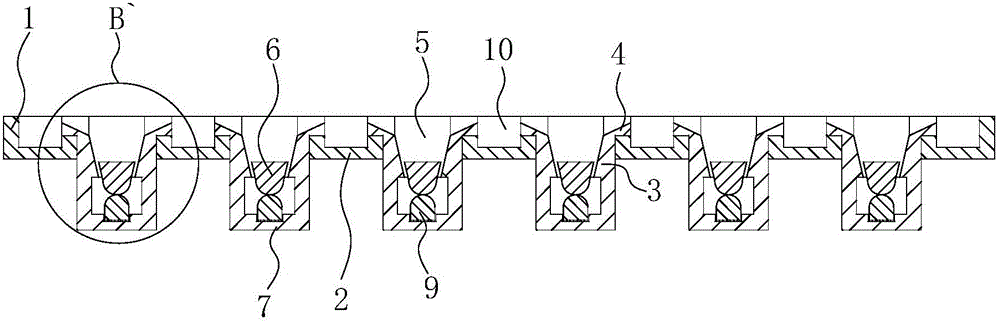

Image

Examples

Embodiment 1

[0045] 1. Seedling cultivation in the greenhouse: In November every year, in the greenhouse, use the plugs to fill the seedling soil, and use the seeds of salvia miltiorrhiza to sow and raise the seedlings; two seedlings should be planted in each hole, and the seedlings for each hole should be determined according to the germination rate of the seeds. The temperature in the greenhouse is controlled at 18-28 ℃, and the temperature control mode of high day and low night is adopted, which is convenient for Danshen to adapt to the field environment in the future, and also uses daytime sunshine to save energy consumption for temperature control.

[0046] The seedling soil is made of 10 parts of sawdust, 100 parts of decomposed farmyard manure, 3 parts of plant ash, 2.5 parts of superphosphate, 10 parts of charcoal slag with a particle size less than 5mm, and 300 parts of natural loam.

[0047] 2. Site selection, site preparation and base fertilizer application

[0048] Choose sandy...

Embodiment 2

[0073] 1. Greenhouse seedling cultivation:

[0074] The seedling soil is made of 15 parts of sawdust, 150 parts of decomposed farmyard manure, 2 parts of plant ash, 2 parts of superphosphate, 5 parts of charcoal slag with a particle size of less than 5mm, and 250 parts of natural loam.

[0075] 2. Site selection, site preparation and base fertilizer application:

[0076] The base fertilizer used is 150kg of urea per mu, 150kg of sawdust, 1500kg of decomposed farmyard manure, 50kg of plant ash, 20kg of superphosphate, 1kg of boric acid, 1kg of zinc sulfate, and 6kg of potassium sulfate.

[0077] Seven. Root spraying of mixed accelerator

[0078] Mixing accelerator configuration: acetylsalicylic acid 0.1g, ethanol 150ml, add 100L clean water, stir to dissolve completely, then adjust the pH value to 6.5-7 with sodium hydroxide or potassium hydroxide, stand or stir for more than 30min to obtain aqueous solution.

[0079] 8. Pest control

[0080] Root rot control method: use an...

Embodiment 3

[0083] 1. Greenhouse seedling cultivation:

[0084] The seedling soil is made of 12 parts of sawdust, 120 parts of decomposed farmyard manure, 2 parts of plant ash, 2 parts of superphosphate, 8 parts of charcoal slag with a particle size less than 5mm, and 250 parts of natural loam.

[0085] 2. Site selection, site preparation and base fertilizer application:

[0086] The base fertilizer used is 150kg of urea per mu, 100kg of sawdust, 2000kg of decomposed farmyard manure, 50kg of plant ash, 20kg of superphosphate, 1kg of boric acid, 2kg of zinc sulfate, and 6kg of potassium sulfate.

[0087] Seven. Root spraying of mixed accelerator

[0088] Mixing accelerator configuration: Add 0.2g of acetylsalicylic acid and 100ml of ethanol into 100L of clean water, stir to dissolve completely, then adjust the pH value to 7-8 with sodium hydroxide or potassium hydroxide, and stand or stir for more than 30 minutes to obtain aqueous solution.

[0089] 8. Pest control

[0090] Root rot co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com