Preparation method of high-nickel ternary material with transition metal element concentration gradient and material prepared by preparation method

A transition metal element, concentration gradient technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve problems such as abnormal growth of primary particles and interdiffusion of transition metal elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

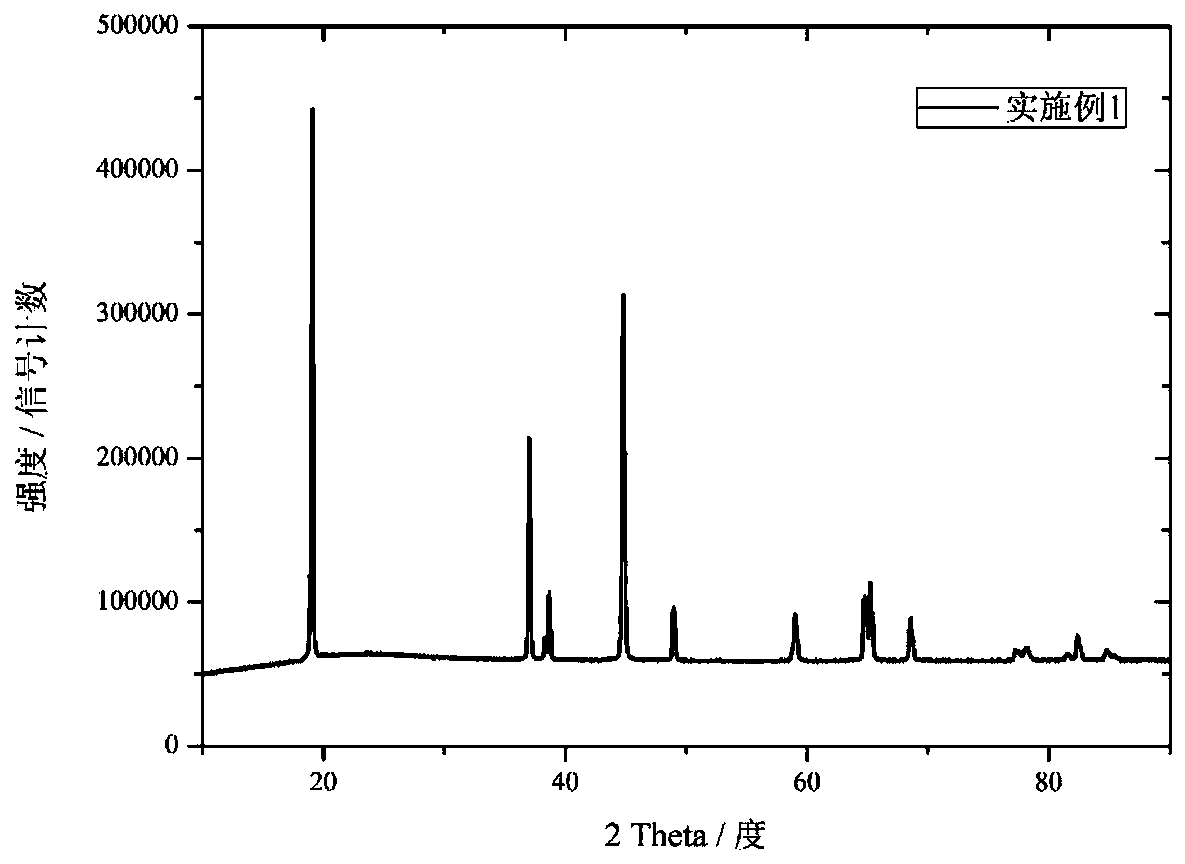

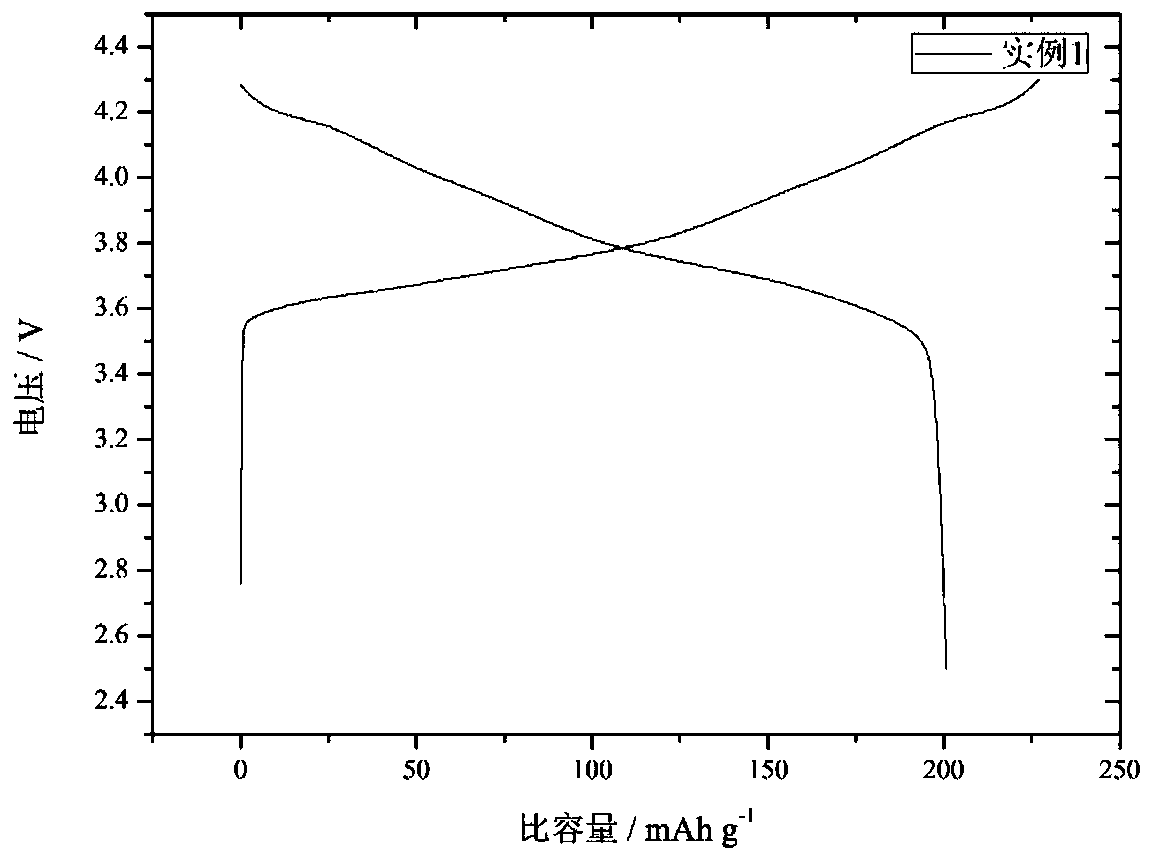

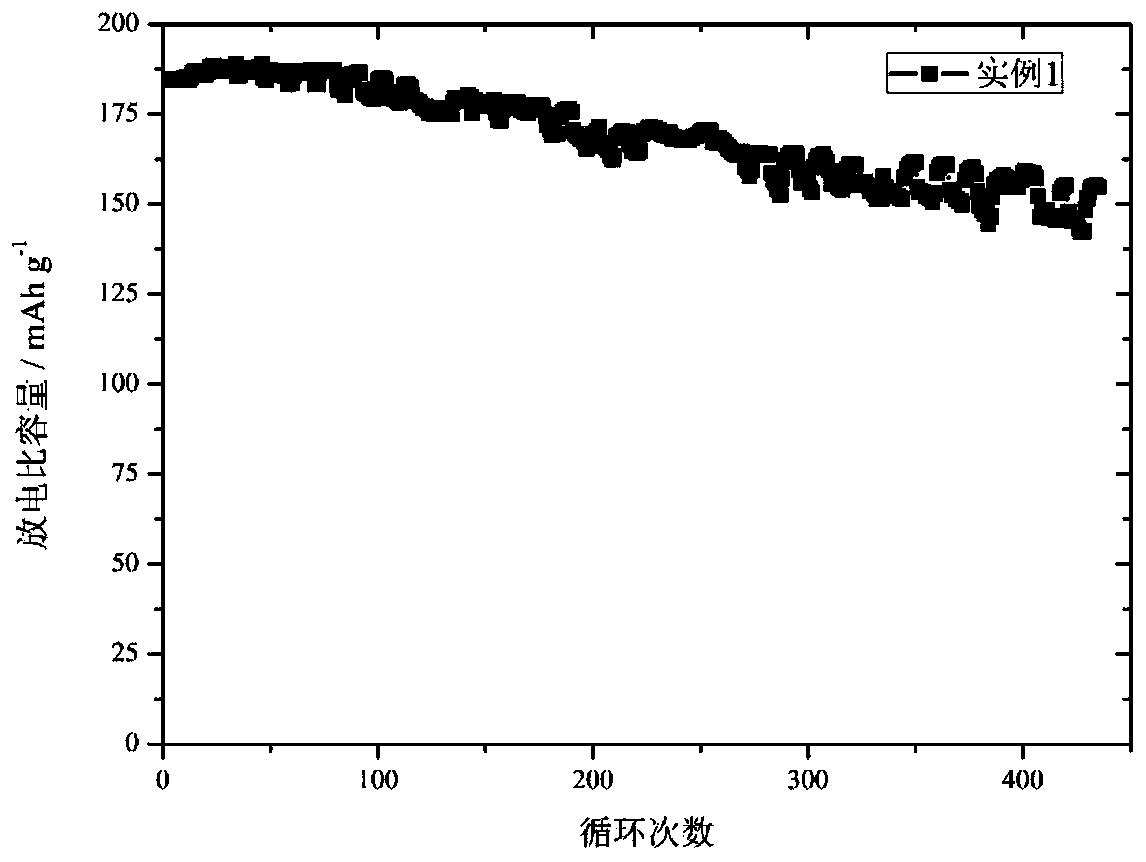

Embodiment 1

[0030] The high-nickel ternary material with transition metal element concentration gradient of this embodiment, its precursor core chemical composition is Ni 0.83 co 0.12 mn 0.05 (OH) 2 , the chemical composition of the shell is Ni 0.5 co 0.2 mn 0.3 (OH) 2 , in this embodiment, the core-shell structure of the precursor is the method of high-speed mechanical fusion to crush Ni 0.5 co 0.2 mn 0.3 (OH) 2 Tightly coated with Ni 0.83 co 0.12 mn 0.05 (OH) 2 Formed above, the precursor core / shell mass ratio is 10:1, and the average chemical composition of the final precursor is Ni 0.800 co 0.127 mn 0.073 (OH) 2 .

[0031] Its preparation method is:

[0032] Step 1. Prepare the mixture: Ni according to the molecular formula 0.800 co 0.127 mn 0.073 (OH) 2 , calculate its molar ratio of 1:1 LiOH·H 2 The mass ratio of O. The above precursors were mixed with 3% LiOH·H 2O is added into the mixing material tank and fully mixed and stirred until uniform to obtain the...

Embodiment 2

[0036] The high-nickel ternary material with transition metal element concentration gradient of this embodiment, its precursor core chemical composition is Ni 0.95 co 0.025 mn 0.025 (OH) 2 , the contents of Ni, Co, and Mn elements gradually change from the core to the outside, until the composition is Ni 0.8 co 0.1 mn 0.1 (OH) 2 , and Ni 0.5 co 0.2 mn 0.3 (OH) 2 In this example, the gradient structure precursor is prepared by the co-precipitation method, and the core-shell structure is obtained by crushing Ni after high-speed mechanical fusion 0.5 co 0.2 mn 0.3 (OH) 2 It is formed by tightly covering the gradient precursor, the core / shell mass ratio is 10:1, and the average chemical composition of the final precursor is Ni 0.875 co 0.050 mn 0.075 (OH) 2 .

[0037] Its preparation method is:

[0038] Step 1. Precursor modification: the above Ni 0.875 co 0.050 mn 0.075 (OH) 2 Precursor with 0.5% nano-additive ZrO 2 Mixing and performing high-speed mechanic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com