Ultraviolet semiconductor light-emitting device and manufacturing method thereof

A light-emitting device and semiconductor technology, applied in the field of optoelectronics, can solve problems such as difficult ohmic contact and lack of effective solutions, and achieve the effect of overcoming large surface resistance, high external quantum efficiency, and high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

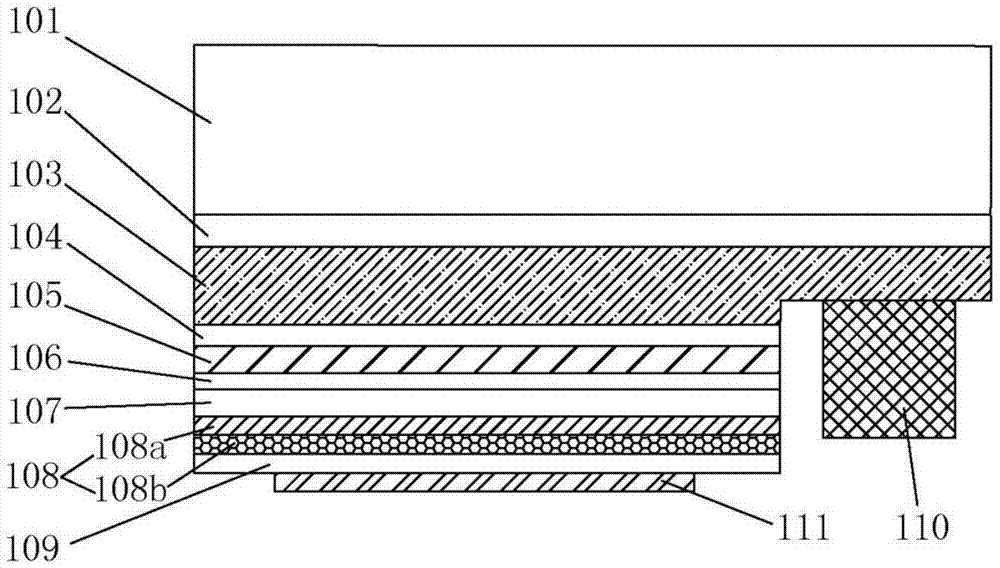

[0051]Embodiment 1 refers to figure 1 , the structure of the GaN-based ultraviolet LED chip is as follows from bottom to top: sapphire substrate 101, epitaxial layer including AlN buffer layer 102, n-AlGaN layer 103, n-AlGaN electron expansion layer 104, multiple quantum well layer 105, AlGaN Electron blocking layer 106, p-AlGaN layer 107, and graphene film cover Ag nano-dot layer 108 (wherein Ag nano-dot layer 108a, graphene film layer 108b), conductive reflection layer 109, n-type electrode 110, p-type electrode 111 .

[0052] The manufacturing steps of the GaN-based ultraviolet LED chip are described in detail below, which includes:

[0053] Step S1: On the sapphire substrate, use the MOCVD process to grow epitaxial layers in sequence. The epitaxial layers include a GaN buffer layer with a thickness of about 2.0 μm, an n-AlGaN layer with a thickness of about 2.0 μm, and an n-AlGaN electron expansion layer with a thickness of about 200 nm. layer, an InGaN / AlGaN multiple qu...

Embodiment 2

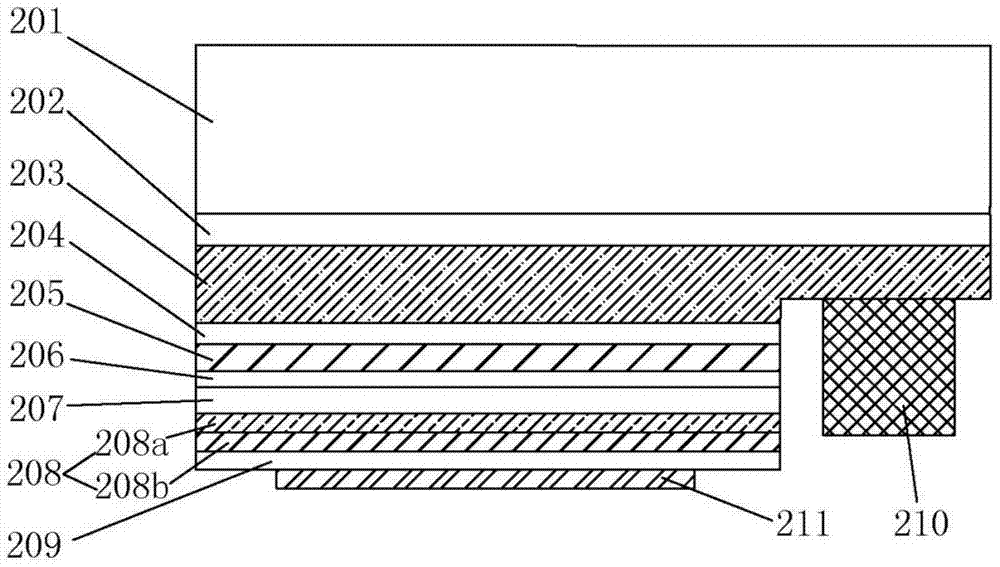

[0062] Embodiment 2 refers to figure 2 The structure of the GaN-based ultraviolet LED chip is as follows from bottom to top: a silicon carbide substrate 201, and the epitaxial layer includes an AlN buffer layer 202, an n-AlGaN layer 203, an n-AlGaN electron expansion layer 204, a multi-quantum well layer 205, p-AlGaN electron blocking layer 206, p-GaN layer 207, and coated graphene quantum dots loaded Ag nanoparticles layer 208 (graphene quantum dots loaded Ag nanoparticles composite layer 208a, intermediate layer 208b), conductive reflective layer 209 , n-type electrode 210, p-type electrode 211.

[0063] The manufacturing steps of the GaN-based ultraviolet LED chip are described in detail below, which includes:

[0064] Step S1: The purified graphene quantum dots and silver nitrate mixed solution are heated and refluxed to prepare the graphene quantum dots loaded Ag nanoparticle complex (reference "Synthesis of Silver Nanoparticles Supported onGraphene Quantum Dots for Oxy...

Embodiment 3

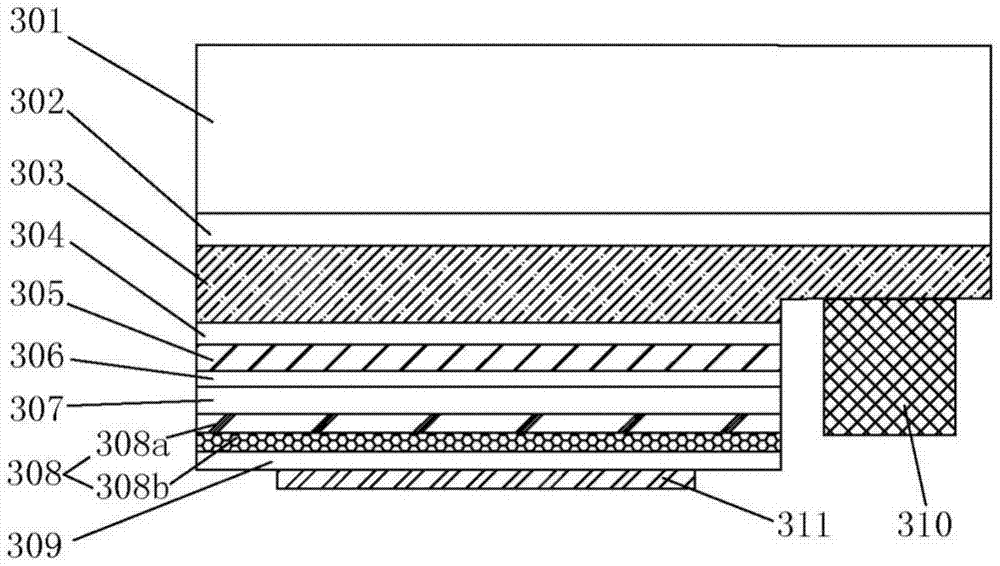

[0070] Embodiment 3 refers to figure 1 , the structure of the GaN-based ultraviolet LED chip is as follows from bottom to top: sapphire substrate 301, epitaxial layer including AlN buffer layer 302, n-AlGaN layer 303, n-AlGaN electron expansion layer 304, multiple quantum well layer 305, AlGaN Electron blocking layer 306, p-AlGaN layer 307, graphene film covering silver nanowire layer 308 (Ag nanowire layer 308a, graphene film layer 308b), conductive reflection layer 309, n-type electrode 310, p-type electrode 311.

[0071] The manufacturing steps of the GaN-based ultraviolet LED chip are described in detail below, which includes:

[0072] Step S1: On the sapphire substrate, use the MOCVD process to grow epitaxial layers in sequence. The epitaxial layers include an AlN buffer layer with a thickness of about 2.0 μm, an n-AlGaN layer with a thickness of about 2.0 μm, and an n-AlGaN electron expansion layer with a thickness of about 200 nm. layer, an InGaN / AlGaN multiple quantum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com