High-temperature coating comprising nickel-chromium-oxygen active diffusion barrier layer and preparation method

An oxygen-active, high-temperature technology, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of anti-oxidation coatings that have not been reported yet, and achieve excellent thermal stability, small impact, and thermal stability sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The base material is DZ125 alloy, the base sample size is 20mm×10mm×3mm, and the purity of the nickel-chromium target is 99.95wt%. After the substrate sample is cleaned on the surface, it is loaded into the working chamber, and the vacuum chamber is heated to 250°C; argon / oxygen mixed gas (volume ratio 1:1) is introduced to maintain the vacuum degree of the working chamber at 1.0Pa, DC bias voltage 600V, arc current 60A. Preparation parameters of NiCrAlY coating: argon gas pressure 0.1Pa, substrate temperature 250°C, arc current 65A, DC bias voltage -10V, duty cycle 20%. In this embodiment, the chemical composition of the nickel-chromium-oxygen inner layer is: chromium content 18wt.%, oxygen content 26wt.%, and the rest is nickel; the chemical composition of the nickel-chromium-aluminum-yttrium coating is: chromium content 24wt.%, aluminum The content is 10wt.%, the yttrium content is 0.5wt.%, and the rest is nickel.

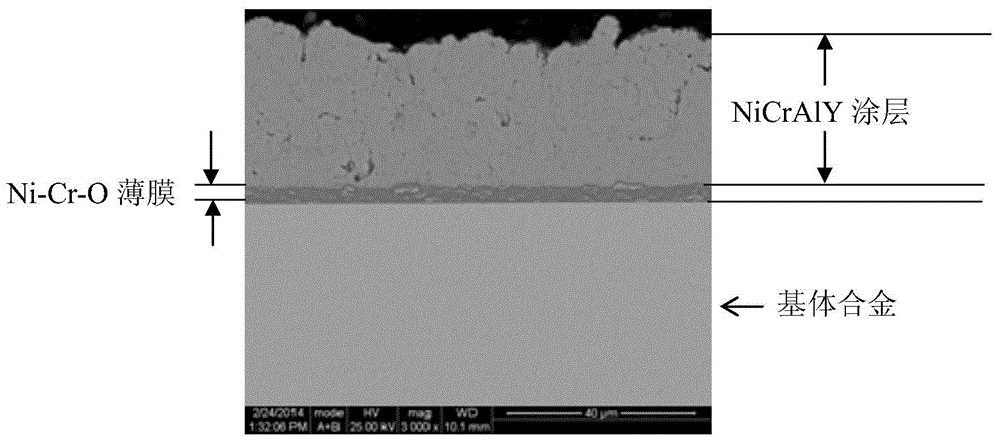

[0036] Such as figure 1 As shown in the cross-se...

Embodiment 2

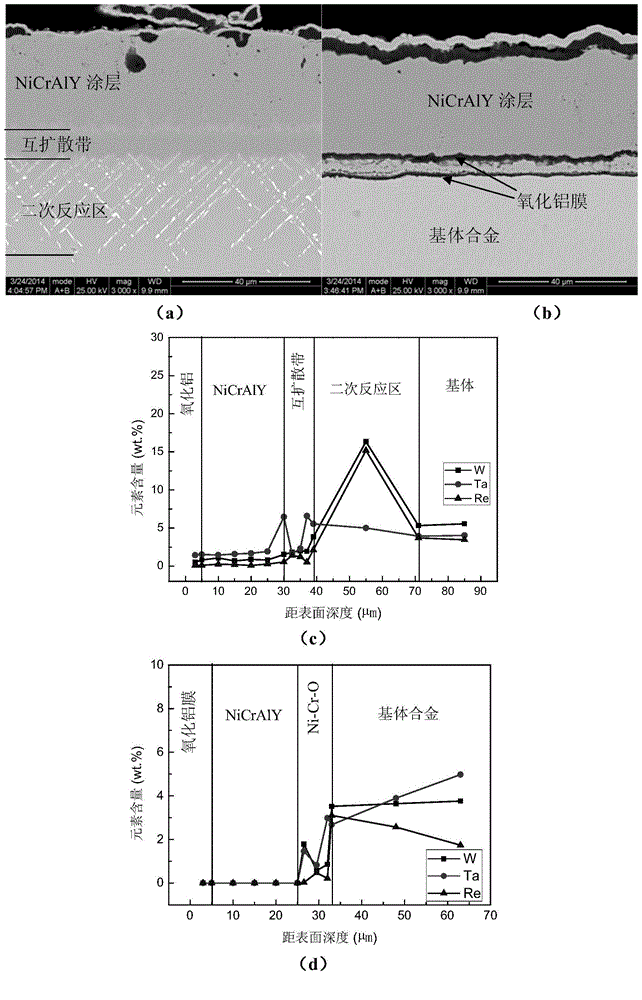

[0038] The base material is DD5 superalloy, the base sample size is 20mm×10mm×3mm, and the target material is a Ni-Cr alloy target with a chromium content of 30wt.%. After the substrate sample is cleaned on the surface, it is loaded into the working room, and the vacuum chamber is heated to 230 °C; the pressure of the argon / oxygen mixture (volume ratio 1:1) is 1.5Pa, the DC bias voltage is 650V, the arc current is 65A, and the nickel-chromium-oxygen film is The thickness is about 3 μm. In this embodiment, the chemical composition and content of the nickel-chromium-oxygen inner layer are as follows: the chromium content is 16wt.%, the oxygen content is 29wt.%, and the rest is nickel. A layer of NiCrAlY (Ni-25Cr-11Al-0.5Y, wt.%) coating with a thickness of about 40 μm was deposited by multi-arc ion plating technology, and the preparation parameters were: argon pressure 0.2Pa, substrate temperature 200°C, arc current 70A, DC bias -20V, duty cycle 30%, deposition 540min. Subsequ...

Embodiment 3

[0041] The base material is a Rene N5 superalloy, the base sample size is 15mm×10mm×3mm, and the target material is a Ni-Cr alloy target with a chromium content of 25wt.%. After the substrate sample is cleaned on the surface, it is loaded into the working room, and the vacuum chamber is heated to 250°C; the argon / oxygen mixture (volume ratio 1:1) has a pressure of 1.2Pa, a DC bias voltage of 620V, and an arc current of 70A. The film thickness is about 4 μm. In this embodiment, the chemical composition of the nickel-chromium oxide layer is: oxygen 25wt%, chromium 22wt.%, and the rest is nickel. A layer of NiCoCrAlY (Ni-22Co-24Cr-10Al-0.5Y, wt.%) coating with a thickness of about 40 μm was deposited on the NiCrO layer by plasma spraying technology. Subsequently, the substrate / coating system was oxidized 200 times at 1100° C. (each cycle consisted of 1 hour of heating and 15 minutes of cooling).

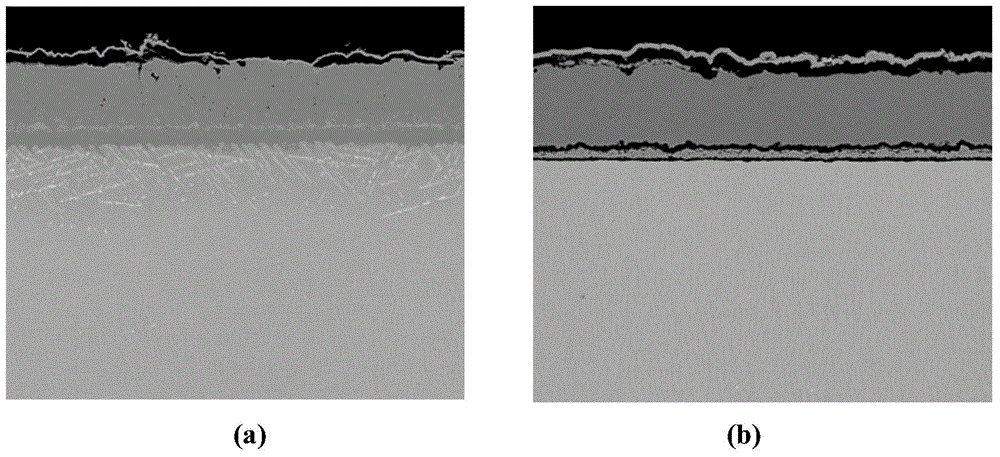

[0042] The cross-sectional morphology of the sample after cyclic oxidation was ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com