Method for preparing high-performance double-main-phase sintered mixed rare earth iron boron magnet through two-step diffusion method

A technology of mixing rare earths and dual main phases, applied in magnets, magnetic objects, magnetic materials, etc., can solve problems such as poor performance, high equipment requirements, and affecting magnet performance, so as to reduce production costs, reduce environmental pollution, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] According to the nominal composition Pr of main phase A 31.5 Fe bal Al 0.4 Cu 0.2 Co 1 Ga 0.2 Zr 0.22 B 0.98 (wt.%), the nominal composition of the main phase B (Nd 0.5 MM 0.5 ) 31.5 Fe bal Al 0.4 Cu 0.2 Co 1 Ga 0.2 Zr 0.22 B 0.98 (wt.%) (La: 27.49wt.% in MM, Ce: 53.93wt.%, Pr: 1.86wt.%, Nd: 16.72wt.%), using a copper roller speed of 1.25m / s to prepare A and B two-component quick-setting thin ribbon with a thickness of 210μm.

[0044] The nominal composition of Pr is prepared by vacuum induction quick-setting furnace 65 Ho 20 Fe 15 And Zr 55 Cu 45 The quick-setting thin strip is roughly broken into small square pieces about 1cm*1cm.

[0045] The quick-setting flakes of two components A and B are hydrogen crushed, and the coarsely crushed magnetic powder is obtained after dehydrogenation.

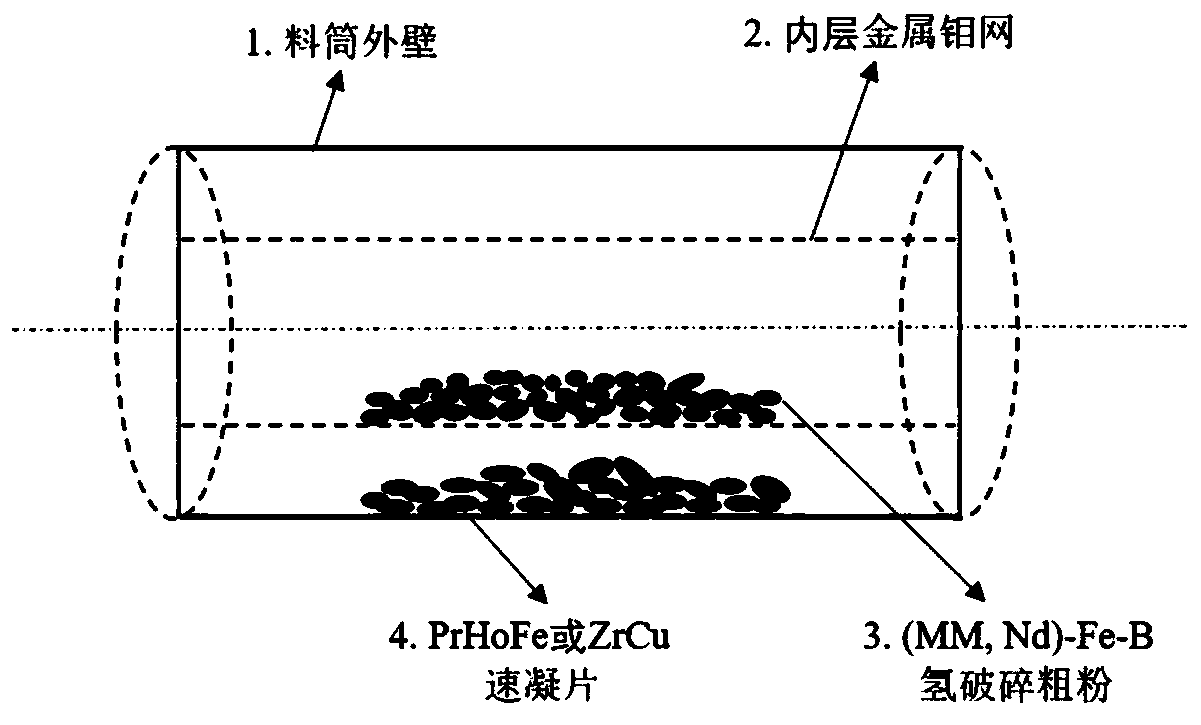

[0046] The hydrogen crushed coarse powder of component B and crushed Pr 65 Ho 20 Fe 15 The quick-setting flakes are respectively placed on the inner and outer layers of a double-layer ci...

Embodiment 2

[0053] According to the nominal composition Pr of main phase A 31.5 Fe bal Al 0.4 Cu 0.2 Co 1 Ga 0.2 Zr 0.22 B 0.98 (wt.%), the nominal composition of the main phase B (Nd 0.5 MM 0.5 ) 31.5 Fe bal Al 0.4 Cu 0.2 Co 1 Ga 0.2 Zr 0.22 B 0.98 (wt.%) (La: 27.49wt.% in MM, Ce: 53.93wt.%, Pr: 1.86wt.%, Nd: 16.72wt.%), using a copper roller speed of 1.25m / s to prepare A and B two-component quick-setting thin ribbon with a thickness of 210μm.

[0054] The nominal composition of Pr is prepared by vacuum induction quick-setting furnace 65 Ho 20 Fe 15 And Zr 55 Cu 45 The quick-setting thin strip is roughly broken into small square pieces about 1cm*1cm.

[0055] The quick-setting flakes of two components A and B are hydrogen crushed, and the coarsely crushed magnetic powder is obtained after dehydrogenation.

[0056] The hydrogen crushed coarse powder of component B and crushed Pr 65 Ho 20 Fe 15 The quick-setting flakes are respectively placed on the inner and outer layers of a double-layer ci...

Embodiment 3

[0063] According to the nominal composition Pr of main phase A 31.5 Fe bal Al 0.4 Cu 0.2 Co 1 Ga 0.2 Zr 0.22 B 0.98 (wt.%), the nominal composition of the main phase B (Nd 0.5 MM 0.5 ) 31.5 Fe bal Al 0.4 Cu 0.2 Co 1 Ga 0.2 Zr 0.22 B 0.98 (wt.%) (La: 27.49wt.% in MM, Ce: 53.93wt.%, Pr: 1.86wt.%, Nd: 16.72wt.%), using a copper roller speed of 1.25m / s to prepare A and B two-component quick-setting thin ribbon with a thickness of 210μm.

[0064] The nominal composition of Pr is prepared by vacuum induction quick-setting furnace 65 Ho 20 Fe 15 And Zr 55 Cu 45 The quick-setting thin strip is roughly broken into small square pieces about 1cm*1cm.

[0065] The quick-setting flakes of two components A and B are hydrogen crushed, and the coarsely crushed magnetic powder is obtained after dehydrogenation.

[0066] The hydrogen crushed coarse powder of component B and crushed Pr 65 Ho 20 Fe 15 The quick-setting flakes are respectively placed on the inner and outer layers of a double-layer ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com