Lanthanum-iron-silicon/gadolinium composite magnetic refrigeration material and preparation technology thereof

A magnetic refrigeration material and magnetic refrigeration technology, applied in the direction of magnetic material, inorganic material magnetism, improvement of process efficiency, etc., can solve the problem that the binder does not have magnetic refrigeration characteristics, affects refrigeration efficiency, and reduces the effective content of magnetic refrigeration working material. and other problems, to achieve the effect of good magnetocaloric effect, high economic value and enhanced mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

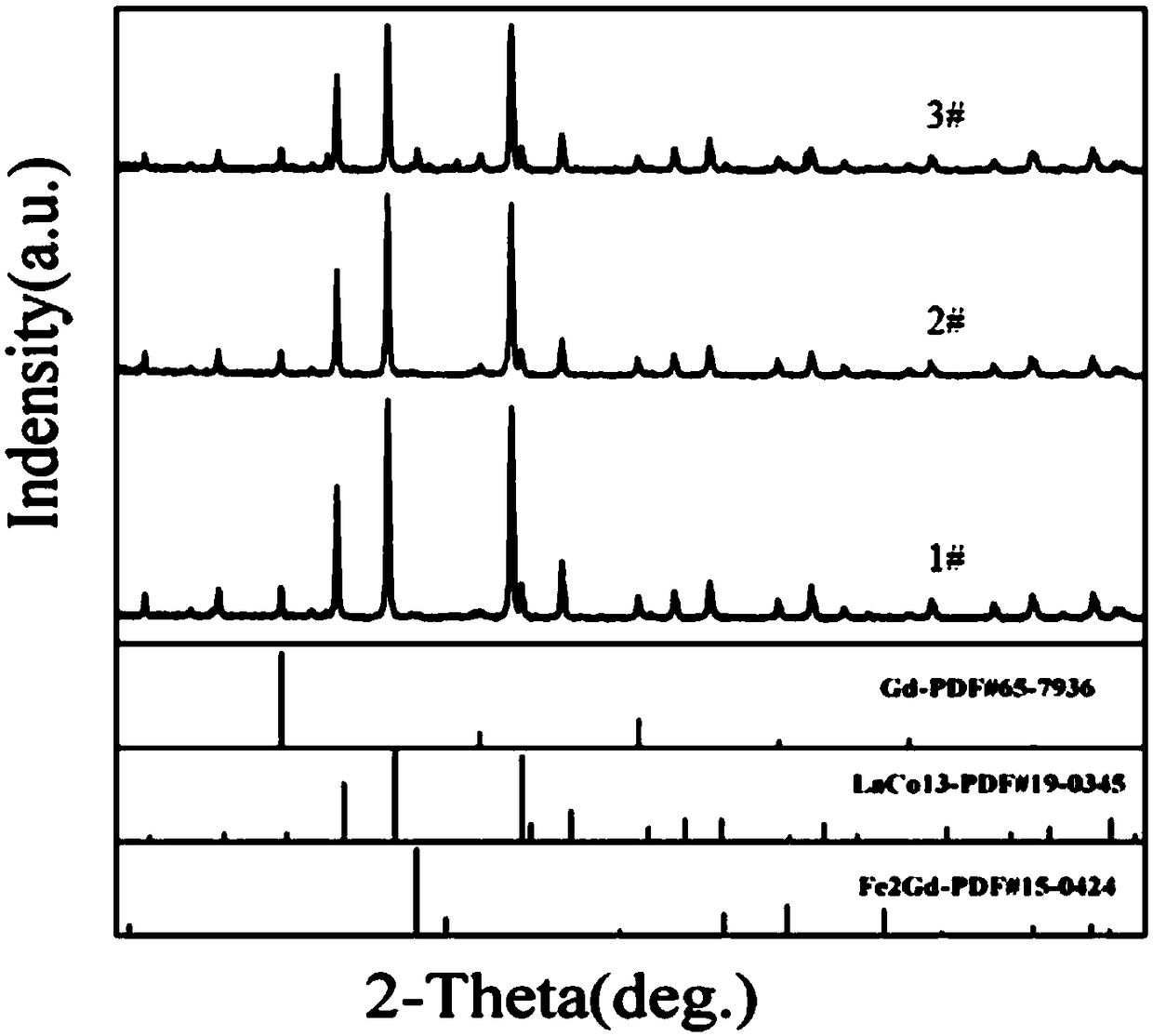

[0051] Embodiment 1: Implement a new type of lanthanum-iron-silicon / gadolinium composite magnetic refrigeration material and its preparation process according to the following specific steps:

[0052] Step 1: LaFe, Fe, Co, and Si are mixed in proportion to obtain LaFe 10.58 co 0.82 Si 1.6 Ingot;

[0053] Step 2, the LaFe that step 1 obtains 10.58 co 0.82 Si 1.6 The ingot is annealed in an inert atmosphere to obtain a uniform NaZn 13 structural organization;

[0054] Step 3, preparing pure Gd into powder particles by quick quenching and ball milling;

[0055] Step 4, sieving the Gd powder particles in the third step to 75-125 μm;

[0056] Step 5, crushing and sieving the alloy obtained in Step 2 to 125-150 μm;

[0057] Step 6, the LaFe obtained in step 5 10.58 co 0.82 Si 1.6 Particles are mixed uniformly with the Gd particles obtained in step 5 in a ratio of 9:1;

[0058] Step 7: Put the mixed powder obtained in Step 6 into an alloy mold, and prepare a block by spa...

Embodiment 2

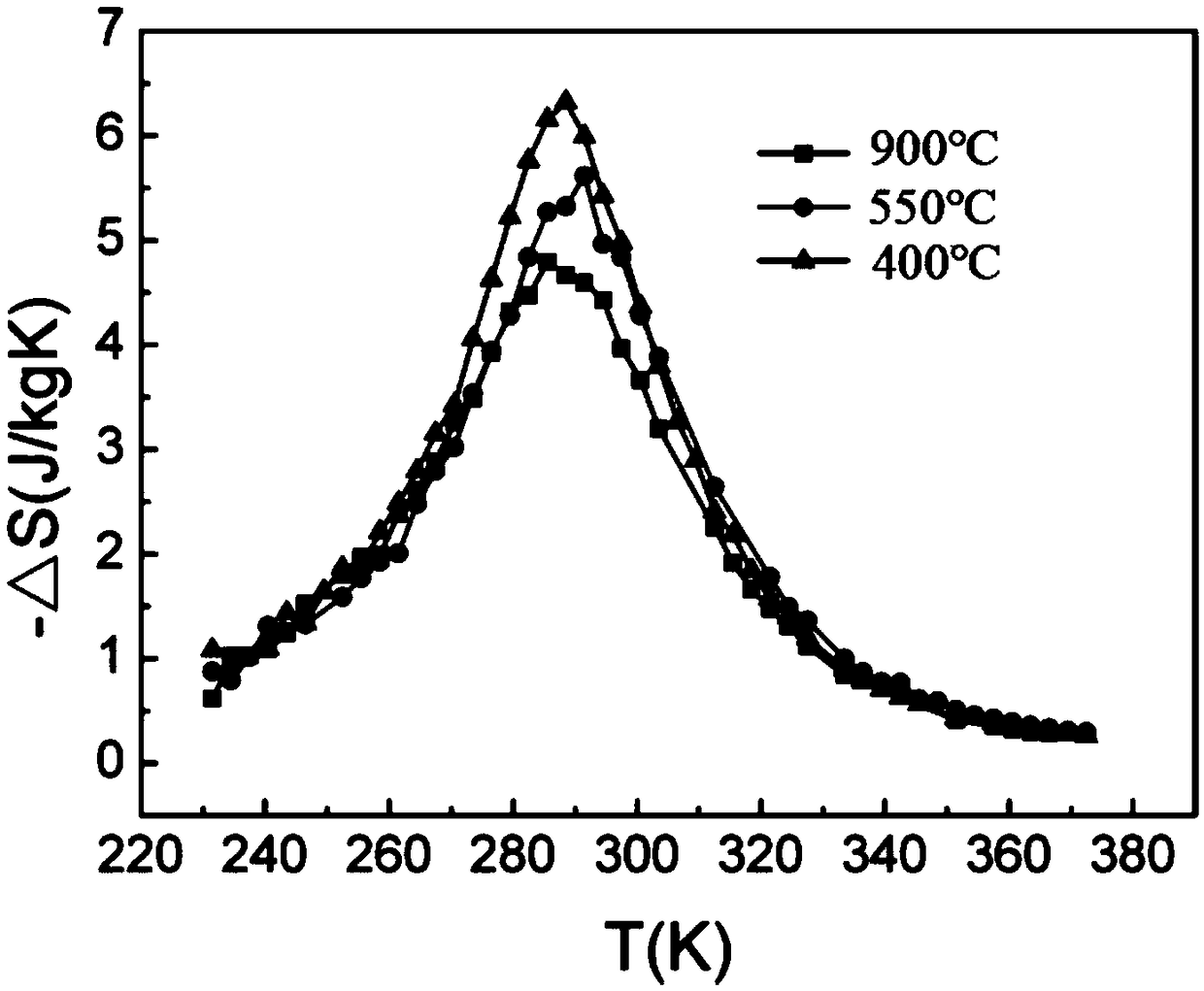

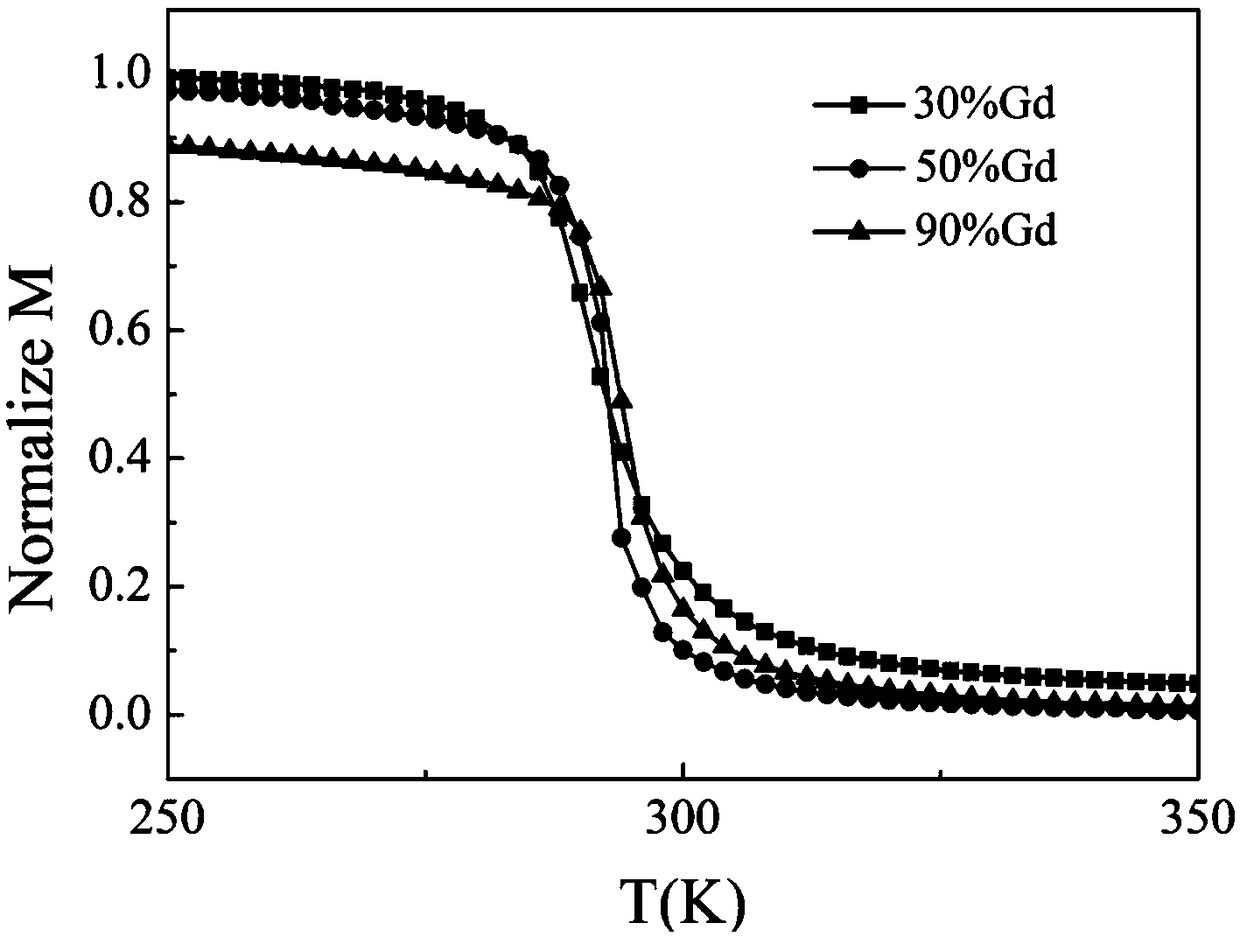

[0063] Embodiment 2: Implement a new type of lanthanum-iron-silicon / gadolinium composite magnetic refrigeration material and its preparation process according to the following specific steps:

[0064] Step 1: La, Pr, Fe-C, Co, and Si are mixed in proportion to prepare La 0.5 PR 0.5 Fe 10.7 co 0.8 Si 1.5 C 0.2 Ingot;

[0065] Step 2, the La obtained in Step 1 0.5 PR 0.5 Fe 10.7 co 0.8 Si 1.5 C 0.2 The ingot is annealed in an inert atmosphere to obtain a uniform NaZn 13 structural organization;

[0066] Step 3, the pure Gd is prepared into powder particles by gas atomization;

[0067] Step 4, sieving the Gd powder particles in the third step to 37-75 μm;

[0068] Step 5, crushing and sieving the alloy obtained in Step 2 to 180-425 μm;

[0069] Step 6, La obtained in step 5 0.5 PR 0.5 Fe 10.7 co 0.8 Si 1.5 C 0.2 Particles are mixed uniformly with the Gd particles obtained in step 5 in proportions of 7:3, 5:5, and 1:9 respectively;

[0070] In step seven, the...

Embodiment 3

[0075] Embodiment 3: Implement a new type of lanthanum-iron-silicon / gadolinium composite magnetic refrigeration material and its preparation process according to the following specific steps:

[0076] Step 1: La, Ce, Fe, Mn, Si are mixed in proportion to prepare La 0.8 Ce 0.2 Fe 12.4 mn 0.3 Si 1.3 Ingot;

[0077] Step 2, the La obtained in Step 1 0.8 Ce 0.2 Fe 12.4 mn 0.3 Si 1.3 The ingot is annealed in an inert atmosphere to obtain a uniform NaZn 13 Structural organization, it is hydrogenated to obtain La 0.8 Ce 0.2 Fe 12.4 mn 0.3 Si 1.3 H particles;

[0078] Step 3, the pure Gd is prepared into powder particles through the method of ventilating and atomizing;

[0079] Step 4, sieving the Gd powder particles in the third step to 125-150 μm;

[0080] Step five, the La obtained in step two 0.8 Ce 0.2 Fe 12.4 mn 0.3 Si 1.3 H particles are sieved to 150-180 μm;

[0081] Step 6, La obtained in step 5 0.8 Ce 0.2 Fe 12.4 mn 0.3 Si 1.3 Mix the H particles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com