Patents

Literature

52results about How to "Alleviate thermal expansion coefficient differences" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

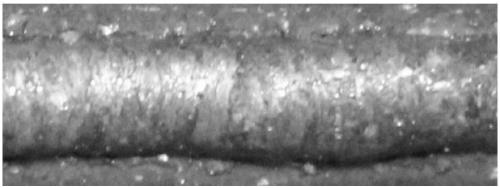

Magnesium alloy surface treatment method

InactiveCN104805345AReduce heat sensitivityImprove solderabilityMolten spray coatingMetallurgyMaterials science

The invention discloses a magnesium alloy surface treatment method which comprises three stages including a pretreatment stage, a spraying stage and an after-spraying treatment stage. By adoption of a compound spraying method, an anti-corrosion and anti-abrasion coating layer which is high in bonding strength, high in compactness and small in environment pollution is formed on the magnesium alloy surface; the surface treatment method is simple and feasible and is low in cost.

Owner:SUZHOU TONGMING MACHINERY

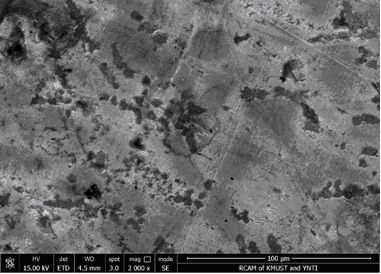

Surface Alloy Coating Composite material Used for High Temperature Resistant Material, Coating and Preparation Method Thereof

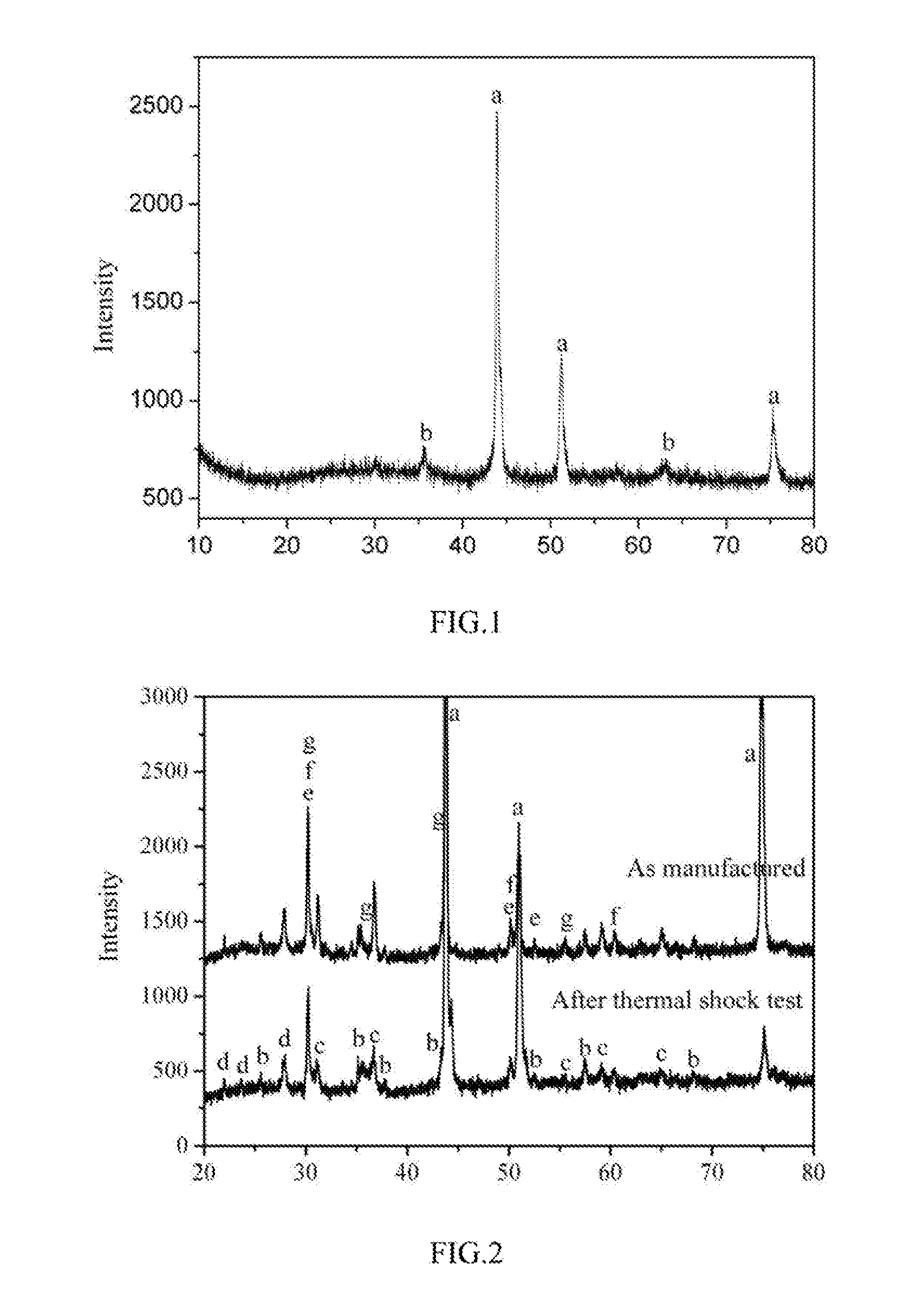

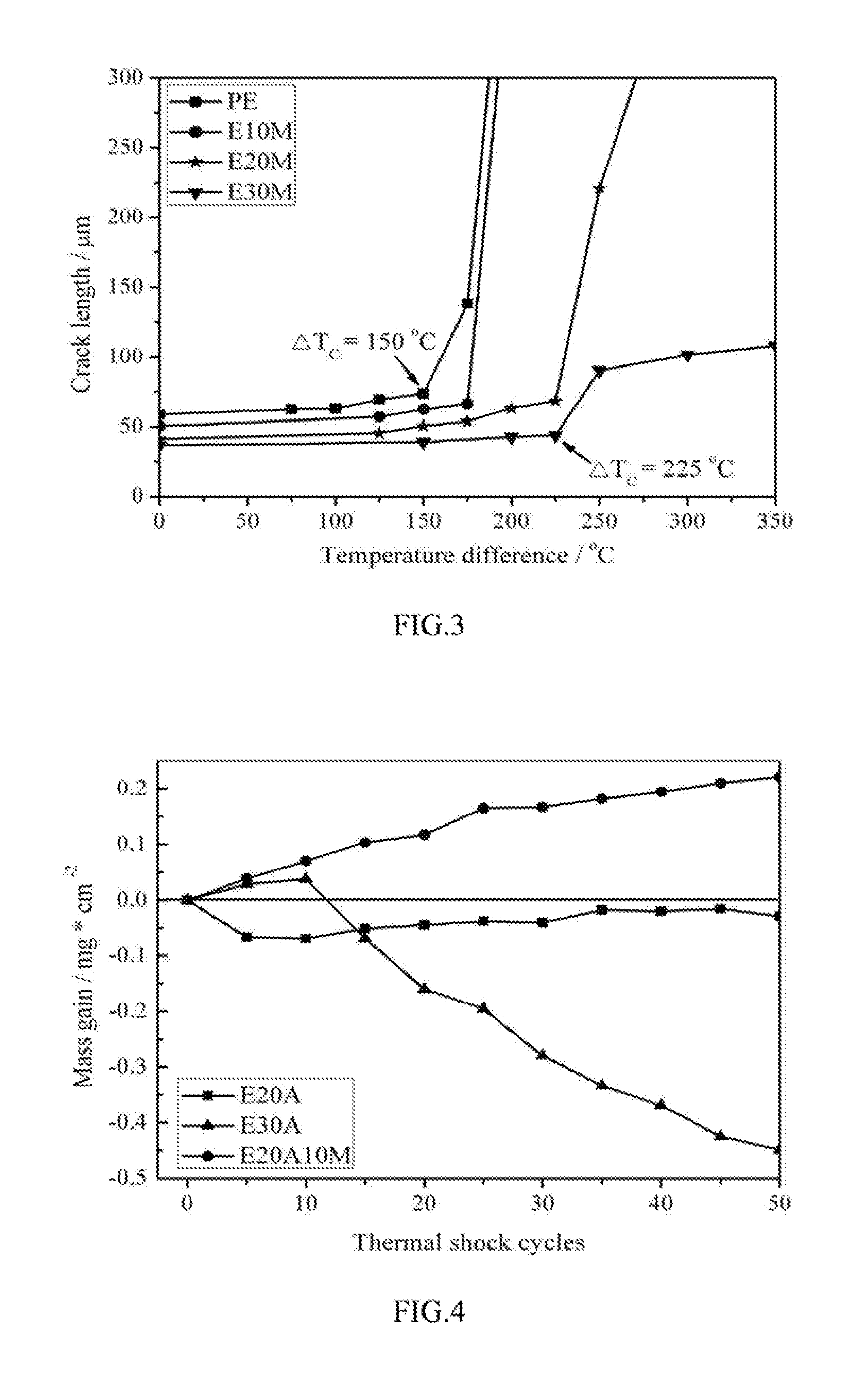

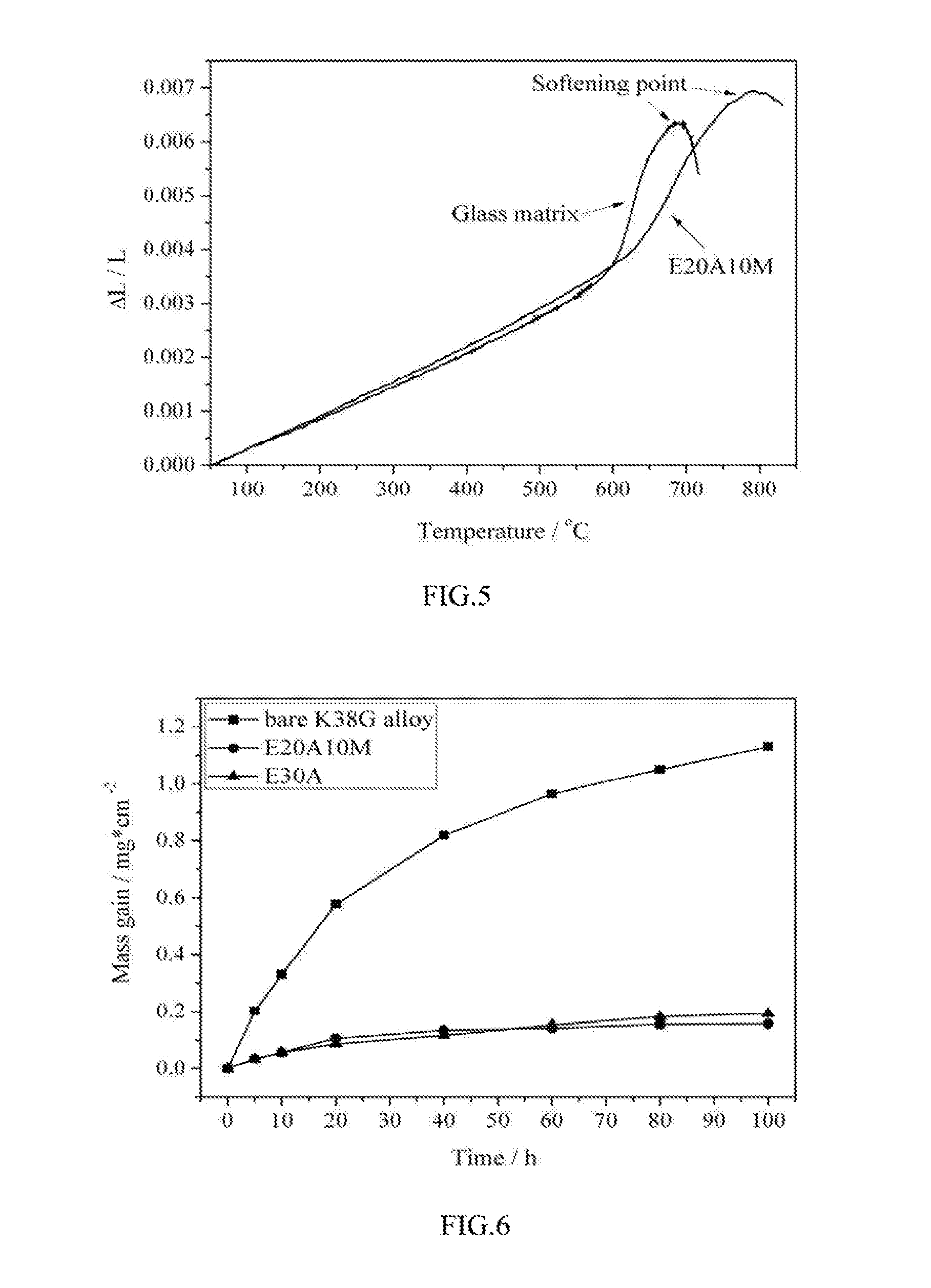

ActiveUS20160122877A1Excellent high temperature oxidation and hot corrosion resistanceExcellent fracture toughnessLiquid surface applicatorsMolten spray coatingRare-earth elementMetal alloy

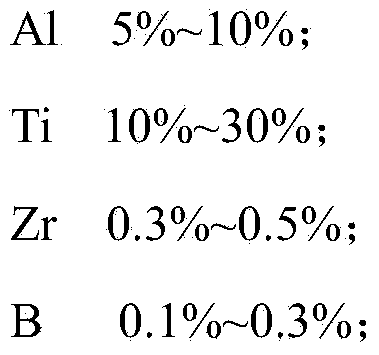

The present invention provides a surface alloy coating composite material for a high temperature resistant material, a coating and a manufacturing method thereof, wherein the surface alloy coating composite material is made of metal alloy powder having a face-centered cubic structure and enamel powder, and a component percentage thereof is as follows: 10-70wt % is the metal alloy powder, and remaining is the enamel powder; the metal alloy powder is selected from at least one type of NiCrAIX, NiCrX and NiCoCrAIX, wherein X is at least one type of hafnium, zirconium, a rare earth element and mixed rare earth, and the mixed rare earth can be two types or more than two types of rare earth elements that are used together or a rare earth element and one type or multiple types of Na, K, Ca, Sr and Ba that are used in a combined way.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

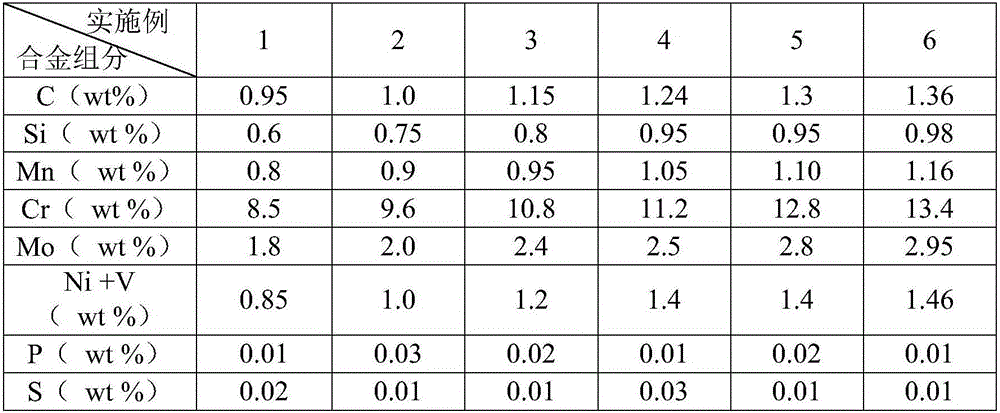

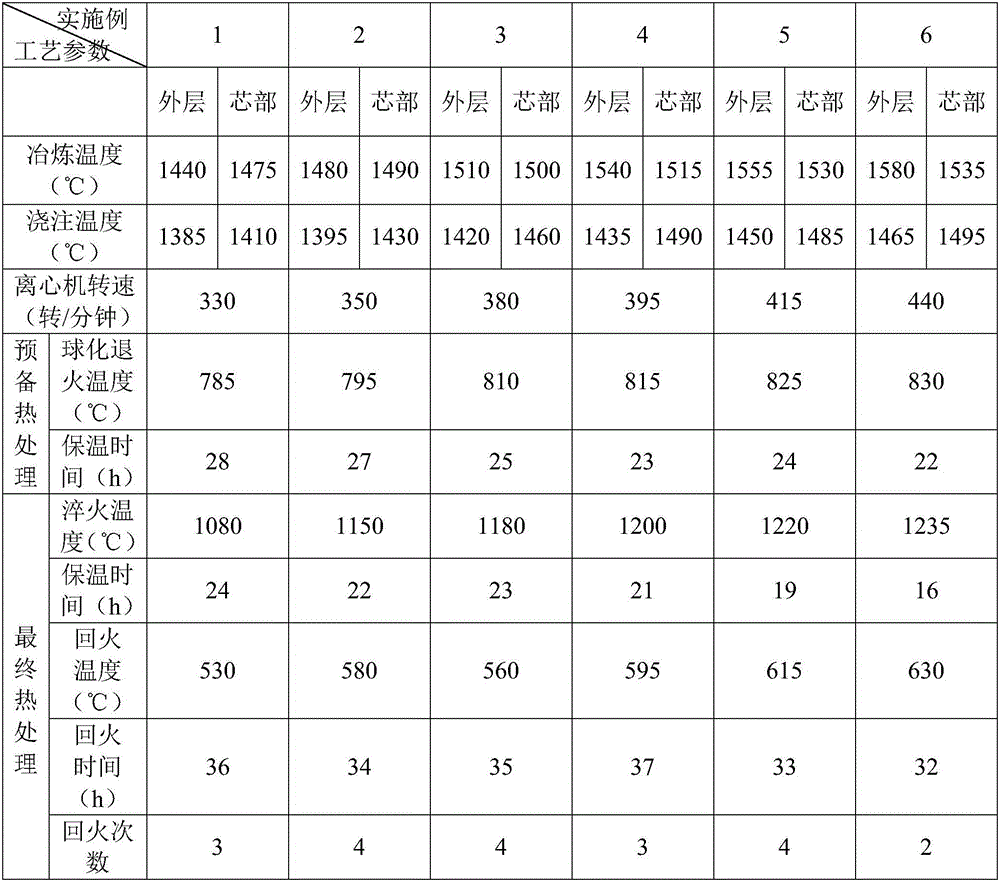

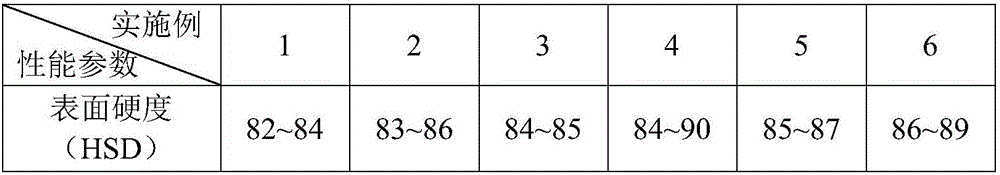

High chrome steel centrifugation roll collar and manufacturing method thereof

The invention discloses a high chrome steel centrifugation roll collar and a manufacturing method thereof, and belongs to the technical field of machining and casting. The high chrome steel centrifugation roll collar comprises an outer layer and a core part, and the proportion of the outer layer to the core part is 1:2; and the outer layer comprises alloy compositions including, by weight, 0.80%-1.40% of C, 0.40%-1.00% of Si, 0.60%-1.20% of Mn, not larger than 0.03% of P, not larger than 0.03% of S, 8.00%-14.0% of Cr, 1.00%-3.00% of Mo, 0.50%-1.50% of Ni+V and the balance Fe and inevitable impurities. The high chrome steel centrifugation roll collar solves the technical problems that a composite casting roll collar is not enough in abrasive resistance, poor in rolled metal surface quality, poor in outer layer and core part interface combination, low in bonding intensity and the like in the using process, and the economic and feasible manufacturing method is provided for producing roll collars of large and small vertical rolls of a hot strip mill.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

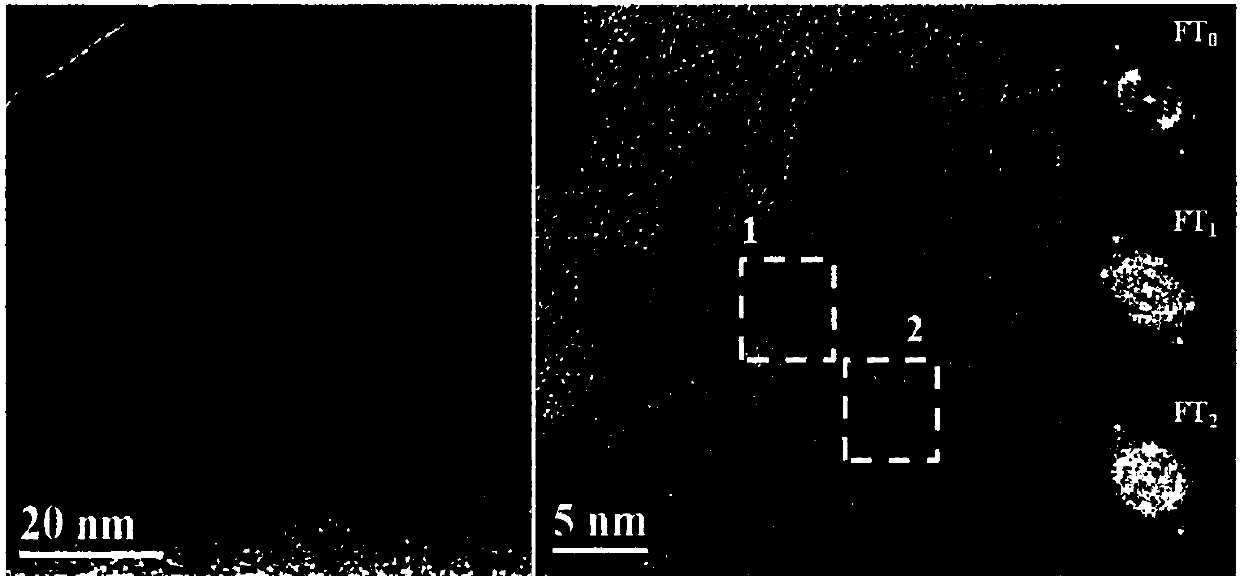

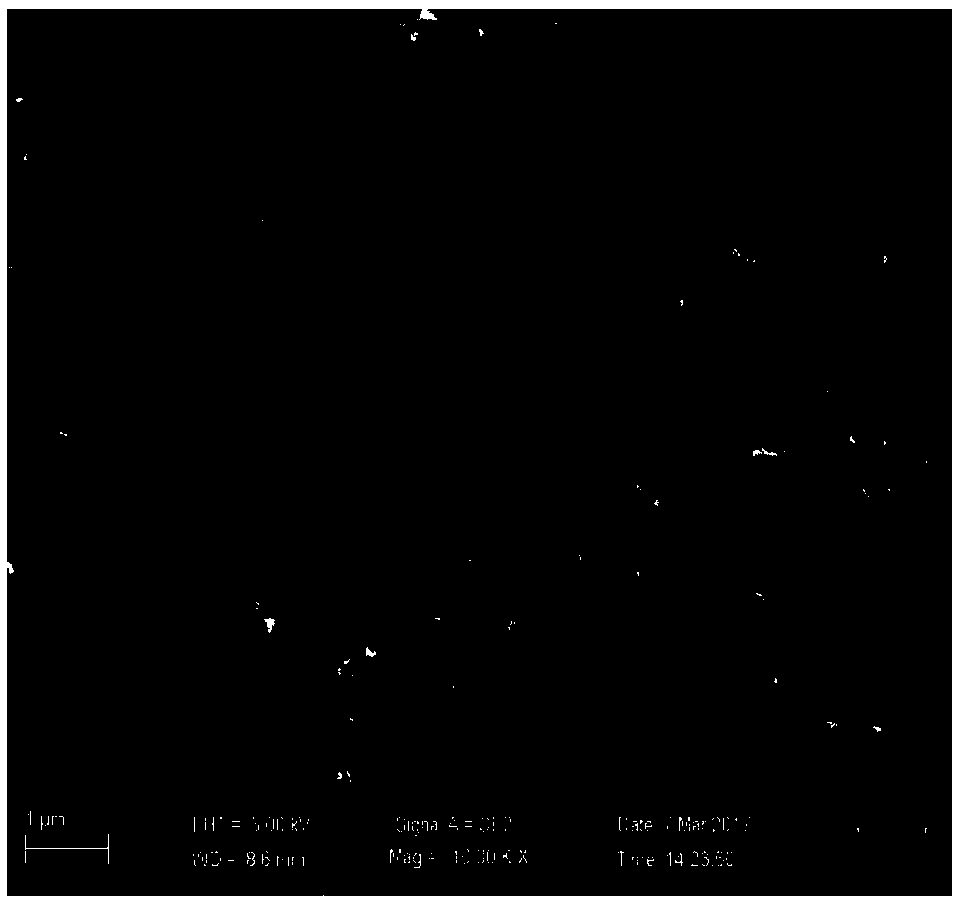

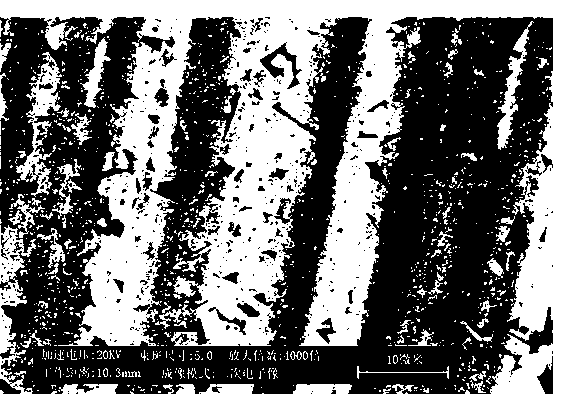

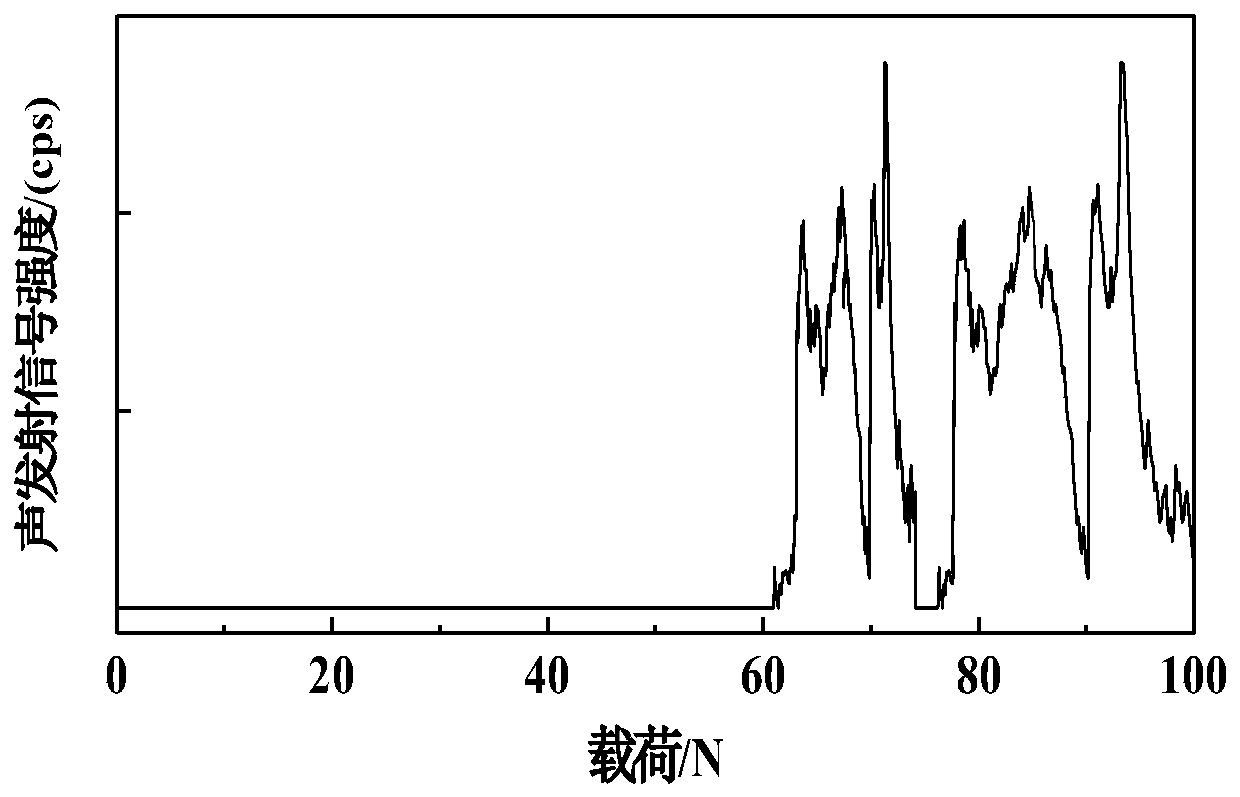

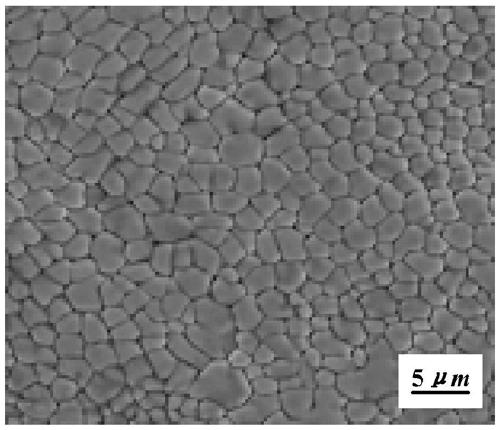

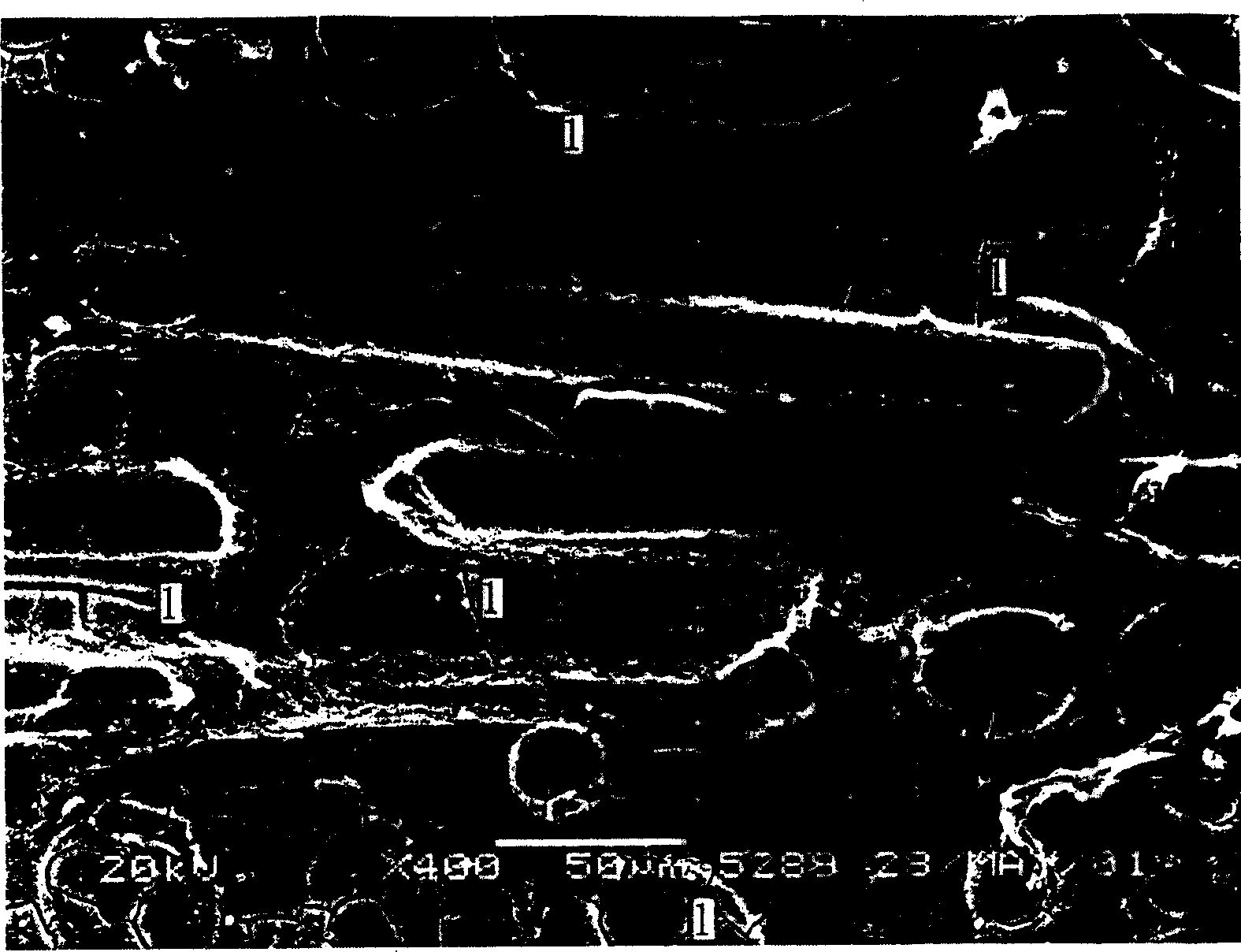

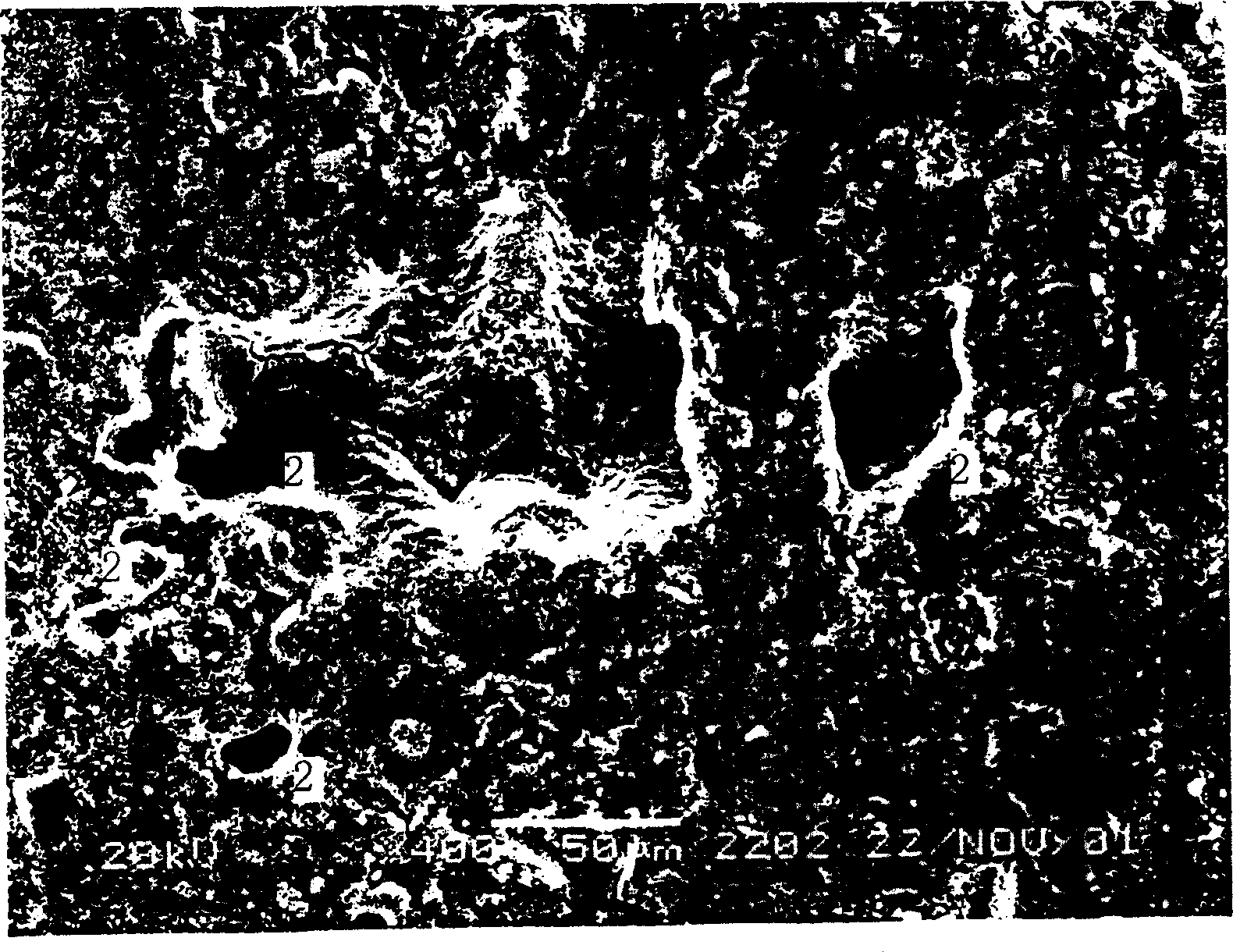

Novel method for depositing diamond film on surface of stainless steel

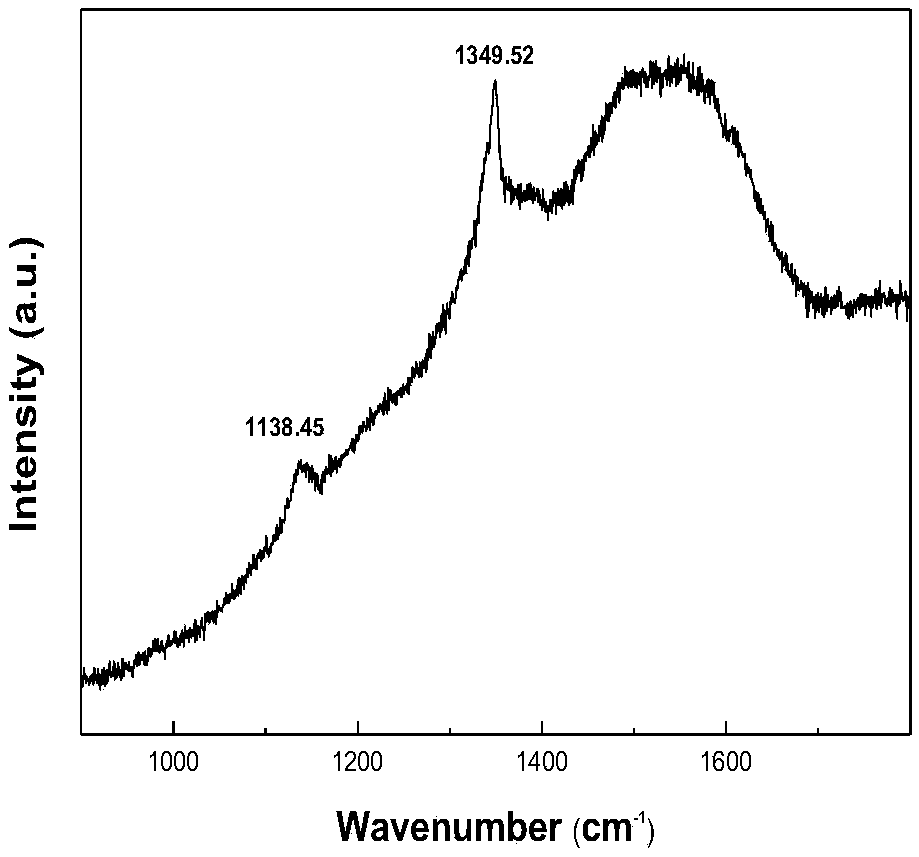

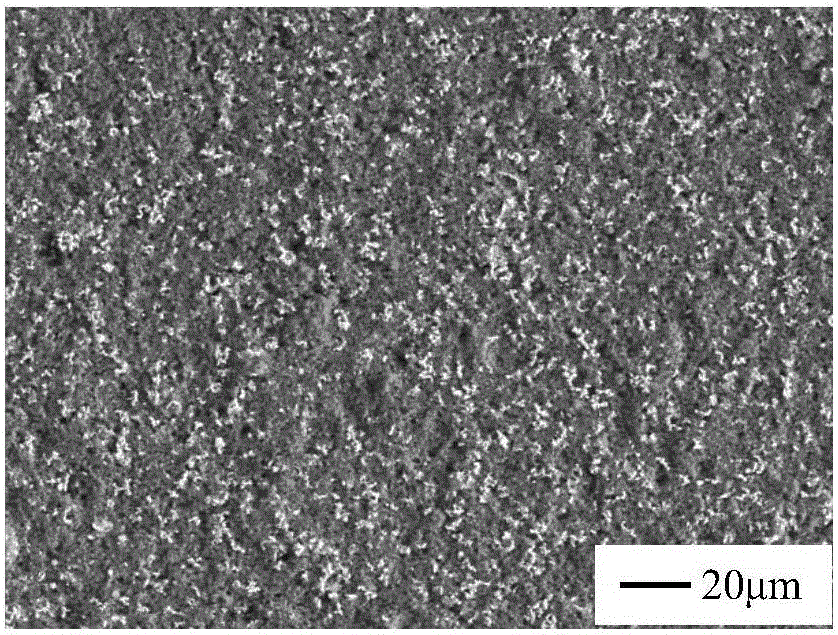

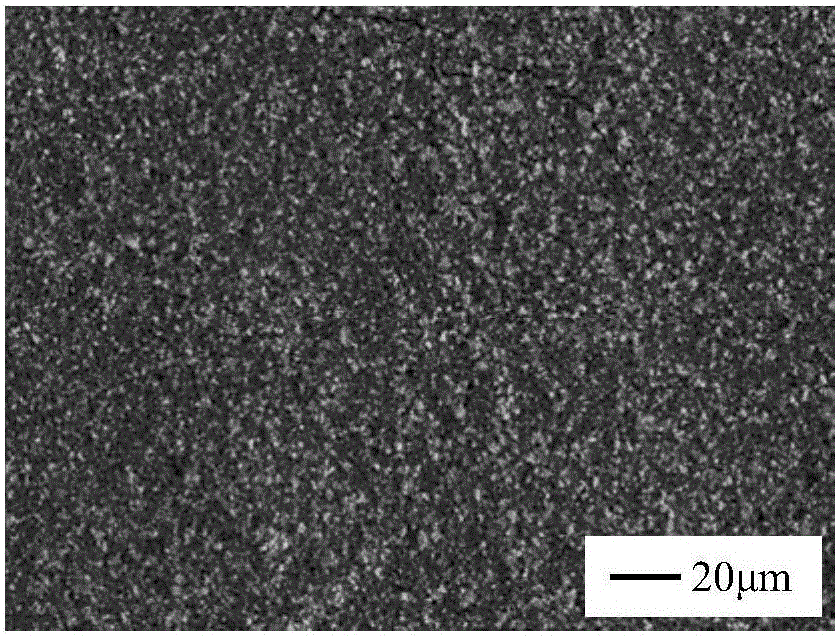

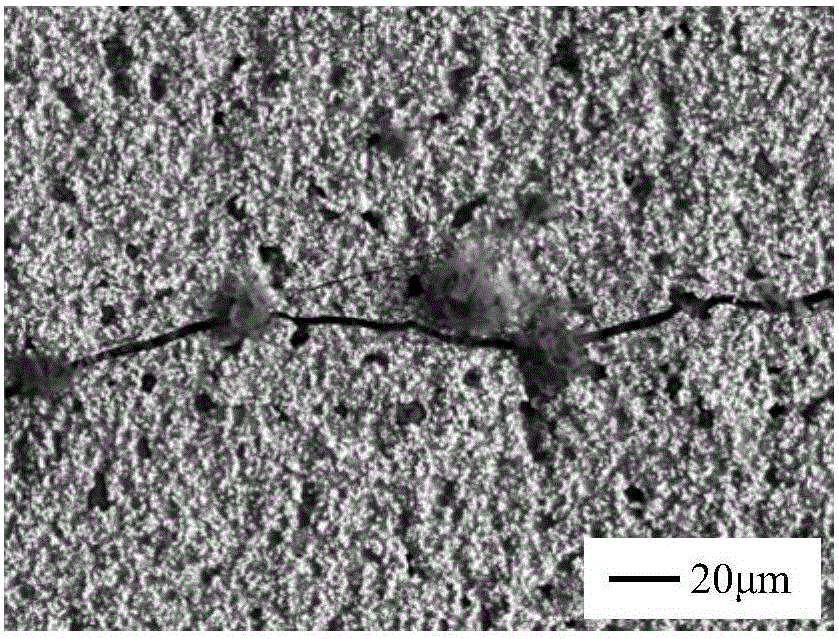

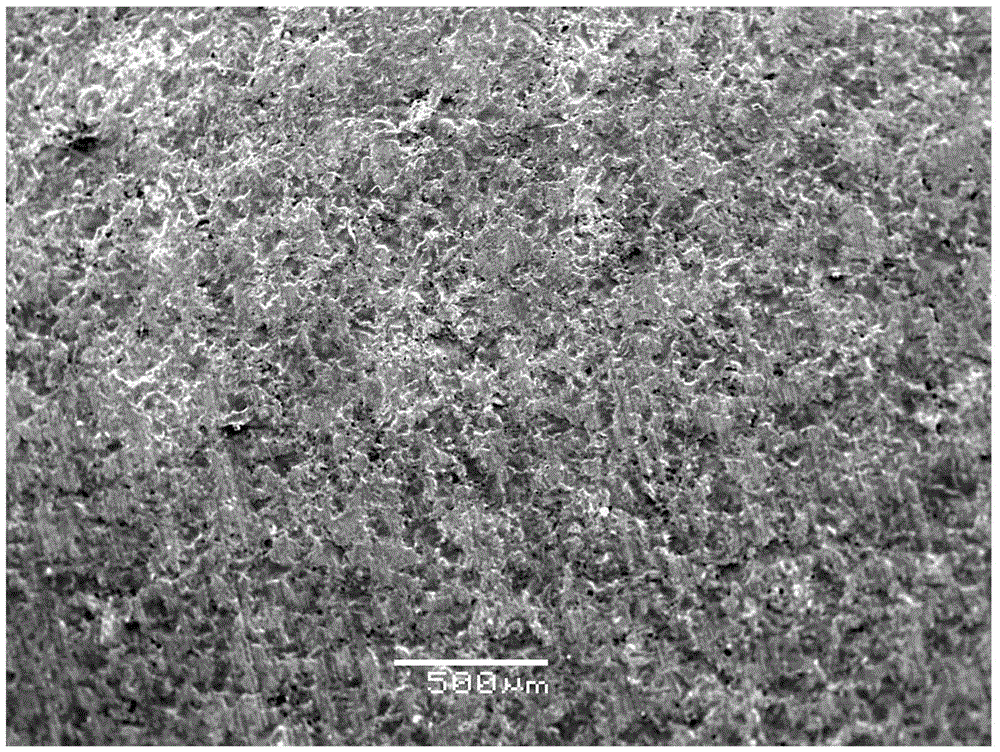

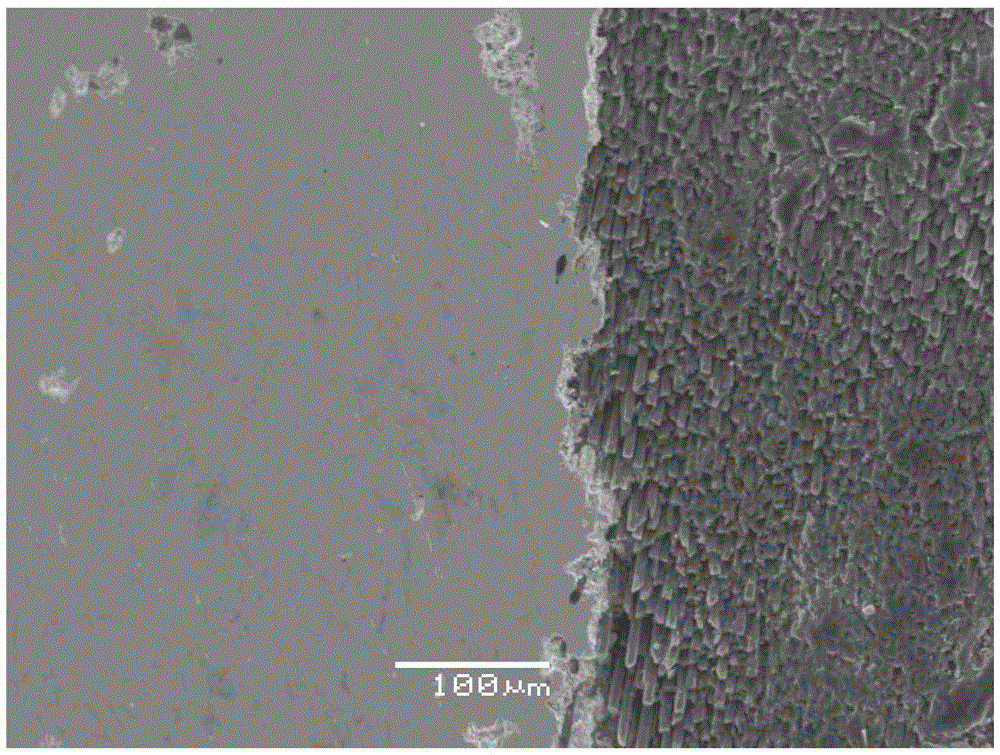

ActiveCN107740068AAlleviate thermal expansion coefficient differencesImprove bindingChemical vapor deposition coatingRoom temperaturePowder suspension

The invention discloses a novel method for depositing a diamond film on the surface of stainless steel. The novel method comprises the following steps that 1), a novel transition layer is firstly sputtered on a stainless steel substrate by adopting a magnetron sputtering method; and 2), the diamond film is grown on the transition layer by adopting a hot-filament chemical vapor deposition method, wherein ultrasonic oscillating is carried out for 30 minutes in diamond powder suspension, then the diamond film deposition is carried out, finally, the diamond film is slowly cooled to the room temperature, and the continuous and compact diamond film can be prepared on the surface of the stainless steel.

Owner:ZHEJIANG UNIV OF TECH

Anti-sticking coating on surface of cemented carbide sintering boat and preparation method thereof

The invention relates to the technical field of sintering boat coatings, in particular to an anti-sticking coating on the surface of a cemented carbide sintering boat and a preparation method thereof.The anti-sticking coating on the surface of the cemented carbide sintering boat comprises an intermediate transition coating and a working surface layer; the intermediate transition coating is an aluminum oxide coating or a silicon carbide coating; the working surface layer is a zirconium oxide layer; and the zirconium oxide layer is doped with a rare earth oxide. With the anti-sticking coating,the sintering boat can be repeatedly used 40 times or more.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

SiC-ZrB2 gradient surface coating of Sic-based composite material and preparation method thereof

ActiveCN105906380AImprove anti-ablation performanceAlleviate thermal expansion coefficient differencesChemical compatibilityOxidation resistant

The invention relates to a SiC-ZrB2 gradient surface coating of a SiC-based composite material and a preparation method thereof, and belongs to the field of ceramic based composite material oxidation protection technology. The method comprises mixing nanometer SiC powder and nanometer ZrB2 powder by different mole ratios, then respectively mixing them with ceramic precursor, solvent and the like to prepare slurries containing different powder proportions, coating the slurries onto the surface of the composite material in sequence from the smaller SiC mole ratio to the greater SiC mole ratio, thereby forming a gradient coating after curing and dissociation. The coating has good physical and chemical compatibilities with the substrate material, without obvious boundary between layers. The self-coalescence ability and the erosion resistance of the coating increase gradually from inside to outside; and the coating is characterized in wide temperature range oxidation resistance. The SiC-ZrB2 gradient surface coating of the SiC-based composite material and the preparation method thereof are simple in process, easy to scale up, suitable for industrial production, with high efficiency and wide process window, and with preparation cost being greatly reduced.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Multilayer antioxidant high-temperature-resistant SiC/Ta/C/Ta/SiC coating and preparation method thereof

ActiveCN103722849AImproves antioxidant propertiesMitigates differences in coefficient of thermal expansionLayered productsOxidation resistantMicrostructure

The invention discloses a multilayer antioxidant high-temperature-resistant SiC / Ta / C / Ta / SiC coating and a preparation method thereof. The multilayer antioxidant high-temperature-resistant SiC / Ta / C / Ta / SiC coating is formed by laminating SiC layers, Ta layers and C layers, and is characterized in that the laminating sequence is the SiC layer, the Ta layer, the C layer, the Ta layer and the SiC layer, or SiC layer, the Ta layer, the C layer, the Ta layer, the SiC layer, SiC layer, the Ta layer, the C layer, the Ta layer, and the SiC layer, or SiC layer, the Ta layer, the C layer, the Ta layer, the SiC layer, SiC layer, the Ta layer, the C layer, the Ta layer, the SiC layer, SiC layer, the Ta layer, the C layer, the Ta layer and the SiC layer; both sides of the C layer are Ta layers; the innermost layer and the outermost layer are SiC layers; and the Ta layer, the C layer, the Ta layer and the SiC layer are sequentially deposited on the prepared SiC layer with a chemical vapor deposition method so as to obtain the multilayer antioxidant high-temperature-resistant SiC / Ta / C / Ta / SiC coating. According to the coating and the preparation method thereof, the outer SiC layer forms a layer of SiO2 film in a high-temperature aerobic environment, so that diffusion of oxygen atoms can be prevented effectively, and meanwhile, a TaC layer can be formed on a contact surface of the Ta layer and the C layer to further improve the antioxidation performance. Alternate deposition of coatings can effectively relieve differences of coefficients of thermal expansion of the coatings and improve the thermal shock performance of the coatings remarkably, the thickness and lay number of a matrix can be controlled by controlling deposition time and deposition times, and the microstructure of the composite coating can be controlled.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

Rust-proof pigment

InactiveCN104789049ALarge specific surface areaImprove corrosion resistanceAnti-corrosive paintsPigment pastesFatty acidPetroleum

The invention discloses a rust-proof pigment. The rust-proof pigment comprises the following raw materials in parts by weight: 30-50 parts of scale-shaped zinc powder, 2-10 parts of modified aluminum tripolyphosphate, 15-20 parts of titanium dioxide powder, 30-35 parts of zinc phosphate, 1-2 parts of calcium phosphate, 8-10 parts of calcium carbonate, 2-7 parts of a pigment dispersing agent, 2-5 parts of a silicane coupling agent, 3-7 parts of ammonium molybdate, 1-2 parts of coconut fatty acid diethanol amide, 10-15 parts of a dinonylnaphthalene sulfonic acid, 5-10 parts of ethyl orthosilicate, 0.5-0.9 part of a polyaspartic acid and 0.5-0.7 part of petroleum sodium sulfonate, and further comprises 1.5-3.2 parts of sepiolite powder. The rust-proof pigment disclosed by the invention is low in production cost; environmental pollution is avoided, that is, an environmental protection function is achieved; the rust-proof pigment is high in storage stability and cost performance, and has a certain of rust-proof and comprehensive performance.

Owner:SHUANGLE CHEM PIGMENT YANGZHOU CITY

Binder-phase wolfram-carbide (WC) hard alloy and preparation method thereof

The invention discloses binder-phase wolfram-carbide (WC) hard alloy and a preparation method thereof. The hard alloy comprises WC powder serving as a hard phase and Fe3Al alloy powder serving as a binder phase, wherein the particle diameter of the WC powder is 3-5 microns, and the Fe3Al alloy powder accounts for 5.5-15% of the hard alloy and has the particle diameter of 1-3 microns. The preparation method of the hard alloy comprises the steps of: firstly proportioning the WC and binder Fe3Al powder which is sieved and selected in advance and has a uniform particle size according to required mass percentage, adding additives, and mixing and grinding in a ball mill; then carrying out vacuum drying, sieving to remove aggregates, and then, granulating and pressing; and finally placing formed press blanks in a vacuum sintering furnace, and carrying out vacuum sintering and hot isostatic pressing treatment, thereby preparing the hard alloy.

Owner:SOUTHEAST UNIV

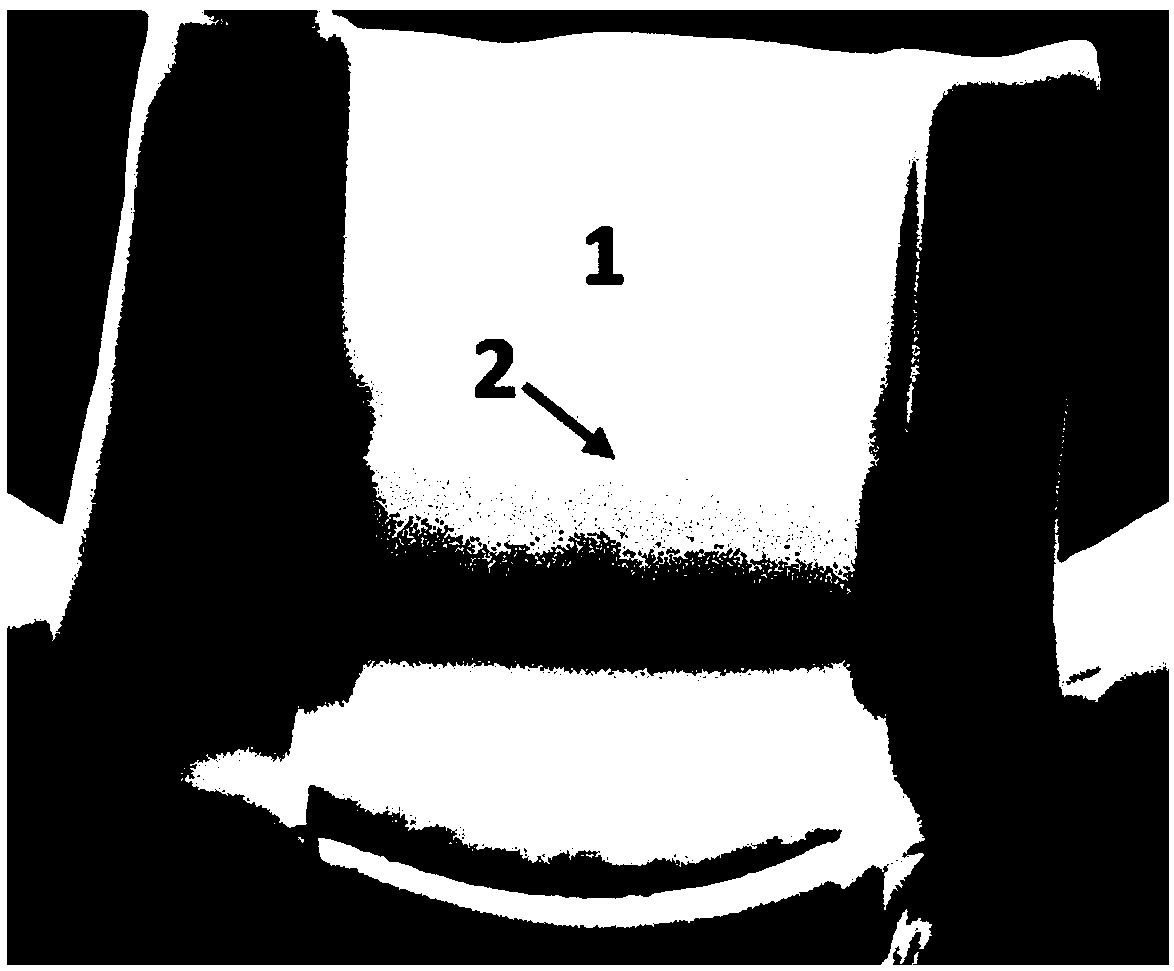

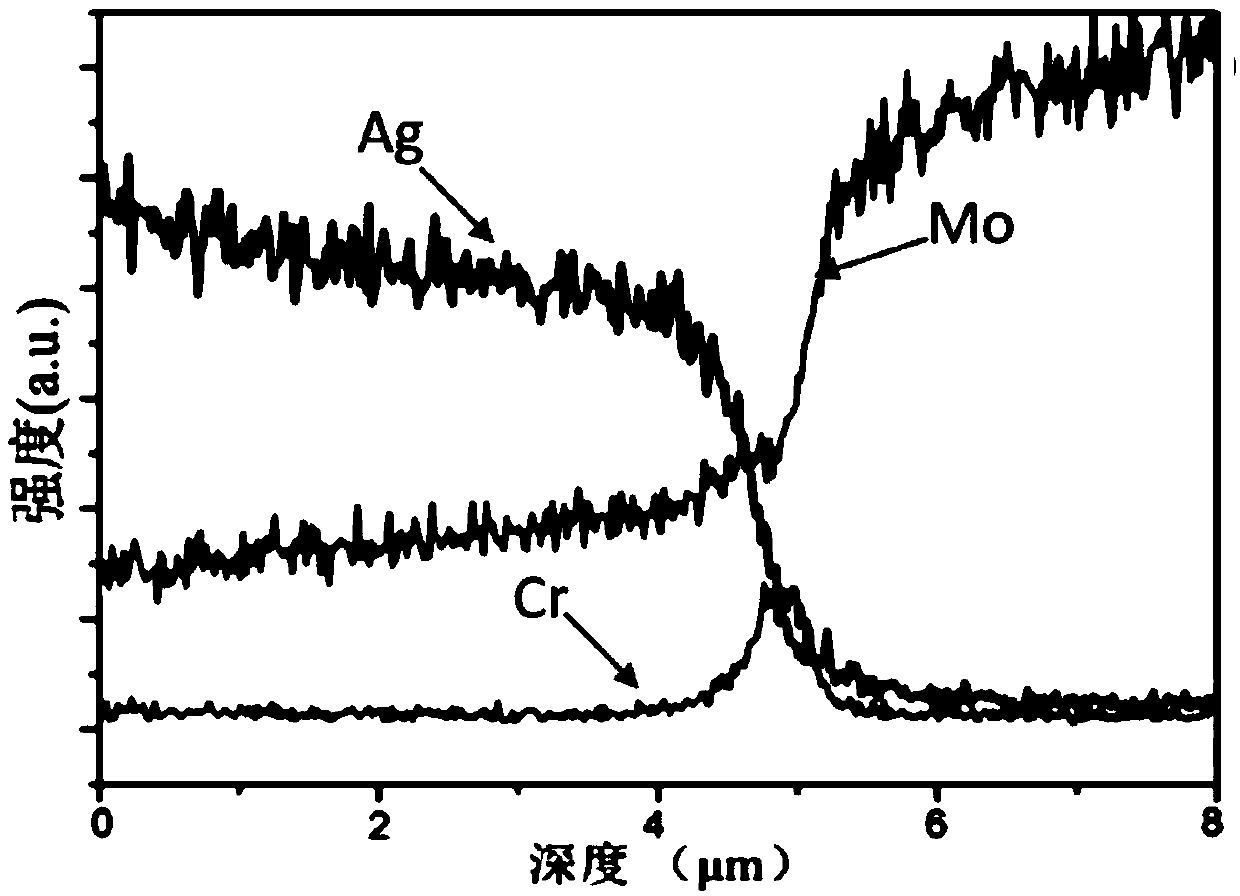

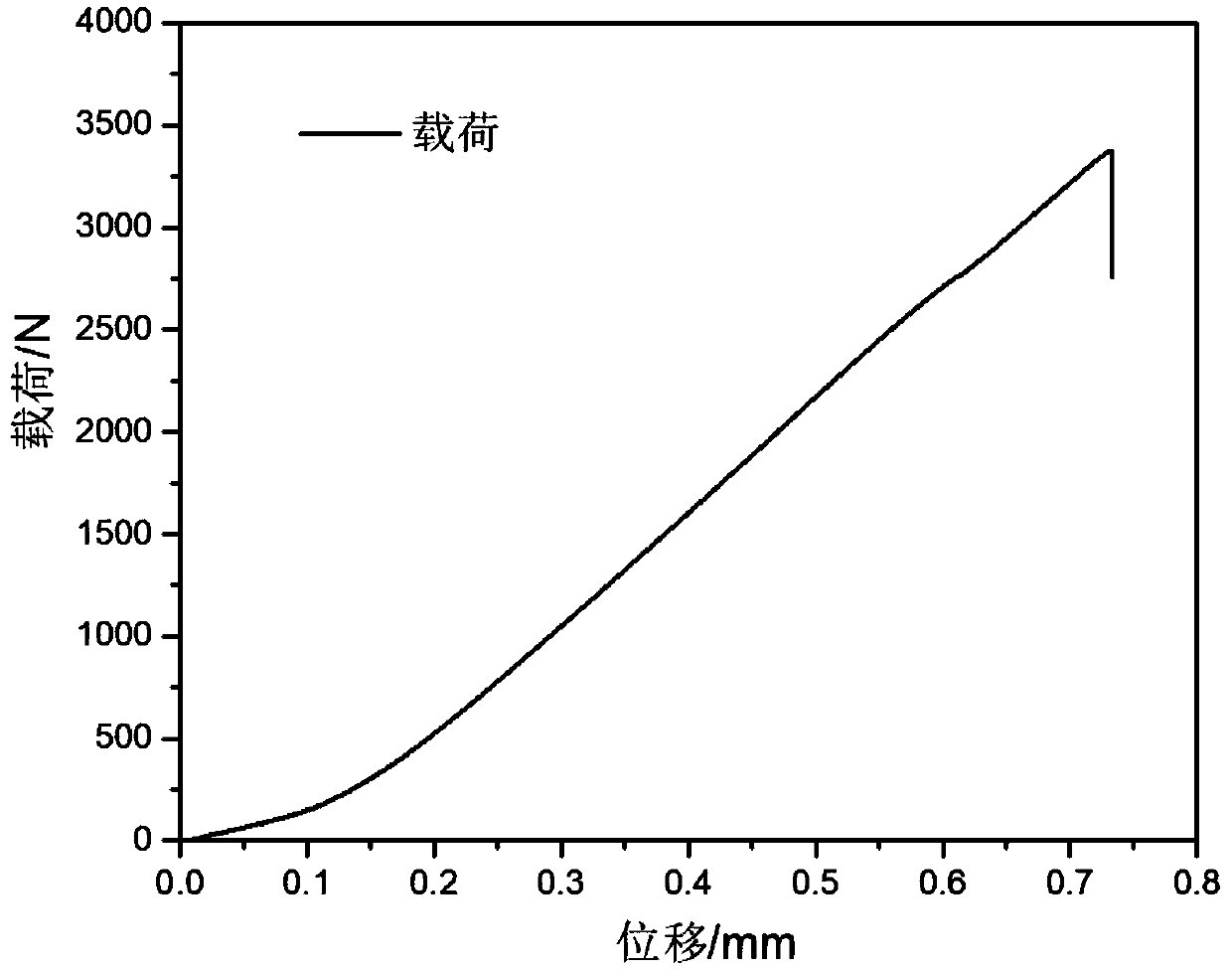

Molybdenum-silver laminar composite material and preparation method and application thereof

ActiveCN110872692AAlleviate thermal expansion coefficient differencesGood solid solution effectVacuum evaporation coatingSputtering coatingThermal fatigueOxidation resistant

The invention discloses a molybdenum-silver laminar composite material and a preparation method and application of the molybdenum-silver laminar composite material. The preparation method includes thesteps that at least a molybdenum base material and a metal target having good solid solubility with molybdenum are placed in a vacuum environment, and a metal intermediate layer is formed on the surface of the molybdenum base material through deposition with a direct-current magnetron sputtering method; at least the molybdenum base material with the metal intermediate layer formed on the surfaceand the metal silver target are placed in a vacuum environment, and a silver layer is formed on the surface of the metal intermediate layer through deposition with the direct-current magnetron sputtering method; and an obtained molybdenum base material-metal intermediate layer-silver layer composite structure is annealed, so that metal elements constituting the metal intermediate layer are continuously diffused into the molybdenum base material and the silver layer. By means of the preparation method, the silver / metal intermediate layer / molybdenum laminar composite material can be successfullyprepared, and the preparation method is environmentally friendly, high in process stability and capable of realizing large-scale production; and besides, the obtained molybdenum-silver laminar composite material is high in density, excellent in bonding strength and excellent in oxidative corrosion resistance and thermal fatigue resistance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

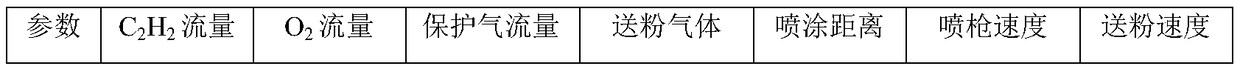

A charcoal/charcoal composite material ablation-resisting coating and a preparing process thereof

InactiveCN105461357AStress reliefAlleviate thermal expansion coefficient differencesSurface layerSpray coating

A charcoal / charcoal composite material ablation-resisting coating and a preparing process thereof are disclosed. The coating comprises a SiC transition coating and a tungsten spraying coating. The surface layer of a substrate is covered with the SiC transition coating. The SiC transition coating is coated with the tungsten spraying coating. The SiC transition coating comprises 70-80% by mass of Si powder, 10-20% by mass of C powder and 5-15% by mass of Al2O3 powder. The preparing process includes subjecting the substrate to surface treatment, preparing the SiC transition coating, screening a tungsten powder material, preparing a tungsten coating / SiC / charcoal / charcoal composite material, relieving stress of a tungsten coating / SiC / charcoal / charcoal composite material coating, and subjecting the coating to ablation performance testing by adopting an oxyacetylene flame ablating device. According to the charcoal / charcoal composite material ablation-resisting coating and the preparing process, oxyacetylene flame ablation resisting time of a charcoal / charcoal composite material at about 2800 DEG C is prolonged from 10 s to 120 s and the coating does not shed.

Owner:CENT SOUTH UNIV

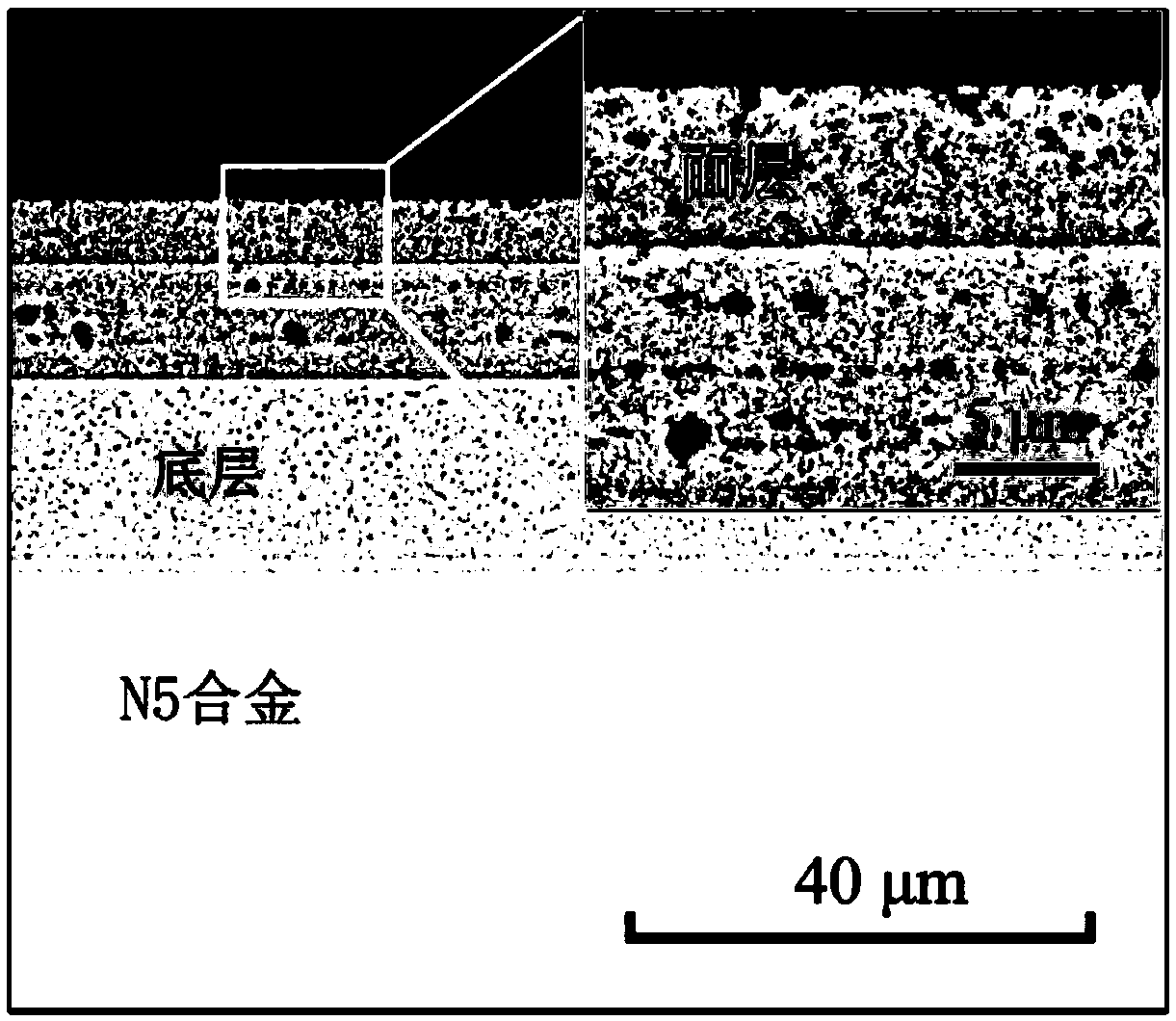

Composite metal ceramic coating for high-temperature alloy protection and preparing method of composite metal ceramic coating

ActiveCN108796461AAlleviate thermal expansion coefficient differencesReduce thermal stressVacuum evaporation coatingSputtering coatingSputteringCrystal structure

The invention discloses a composite metal ceramic coating for high-temperature alloy protection and a preparing method of the composite metal ceramic coating. The coating comprises a face layer and abottom layer with a nano columnar crystal structure. The face layer comprises at least two metal ceramic sub layers, and a metal parent phase and a dispersed distribution nitride ceramic phase are specifically included. In the direction from the surface of the composite metal ceramic coating to an alloy matrix, the doping amount of the nitride ceramic phase is gradually reduced, and the distribution interval of the volume fraction of the nitride ceramic phase is 0.1-60%. According to the preparing method of the coating, magnetic control sputtering is adopted for preparing a bottom layer coating, and then, non-balance reaction magnetic control sputtering is utilized for preparing the face layer of the doped ceramic phase. Through the structure, the heat expansion coefficient of the coatingis gradually increased from top to bottom, jumping changes of the heat expansion coefficient on the coating / oxide film interface are reduced, accordingly, the heat stress in an oxide film in the heatcirculation process is relieved, and the capability of oxide film peeling resisting of the coating in the heat circulation is enhanced.

Owner:JINAN UNIVERSITY

Tin-based solder and preparation method thereof

ActiveCN112342417AHigh bonding strengthImprove reliabilityWelding/cutting media/materialsSoldering mediaTinMicrostructure

The invention discloses tin-based solder and a preparation method thereof, and belongs to the technical field of electronic materials and electronic preparation. The tin-based solder comprises the following components in percentage by mass: 9.0 percent of Zn, 2.0 percent of Bi, 1.0 percent to 2.0 percent of Ag, 1.0 percent to 2.0 percent of Sb, and the balance Sn. The novel tin-based lead-free solder provided by the invention can replace traditional tin-lead solder, and has the advantages of lower melting point, favorable wettability, favorable mechanical strength, favorable thermal fatigue property, high bonding strength and high weldability. According to the tin-based solder and the preparation method thereof provided by the invention, an Sn-Ag intermediate alloy is prepared preferentially, and then the required alloy elements are proportioned according to requirements, packaged into a glass test tube in a vacuum mode and smelted to prepare the Sn-based novel lead-free solder, so that that microalloy elements can be ensured to be added into solder alloy more evenly, and accurate control over components and a good microstructure can be guaranteed; and the finally obtained solder is high in bonding strength and high in reliability.

Owner:KUNMING UNIV OF SCI & TECH

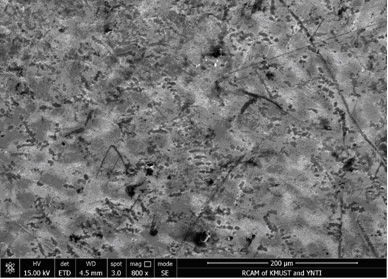

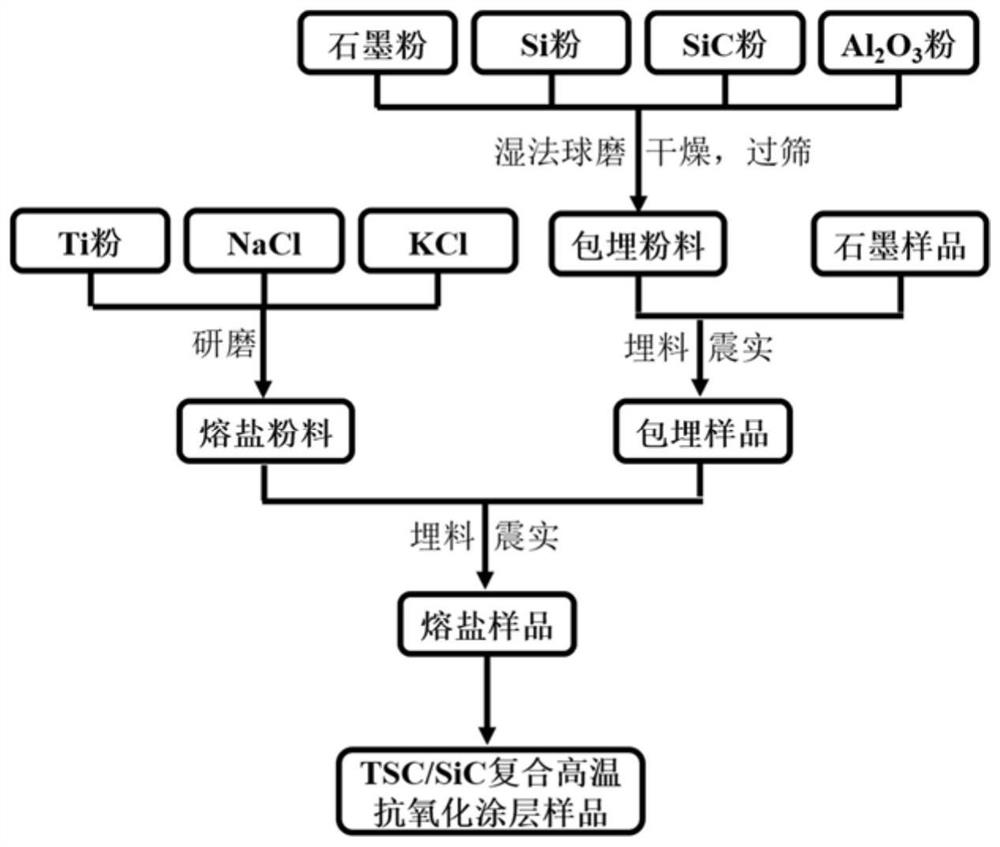

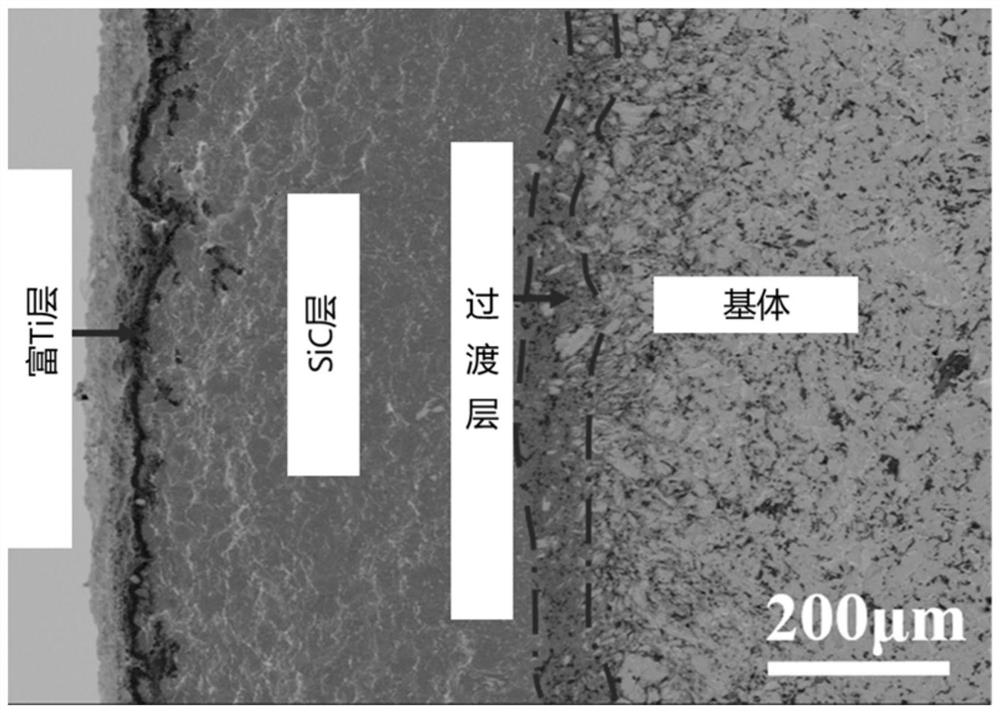

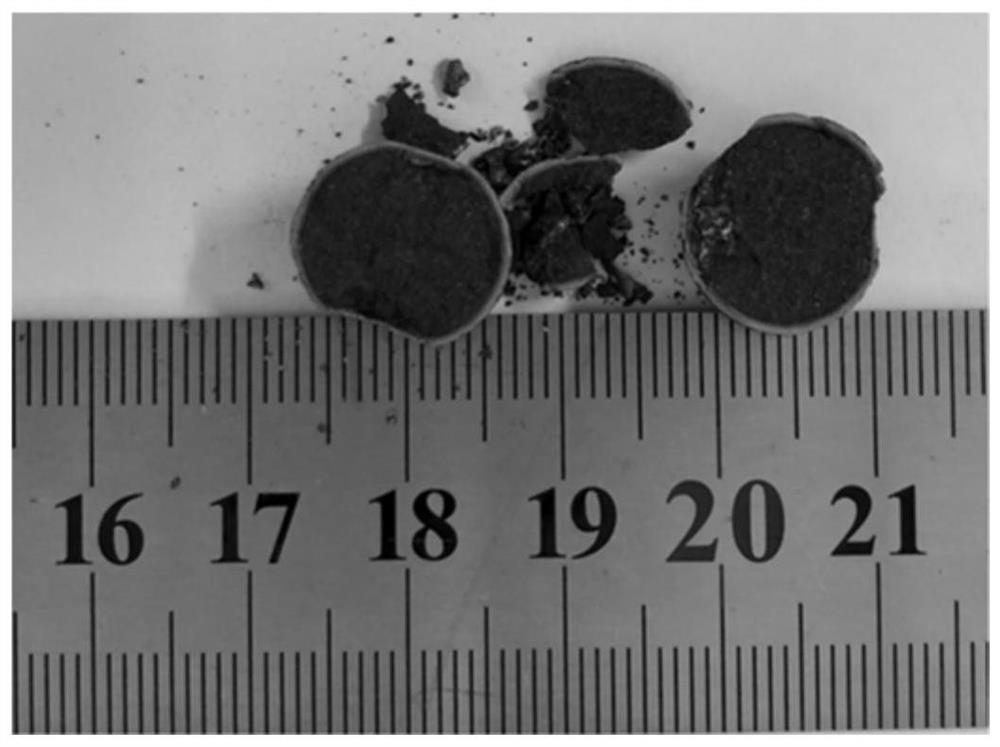

Composite high-temperature anti-oxidation coating of graphite material for nuclear reactor and preparation method of composite high-temperature anti-oxidation coating

ActiveCN113526983AImprove antioxidant capacityHigh bonding strengthNuclear energy generationNuclear reactorMolten salt

The embodiment of the invention relates to the technical field of nuclear application, in particular to a composite high-temperature anti-oxidation coating of a graphite material for a nuclear reactor and a preparation method of the composite high-temperature anti-oxidation coating. The preparation method comprises the following steps: mixing Si powder, SiC powder, Al2O3 powder and graphite powder to obtain embedding powder; embedding the graphite sample in the embedding powder to obtain an embedded sample; blending the Ti powder, NaCl and KCl to obtain molten salt powder; embedding the embedding treatment sample in molten salt powder to obtain a molten salt treatment sample; and washing and drying the sample to remove residual powder on the surface to obtain the product, wherein the sintering atmosphere during embedding is inert atmosphere, and the heat preservation time is less than or equal to 2 hours; the temperature during molten salt sintering is 700-1200 DEG C, and the heat preservation time is longer than or equal to 2 hours. According to the preparation method, an embedding method and a molten salt method are combined, so that the Ti3SiC2 / SiC composite high-temperature anti-oxidation coating is prepared on the surface of the graphite material for the nuclear reactor. The preparation temperature is low, the composite coating is high in oxidation resistance, the bonding strength between the composite coating and a graphite base material is high, and the grain size of the formed composite coating is small inside and large outside.

Owner:TSINGHUA UNIV

Composite coating for titanium alloy gasket and preparation method thereof

PendingCN113755780AReduce stressImprove wear resistanceMolten spray coatingTitanium alloyGalvanic corrosion

The invention discloses a composite coating for a titanium alloy gasket and a preparation method thereof. The composite coating is composed of a nickel-based metal transition layer with the thickness of 0.06mm and a ceramic surface layer with the thickness of 0.3-0.4 mm. The nickel-based metal transition layer comprises, by mass, 60-85% of Ni, 10-30% of Cr, 3-6% of B, 3-6% of Si, 2-5% of Fe and 2-5% of Mo. The ceramic surface layer comprises, by mass, 70-90% of Al2O3, 15-30% of TiO2 and 3-10% of ZrO2. The preparation method of the composite coating comprises the steps that firstly, oil stains, impurities and the like on the surface of the titanium alloy gasket are removed in a surface cleaning and compressed air sand blasting roughening mode; and then a uniform and compact insulating, wear-resistant and corrosion-resistant composite coating is prepared through a supersonic flame spraying technology and a high-speed plasma spraying technology, so that the insulating, wear-resistant and corrosion-resistant characteristics of the titanium alloy gasket are improved, contact potential is isolated, galvanic corrosion is avoided, and accordingly the sealing reliability of pipeline system equipment and accessories is improved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

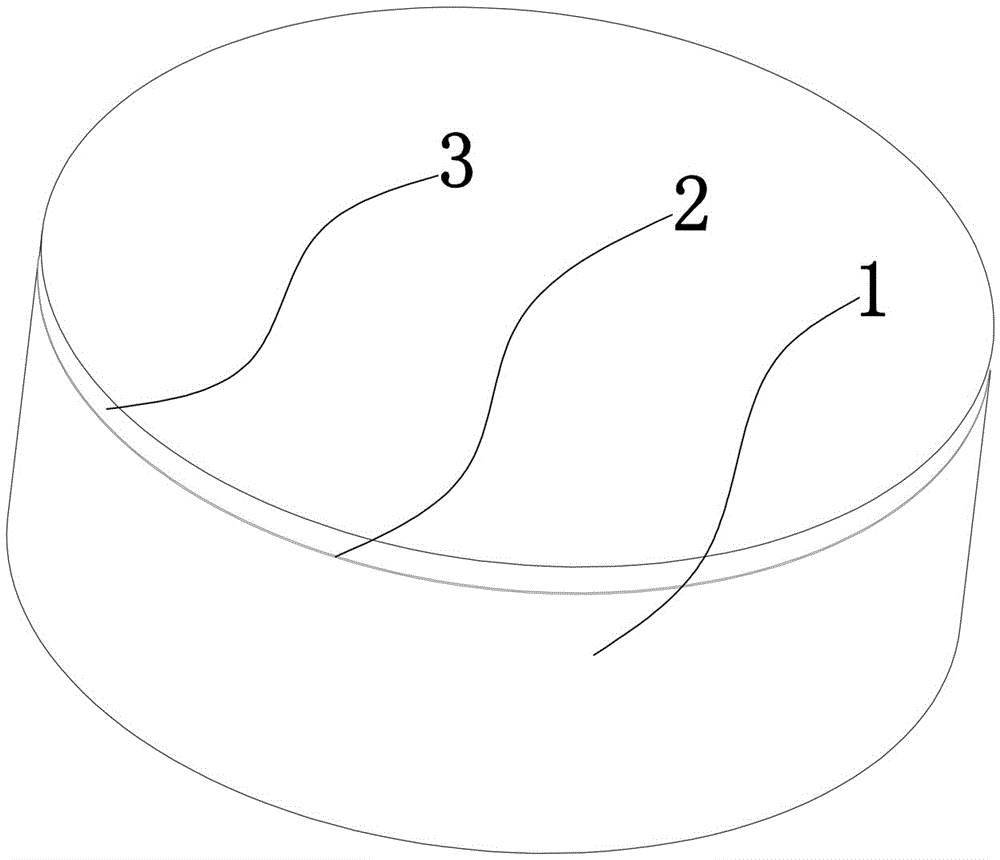

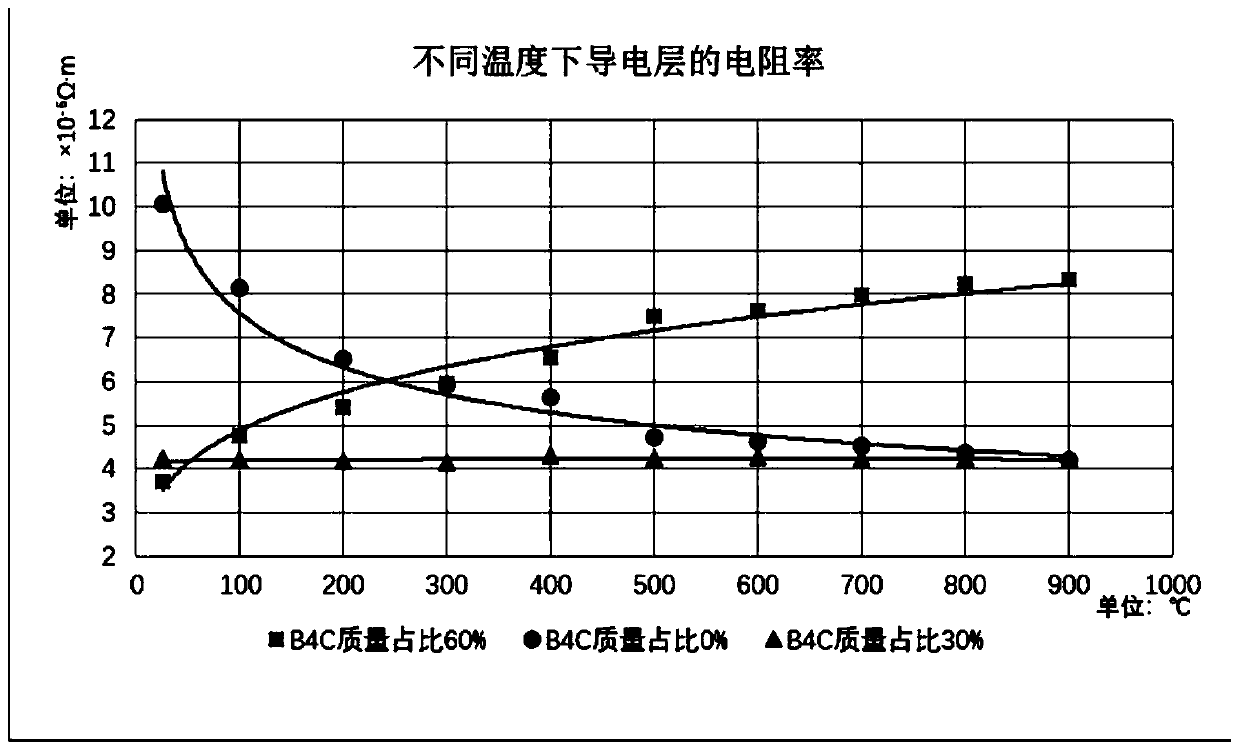

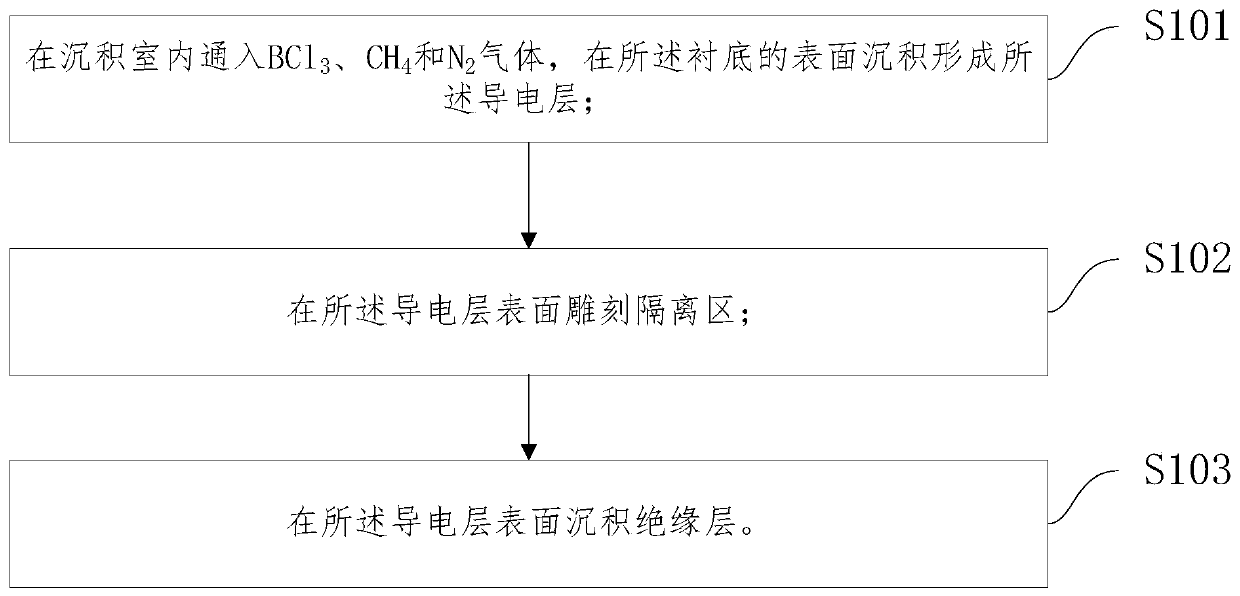

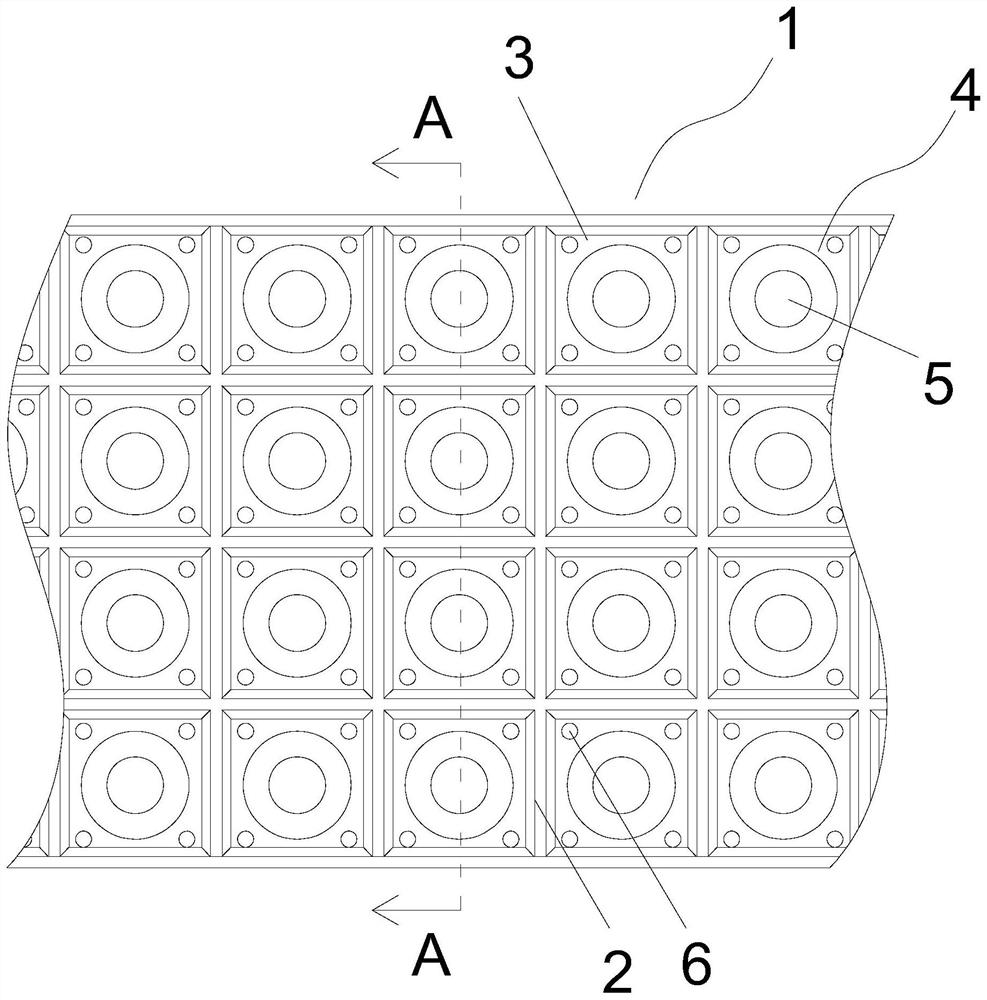

Heater and preparation method thereof

ActiveCN110662314ASimplify the temperature control programSolve the negative temperature characteristic of resistivityOhmic-resistance heating detailsHeating element materialsThermal dilatationTemperature control

The invention discloses a heater and a preparation method thereof. The heater comprises a pyrolytic boron nitride substrate (1), a conducting layer (2) and an insulating layer (3), wherein the conducting layer (2) and the insulating layer (3) are sequentially arranged on the surface of the substrate (1) in a stacked mode; and the conducting layer (2) comprises pyrolytic graphite doped with boron carbide; the mass of the boron carbide is 0.1%-50% of that of the new conducting layer. According to the embodiments of the invention, the new conducting layer is arranged in the heater; the differencebetween the expansion coefficient of the new conducting layer and the expansion coefficients of the insulating layer and the substrate is small, so that a layering phenomenon is not liable to occur.Moreover, the resistance of the new conducting layer does not fluctuate greatly along with the rise of temperature, so that a heating effect is good. With the heater and the preparation method thereofof the invention adopted, the problem of the resistivity negative temperature characteristic of the pyrolytic graphite conductive coating is solved; the thermal expansion coefficient difference of aconducting coating and a boron nitride substrate in the prior art is reduced; the temperature control procedure of the heater can be simplified; and the layering problem of the conducting coating canbe solved.

Owner:博宇(天津)半导体材料有限公司 +1

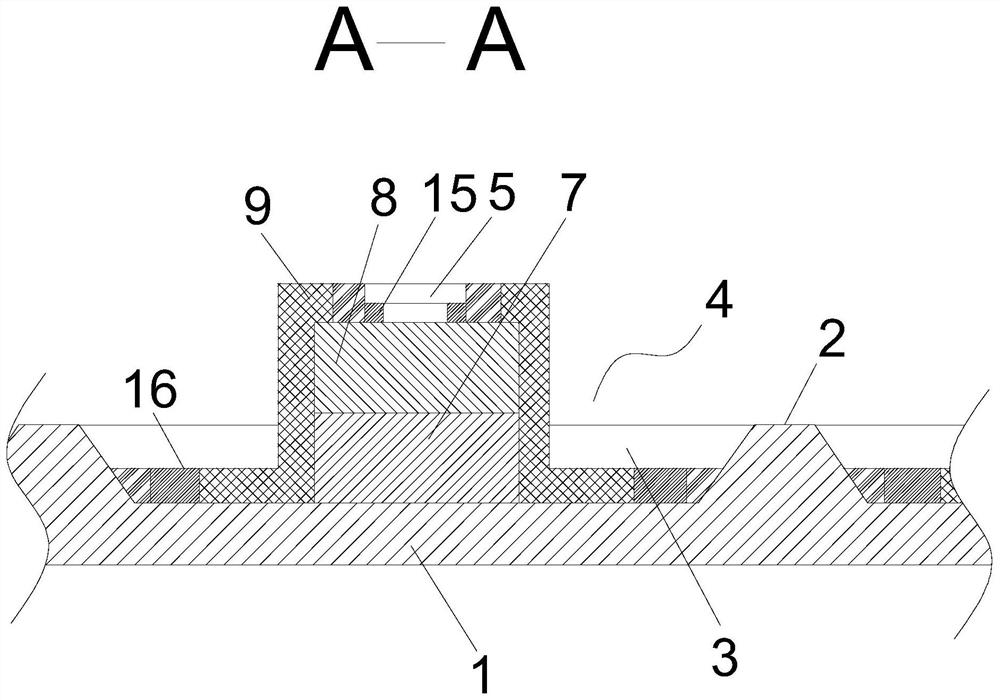

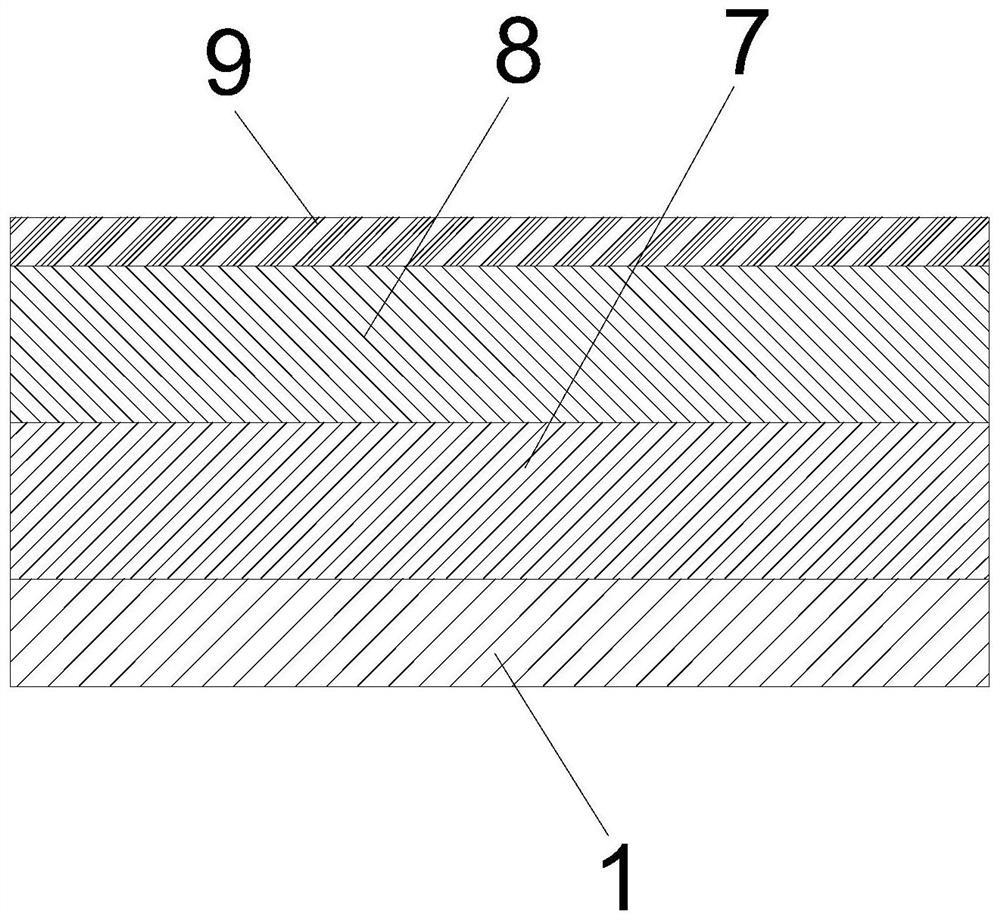

VCSEL chip and manufacturing method thereof

PendingCN111900621AHigh strengthIncrease stiffnessLaser detailsSemiconductor lasersSemiconductorMaterials science

The invention discloses a VCSEL chip and a manufacturing method thereof. The VCSEL chip comprises a semiconductor substrate,the surface of one side of the semiconductor substrate is provided with a plurality of emitting laser cavities which are uniformly arranged in the transverse direction and the vertical direction, anemitting laser unit is arranged in the emitting laser cavity, the emitting laser unit comprises an N-type Bragg reflector layer, the N-type Bragg reflector layer is in contact with the surface of the semiconductor substrate, a P-type Bragg reflector layer is arranged on the surface of one side, back to the semiconductor substrate, of the N-type Bragg reflector layer, and oxide layers cover the outer sides of the P-type Bragg reflector layer and the N-type Bragg reflector layer. The VCSEL chip is stable in structure, high in reliability, good in heat dissipation performance and long in service life.

Owner:江苏英弗德电子有限公司

Binding-phase TiC/WC composite hard alloy and preparation method thereof

ActiveCN103898387ASuperior wear and corrosion resistanceGood wear resistanceCemented carbideHot isostatic pressing

The invention discloses a binding-phase TiC / WC composite hard alloy and a preparation method thereof. The binding-phase TiC / WC composite hard alloy is prepared from the following raw materials in percentage by mass: 84-94% of hard-phase TiC and WC mixed powder, 5-15% of ternary intermetallic compound Co2AlTi powder and 0.5-1% of stearic acid additive, wherein the hard-phase TiC and WC mixed powder serves as a hard phase and has uniform granularity, and the ternary intermetallic compound Co2AlTi powder serves as a binding phase. The method comprises the steps of firstly, mixing and grinding the raw materials in a ball mill; carrying out vacuum drying, then, screening to remove aggregates, then, granulating, and then, pressing at the pressure of 800-1,200kg / cm<2>; putting a prepared pressed shape in a vacuum sintering furnace with the degree of vacuum of 3*10<-4> to 5*10<-4>MPa, heating to the temperature of 1,200-1,350 DEG C, carrying out vacuum sintering for 1-2 hours, then, carrying out hot isostatic pressing treatment for 1-5 hours at the temperature of 1,200-1,350 DEG C and the pressure of 80-100MPa, cooling, and then, taking out, thereby obtaining the hard alloy.

Owner:SOUTHEAST UNIV

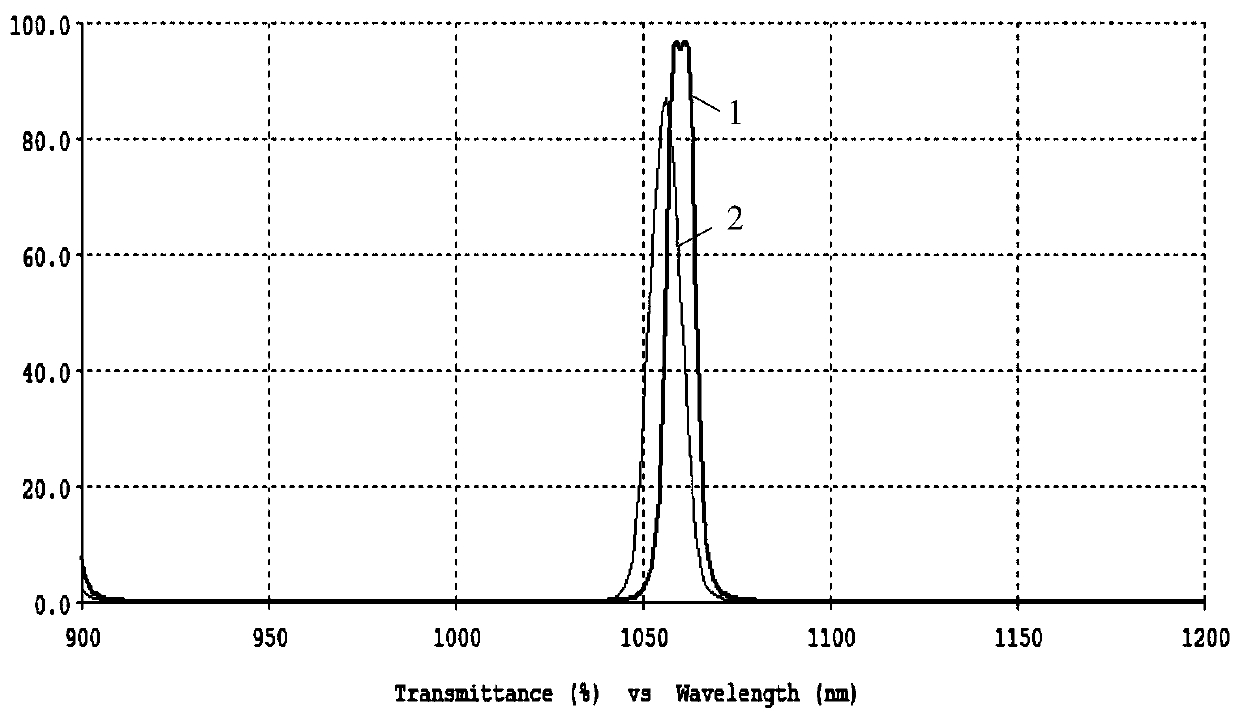

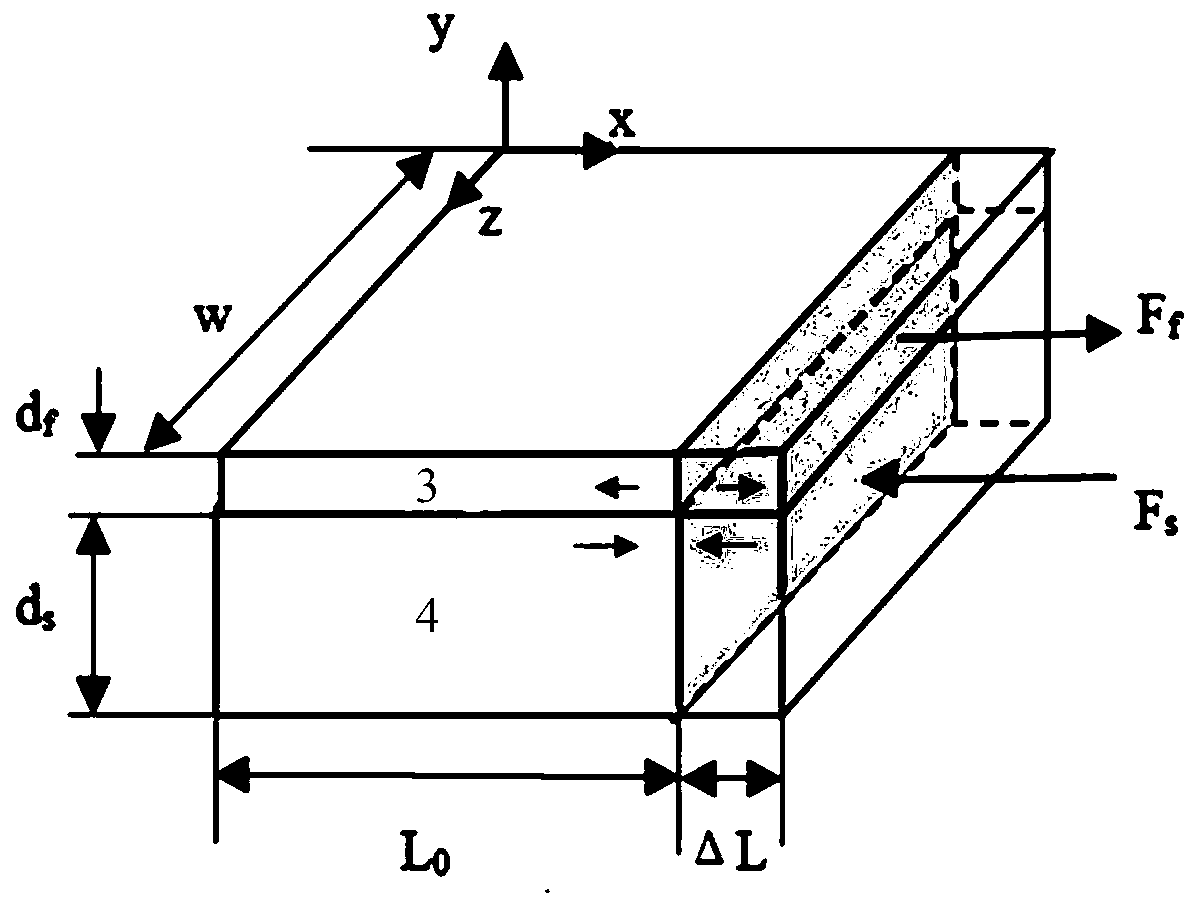

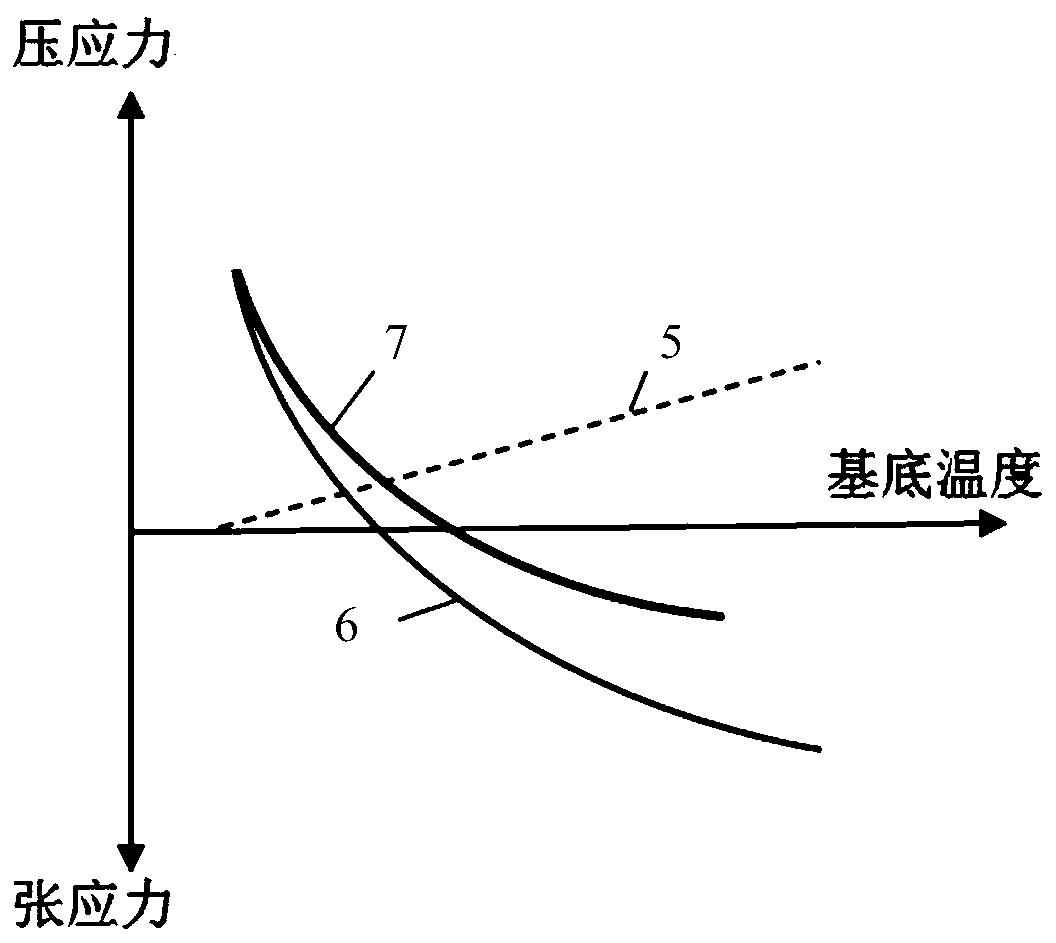

Low-stress multilayer film optical filter and preparation method thereof

PendingCN111399103AIncrease aggregation densityIncrease the tensile stressOptical elementsPhysical chemistryThin membrane

The invention discloses a low-stress multilayer film optical filter and a preparation method thereof, a substrate is 3.3 borosilicate glass, and the multilayer film optical filter is a double-half-wave narrow-band interference optical filter. 3.3 borosilicate glass has a linear expansion coefficient of 3.3 * 10 <-6 > / degree; in order to reduce the junction stress of the optical filter, two technologies of substrate heating and ion assistance are adopted. When the temperature of the substrate is 250 DEG C, the aggregation density of the TiO2 film is close to 1, the aggregation density of the SiO2 film is close to 0.92, and the accumulated tensile stress of the optical filter is 10.8 MPa; if the ion energy is selected to be 350 eV, the ratio JI / JM of the number of the auxiliary ions reachingthe substrate to the number of the deposited integrators is 0.15 and 0.05 respectively, so that the aggregation densities of TiO2 and SiO2 are close to 1 and 0.96 respectively, and the junction cumulative pressure stress of the optical filter is-7MPa. The low-stress film optical filter can be widely applied to various photoelectric instruments.

Owner:HANGZHOU KOTI OPTICAL TECH

Special low-crack-sensitivity and high-performance Ni-based composite powder for laser cladding

InactiveCN106400009AReduce sensitivityHigh hardnessMetallic material coating processesHardnessHigh surface

The invention provides special low-crack-sensitivity and high-performance Ni-based composite powder for laser cladding. The powder is prepared from raw materials in percentage by mass as follows: 8.0%-10.0% of Co powder, 8.5%-12.0% of Fe powder, 10.0%-13.0% of Cr powder, 2.0%-3.5% of Si powder, 28.0%-30.0% of WC powder and the balance of Ni powder. According to the special low-crack-sensitivity and high-performance Ni-based composite powder for laser cladding, by the aid of the solution strengthening mechanism, the fine grain strengthening mechanism and other mechanisms which are formed under mutual effects of Cr, Fe, Co, Ni and WC, a cladding layer has the high hardness and the high toughness and has the relatively low crack sensitivity; the cladding layer prepared from the powder has the high surface hardness, the high corrosion resistance and the high-temperature resistance; and the powder is prepared with a mechanical mixing method, the production technology is simple, and the price advantage is obvious.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

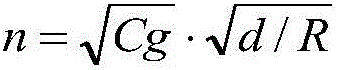

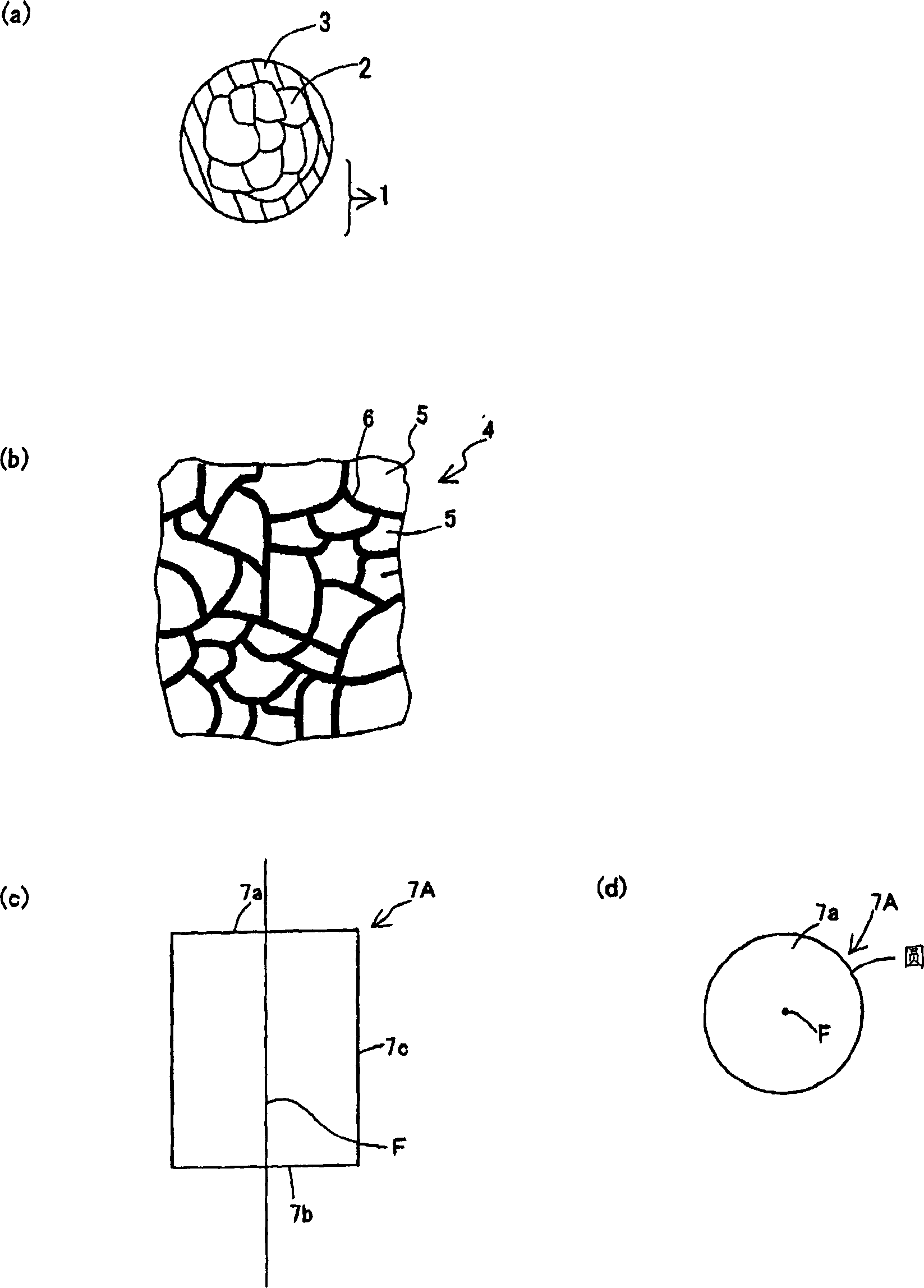

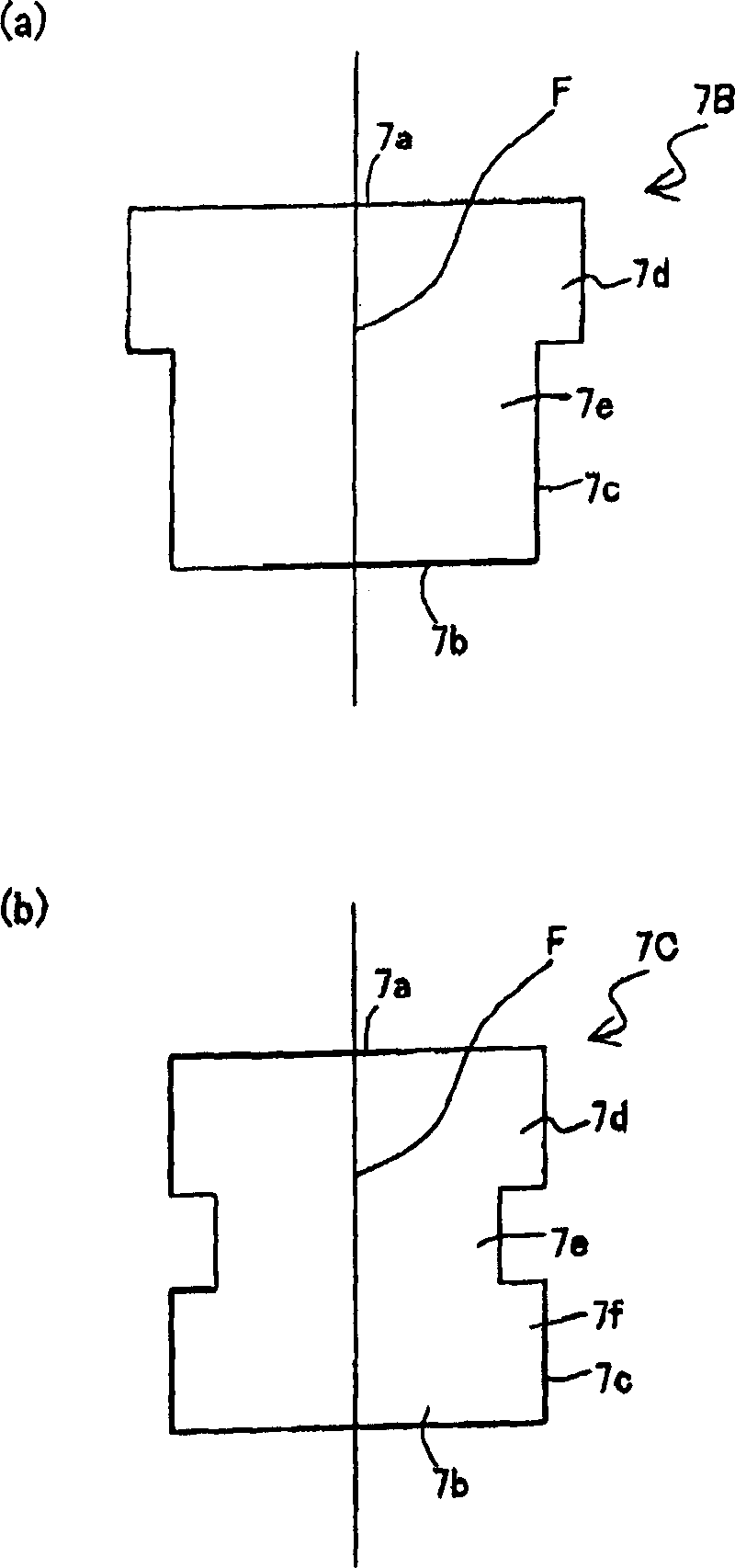

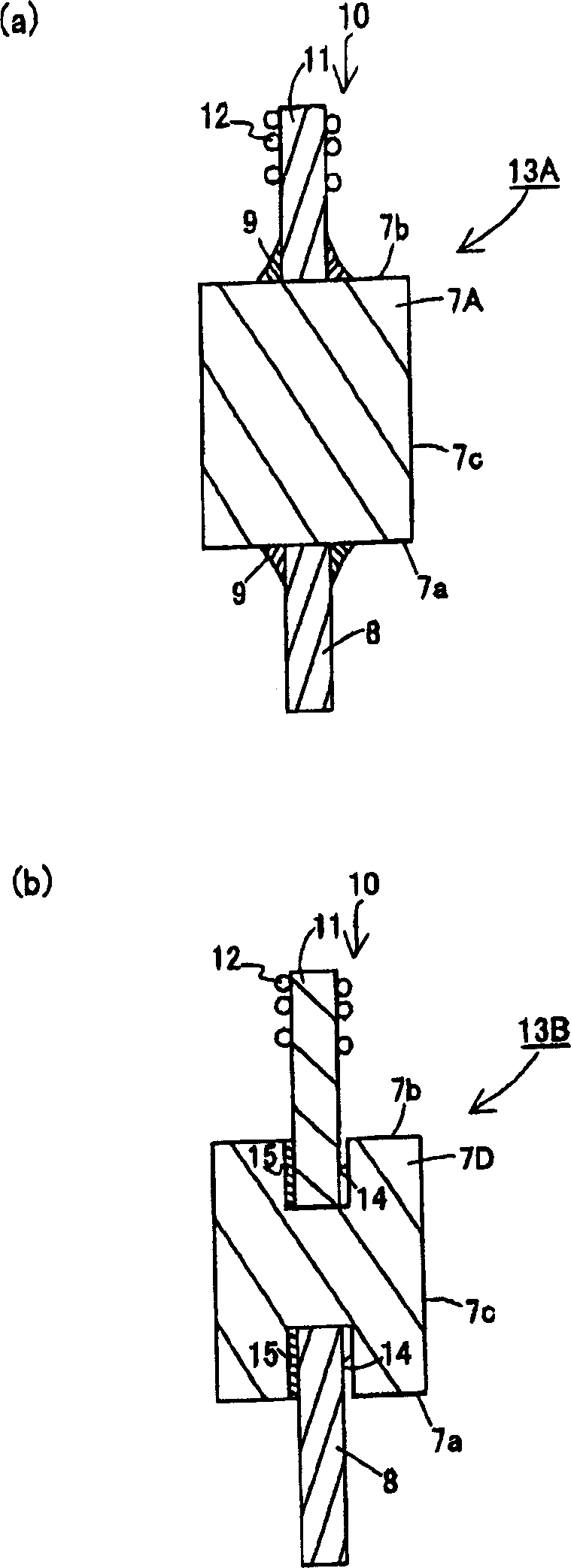

High voltage mercury lamp and sealing material for same

InactiveCN1463028AAlleviate thermal expansion coefficient differencesIncrease internal pressureElectric discharge tubesGas discharge lamp detailsStress concentrationEngineering

An object of the invention is to reduce the adverse effects due to a difference of thermal expansion between a conductive sealing member (7A) and a light-emitting vessel (16) and to provide a reliable high pressure mercury lamp, even when the lamp is operated at a high pressure. The lamp has a light-emitting vessel (16) of quartz and having end portions, an electrode member (10) contained in the vessel (16), and a conductive sealing member (7A). The sealing member (7A) is fixed in the end portion (18) and connected to the electrode member (10). The conductive member (7A) is composed of a sintered body (4) made from silica granules (1) each having a coating (3) of a metal or a metal compound. The sintered body (4) has a conductive network structure made of the metal and having a content of the metal of not higher than 20 volume percent.

Owner:NGK INSULATORS LTD

Workpiece wear-resistant coating and spraying method for same

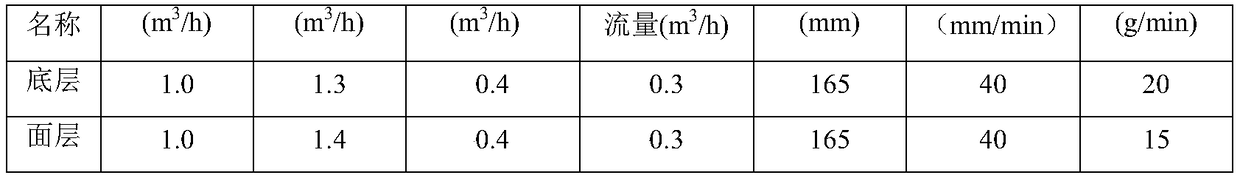

PendingCN109321860AImprove wear resistanceExtended service lifeMolten spray coatingWear resistantCopper

The invention relates to a workpiece wear-resistant coating and a spraying method for the same and belongs to the field of superficial technologies. According to the invention, on one side, the problems that wear-resistant coatings of single-layer structures in the prior art are poor in wear resistance, short in service life, long in replacement duration after halt and low in yield and productionefficiency of slabs can be solved; and on the other side, the problems that offline crystallizers cannot be partially repaired with the prior art, narrow-edged copper plates of the damaged crystallizers can only be used for other purposes and thus production materials are wasted can be solved. The workpiece wear-resistant coating comprises a bottom layer and a face layer, wherein the bottom layerserves as a transition layer and only covers a worn and damaged part of a clad layer; and the face layer covers an entire coating of a workpiece. The spraying method provided by the invention comprises the steps that areas outside a to-be-sprayed area are protected; the bottom layer is sprayed at first; and then protection is removed and the face layer is sprayed. According to the invention, bonding strength between the face layer and a copper base body can be improved; thermal shock resistance of the coating can be enhanced; and the service life of the surface coating of the copper plate of the crystallizer can be prolonged.

Owner:NEW METALLURGY HI TECH GRP

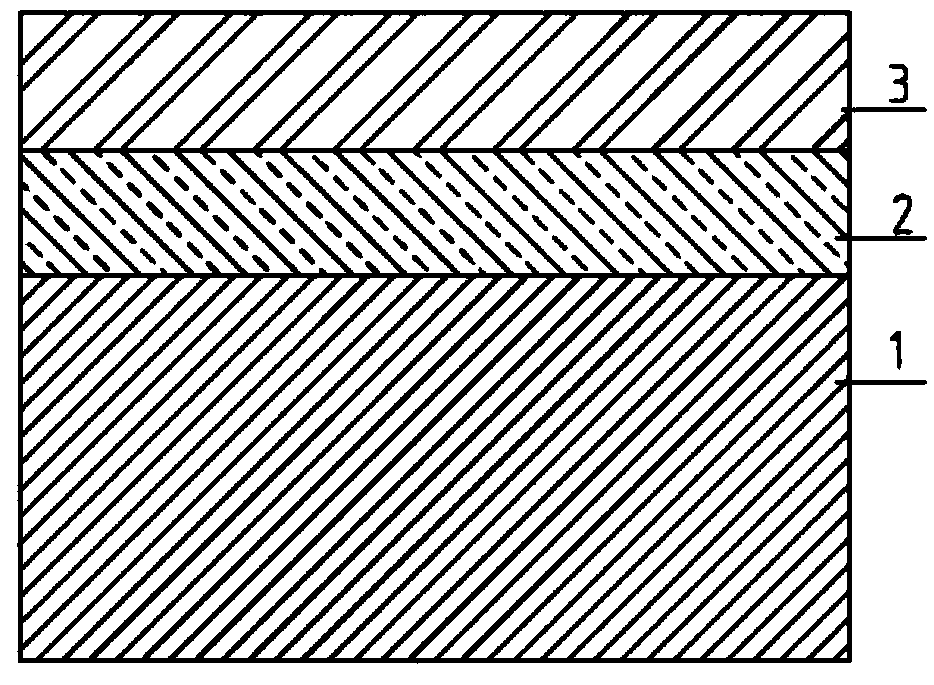

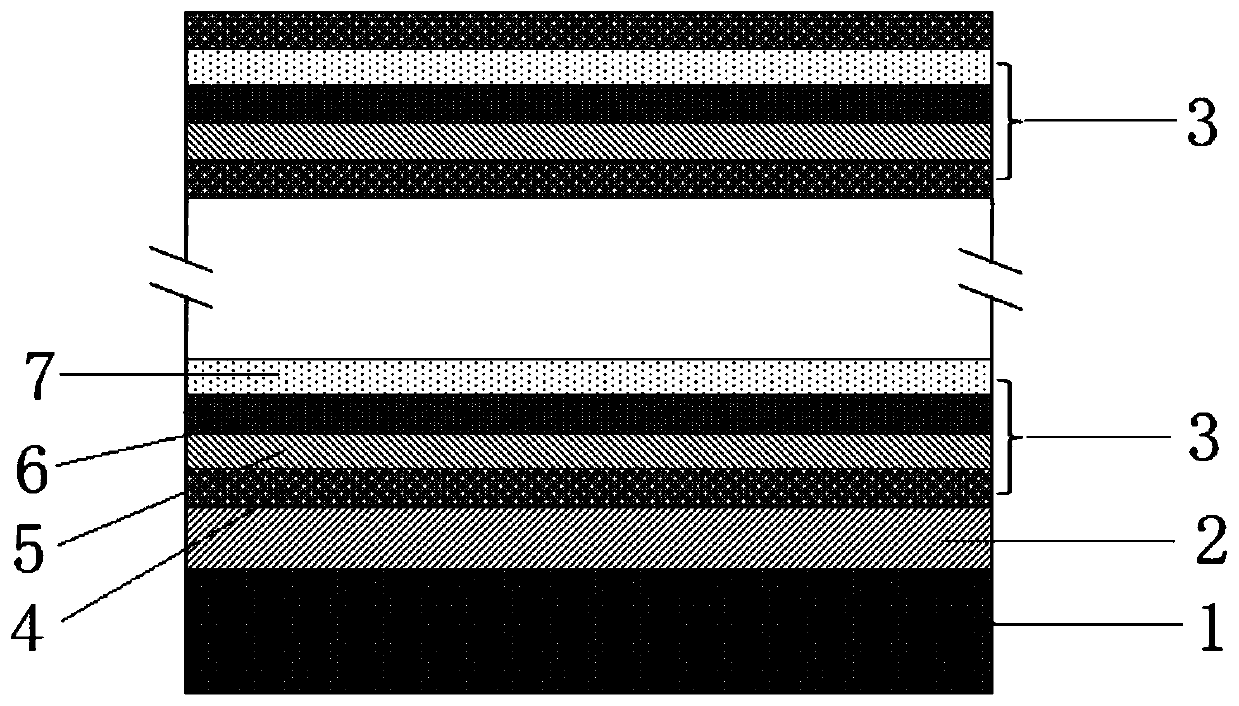

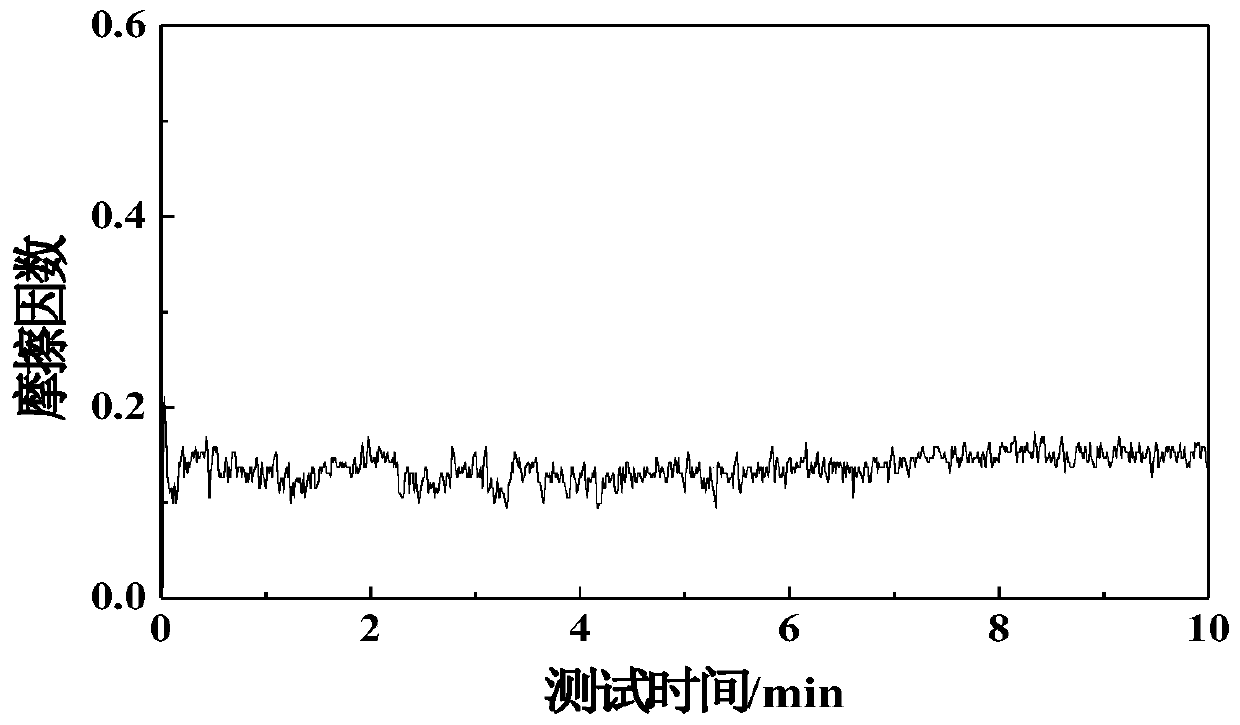

DLC/CNx/MeN/CNx nano-multilayer film and preparation method thereof

ActiveCN110777341AHigh affinityAlleviate thermal expansion coefficient differencesVacuum evaporation coatingSputtering coatingMultilayer membraneThin membrane

The invention relates to the technical field of thin-film materials, and provides a DLC / CNx / MeN / CNx nano-multilayer film for solving the problems that the bonding strength of a traditional DLC thin film and a matrix material is poor, and the wear-resisting performance can also be reduced due to the fact that stress is reduced, and the bonding strength is improved. The DLC / CNx / MeN / CNx nano-multilayer film includes a matrix (1), and further includes a metal transition layer (2) and a nano-multilayer film which are successively deposited on the surface of the matrix, the nano-multilayer film is composed of a plurality of nano-composite units (3), and each nano-composite unit is provided with a DLC layer (4), a first gradient CNx layer (5), a metal nitride layer (6) and a second gradient CNx layer (7) which are successively arranged from bottom to top. The nano-multilayer film can effectively solve the problem of low film-matrix bonding strength of a traditional deposition method, meanwhile internal stress is reduced, and excellent wear resistance is achieved; and the steps of a preparation method are simple, process conditions are easy to control, the preparation process is safe and pollution-free, the cost is low, and industrialization is easy to realize.

Owner:ZHEJIANG UNIV OF TECH

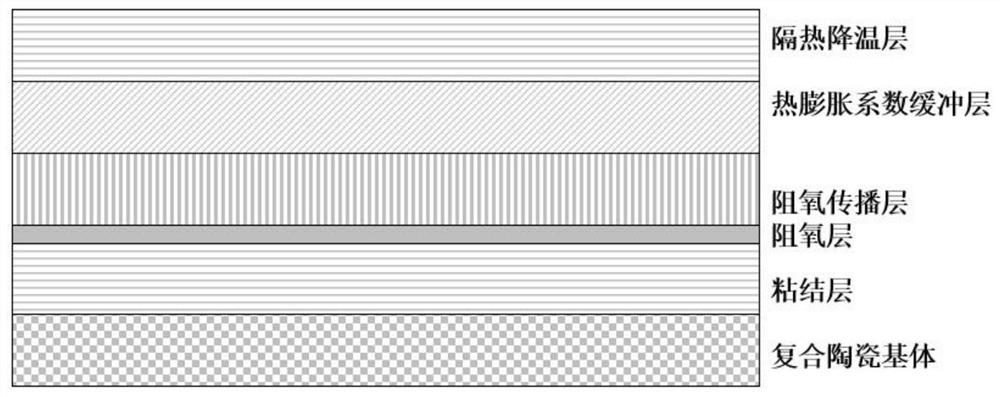

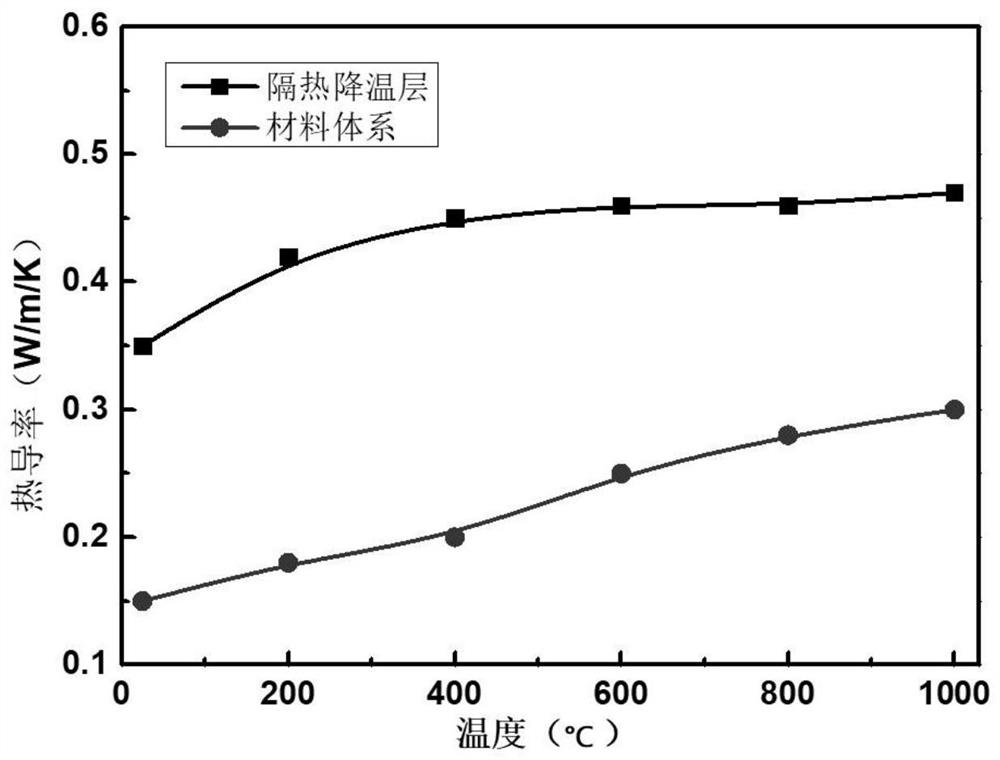

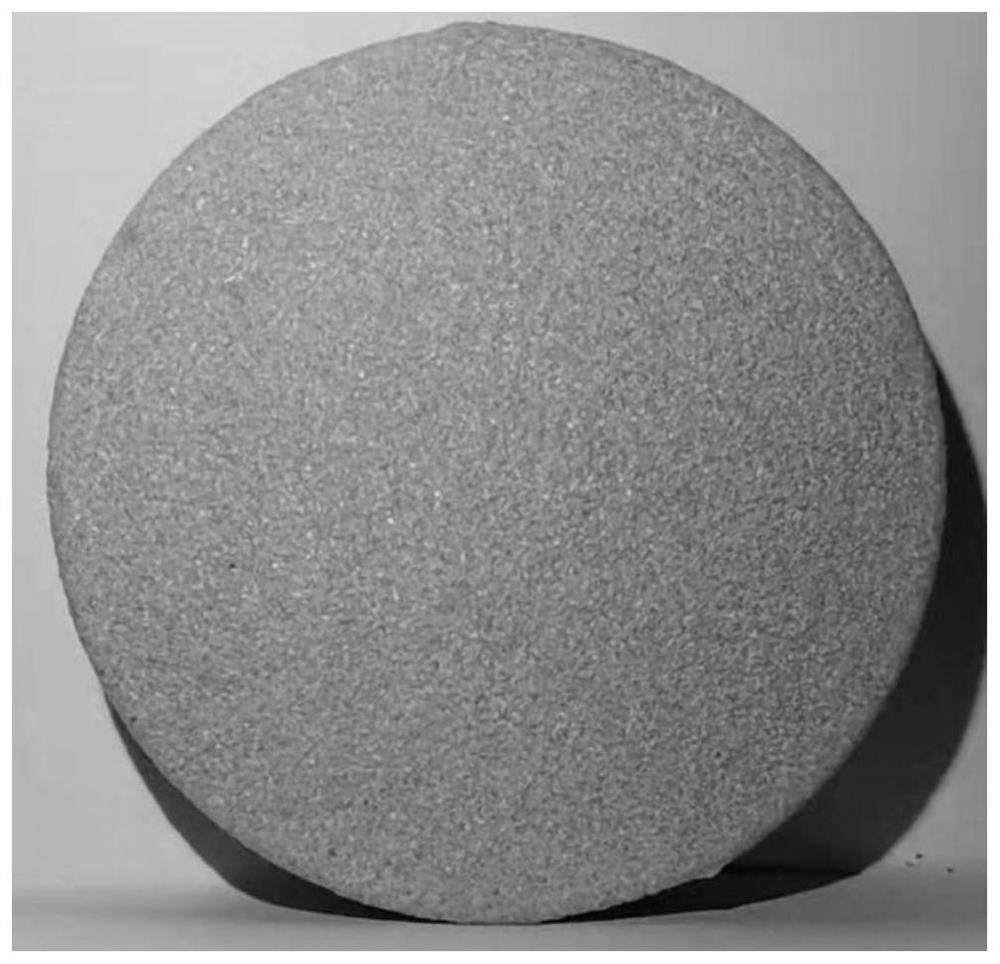

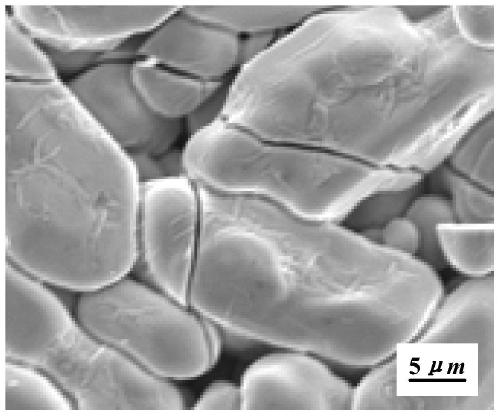

Ceramic-based composite material system on surface of unmanned aerial vehicle and preparation method of ceramic-based composite material system

ActiveCN114163260AAlleviate thermal expansion coefficient differencesExtended service lifePressure inorganic powder coatingThermal dilatationComposite ceramic

The invention discloses a ceramic-based composite material system on the surface of an unmanned aerial vehicle and a preparation method of the ceramic-based composite material system. The ceramic-based composite material system comprises a ceramic-based composite material matrix which covers the surface of a fuselage of the unmanned aerial vehicle; a bonding layer, an oxygen barrier layer, an oxygen barrier propagation layer, a thermal expansion coefficient buffer layer and a heat insulation cooling layer are sequentially deposited on the ceramic-based composite material matrix; wherein the thickness of the bonding layer is 100-200 [mu] m, the thickness of the oxygen propagation prevention layer is 30-50 [mu] m, the thickness of the thermal expansion coefficient buffer layer is 30-50 [mu] m, and the thickness of the heat insulation cooling layer is 100-1000 [mu] m. The ceramic-based composite material system prepared by the invention has a coating with remarkable high-temperature resistance, high heat insulation, oxidation resistance and high oxygen resistance, so that the ceramic-based composite material system can be used for a long time in high-temperature fire rescue, the service temperature exceeds 1000 DEG C, and the temperature of internal parts of a fire scene rescue unmanned aerial vehicle is ensured to be below the limit working temperature; and meanwhile, the surface-layer ceramic-based composite ceramic material has extremely high oxidation resistance.

Owner:KUNMING UNIV OF SCI & TECH

A kind of heat-resisting thermal insulation coating and preparation method thereof

ActiveCN107201067BImprove thermal conductivityImprove insulation effectFireproof paintsAlkali metal silicate coatingsCarboxymethyl celluloseCellulose

Owner:北京志盛威华化工有限公司

Preparation method of TD3 alloy surface oxidation-resistant coating

InactiveCN111058018ASimple processing methodEasy to implementLiquid/solution decomposition chemical coatingComposite ceramicOxidation resistant

The invention relates to a preparation method of a TD3 alloy surface oxidation-resistant coating, and belongs to the technical field of high-temperature-resistant coating preparation. According to thepreparation method, a transition layer selects NiO sol as raw materials, a composite ceramic layer selects Al2O3-SiO2 sol as the raw materials, and preparation is carried out by combining sol-gel, low-temperature sintering and electron beam cladding. The method is simple in process and easy to realize, and the prepared oxidation-resistant coating and the substrate have good bonding force, and also have good high-temperature oxidation corrosion resistance and washing-out resistance.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

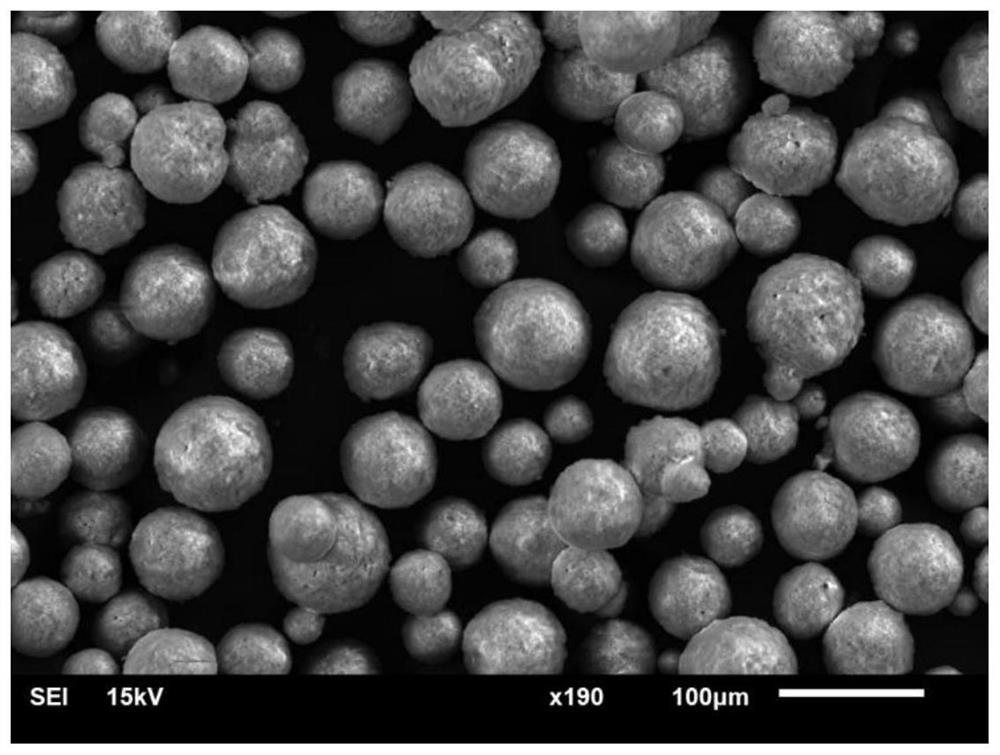

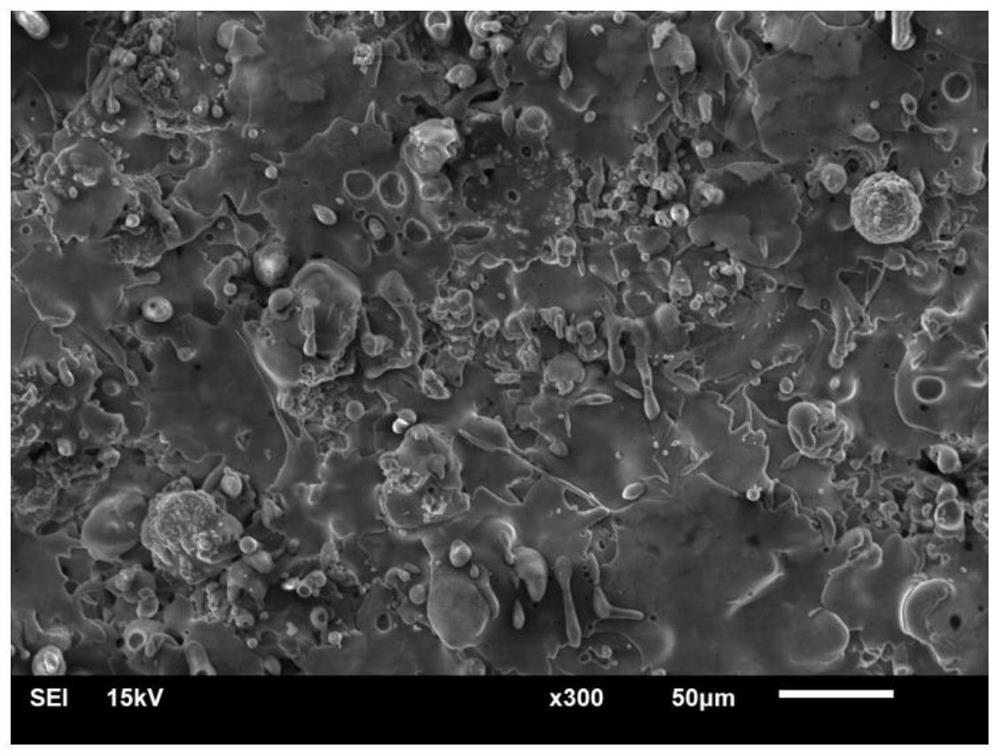

Preparation method of corrosion-resistant baffle surface coating for TFT (thin film transistor) process and coating

PendingCN114773884AReduce porosityImprove corrosion resistanceMolten spray coatingAnti-corrosive paintsComposite ceramicDisplay device

The invention discloses a preparation method of a corrosion-resistant baffle surface coating for a TFT (Thin Film Transistor) process, which comprises the following steps: (1) powder preparation: (1) taking a composite ceramic powder raw material, and mixing to form slurry; (2) adding a binder into the slurry formed in the step (1), and mixing to form granulation slurry; (3) carrying out spray granulation on the granulation slurry formed in the step (2) in a spray granulator to form basically spherical composite ceramic spray particles; (2) pretreatment: carrying out pretreatment on the baffle element base body; and (3) plasma spraying: performing plasma spraying on the composite ceramic spray particles to form a composite ceramic layer. According to the invention, the defects of black spots, short circuit and the like of the TFT film are reduced, and the display quality of LED and OLED displays is improved.

Owner:成都拓维高科光电科技有限公司

Carbon/carbon composite material anti oxidant coating and its preparing method

The present invention relates to liquid coating process, and is especially low temperature antioxidant method of composite C / C material. The present invention features that the sol for soaking composite C / C material is prepared with alcohol as partial solvent to replace distilled water, and has the components including silica 20-40 wt%, phosphoric acid 5-25 wt%, zinc dihydrogen phosphate 40-65 wt% and boric acid 1-10 wt%. Soaking composite C / C material with the sol of the present invention can form oxide coating with no crack, hole and other faults, excellent combination with C, high compactness, high healing capacity, raised oxygen permeation resistance, delayed contact between oxygen and composite C / C material and raised antioxidant performance.

Owner:CENT SOUTH UNIV

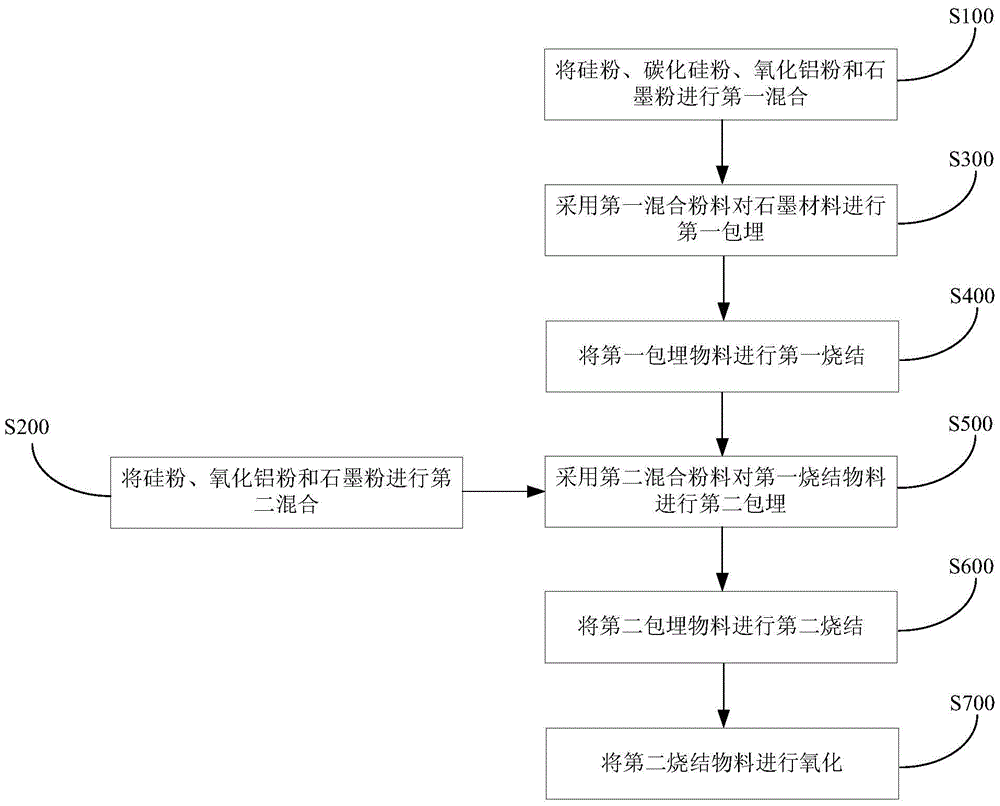

Preparation of sic/sio on the surface of graphite materials for reactors 2 Composite high temperature anti-oxidation coating and composite materials

The invention discloses a method for preparing a SiC / SiO2 composite high-temperature oxidation resistant coating from the surface of a graphite material at a reactor and a composite material. The method comprises the following steps: (1) mixing silica powder, silicon carbide powder, alumina powder and graphite powder, so as to obtain mixed powder; (2) mixing silica powder, alumina powder and graphite powder, so as to obtain second mixed powder; (3) embedding the graphite material with the first mixed powder, so as to obtain a first embedded material; (4) sintering the first embedded material, so as to obtain a first sintered material; (5) embedding the first sintered material into the second mixed powder, so as to obtain a second embedded material; (6) sintering the second embedded material, so as to obtain a second sintered material; and (7) oxidizing the second sintered material, so as to obtain the SiC / SiO2 composite high-temperature oxidation resistant coating. According to the method, the SiC / SiO2 composite high-temperature oxidation resistant coating with uniform thickness, thermal shock resistance and excellent oxidation resistance can be prepared from the surface of the graphite material at the reactor.

Owner:TSINGHUA UNIV

A low-crack-sensitivity high-performance Ni-based composite powder for laser cladding

InactiveCN106400009BReduce sensitivityHigh hardnessMetallic material coating processesSolid solution strengtheningHardness

The present invention provides a low-crack-sensitivity high-performance Ni-based composite powder for laser cladding. The raw materials and mass percentages used are as follows: Co powder 8.0-10.0%, Fe powder 8.5-12.0%, Cr powder 10.0-13.0%, Si Powder 2.0~3.5%, WC powder 28.0~30.0%, and the balance Ni powder. A low-crack-sensitive high-performance Ni-based composite powder for laser cladding uses the mechanism of solid solution strengthening and fine-grain strengthening formed by the interaction of Cr, Fe, Co, Ni, and WC, so that the cladding layer has high hardness and high toughness , has low crack sensitivity; the cladding layer prepared by using this powder has high surface hardness, strong corrosion resistance, and high temperature resistance; it is prepared by mechanical mixing method, the production process is simple, and the price advantage is obvious.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com