Heater and preparation method thereof

A heater and pyrolysis technology, applied in the direction of ohmic resistance heating, heating element materials, ohmic resistance heating parts, etc., can solve the problems of prolonging the cooling time, high power requirements, and easy delamination, etc., to reduce thermal expansion Coefficient difference, simplified temperature control program, and the effect of solving stratification problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Using nitrogen as a carrier gas, the BCl 3 and NH3 into the heated deposition furnace, control BCl 3 and NH 3 The volume ratio is 2.5:1, the reaction chamber temperature is 1600°C, and the vacuum degree is 133pa. Pyrolytic boron nitride with a thickness of 1.5mm is deposited on the surface of a conventional graphite mold, and then the above-mentioned pyrolytic boron nitride substrate is raised under vacuum. The temperature is raised to 1950°C and kept for 3 hours to form pyrolytic boron nitride used as a heater substrate.

[0071] Fix the boron nitride substrate on the rotating frame of the sandblasting equipment, turn on the equipment to rotate at a speed of 10r / min, and then use corundum sand with a mesh number of 120 for surface sandblasting, with a sandblasting pressure of 0.2MPa and a sandblasting distance of 250mm, the surface roughness of the blasted substrate is 3.42μm.

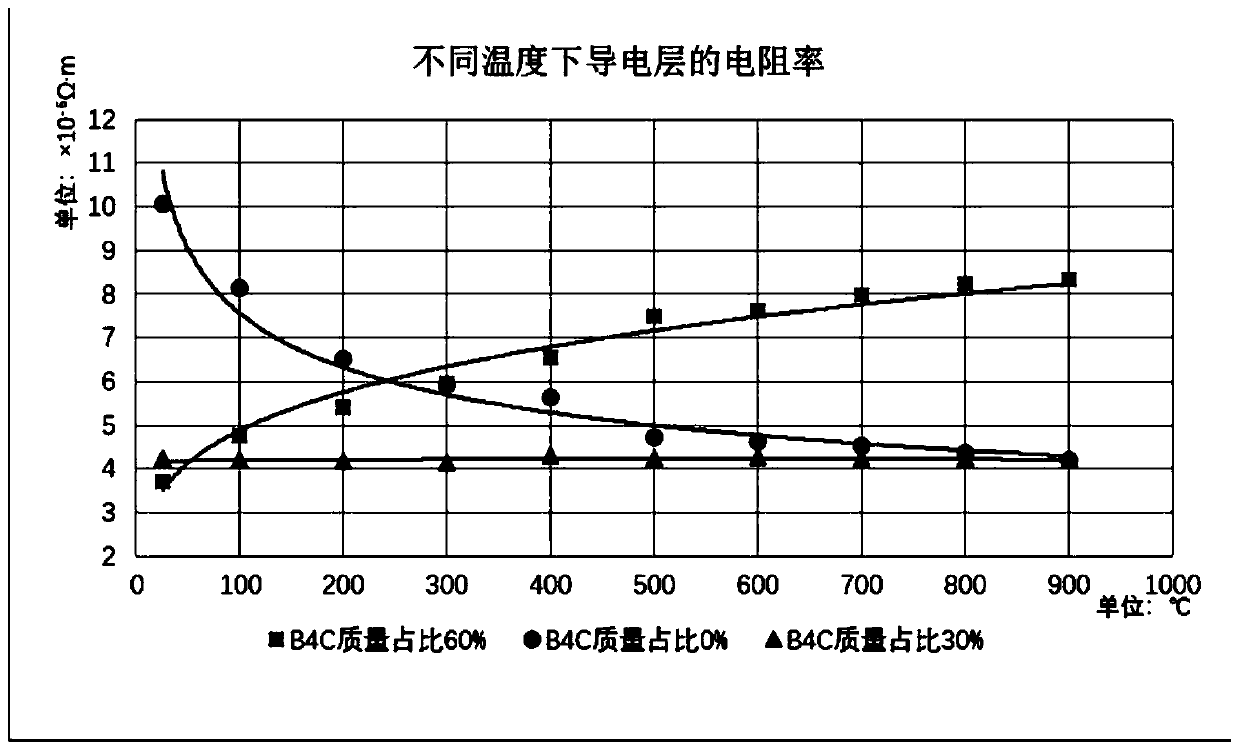

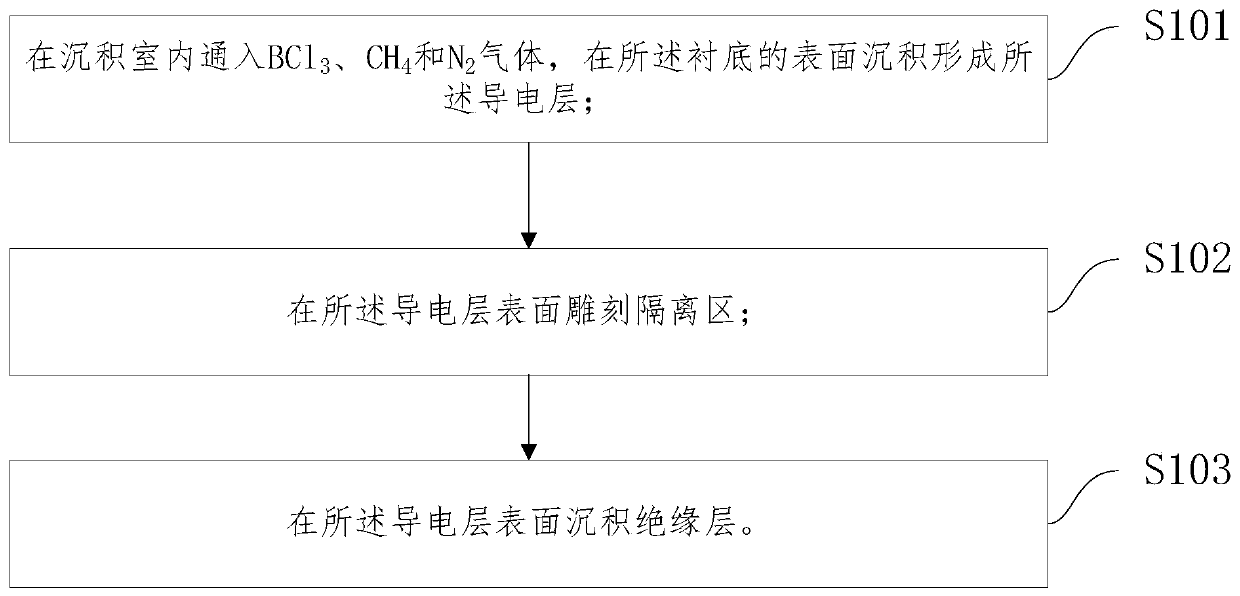

[0072] Then hang the boron nitride substrate processed in 2 into the CVD equipment for t...

Embodiment 2

[0077]Using nitrogen as a carrier gas, the BCl 3 and NH3 into the heated deposition furnace, control BCl 3 : NH 3 =2.5:1, the temperature of the reaction chamber is 1600°C, the degree of vacuum is 133pa, deposit and form pyrolytic boron nitride with a thickness of 1.5mm on the surface of a conventional graphite mold, and then raise the temperature of the above pyrolytic boron nitride matrix under vacuum to 1950°C, heat preservation for 3 hours to form pyrolytic boron nitride used as a heater substrate.

[0078] Fix the boron nitride substrate on the rotating frame of the sandblasting equipment, turn on the equipment to rotate at a speed of 10r / min, and then use corundum sand with a mesh number of 120 for surface sandblasting, with a sandblasting pressure of 0.2MPa and a sandblasting distance of 250mm, the surface roughness of the blasted substrate is 3.42μm.

[0079] Then hang the boron nitride substrate processed in 2 into the CVD equipment for the deposition of surface co...

Embodiment 3

[0082] Using nitrogen as a carrier gas, the BCl 3 and NH3 into the heated deposition furnace, control BCl 3 : NH 3 =2.5:1, the temperature of the reaction chamber is 1600°C, the degree of vacuum is 133pa, deposit and form pyrolytic boron nitride with a thickness of 1.5mm on the surface of a conventional graphite mold, and then raise the temperature of the above pyrolytic boron nitride matrix under vacuum to 1950°C, heat preservation for 3 hours to form pyrolytic boron nitride used as a heater substrate.

[0083] Fix the boron nitride substrate on the rotating frame of the sandblasting equipment, turn on the equipment to rotate at a speed of 10r / min, and then use corundum sand with a mesh number of 120 for surface sandblasting, with a sandblasting pressure of 0.2MPa and a sandblasting distance of 250mm, the surface roughness of the blasted substrate is 3.42μm.

[0084] Then hang the boron nitride substrate processed in 2 into the CVD equipment for the deposition of surface c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com