Novel method for depositing diamond film on surface of stainless steel

A diamond film and surface deposition technology, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problem that the bonding force of diamond film cannot be taken into account at the same time, the increase of uncontrollable factors affecting each other, and the nucleation rate of diamond film Low-level problems, to achieve the effect of easy control of experimental operating conditions, reduction of thermal expansion coefficient difference, and enhanced mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

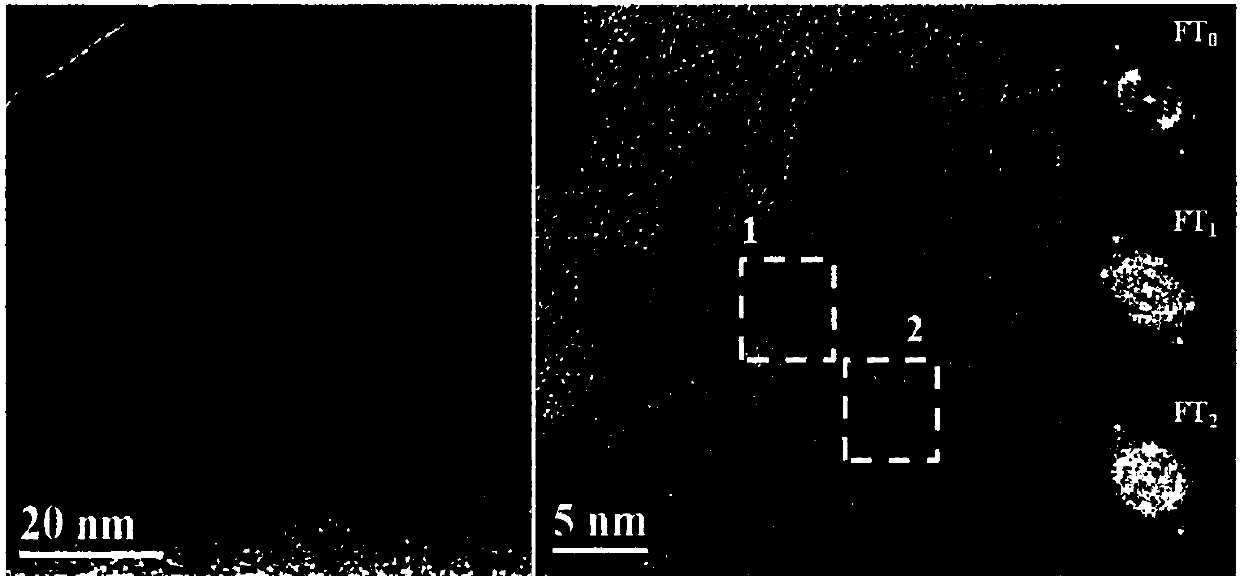

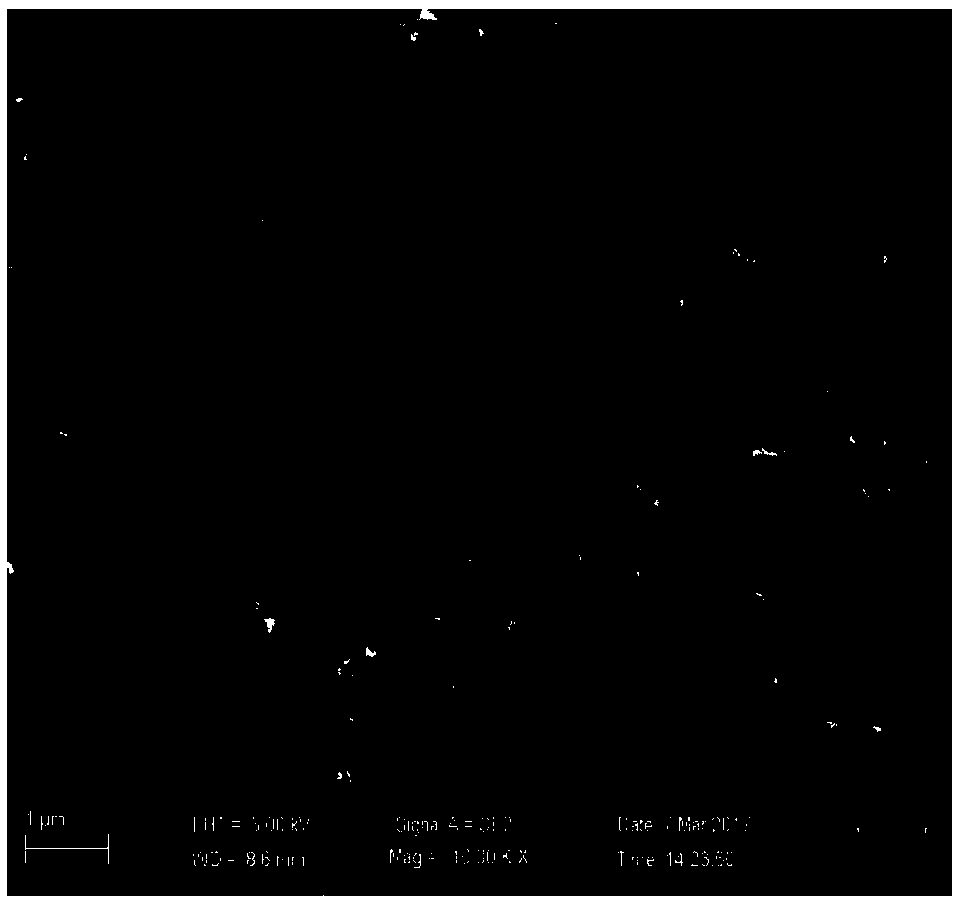

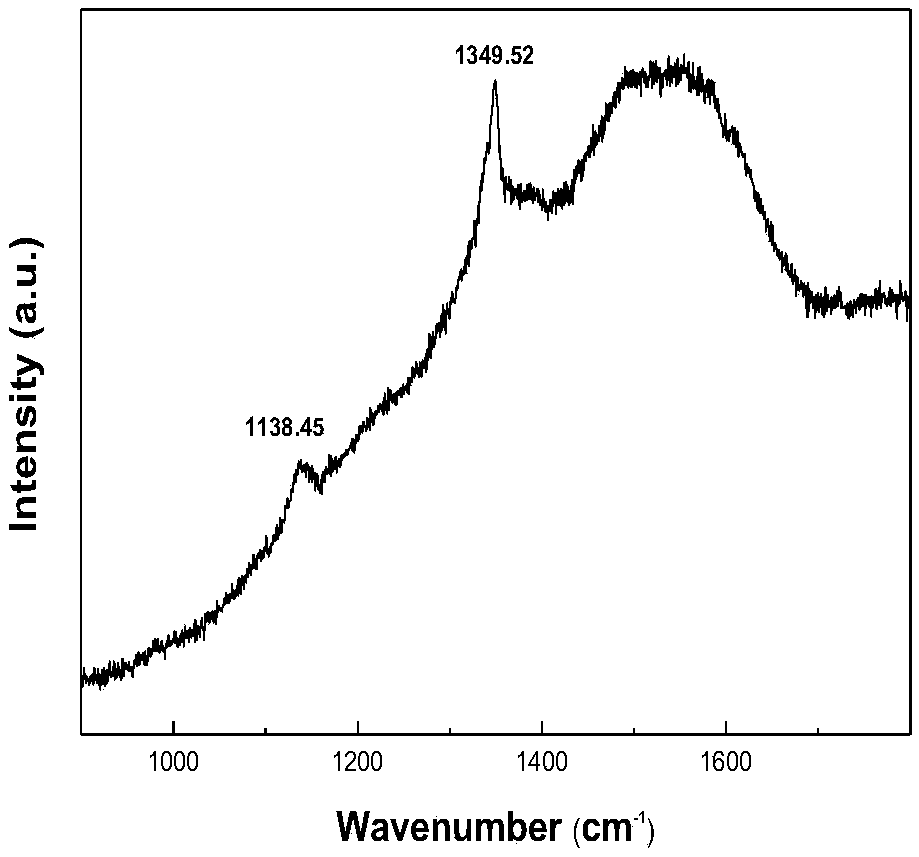

[0041] 3Cr13 stainless steel was selected as the base material, and the steel plate was cut into block samples with a size of 10mm×10mm×3mm by wire-cutting technology, and then polished with sandpaper on a polishing machine, and then the samples were pretreated: first, ultrasonic vibration in acetone for 20 minutes, then no Sonicate in water and ethanol for 20 minutes, and finally take out the sample, dry it, and set it aside. Then proceed to the preparation of the CrSiN transition layer. The magnetron sputtering equipment was developed by the Chinese Academy of Sciences, and the JGP-450 fast ion coating apparatus manufactured by Zhongke Instrument (Shenyang) Co., Ltd. The experimental parameters are: argon gas flow rate 15 sccm, substrate temperature 350°C, bias voltage 120V. Carry out the sputtering of Cr transition layer, sputtering time is 15min; Regulate nitrogen flow to 5sccm, regulate working pressure to 0.8Pa, carry out the sputtering of CrSiN transition layer in the ...

Embodiment 2

[0044] The base material is 3Cr13 stainless steel, and the steel plate is cut into 10mm×10mm×3mm block samples by wire-cutting process, and then polished with sandpaper on a polishing machine, and then the samples are pretreated: first, ultrasonic vibration in acetone for 20 minutes, then no Sonicate in water and ethanol for 20 minutes, and finally take out the sample, dry it, and set it aside. Then proceed to the preparation of the CrSiN transition layer. The magnetron sputtering equipment was developed by the Chinese Academy of Sciences, and the JGP-450 fast ion coating apparatus manufactured by Zhongke Instrument (Shenyang) Co., Ltd. The experimental parameters are: the flow rate of argon gas is 20 sccm, the substrate temperature is 300° C., and the bias voltage is 100 V. Carry out the sputtering of Cr transition layer, sputtering time is 30min, adjust nitrogen flow to 7sccm, regulate working pressure to 0.8Pa, carry out the sputtering of CrSiN transition layer in the mixe...

Embodiment 3

[0047] 3Cr13 stainless steel was selected as the base material, and the steel plate was cut into block samples with a size of 10mm×10mm×3mm by wire-cutting technology, and then polished with sandpaper on a polishing machine, and then the samples were pretreated: first, ultrasonic vibration in acetone for 20 minutes, then no Sonicate in water and ethanol for 20 minutes, and finally take out the sample, dry it, and set it aside. Then proceed to the preparation of the CrSiN transition layer. The magnetron sputtering equipment was developed by the Chinese Academy of Sciences, and the JGP-450 fast ion coating apparatus manufactured by Zhongke Instrument (Shenyang) Co., Ltd. The experimental parameters are: argon gas flow rate 30 sccm, substrate temperature 400°C, bias voltage 150V. Carry out the sputtering of Cr transition layer, sputtering time is 30min; Regulate nitrogen flow to 7sccm, regulate working pressure to 0.8Pa, carry out the sputtering of CrSiN transition layer in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com