Preparation of sic/sio on the surface of graphite materials for reactors 2 Composite high temperature anti-oxidation coating and composite materials

A technology of high-temperature anti-oxidation, graphite material, applied in the field of nuclear applications, can solve the problems of large particle size of coating slurry, difficult to uniform coating thickness, unsatisfactory micropore impregnation, etc., to achieve excellent anti-oxidation performance and ease thermal expansion Coefficient difference, the effect of improving thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] The first mixed powder composition formula: 60wt% silicon powder, 20wt% silicon carbide powder, 10wt% alumina powder, 10wt% natural graphite powder;

[0079] The second mixed powder composition formula: 80wt% silicon powder, 2wt% alumina powder, 18wt% natural graphite powder;

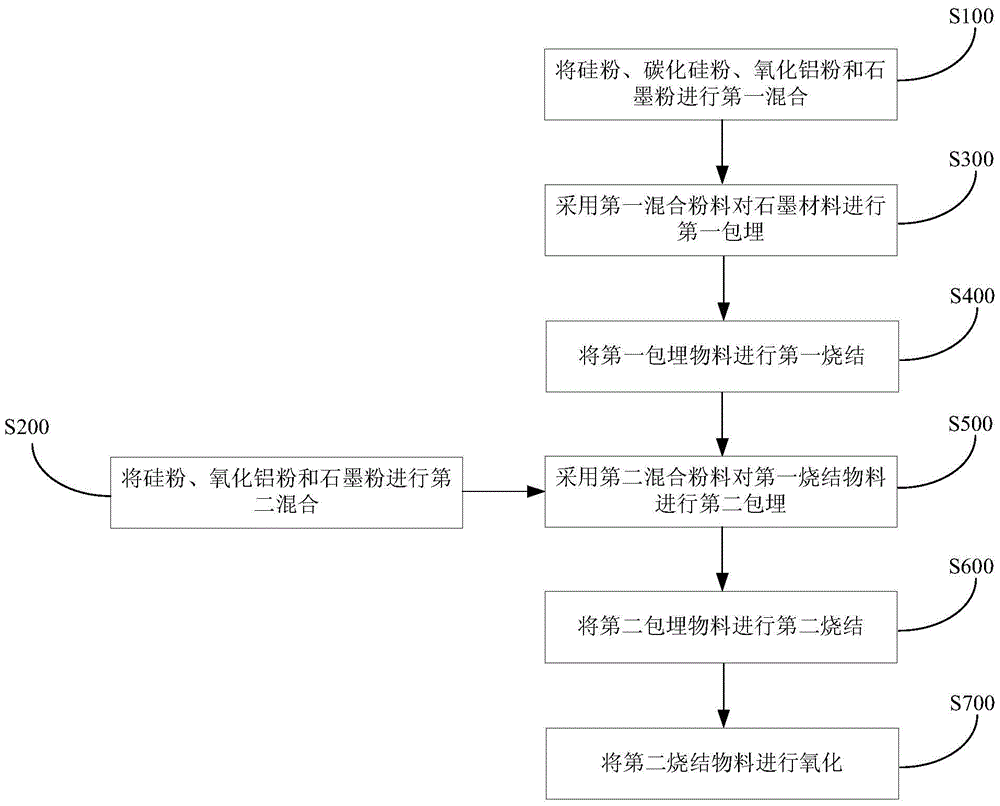

[0080] Preparation method: put silicon powder, silicon carbide powder, alumina powder and natural graphite powder in a ball mill tank according to the first mixed powder composition formula, add acetone, adjust the speed of the ball mill to 300rpm, and mix for 4 hours after ball milling, then take it out at 120 Dry in a vacuum drying oven at ℃ for 2 hours and sieve to obtain the first mixed powder. Similarly, silicon powder, alumina powder and natural graphite powder are mixed in a ball mill according to the composition formula of the second mixed powder to obtain the second mixed powder. Second, mix the powder, then bury the graphite material in the graphite crucible filled with the first mixed ...

Embodiment 2

[0082] The first mixed powder composition formula: 55wt% silicon powder, 20wt% silicon carbide powder, 10wt% alumina powder, 15wt% natural graphite powder;

[0083] The second mixed powder composition formula: 85wt% silicon powder, 5wt% alumina powder, 10wt% natural graphite powder;

[0084] Preparation method: the same as in Example 1, wherein the first sintering is carried out at 1600° C. for 3 hours under vacuum atmosphere, the second sintering is carried out at 1800° C. for 3 hours under vacuum atmosphere, and the oxidation treatment is carried out at 1600° C. under static air atmosphere. °C for 2 hours.

Embodiment 3

[0086] The first mixed powder composition formula: 60wt% silicon powder, 25wt% silicon carbide powder, 5wt% alumina powder, 10wt% natural graphite powder;

[0087] The second mixed powder composition formula: 75wt% silicon powder, 5wt% alumina powder, 20wt% natural graphite powder;

[0088] Preparation method: Same as Example 1, wherein the first sintering is carried out at 1700°C for 3 hours under vacuum atmosphere, the second sintering is carried out at 1850°C for 3 hours under vacuum atmosphere, and the oxidation treatment is carried out at 1650°C under static air atmosphere. °C for 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com