Preparation method of TD3 alloy surface oxidation-resistant coating

An anti-oxidation coating and alloy technology, which is applied in the direction of metal material coating process, coating, liquid chemical plating, etc. Large stress and other problems, to achieve the effect of reducing the difference in thermal expansion coefficient, improving bonding performance, and continuous and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The specific steps for preparing anti-oxidation coating on the surface of TD3 alloy are as follows:

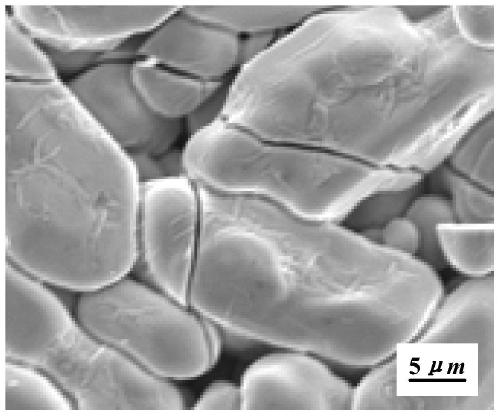

[0035] (1) Choose TD3 alloy with a size of 70mm×8mm×1mm as the substrate, and perform grinding, polishing, degreasing, pickling, cleaning and drying treatments on the surface of the substrate to make its surface roughness 5μm;

[0036] (2) Immerse the roughened substrate into NiO sol with a concentration of 0.65mol / L, and then pull it out slowly at a uniform speed to make the NiO sol evenly cover the surface of the substrate. After the NiO sol is dried at room temperature, it is placed in 200 Dry for 1 hour at ℃, repeat the immersion-pull-out-drying operation twice to form a transition layer with a thickness of 5μm on the surface of the substrate;

[0037] (3) SiO with a mass fraction of 30% 2 Aqueous solution, Al with an average particle size of 30nm 2 O 3 Powder, Al with an average particle size of 0.5μm 2 O 3 Powder, Al(H 2 PO 4 ) 3 And Na 2 SiO 3 According to the mass rati...

Embodiment 2

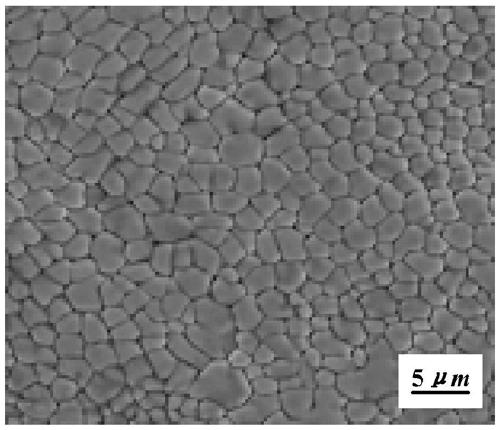

[0043] The specific steps for preparing anti-oxidation coating on the surface of TD3 alloy are as follows:

[0044] (1) Select the TD3 alloy with a size of 70mm×8mm×1mm as the substrate, and perform grinding, polishing, degreasing, pickling, cleaning and drying treatments on the surface of the substrate to make the surface roughness 2μm;

[0045] (2) Immerse the roughened substrate in NiO sol with a concentration of 0.8 mol / L, and then pull it out slowly at a uniform speed to make the NiO sol evenly cover the surface of the substrate. After the NiO sol is dried at room temperature, it is placed in 200 Dry for 1 hour at ℃, repeat the immersion-pull-out-drying operation 3 times to form a transition layer with a thickness of 10μm on the surface of the substrate;

[0046] (3) SiO with a mass fraction of 25% 2 Aqueous solution, Al with an average particle size of 10nm 2 O 3 Powder, Al with an average particle size of 0.5μm 2 O 3 Powder, Al(H 2 PO 4 ) 3 And Na 2 SiO 3 According to the mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com