Carbon/carbon composite material anti oxidant coating and its preparing method

A technology of carbon composite material and anti-oxidation coating, which is applied in the direction of coating, etc., can solve the problems of reducing coating technology, economic advantages, increasing coating preparation process steps, and large difference in thermal expansion coefficient, so as to increase the coating precursor Composition, improvement of self-healing ability, and effect of reducing the difference in thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

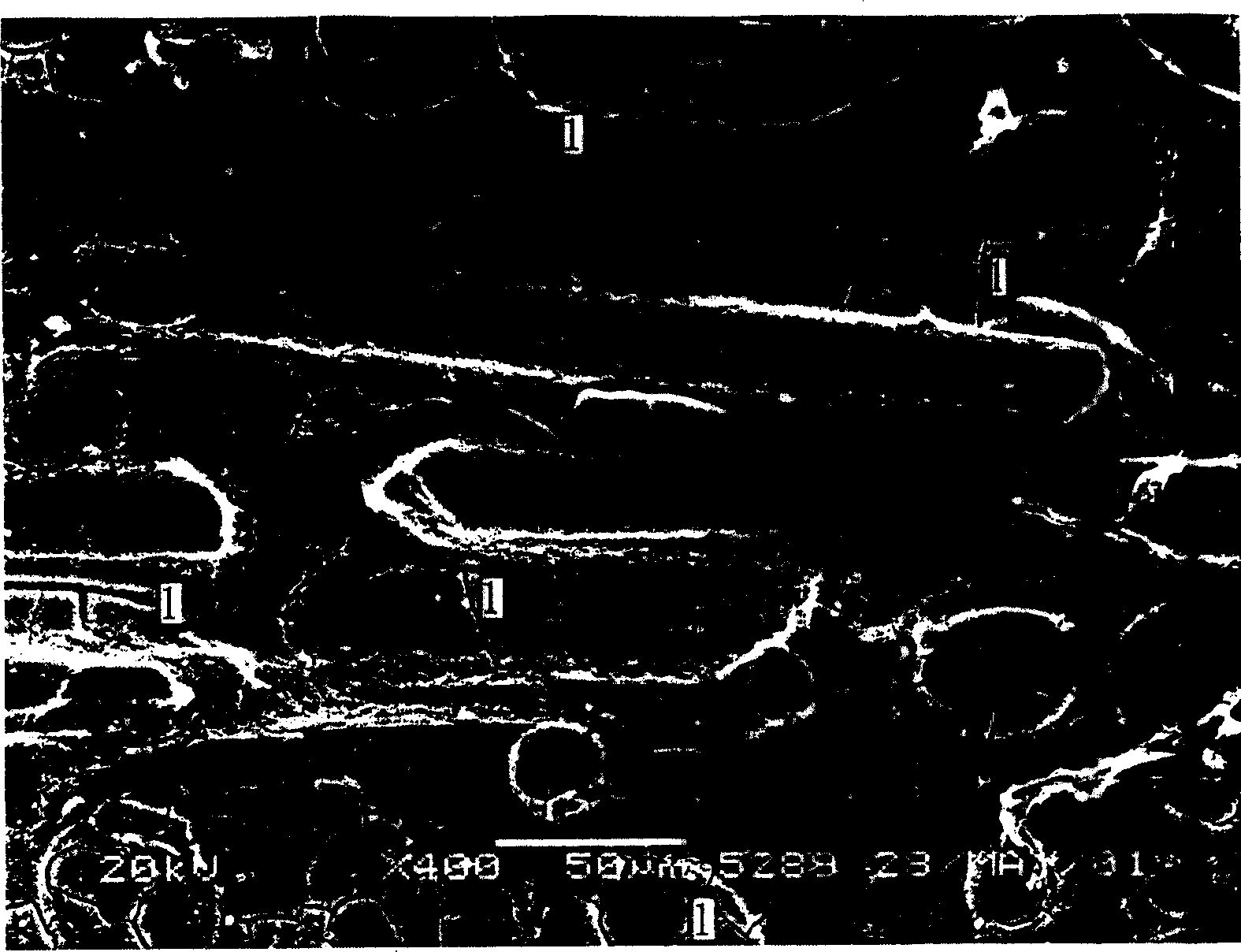

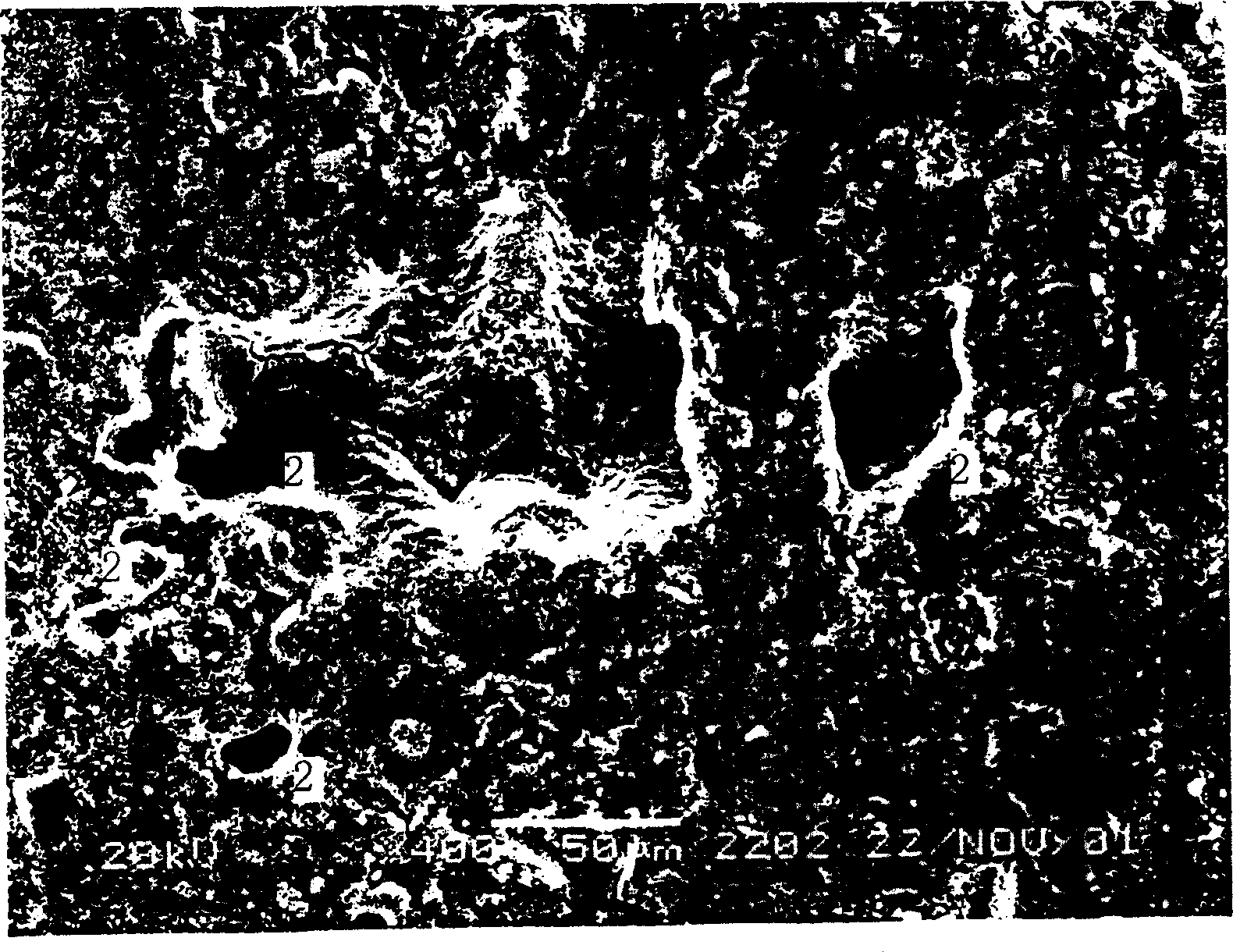

Image

Examples

Embodiment 1

[0023] Preparation of sol dip coating:

[0024] ① Weigh 1.5g of boric acid, dissolve it in 50ml of absolute ethanol, measure 10ml of TEOS and dissolve it in the solution.

[0025] ② Dilute 30ml of 85% phosphoric acid solution into 20ml of deionized water.

[0026] ③ Mix the solutions prepared in ① and ② together and stir to make a sol.

[0027] ④Dissolve 10g of ammonium pentaborate in 100ml of deionized water, mix 10ml of the solution with the sol prepared in ③, and stir until it stands still and becomes transparent.

[0028] ⑤Prepare 40wt% zinc dihydrogen phosphate aqueous solution.

[0029] ⑥Mix the sol prepared in ④ with the solution in ⑤ according to the volume ratio of 1:1, and stir until the sol is transparent.

[0030] ⑦ Bake the prepared carbon / carbon composite material sample at 150°C for 2 hours, and quickly immerse it in the prepared sol for 24 hours.

[0031] ⑧Take out the impregnated carbon / carbon composite material sample and place it on the carbon felt, and ...

Embodiment 2

[0034] Preparation of sol dip coating:

[0035] ①Weigh 1.0g of boric acid, dissolve it in 50ml of absolute ethanol, and dissolve 10ml of TEOS in it.

[0036] ② Dilute 10ml of 85% phosphoric acid solution into 20ml of deionized water.

[0037] ③ Mix the solutions prepared in ① and ② together, stir until transparent to form a sol, and let stand for 24 hours.

[0038] ④Weigh 10g of ammonium pentaborate and dissolve it in 100ml of deionized water, add 10ml of the solution into the sol in ③, and stir until transparent.

[0039] ⑤ Prepare 40 (wt)% zinc dihydrogen phosphate aqueous solution.

[0040] ⑥ Mix the sol prepared in ④ with the solution in ⑤ according to the volume ratio of 2:3, and stir until the sol is transparent.

[0041] ⑦ Bake the prepared carbon / carbon composite material sample at 180°C for 2 hours, and quickly immerse it in the prepared sol for 24 hours.

[0042] ⑧Take out the impregnated carbon / carbon composite material sample and place it on the carbon felt, an...

Embodiment 3

[0045] Preparation of sol dip coating:

[0046] ①Weigh 1.5g of boric acid, dissolve it in 50ml of absolute ethanol, and dissolve 10ml of TEOS in it.

[0047] ② Dilute 10ml of 85% phosphoric acid solution into 20ml of deionized water.

[0048] ③Mix the solutions prepared in ① and ② together, and stir until transparent to form a sol.

[0049] ④Weigh 10g of ammonium pentaborate and dissolve it in 100ml of deionized water, add 10ml of the solution into the sol in ③, and stir until transparent.

[0050] ⑤Prepare 40wt% zinc dihydrogen phosphate aqueous solution.

[0051] ⑥ Mix the sol prepared in ④ with the solution in ⑤ according to the volume ratio of 1:3, and stir until the sol is transparent.

[0052] ⑦ Bake the prepared carbon / carbon composite material sample at 180°C for 2 hours, and quickly immerse it in the prepared sol for 24 hours.

[0053] ⑧Take out the impregnated carbon / carbon composite material sample and place it on the carbon felt, and place it in a drying oven t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com