A low-crack-sensitivity high-performance Ni-based composite powder for laser cladding

A composite powder and laser cladding technology, which is applied in the coating process and coating of metal materials, can solve the problems of cladding layer cracking and failure to meet repair requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

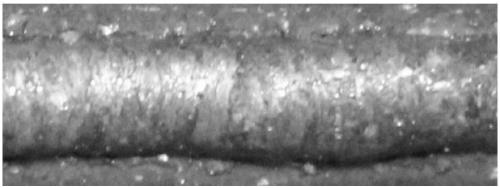

Examples

Embodiment 1

[0037] In the following, the powder materials of the present invention are selected for comparison with the powders of the present invention, in order to specifically illustrate the low-crack-sensitivity high-performance Ni-based composite powders specially used for laser cladding.

[0038] A low-crack-sensitivity high-performance Ni-based composite powder for laser cladding in this embodiment, the raw materials and mass percentages used are as follows: Co 8.4%, Fe 10.5%, Cr 11.2%, Si 2.8%, WC 30.0%, Ni 37.1 %.

[0039] The method of using the above raw material components to produce low-crack-sensitivity high-performance Ni-based composite powder for laser cladding is as follows: add the mixed powder into the material cylinder of the XQM-1L planetary ball mill, and weigh the volume of the powder not more than the material cylinder of the ball mill used. 1 / 3 of the volume of the ball mill, and then put 8 stainless steel balls for stirring, set the mixing time for 50 minutes, a...

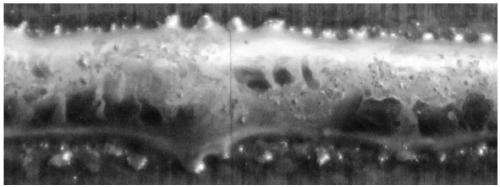

Embodiment 2

[0047] A Ni-based composite powder with low crack sensitivity and high hardness for laser cladding. The raw materials and mass percentages used are as follows: 10.0% Co powder, 12.0% Fe powder, 13.0% Cr powder, 2.0% Si powder, 30.0% WC powder, and the remaining Measure Ni powder. The preparation method is the same as in Example 1.

[0048] When preparing the cladding layer, the process parameters used are: fiber laser cladding (laser wavelength 950-1100nm), laser power 1000W, scanning speed 5mm / s. The macroscopic appearance of the prepared cladding layer is uniform, continuous, flat, without cracks, and the hardness is higher than 562HV 0.2 , The contact angle is between 120° and 150°.

Embodiment 3

[0050] A Ni-based composite powder with low crack sensitivity and high hardness for laser cladding, the raw materials and mass percentages used are as follows: 8.0% Co powder, 8.5% Fe powder, 10.0% Cr powder, 3.5% Si powder, 28.0% WC powder, and the remaining Measure Ni powder. The preparation method is the same as in Example 1.

[0051] When preparing the cladding layer, the process parameters used are: fiber laser cladding (laser wavelength 950-1100nm), laser power 1100W, and scanning speed 7mm / s. The macroscopic appearance of the prepared cladding layer is uniform, continuous, flat, without cracks, and the hardness is higher than 562HV 0.2 , The contact angle is between 120° and 150°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com