High chrome steel centrifugation roll collar and manufacturing method thereof

A manufacturing method and technology of high chromium steel, applied in the field of roll ring and its manufacture, high chromium steel roll ring and its manufacture, can solve the problem of insufficient wear resistance of composite casting roll ring, poor interface bonding between outer layer and core, rolling Problems such as poor surface quality of materials can be solved to achieve the effect of improving performance indicators, ensuring purity, and improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

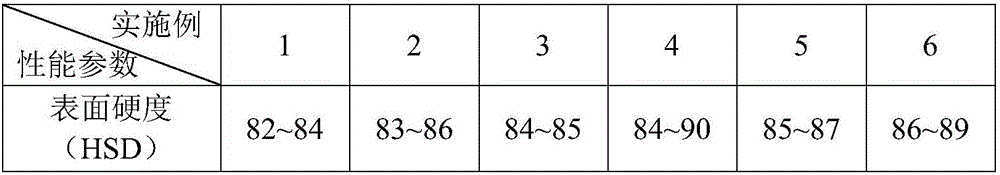

[0026] In the present invention, the test method for the surface hardness of the roller ring is: use a Shore hardness tester to detect the HSD value according to the method of GB / T13313-2008.

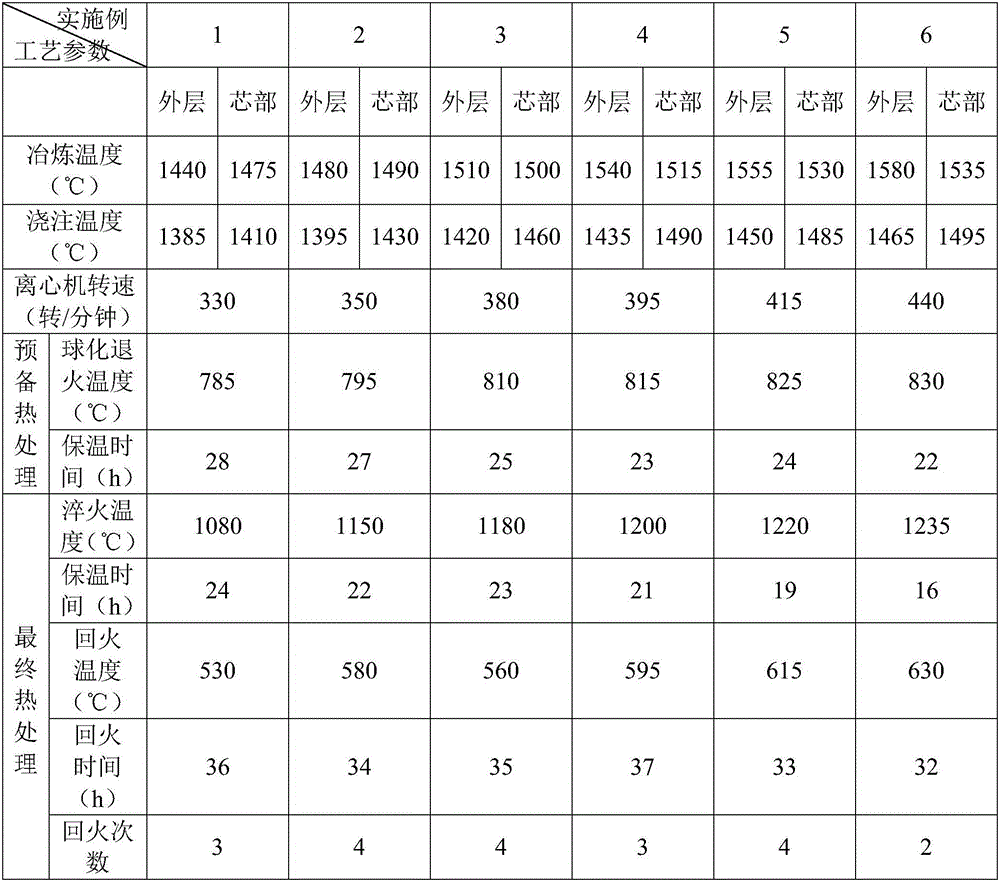

[0027] Below in conjunction with embodiment the present invention is described in further detail:

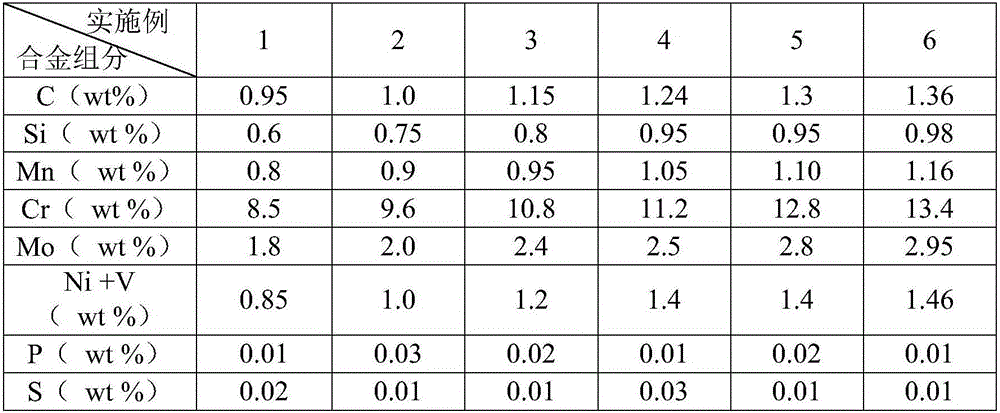

[0028] A high-chromium steel roll ring, including an outer layer and a core, the ratio of the outer layer to the core is 1:2, the alloy composition of the outer layer and the weight percentage of each alloy composition are: C: 0.80-1.40%, Si: 0.40~1.00%, Mn: 0.60~1.20%, P≤0.03%, S≤0.03%, Cr: 8.00%~14.0%, Mo: 1.00~3.00%, Ni+V: 0.50~1.50%, the rest is Fe and unavoidable impurities; among them, Ni and V are the main alloying elements, and the total content of the two elements is controlled between 0.50% and 1.50%.

[0029] The alloy composition of the core and the weight percentage of each alloy composition are: C: 0.5-1.5%, Si: 1.0-2.0%, Mn: 0.3-1.0%, P≤0.03%, S≤0.03%, Cr≤0.5 %, Ni≤0.5%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com