Composite high-temperature anti-oxidation coating of graphite material for nuclear reactor and preparation method of composite high-temperature anti-oxidation coating

A technology of high-temperature anti-oxidation and graphite materials, which is applied in the field of nuclear applications, can solve the problems of high sintering temperature and poor oxidation resistance of coatings, and achieve the effects of high bonding strength, strong anti-oxidation ability and excellent anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

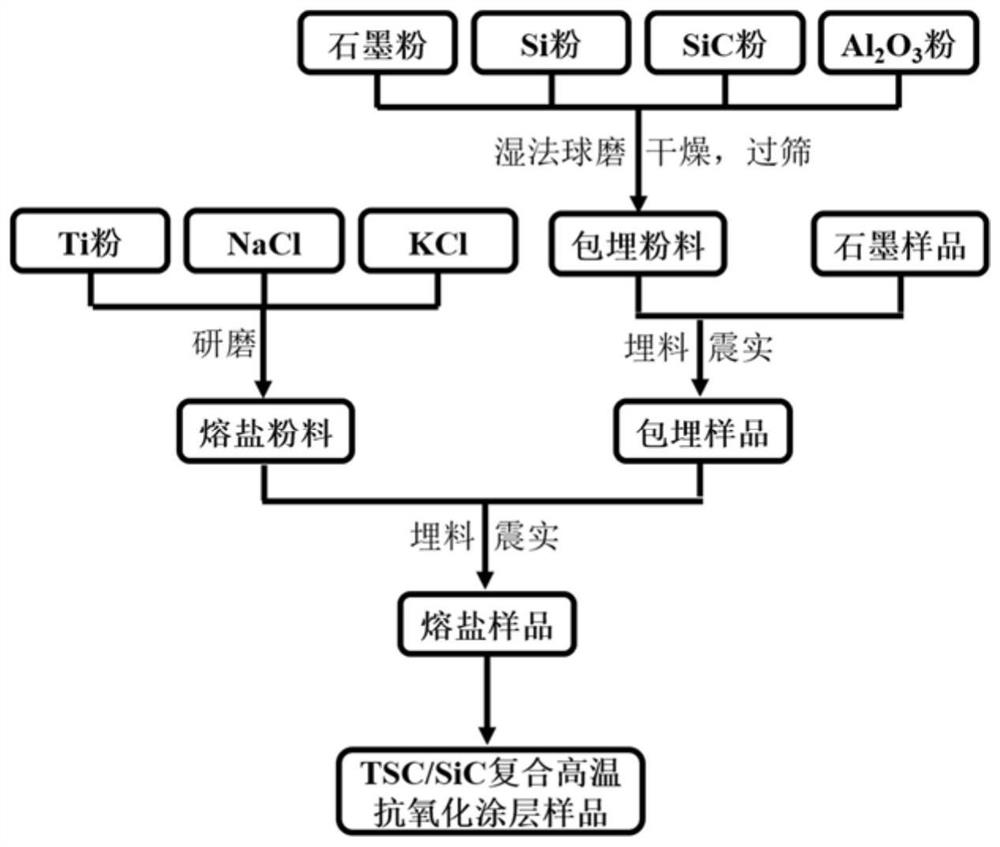

[0057] A preparation method of a composite high-temperature anti-oxidation coating of a graphite material for a nuclear reactor, the preparation method comprising the steps of:

[0058] Preparation of embedding powder

[0059] Embedding powder: Weigh 30g of 300μm Si powder, with a mass fraction of 60%; 10g of 300μm SiC powder, with a mass fraction of 20%; 300μm of Al 2 o 3 Powder 5g, mass fraction is 10%; Reactor uses natural graphite powder 5g, mass fraction is 10%;

[0060] Put the above mixed powders into ball mill jars respectively, add 100ml of alcohol, and adjust the speed of ball mill to 300rpm; after ball milling and mixing for 12 hours, take it out and dry in a vacuum oven at 50°C for 24 hours for later use.

[0061] Preparation of molten salt powder

[0062] Molten salt powder: Weigh 2.5g of 300μm Ti powder with a mass fraction of 20%; 4.4g of a purity of 98% NaCl powder with a mass fraction of 35.2%; 5.6g of a purity of 98% of KCl powder with a mass fraction of 4...

Embodiment 2-4

[0071] The preparation methods of Examples 2-4 refer to Examples, and the parameters of each step are shown in Table 1.

[0072] Table 1

[0073]

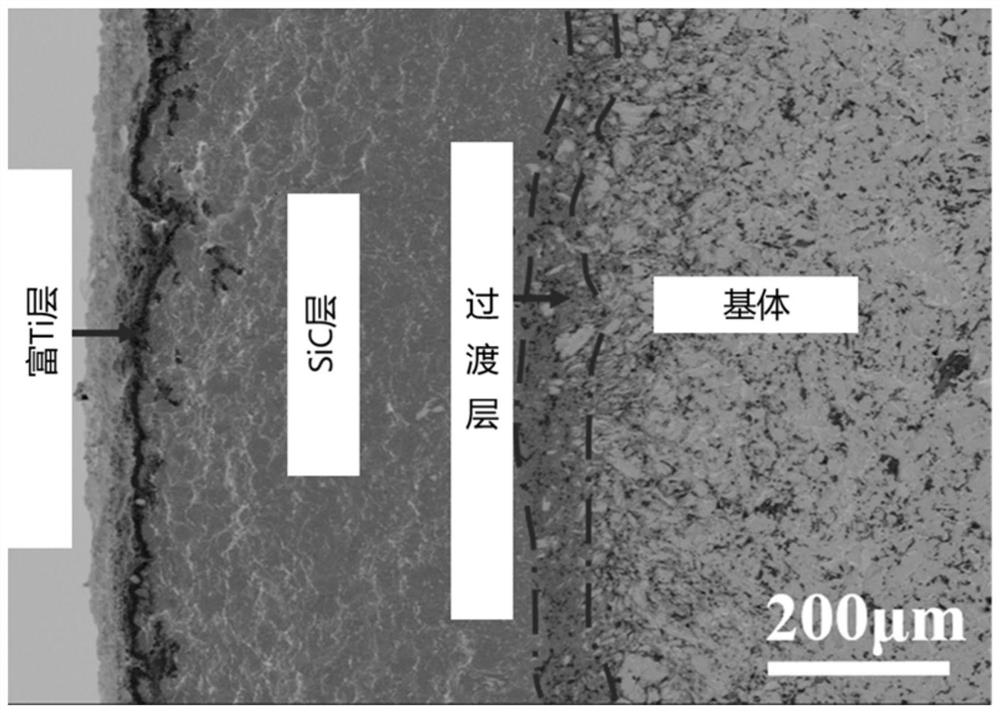

[0074] In the preparation methods of Examples 2-4, the amount of Ti powder used in the molten salt process is different, resulting in the Ti-rich layer of the composite coating being generated containing different phases and the contents of different phases are different. The composite coating composition of each embodiment as follows:

example 2

[0075] Example 2: Ti-rich layer (Ti 3 SiC 2 and TiC), SiC layer (SiC), transition layer (SiC and graphite);

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com