Binder-phase wolfram-carbide (WC) hard alloy and preparation method thereof

A cemented carbide and tungsten carbide technology, applied in the field of cemented carbide, can solve the problems of reduced cemented carbide properties, decreased alloy hardness, poor toughness, etc., to achieve excellent hardness and wear resistance, improve hardness and wear resistance, The effect of reducing the difference in coefficient of linear expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

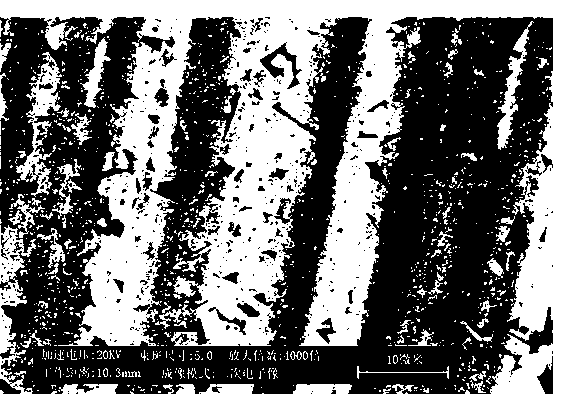

Image

Examples

Embodiment 1

[0031] a) Firstly, the WC powder with a uniform particle size of 3-5 μm and the binder Fe with a particle size of 1-3 μm are screened in advance 3 Al powder is prepared according to the mass percentage of 85% and 15%, of which Fe 3 The composition of Al alloy is (accounting for Fe 3 Al alloy (mass percentage): Al17%; Cr5.2%; Nb2.0%; Zr0.3%; B0.1%; Ce0.5%; Fe75%. And add 1% stearic acid batching as additive, mix and grind 45 hours in ball mill;

[0032] b) The mixed and ground raw materials are vacuum-dried and sieved to remove aggregates, then granulated, and then mixed at 900kg / cm 2 Precise pressing under high pressure to make a green compact;

[0033] c) Place the finished compact in a vacuum of 4×10 -4 MPa vacuum sintering furnace heated to 1250 ° C vacuum sintering for 1 hour, followed by hot isostatic pressing at 1250 ° C and 100 MPa for 1 hour to make cemented carbide. Take it out after cooling to get the finished product.

Embodiment 2

[0035] a) First, pre-screened WC with a uniform particle size of 3-5 μm and binder Fe with a particle size of 1-3 μm 3 Al powder is prepared according to the mass fraction of 92% and 8%, of which Fe 3 The composition of Al alloy is (accounting for Fe 3 Al alloy (mass percentage): Al15.6%; Cr1.3%; Nb2.2%; Zr0.4%; B0.2%; Ce0.3%; Fe80%. And add 0.8% stearic acid batching as additive, mix and grind 48 hours in ball mill;

[0036] b) The mixed and ground raw materials are vacuum-dried and sieved to remove aggregates, then granulated, and then mixed at 1000kg / cm 2 Pressed under the pressure to make a green compact;

[0037] c) Place the finished compact in a vacuum of 4.5×10 -4 Heating to 1300°C for vacuum sintering in MPa vacuum sintering furnace for 1.5 hours, followed by hot isostatic pressing at 1300°C and 110MPa for 1.5 hours to make cemented carbide. Take it out after cooling to get the finished product.

Embodiment 3

[0039] a) First, pre-screened WC with a uniform particle size of 3-5 μm and binder Fe with a particle size of 1-3 μm 3 Al is prepared according to the mass fraction of 94.5% and 5.5%, of which Fe 3 The composition of Al alloy is (accounting for Fe 3Al alloy (mass percentage): Al14%; Cr6%; Nb2.4%; Zr0.5%; B0.3%; Ce0.2%; Fe76.6%. And add 0.5% additive stearic acid batching, mix and grind in ball mill for 50 hours;

[0040] b) The mixed and ground raw materials are vacuum-dried, sieved to remove aggregates, and then granulated. 2 Pressed under the pressure to make a green compact;

[0041] c) Place the finished compact in a vacuum of 5×10 -4 MPa vacuum sintering furnace heated to 1350 ° C vacuum sintering for 2 hours, followed by hot isostatic pressing at 1350 ° C and 120 MPa for 2 hours to make cemented carbide. Take it out after cooling to get the finished product.

[0042] Properties of cemented carbide

[0043] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com