High voltage mercury lamp and sealing material for same

A technology for high-pressure mercury lamps and sealing materials, which is applied in the manufacture of discharge lamps, gas discharge lamps, discharge tubes/lamps, etc., can solve problems such as the influence of luminous characteristics, and achieve the effects of improving reliability and reducing thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

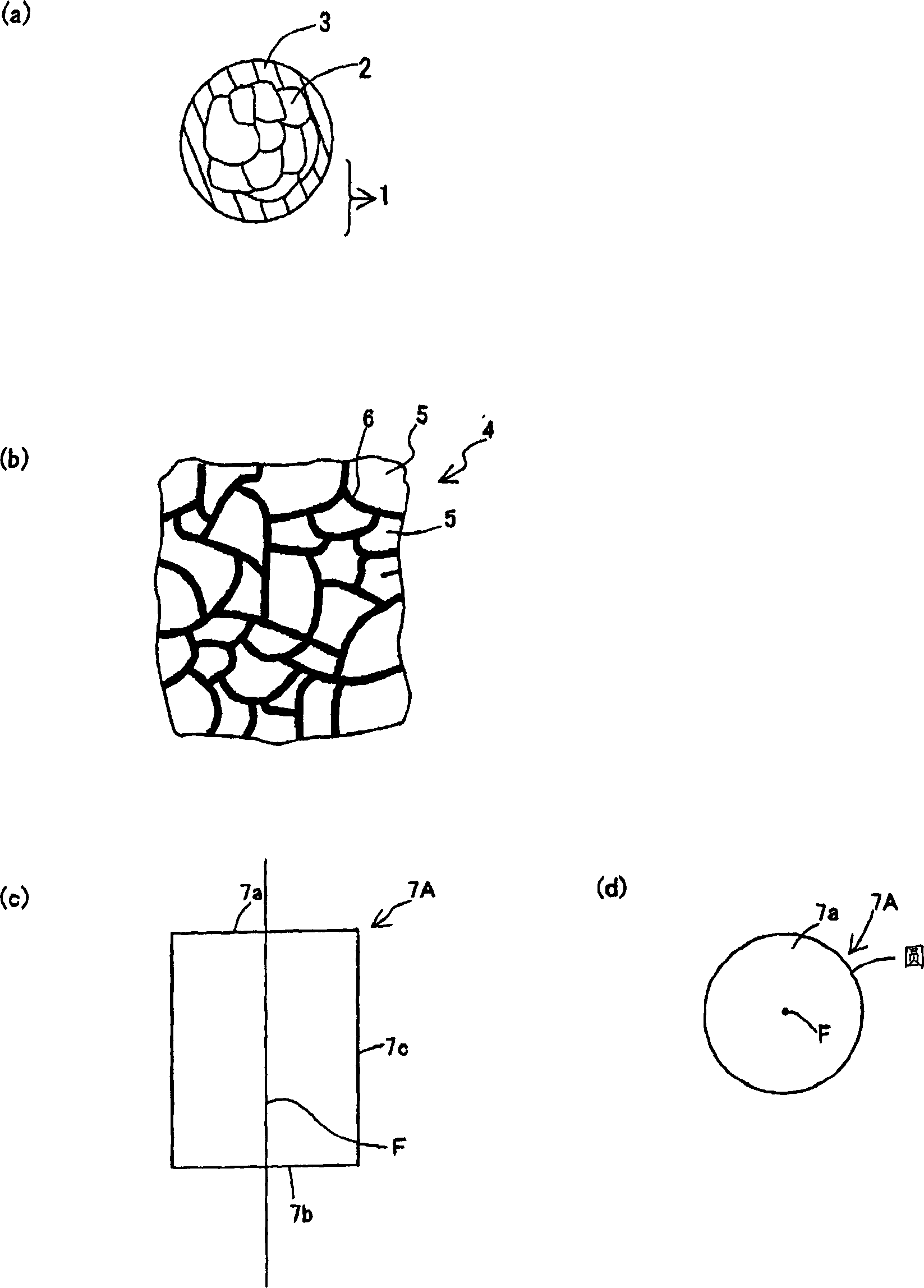

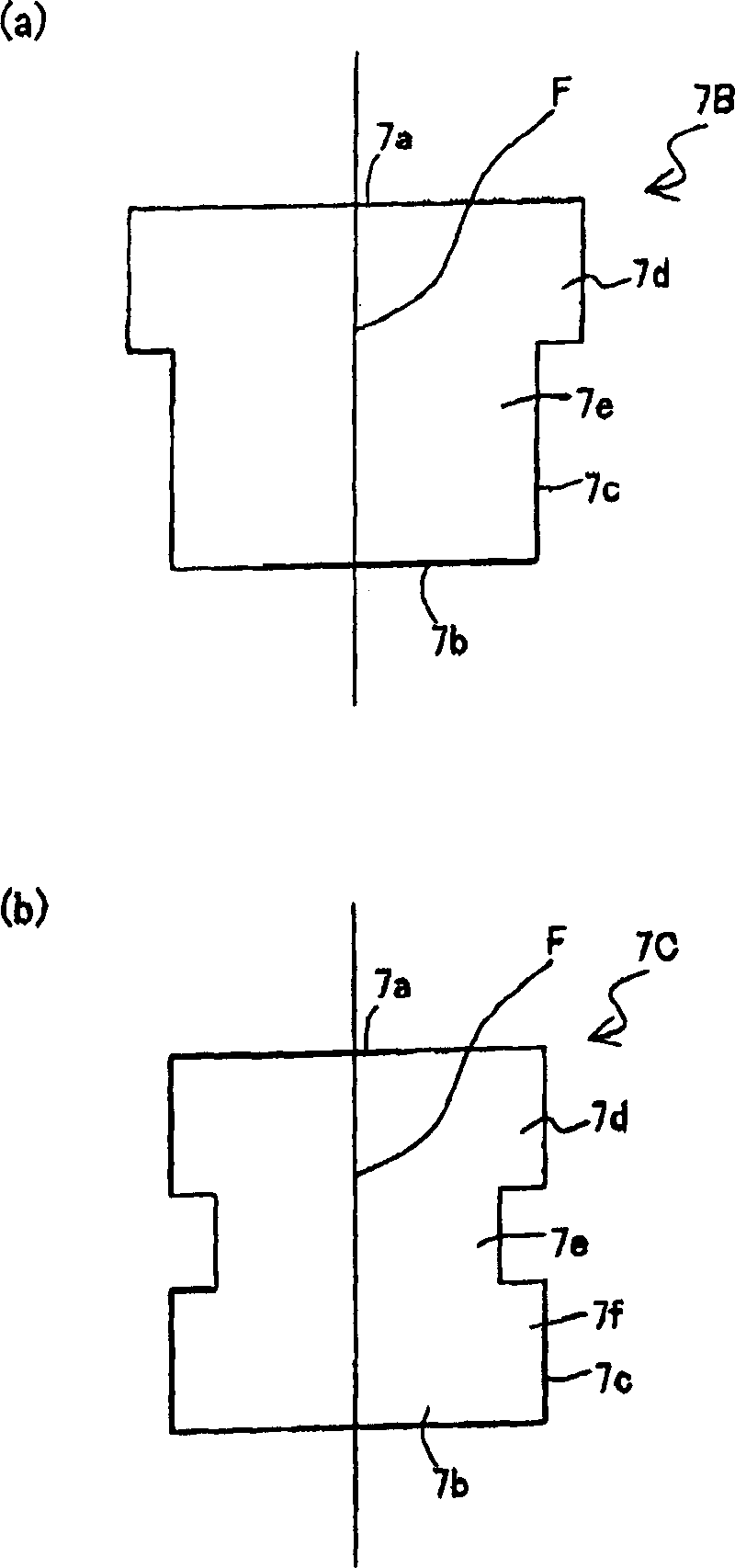

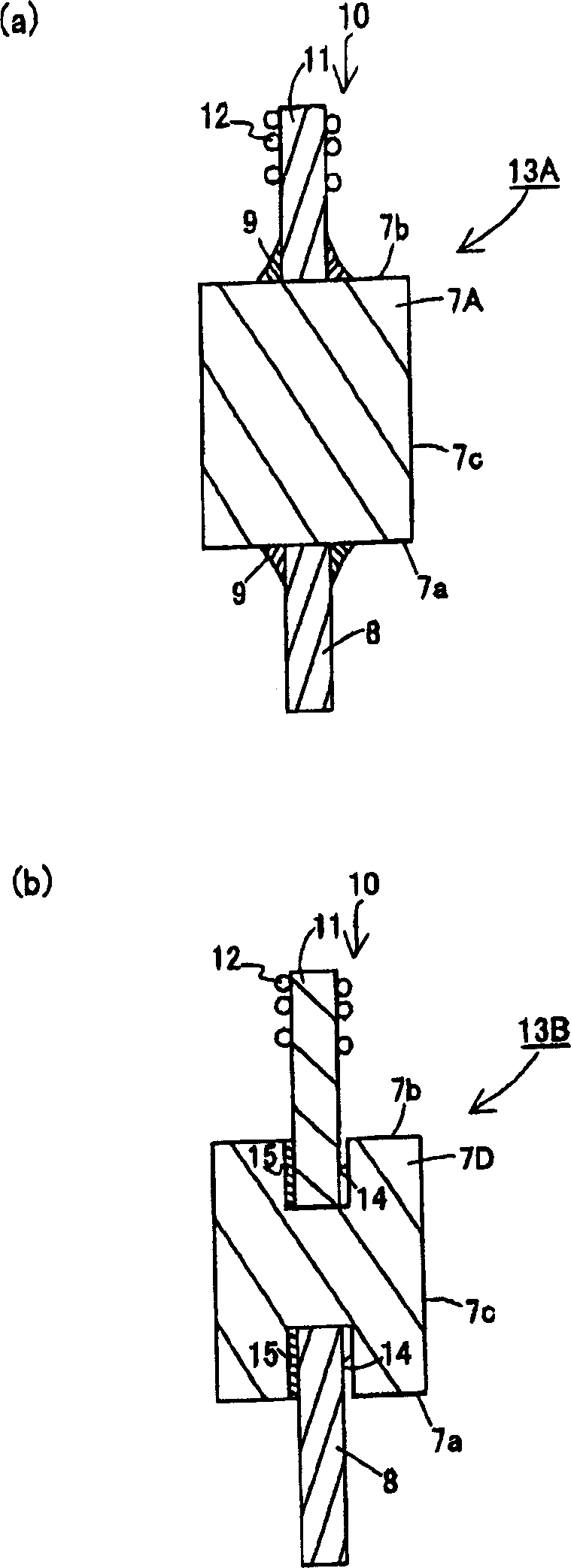

[0058] Embodiment (Experiment 1)

[0059] According to reference Figure 1 to Figure 6 To illustrate the method, manufacture as Figure 6 A high pressure mercury lamp of the form shown. Specifically, polyvinyl alcohol was added to silica powder to obtain silica particles. The aqueous solution of nickel nitrate is added to the tungsten oxide powder and mixed evenly, and then it is coated on the surface of the silica particles. The obtained raw material powder, with 0.5~3.0t / cm 2 Press forming under high pressure to obtain a cylindrical shape. The molded body is degreased at a temperature of 600 to 800°C in the air, and fired at a temperature of 1500 to 1700°C in a reducing atmosphere to obtain a cylindrical conductive sealing material made of cermet. The conductive sealing material had an average particle diameter of 300 μm, a tungsten content of 10% by volume, and a nickel content of 1 / 100 by weight of tungsten.

[0060] Ru-Mo-B solder was adhered to both end surfaces of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com