Ceramic-based composite material system on surface of unmanned aerial vehicle and preparation method of ceramic-based composite material system

A composite material and ceramic-based technology, applied in the field of materials, can solve the problems that ceramic-based composite materials are difficult to apply at high temperature, and the surface materials of the fuselage of fire rescue drones cannot withstand high temperature and oxidation, so as to improve the effect of heat insulation and cooling, low heat The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

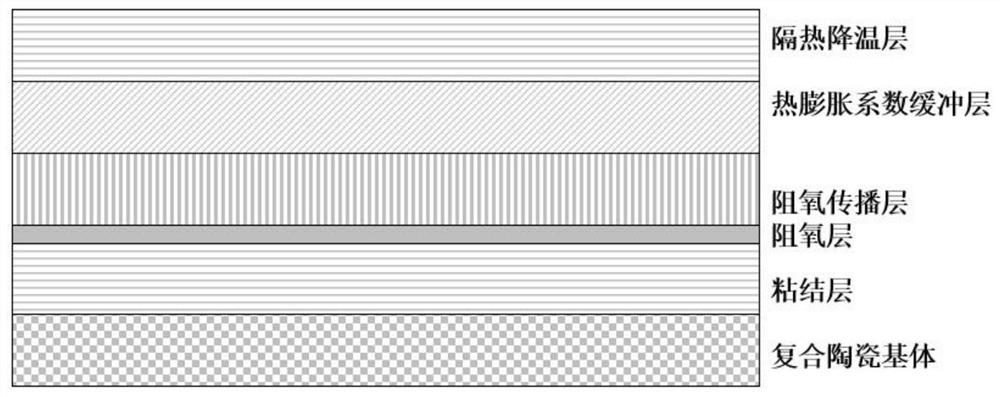

[0030] The invention proposes a ceramic matrix composite material system for the surface of an unmanned aerial vehicle and a preparation method thereof. refer to figure 1, according to an embodiment of the present invention, comprising a ceramic matrix composite material matrix silicon carbide fiber-reinforced silicon carbide, on which a bonding layer with a thickness of 100 μm, an oxygen barrier layer with a thickness of less than 1 μm, and a 30 μm thickness are sequentially deposited on the silicon carbide fiber-reinforced silicon carbide matrix Thick oxygen barrier transmission layer, 30μm thick thermal expansion coefficient buffer layer and 100m thick heat insulation and cooling layer; metal tantalum Ta is used as the material of the bonding layer; oxygen barrier transmission layer is made of rare earth tantalate RETaO 4 Ceramic coating, wherein, RE is Yb; thermal expansion coefficient buffer layer adopts RETa 3 o 9 Ceramics, where RE is Tm.

[0031] Specifically: (1) P...

Embodiment 2

[0036] The invention proposes a ceramic matrix composite material system for the surface of an unmanned aerial vehicle and a preparation method thereof. refer to figure 1 , according to an embodiment of the present invention, comprising a ceramic matrix composite material matrix silicon carbide fiber-reinforced carbon, on which a bonding layer with a thickness of 200 μm, an oxygen barrier layer with a thickness of less than 1 μm, and a 50 μm-thick Oxygen barrier transmission layer, 50μm thick thermal expansion coefficient buffer layer and 100m thick heat insulation and cooling layer; metal tantalum Ta is used as the material of the bonding layer; oxygen barrier transmission layer is made of rare earth tantalate RETaO 4 Ceramic coating, wherein, RE is Yb and Lu; thermal expansion coefficient buffer layer adopts RETa 3 o 9 Ceramics, where RE is La, Ho and Tm.

[0037] Specifically: (1) Prepare a tantalum-Ta bonding layer with a thickness of 200 μm on the upper surface of the ...

Embodiment 3

[0042] The invention proposes a ceramic matrix composite material system for the surface of an unmanned aerial vehicle and a preparation method thereof. refer to figure 1 , according to an embodiment of the present invention, comprising a ceramic matrix composite material matrix carbon fiber reinforced silicon carbide, a bonding layer with a thickness of 150 μm, an oxygen barrier layer with a thickness of less than 1 μm, and an oxygen barrier layer with a thickness of 35 μm are sequentially deposited on the carbon fiber reinforced silicon carbide substrate. Propagation layer, thermal expansion coefficient buffer layer with a thickness of 35 μm and heat insulation and cooling layer with a thickness of 1000 μm; metal tantalum Ta is used as the material of the bonding layer; the oxygen barrier transmission layer is made of rare earth tantalate RETaO 4 Ceramic coating, wherein, RE is Sc; thermal expansion coefficient buffer layer adopts RETa 3 o 9 Ceramics, where RE is La.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com