Tin-based solder and preparation method thereof

A solder and tin-based technology, applied in the field of tin-based solder and its preparation, can solve problems such as cracking and solder joint failure, and achieve the effects of avoiding coarsening, preventing solder joint cracks, and reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

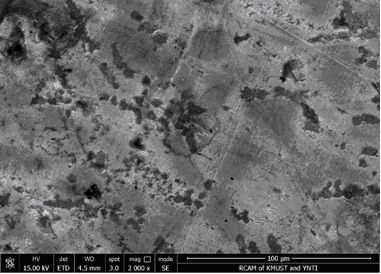

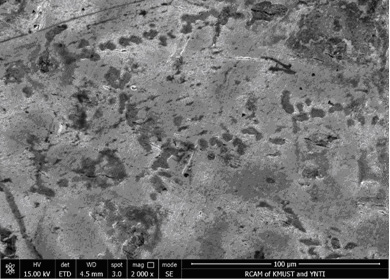

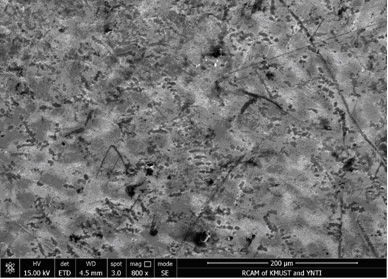

Image

Examples

Embodiment 1

[0028] A kind of tin-based solder provided by the present invention comprises Sn, Zn, Bi, Ag and Sb, and the mass percent of each component is respectively Zn: 9.0%, Bi: 2.0%, Ag: 1.0%, Sb: 1.0%, surplus is Sn.

[0029] The preparation method of described tin-based solder comprises the following steps:

[0030] (1) Weigh the pure metal raw materials Sn and Ag according to the mass ratio of 1:1, adopt vacuum induction melting, the melting temperature is 900°C, and the vacuum degree is 10 -3 Pa, the smelting time is 2 hours, the electromagnetic stirring effect ensures that the alloy composition is uniform, and the Sn-Ag master alloy is prepared.

[0031] (2) According to the design composition of Sn-based lead-free solder, weigh the Sn-Ag master alloy prepared in step (1) and the raw materials Sn, Zn, Bi, Sb, put them into a glass test tube for vacuum packaging, and the vacuum degree is 10 -4 Pa, put the glass tube with raw materials into a 16-channel heat treatment furnace wi...

Embodiment 2

[0035] A kind of tin base solder that the present invention provides comprises Sn, Zn, Bi, Ag and Sb, and each component mass percent is Zn: 9.0%, Bi: 2.0%, Ag: 1.0%, Sb: 2.0%, balance is Sn.

[0036] The preparation method of described tin-based solder comprises the following steps:

[0037] (1) Weigh the pure metal raw materials Sn and Ag according to the mass ratio of 1:1, adopt vacuum induction melting, the melting temperature is 900°C, and the vacuum degree is 10 -3 Pa, the smelting time is 2 hours, the electromagnetic stirring effect ensures that the alloy composition is uniform, and the Sn-Ag master alloy is prepared.

[0038] (2) According to the design composition of Sn-based lead-free solder, weigh the Sn-Ag master alloy prepared in step (1) and the raw materials Sn, Zn, Bi, Sb, put them into a glass test tube for vacuum packaging, and the vacuum degree is 10 -4Pa, put the glass tube with raw materials into a 16-channel heat treatment furnace with swing function, t...

Embodiment 3

[0042] A kind of tin-based solder provided by the present invention comprises Sn, Zn, Bi, Ag and Sb, and the mass percent of each component is respectively Zn: 9.0%, Bi: 2.0%, Ag: 2.0%, Sb: 1.0%, surplus is Sn.

[0043] The preparation method of described tin-based solder comprises the following steps:

[0044] (1) Weigh the pure metal raw materials Sn and Ag according to the mass ratio of 1:1, adopt vacuum induction melting, the melting temperature is 900°C, and the vacuum degree is 10 -3 Pa, the smelting time is 2 hours, the electromagnetic stirring effect ensures that the alloy composition is uniform, and the Sn-Ag master alloy is prepared.

[0045] (2) According to the design composition of Sn-based lead-free solder, weigh the Sn-Ag master alloy prepared in step (1) and the raw materials Sn, Zn, Bi, Sb, put them into a glass test tube for vacuum packaging, and the vacuum degree is 10 -4 Pa, put the glass tube with raw materials into a 16-channel heat treatment furnace wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com