Workpiece wear-resistant coating and spraying method for same

A technology for wear-resistant coatings and workpieces, applied in coatings, metal material coating processes, fusion spraying, etc., can solve problems such as inability to repair offline crystallizers, low slab output and production efficiency, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

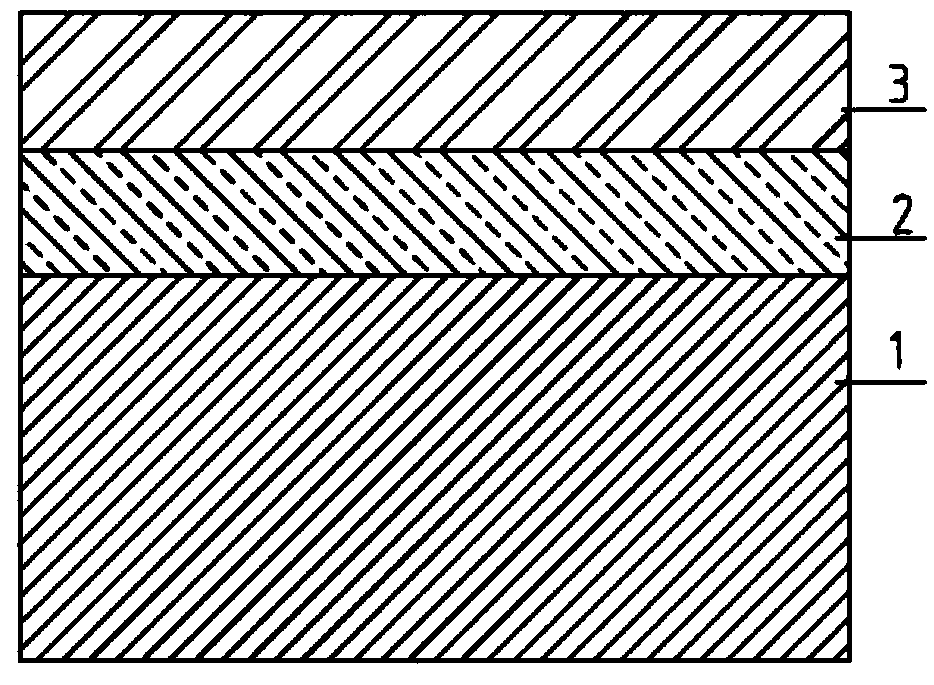

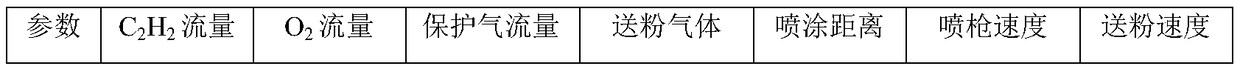

[0055] Raw materials: bottom layer NiCr composite powder, composition 80%Ni-20%Cr, powder particle size 15-50μm; surface layer NiCr-Cr 3 C 2 Composite powder, composition 25% NiCr-75% Cr 3 C 2 , The particle size of the powder is 15-50 μm.

[0056] The object to be sprayed is a brand-new mold narrow-side copper plate, and the base material is chrome-zirconium copper. First, decontaminate the surface to be sprayed and use acetone to remove surface dirt. Afterwards, use 24# brown corundum sand to carry out sandblasting and roughening treatment on the surface of the copper substrate to be sprayed, until the surface roughness is greater than 6 μm. The coating is prepared by explosive spraying process, first spraying NiCr composite powder, and then spraying the bottom layer, the bottom spraying time is 3min; then spraying NiCr-Cr on the bottom layer 3 C 2 Composite powder, complete the spraying of the surface layer, and the spraying time of the surface layer is 15 minutes. T...

Embodiment 2

[0063] Raw materials: bottom layer NiCr composite powder, composition 80%Ni-20%Cr, powder particle size 15-50μm; surface layer NiCr-Cr 3 C 2 Composite powder, composition 25% NiCr-75% Cr 3 C 2 , Powder particle size 15 ~ 50μm.

[0064] The object to be sprayed is a brand-new mold narrow-side copper plate, and the base material is chrome-zirconium copper. First, decontaminate the surface to be sprayed and use acetone to remove surface dirt. Afterwards, use 24# brown corundum sand to carry out sandblasting and roughening treatment on the surface of the copper substrate to be sprayed, until the surface roughness is greater than 6 μm. The coating is prepared by explosive spraying process, first spraying NiCr composite powder, and then spraying the bottom layer, the bottom spraying time is 6min; then spraying NiCr-Cr on the bottom layer 3 C 2 Composite powder, complete the spraying of the surface layer, and the spraying time of the surface layer is 25 minutes. The technical ...

Embodiment 3

[0070] Raw materials: bottom layer NiCr composite powder, composition 80%Ni-20%Cr, powder particle size 15-50μm; surface layer NiCr-Cr 3 C 2 Composite powder, composition 25% NiCr-75% Cr 3 C 2 , The particle size of the powder is 15-50 μm.

[0071] The object to be sprayed is a brand-new mold narrow-side copper plate, and the base material is chrome-zirconium copper. First, decontaminate the surface to be sprayed and use acetone to remove surface dirt. Afterwards, use 24# brown corundum sand to carry out sandblasting and roughening treatment on the surface of the copper substrate to be sprayed, until the surface roughness is greater than 6 μm. The coating is prepared by explosive spraying process, first spraying NiCr composite powder, and then spraying the bottom layer, the bottom spraying time is 4min; then spraying NiCr-Cr on the bottom layer 3 C 2 Composite powder, complete the spraying of the surface layer, and the spraying time of the surface layer is 20 minutes. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com