Binding-phase TiC/WC composite hard alloy and preparation method thereof

A technology of cemented carbide and binder phase, which is applied in the field of cemented carbide, can solve problems such as the limitation of the application environment of cemented carbide, peeling, the oxidation resistance and corrosion resistance of cemented carbide are not outstanding, and achieve the reduction of density and production Cost, good wear resistance, superior wear and corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

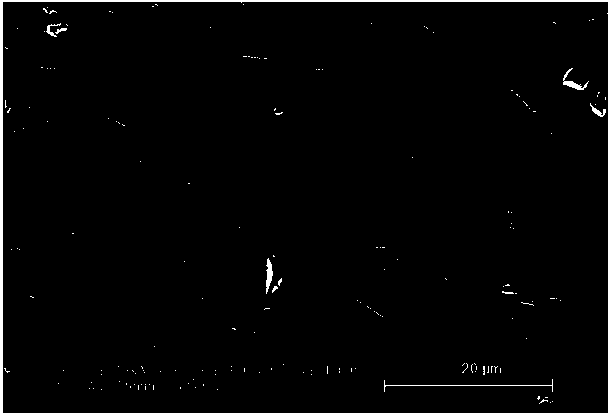

Image

Examples

Embodiment 1

[0028] First, the TiC and WC powders with a uniform particle size of 3-5 μm, which have been screened in advance, are mixed according to the mass fraction of 100% and 0%, and then the mixed TiC / WC powder with a raw material mass percentage of 94% is weighed, and then the mixed TiC / WC powder and Co with a particle size of 1-3μm 2 AlTi powder is prepared according to the mass fraction of 94% and 5%, and 1% of the total mass of stearic acid is added, and then mixed and ground in a ball mill for 12 hours; the mixed and ground raw materials are vacuum-dried and sieved to remove agglomerates body, then granulated, and then at 1000kg / cm 2 Precisely press under the pressure to make a compact; place the prepared compact in a vacuum of 3×10 -4 MPa vacuum sintering furnace heated to 1200 ° C vacuum sintering for 2 hours, followed by hot isostatic pressing at 1200 ° C and 80 MPa for 5 hours to make cemented carbide. Take it out after cooling to get the finished product.

Embodiment 2

[0030]First, the TiC and WC powders with a uniform particle size of 3-5 μm, which have been screened in advance, are prepared and mixed according to the mass fraction of 90% and 10%, and then the mixed TiC / WC powder with a raw material mass percentage of 91% is weighed, and then the mixed TiC / WC powder and Co with a particle size of 1-3μm 2 AlTi powder is prepared according to the mass fraction of 91% and 8%, and 0.9% of the total mass of stearic acid is added, and then mixed and ground in a ball mill for 15 hours; the mixed and ground raw materials are vacuum-dried and sieved to remove agglomerates body, then granulated, and then at 900kg / cm 2 Precisely press under the pressure to make compacts; put the finished compacts in a vacuum of 3.5×10 -4 Heating to 1280°C for vacuum sintering in MPa vacuum sintering furnace for 1.8 hours, followed by hot isostatic pressing at 1230°C and 850MPa for 4.5 hours to make hard alloy. Take it out after cooling to get the finished product. ...

Embodiment 3

[0032] Firstly, the TiC and WC powders with a uniform particle size of 3-5 μm, which have been screened in advance, are mixed evenly according to the mass fraction of 80% and 20%, and then the mixed TiC / WC powder with a raw material mass percentage of 89% is weighed, and then the mixed TiC / WC powder is weighed. WC powder with particle size of 1~3μmCo 2 AlTi powder is prepared according to the mass fraction of 89% and 10%, and 0.8% of the total mass of stearic acid is added, and then mixed and ground in a ball mill for 24 hours; the mixed and ground raw materials are vacuum-dried and sieved to remove agglomerates body, then granulated, and then at 900kg / cm 2 Press under the pressure to make a green compact; place the finished green compact in a vacuum of 4×10 -4 MPa vacuum sintering furnace heated to 1250 ° C vacuum sintering for 1.5 hours, followed by hot isostatic pressing at 1250 ° C and 90 MPa for 2 hours to make cemented carbide. Take it out after cooling to get the fini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com