Low-stress multilayer film optical filter and preparation method thereof

A multi-layer thin film and optical filter technology, applied in optics, optical components, instruments, etc., can solve problems that have not been solved fundamentally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

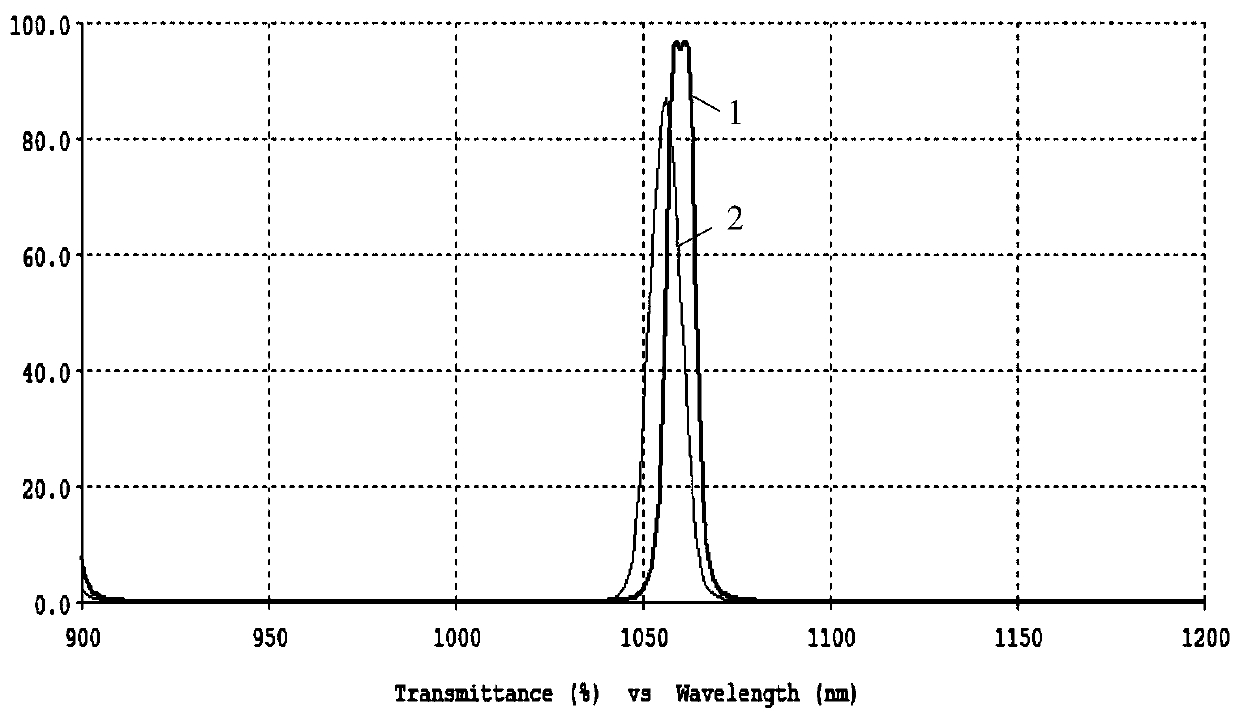

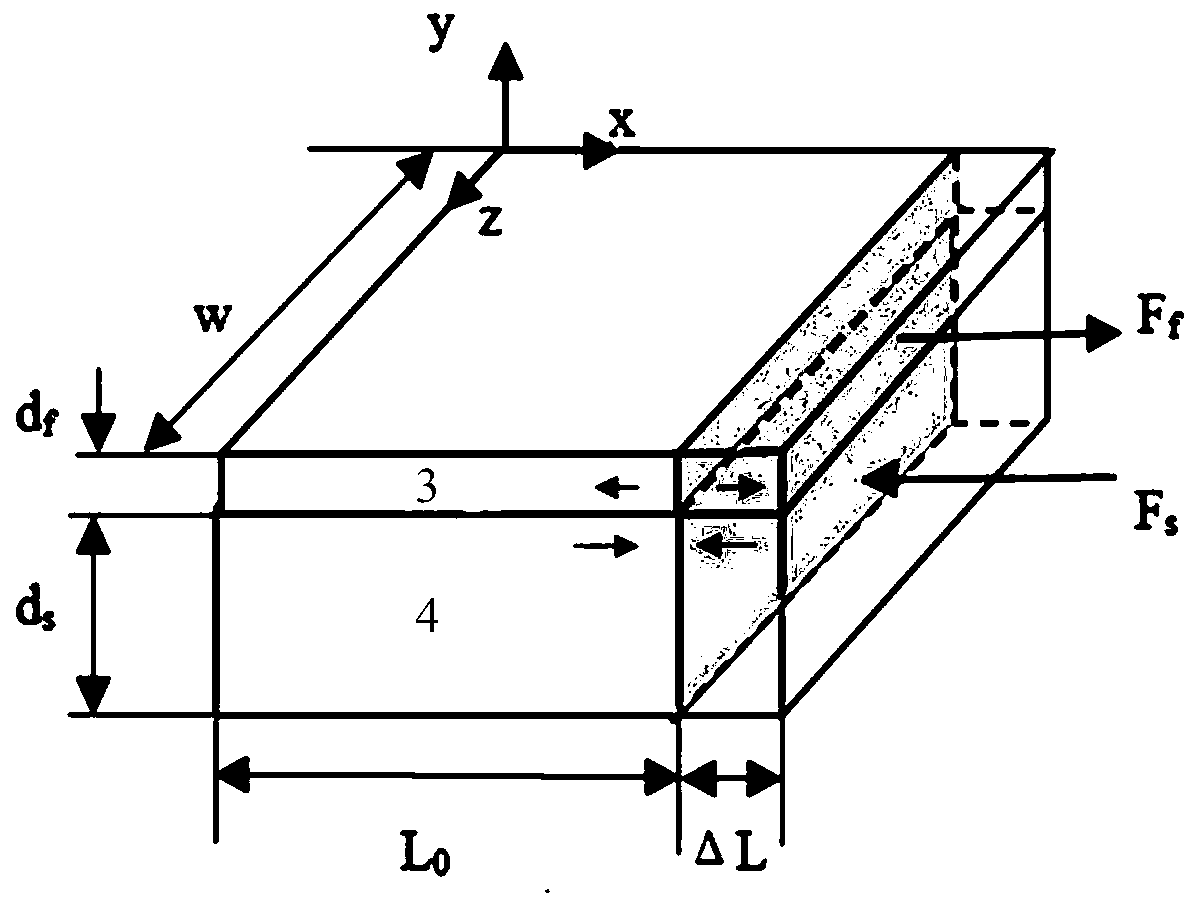

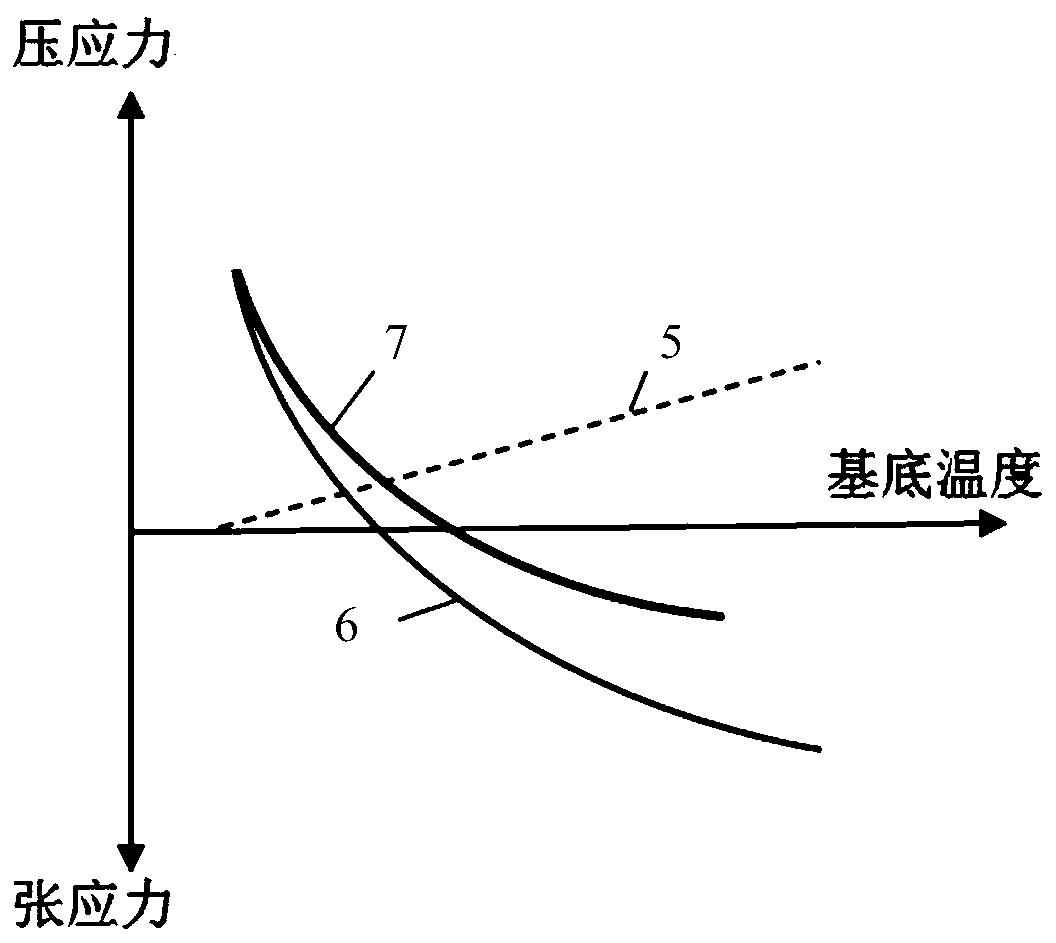

Embodiment 1

[0066] As Embodiment 1, the present invention uses a conventional process to prepare a narrow-band interference filter. If the ion source is not installed on the coating equipment, the filter can only be prepared by the conventional process. The temperature of the substrate is controlled at 250°C, and a high-refractive-index film and a low-refractive-index film are alternately prepared on the substrate by using a coating device. The coating equipment uses titanium pentoxide (Ti 2 o 5 ) as the initial evaporation material of the high refractive index film, and the coating equipment uses silicon dioxide (SiO 2 ) as the initial evaporation material for low refractive index films. Since the substrate temperature is very sensitive to stress in the conventional process, the present invention attempts to make TiO 2 film and SiO 2 The purpose of the stress value of the membrane is similar and the direction is opposite. In view of the fact that the increase of substrate temperatu...

Embodiment 2

[0069] As a second embodiment, the present invention uses weak ion assistance to prepare a narrow-band interference filter. Most of the existing imported coating equipment are equipped with ion sources, because the ion assist is very sensitive to the internal stress of the film aggregation density, so the present invention attempts to realize the TiO2 by adjusting the ion assist parameters. 2 film and SiO 2 The purpose of the stress value of the film is very small and in the opposite direction. A coating device with an ion source is used to prepare a high-refractive-index film and a low-refractive-index film alternately on a substrate with weak ion assistance. Coating equipment with an ion source uses titanium pentoxide (Ti 2 o 5 ) as the initial evaporation material of the high refractive index film, and the coating equipment with ion source uses silicon dioxide (SiO 2 ) as the initial evaporation material for low refractive index films.

[0070] The present invention se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Stress | aaaaa | aaaaa |

| Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com