Preparation method for ultraviolet reflecting film used in space

A technology of reflective film and ultraviolet, which is applied in the field of preparation of ultraviolet reflective film for space, can solve problems such as not being able to meet the filtering requirements of solar cells, and achieve the effect of excellent optical performance and high light reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

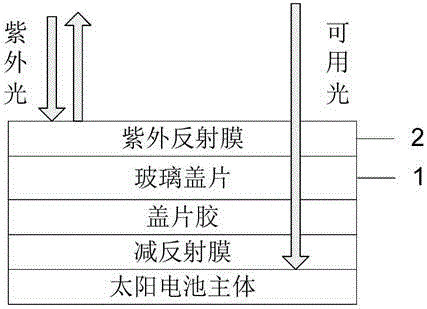

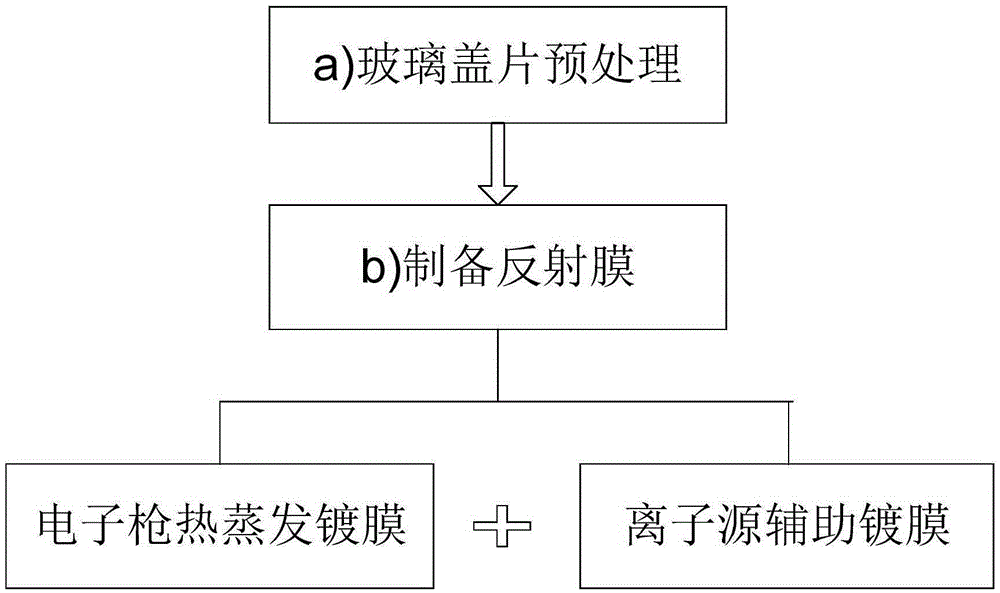

[0028] Such as figure 1 As shown, a method for preparing an ultraviolet reflective film suitable for space use in triple-junction gallium arsenide solar cells mainly includes the following steps:

[0029] a) pre-treating the cover glass 1: cleaning the cover glass 1;

[0030] b) Preparing the reflective film 2: depositing the reflective film 2 on the surface of the cover glass 1 by electron gun thermal evaporation, and using an ion source to assist the deposition of the reflective film 2 on the surface of the cover glass 1 .

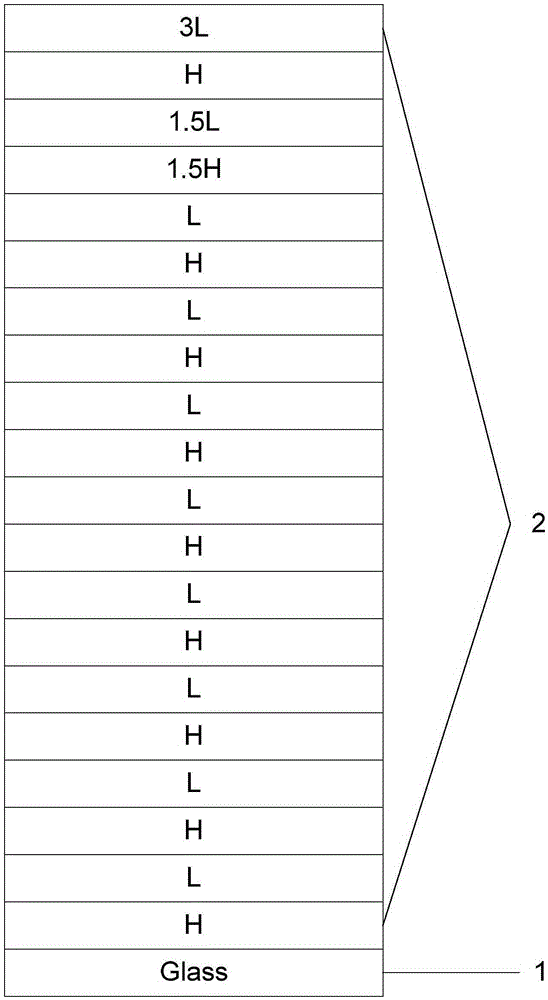

[0031] Wherein, the reflective film 2 is made of high refractive index material HfO 2 and low refractive index material MgF 2 Composite. The reason for this design is that the HfO 2 The layer belongs to the optically transparent band after the sunlight wavelength of 200nm, that is, the absorption is very small, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com